Professional Documents

Culture Documents

(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )

(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )

Uploaded by

Elias EliasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )

(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )

Uploaded by

Elias EliasCopyright:

Available Formats

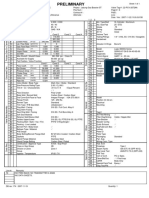

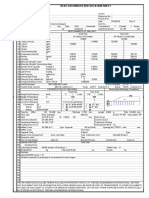

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-1312

Control Valve Specification PO # : Proj Num : Page # : 1

Prepared By : Serial # : .001 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-21 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 18.000 / 18.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 80 / 80 52 Act. Size/Fab 100 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke 6.00

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. HC GAS / N/A 54 Spring None

Actuator

5 Design Press./Temp. 1650 PSIG / 230 DEGF 55 Air To Close

6 NOR MIN MAX Cond 4 56 Volume Tank 10 Gal

7 Temperature (°F) 112.500 97.200 122.500 57 Tubing/Fittings 3/8" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 1235.700 1063.100 1309.500 58 Handwheel

9 Outlet Press (psi (g)) 954.800 995.300 852.353 59

10 Liq Flow Rate (galUS/min) 0 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (kg/h) 438541.000 96561.000 474512.000 61

12 Viscosity (cP) 0.015 0.014 0.015 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 0.000 63 Model # 3200IQ-15-D6-E-04-40-0G-0F

14 SG-MW 18.920 18.920 18.920 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 1650.000 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 80.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 NOR MIN MAX Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 547.256 231.592 501.554 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 67.000 23.000 59.000 70 Feedback 4-20 mA Feedback

21 Pressure Drop (psi ) 280.900 67.800 457.147 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 668.512 521.441 687.439 72 Positioner Tag

23 Noise [IEC] (dBA) 70.000 <70 77.000 73 Model

24 Valve Vel (mach#) 0.126 0.026 0.154 74

25 Pipe Vel (mach#) 0.052 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / MegaStream 76

27 Size/Pressure Rating/Type 10.00 / CL 900 / 77

28 Trim # - Cv / Characteristic 8.00 Cv:683 / Linear 78

29 Stages/DWG/Ret Guiding 1 Stage / C / Guided 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.06 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type P/B PTFE / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 316 SS 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Carbon Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Intr Safe 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

31 A216-WCB

32 RF FLANGES

We offer Megastream trim to reduce noise.

we offer 10" size instead of 12".

DB rev: 174 : 2007-11-19 Quantity: 1

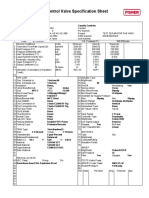

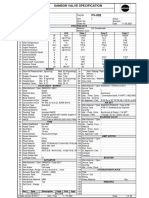

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2302

Control Valve Specification PO # : Proj Num : Page # : 2

Prepared By : Serial # : .002 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-21 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 10S / 10S 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. UTILITY AIR / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. 175 PSIG / 160 DEGF 55 Air To Open

6 NOR MIN MAX Cond 4 56 Volume Tank

7 Temperature (°F) 86.000 77.000 122.000 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 116.000 102.000 152.000 58 Handwheel

9 Outlet Press (psi (g)) 94.000 80.000 130.000 59

10 Liq Flow Rate (galUS/min) 0 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (kg/h) 150.000 21.800 218.000 61

12 Viscosity (cP) 0.003 0.002 0.003 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 0.000 63 Model # 3200IQ-15-D6-E-04-40-0G-00

14 SG-MW 28.950 28.950 28.950 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 175.000 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 80.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Close / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 NOR MIN MAX Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.499 0.231 1.959 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 55.000 13.000 61.000 70 Feedback None

21 Pressure Drop (psi ) 22.000 22.000 22.000 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 98.025 87.525 125.025 72 Positioner Tag

23 Noise [IEC] (dBA) <70 <70 <70 73 Model

24 Valve Vel (mach#) 0.027 0.004 0.030 74

25 Pipe Vel (mach#) 0.006 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 1.00 / CL 150 / 77

28 Trim # - Cv / Characteristic .50 Cv:6.5 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Intr Safe 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

31 A216-WCB

32 RF FLANGES

We offer Megastream trim to reduce noise.

we offer 10" size instead of 12".

DB rev: 174 : 2007-11-19 Quantity: 1

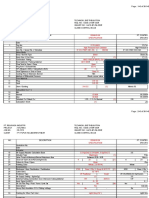

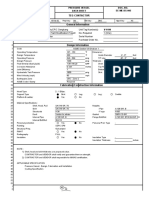

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-1405

Control Valve Specification PO # : Proj Num : Page # : 3

Prepared By : Serial # : .003 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-21 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 18.000 / 18.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 80 / 80 52 Act. Size/Fab 100 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke 4.00

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. HC GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. 1650 PSIG / 160 DEGF 55 Air To Open

6 CASE1 INIT CASE1 FINA CASE2 INIT CASE2 FINA 56 Volume Tank 6 Gal

7 Temperature (°F) 95.000 22.070 95.000 28.070 57 Tubing/Fittings 3/8" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 1170.000 100.000 1518.000 100.000 58 Handwheel

9 Outlet Press (psi (g)) 66.350 66.040 4.600 40.920 59

10 Liq Flow Rate (galUS/min) 0 0 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (kg/h) 247603.000 134046.197 58350.000 156018.514 61

12 Viscosity (cP) 0.014 0.010 0.015 0.010 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 0.000 0.000 63 Model # 3200IQ-15-D6-E-04-40-0G-0F

14 SG-MW 18.740 18.740 18.740 18.740 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 1650.000 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 80.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Close / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 CASE1 INIT CASE1 FINA CASE2 INIT CASE2 FINA 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 224.660 1450.000 40.909 1450.000 69 Action 4-Way

Calculated Data

20 Est Stroke (% Signal) 51.000 99.000 9.000 100.000 70 Feedback 4-20 mA Feedback

21 Pressure Drop (psi ) 1103.650 33.960 1513.400 59.080 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 888.525 86.025 1149.525 86.025 72 Positioner Tag

23 Noise [IEC] (dBA) 112.000 95.000 86.000 109.000 73 Model

24 Valve Vel (mach#) 0.484 0.249 0.480 0.419 74

25 Pipe Vel (mach#) 0.284 75 Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 14.00 / CL 900 / 77

28 Trim # - Cv / Characteristic 9.00 Cv:1450 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.06 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. P/B PTFE / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 316 SS 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Carbon Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Intr Safe 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

We offer Globe valve instead of Butterfly valve since the Class CL900 and high press drop.

Flowrate are too big at case1 final and case2 final. maximum is only 134046.197 kg/h at case1

final, and 156018.514 kg/h at case2 final.

Noise are 112dB, 95dB 86dB and 109 dB. Please re-check the data process.

DB rev: 174 : 2007-11-19 Quantity: 1

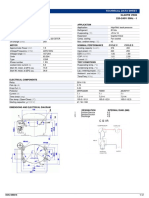

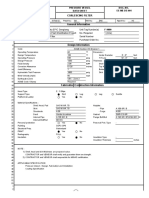

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-1410

Control Valve Specification PO # : Proj Num : Page # : 4

Prepared By : Serial # : .004 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-21 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 8.000 / 8.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 80S / 80S 52 Act. Size/Fab 100 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke 3.00

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. HC GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. 1650 PSIG / 160 DEGF 55 Air To Close

6 INIT FINAL Cond 3 Cond 4 56 Volume Tank 6 Gal

7 Temperature (°F) 95.000 15.890 57 Tubing/Fittings 3/8" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 1262.000 100.000 58 Handwheel

9 Outlet Press (psi (g)) 7.800 7.860 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (kg/h) 33199.000 33199.000 61

12 Viscosity (cP) 0.015 0.010 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-15-D6-E-04-40-0G-0F

14 SG-MW 18.740 18.740 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 1650.000 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 80.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 INIT FINAL Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 39.256 311.188 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 19.000 90.000 70 Feedback 4-20 mA Feedback

21 Pressure Drop (psi ) 1254.200 92.140 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 485.146 73.817 72 Positioner Tag

23 Noise [IEC] (dBA) 99.000 89.000 73 Model

24 Valve Vel (mach#) 0.616 0.571 74

25 Pipe Vel (mach#) 0.597 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / MegaStream 76

27 Size/Pressure Rating/Type 8.00 / CL 900 / 77

28 Trim # - Cv / Characteristic 5.00 Cv:330 / Equal Percent 78

29 Stages/DWG/Ret Guiding 2 Stage / C / Guided 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.06 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type P/B PTFE / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 316 SS 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Carbon Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Intr Safe 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

31 A216-WCB

32 RF FLANGES

We offer Megastream trim to reduce noise.

noise are 99 dB and 89dB.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-1420

Control Valve Specification PO # : Proj Num : Page # : 5

Prepared By : Serial # : .005 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-21 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 8.000 / 8.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 80S / 80S 52 Act. Size/Fab 100 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke 3.00

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. HC GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. 1650 PSIG / 160 DEGF 55 Air To Close

6 INIT FINAL Cond 3 Cond 4 56 Volume Tank 6 Gal

7 Temperature (°F) 95.000 15.890 57 Tubing/Fittings 3/8" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 1262.000 100.000 58 Handwheel

9 Outlet Press (psi (g)) 7.800 7.860 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (kg/h) 33199.000 33199.000 61

12 Viscosity (cP) 0.015 0.010 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-15-D6-E-04-40-0G-0F

14 SG-MW 18.740 18.740 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 1650.000 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 80.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 INIT FINAL Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 39.256 311.188 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 19.000 90.000 70 Feedback 4-20 mA Feedback

21 Pressure Drop (psi ) 1254.200 92.140 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 485.146 73.817 72 Positioner Tag

23 Noise [IEC] (dBA) 99.000 89.000 73 Model

24 Valve Vel (mach#) 0.616 0.571 74

25 Pipe Vel (mach#) 0.597 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / MegaStream 76

27 Size/Pressure Rating/Type 8.00 / CL 900 / 77

28 Trim # - Cv / Characteristic 5.00 Cv:330 / Equal Percent 78

29 Stages/DWG/Ret Guiding 2 Stage / C / Guided 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.06 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type P/B PTFE / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 316 SS 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Carbon Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Intr Safe 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

31 A216-WCB

32 RF FLANGES

We offer Megastream trim to reduce noise.

noise are 99 dB and 89dB.

DB rev: 174 : 2007-11-19 Quantity: 1

You might also like

- SP-OS-PL-CAL-0003 Rev. 0 Pipeline Stress AnalysisDocument19 pagesSP-OS-PL-CAL-0003 Rev. 0 Pipeline Stress AnalysisElias EliasNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- Sizing Sheet Dengan Cv. 133 PDFDocument3 pagesSizing Sheet Dengan Cv. 133 PDFJoko WisnugrohoNo ratings yet

- Specification Sheet Rev 1Document12 pagesSpecification Sheet Rev 1nishanth NTNo ratings yet

- Data Sheets-T220425-499Document9 pagesData Sheets-T220425-499pedro torresNo ratings yet

- combinepdf (10)Document3 pagescombinepdf (10)valveNo ratings yet

- combinepdf (9)Document3 pagescombinepdf (9)valveNo ratings yet

- 401-042825-01 Specifications & SizingDocument2 pages401-042825-01 Specifications & SizingJackNo ratings yet

- Actuator DatasheetDocument1 pageActuator DatasheetKo Aung KoNo ratings yet

- PDF Actuator Datasheet - CompressDocument1 pagePDF Actuator Datasheet - Compresshellraizer1978No ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data Sheetsiseset100% (1)

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- SizingDocument4 pagesSizingAlberto ReyesNo ratings yet

- File 5Document1 pageFile 5VENKATACHALAM SUBBARAJNo ratings yet

- JVCVReport1215 PDFDocument1 pageJVCVReport1215 PDFUlises BadilloNo ratings yet

- Enerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSDocument4 pagesEnerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSHamza ShujaNo ratings yet

- VRQ 3Document2 pagesVRQ 3Esteban ArguelloNo ratings yet

- KSB MIL Control Valves Specification V0998-SPECDocument36 pagesKSB MIL Control Valves Specification V0998-SPECNutan PowerNo ratings yet

- 265-PV-092 095 098Document3 pages265-PV-092 095 098Juan Pablo Palma PizarroNo ratings yet

- 1-Fisher Specification and Sizing Sheets - RevCDocument3 pages1-Fisher Specification and Sizing Sheets - RevCheikelNo ratings yet

- Control Valve DatasheetDocument1 pageControl Valve DatasheetretrogradesNo ratings yet

- A11627SE-08 - CVDS Rev B Technical Specification 840GDocument2 pagesA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNo ratings yet

- Severn GloconDocument6 pagesSevern GloconAmit Surti0% (1)

- Data - Sheet Hora CV Act DetailsDocument2 pagesData - Sheet Hora CV Act DetailsAnand K. MouryaNo ratings yet

- VRQ 4Document2 pagesVRQ 4Esteban ArguelloNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- Severn Glocon 3Document10 pagesSevern Glocon 3Amit SurtiNo ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- 05 PCV 07 296a, BDocument2 pages05 PCV 07 296a, BSTG INSTRUMENTNo ratings yet

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessNo ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- Control Valves Specification Sheet: PT. PI EnergiDocument1 pageControl Valves Specification Sheet: PT. PI EnergiAnoNo ratings yet

- ANTAM Datasheet 10LAD21AA121 00Document1 pageANTAM Datasheet 10LAD21AA121 00heviNo ratings yet

- Control Valve Technical Specification Sheet Globe Service: GasDocument1 pageControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessNo ratings yet

- Control Valve Specification Sheet - LCV 2inch 600# R 1Document1 pageControl Valve Specification Sheet - LCV 2inch 600# R 1FIRMANSYAHNo ratings yet

- 2x GSD80485VA - Q1205,3 R410A t0 50 TC 105Document7 pages2x GSD80485VA - Q1205,3 R410A t0 50 TC 105viniciusschwabNo ratings yet

- Quick Size-Quick Size-1-20240429Document2 pagesQuick Size-Quick Size-1-20240429Raj MNo ratings yet

- AnnexureDocument391 pagesAnnexureTommy ArjanggiNo ratings yet

- Vortice-150-6-Ar (3-3 Exf-03)Document3 pagesVortice-150-6-Ar (3-3 Exf-03)RAMI HAMADNo ratings yet

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Document1 pagePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNo ratings yet

- Hojas de Datos Valvulas de ControlDocument4 pagesHojas de Datos Valvulas de ControlMauricio Cuevas HinojosaNo ratings yet

- Documents For Approval Rev-1 - ApprovedDocument42 pagesDocuments For Approval Rev-1 - ApprovedAbhijeet WayaseNo ratings yet

- GBCPP PCV 2030Document1 pageGBCPP PCV 2030Firstyan Dhika AldaniNo ratings yet

- Project Survey: Selected CompressorsDocument7 pagesProject Survey: Selected CompressorsviniciusschwabNo ratings yet

- Sperre Air CompressorDocument37 pagesSperre Air CompressorRK Panchal100% (2)

- Pressure Loss ExampleDocument2 pagesPressure Loss ExampleRufus D SNo ratings yet

- (cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationDocument2 pages(cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationmoceNo ratings yet

- Item 001A - 79.49 m3 HRDocument3 pagesItem 001A - 79.49 m3 HRAnonymous O0lyGOShYGNo ratings yet

- 113 80 330 FD 202 - Rev1 17Document1 page113 80 330 FD 202 - Rev1 17Maria Eduarda AndradeNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- Selection: Scroll-Compressor: Input ValuesDocument6 pagesSelection: Scroll-Compressor: Input ValuesviniciusschwabNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- T070420 Spec (PCV2)Document12 pagesT070420 Spec (PCV2)Elias EliasNo ratings yet

- 7400 Series DatasheetDocument3 pages7400 Series DatasheetBenderNo ratings yet

- Control Valve Specification Sheet ISMAEL CABALLERODocument1 pageControl Valve Specification Sheet ISMAEL CABALLERORodrigoNo ratings yet

- 65A10184-09-0905-01-008 Rev.2 (FLow Meter Sizing Cal)Document8 pages65A10184-09-0905-01-008 Rev.2 (FLow Meter Sizing Cal)chhandak beraNo ratings yet

- E0805-220-V-903-120-3A (Latihan)Document65 pagesE0805-220-V-903-120-3A (Latihan)Sabrang LorNo ratings yet

- 05 PCV 07 252a, BDocument2 pages05 PCV 07 252a, BSTG INSTRUMENTNo ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Data sheetCExlsDocument1 pageData sheetCExlsElias Elias100% (1)

- PSV Report BlockedDocument5 pagesPSV Report BlockedElias EliasNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasNo ratings yet

- Cover Coalescing Filter (F-9000)Document1 pageCover Coalescing Filter (F-9000)Elias EliasNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Attachment For FireDocument8 pagesAttachment For FireElias EliasNo ratings yet

- Singgar Mulia Engineering: Vertical Separator Design BasisDocument2 pagesSinggar Mulia Engineering: Vertical Separator Design BasisElias EliasNo ratings yet

- Specific Project SpecificationDocument5 pagesSpecific Project SpecificationElias EliasNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias Elias100% (1)

- Appendix ADocument16 pagesAppendix AElias EliasNo ratings yet

- Project Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateDocument3 pagesProject Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateElias EliasNo ratings yet

- Production Pump Sizing P. 0920 A, B, C: CalculationDocument5 pagesProduction Pump Sizing P. 0920 A, B, C: CalculationElias EliasNo ratings yet

- Appendix BDocument66 pagesAppendix BElias EliasNo ratings yet

- Hazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesDocument13 pagesHazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesElias EliasNo ratings yet

- Hazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesDocument12 pagesHazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesElias EliasNo ratings yet

- Piping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaDocument3 pagesPiping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaElias EliasNo ratings yet

- Cost Breakdown-Sent To Contractors (ESA Process Review)Document6 pagesCost Breakdown-Sent To Contractors (ESA Process Review)Elias EliasNo ratings yet

- UICAFE12815-ENG-CAL-XXXX Rev ADocument23 pagesUICAFE12815-ENG-CAL-XXXX Rev AElias EliasNo ratings yet

- 0708-L-CC-002 Pipeline Stress Calculation From GRF Keramasan To AKE Rev BDocument10 pages0708-L-CC-002 Pipeline Stress Calculation From GRF Keramasan To AKE Rev BElias EliasNo ratings yet

- Appendix ADocument38 pagesAppendix AElias EliasNo ratings yet

- 0708-Q-CC-001 Pipe Stress Calculation From Pipeline To Gas Scrubber Rev BDocument11 pages0708-Q-CC-001 Pipe Stress Calculation From Pipeline To Gas Scrubber Rev BElias Elias100% (1)

- Hydraulic Symbol Hydraulic & Electric Circuit HandbookDocument4 pagesHydraulic Symbol Hydraulic & Electric Circuit HandbookJorge RojasNo ratings yet

- PCV-2013 DatasheetDocument1 pagePCV-2013 DatasheetraufyNo ratings yet

- Revision Sasbadi 3 Pressure PrincipleDocument7 pagesRevision Sasbadi 3 Pressure PrincipleHazrina AwangNo ratings yet

- MEP 210 - Advanced Fluids - Group 6Document43 pagesMEP 210 - Advanced Fluids - Group 6Engr ModestoNo ratings yet

- Plan 11: Investa (Pumps PVT LTD CIP-1 65x40-160Document1 pagePlan 11: Investa (Pumps PVT LTD CIP-1 65x40-160DHAVALESH AMNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- 694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Document549 pages694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Martín Lescano ParedesNo ratings yet

- Yarway Series 7100Document12 pagesYarway Series 7100Cecep AtmegaNo ratings yet

- SCI Pipe Nipples Carbon-Stainless-BrassDocument10 pagesSCI Pipe Nipples Carbon-Stainless-BrassArunprasad MurugesanNo ratings yet

- Heat Transfer by Convection: Dr. Şaziye Balku 1Document30 pagesHeat Transfer by Convection: Dr. Şaziye Balku 1marioaladro1No ratings yet

- Curriculum Vitae: ObjectiveDocument6 pagesCurriculum Vitae: ObjectiveSyed KhalidNo ratings yet

- PUMP PP PDFDocument44 pagesPUMP PP PDFFarhan HaidaryNo ratings yet

- H.W.4 Pump and Pipeline DesignDocument2 pagesH.W.4 Pump and Pipeline DesignMr. nobodyNo ratings yet

- Chapter 8-9-10 Hydraulics System - 2020Document180 pagesChapter 8-9-10 Hydraulics System - 2020Tran Nhu Minh Khanh100% (1)

- Test Data Input Sheet: General InformationDocument2 pagesTest Data Input Sheet: General InformationdaveNo ratings yet

- Concepts of Pipe Stress AnalysisDocument54 pagesConcepts of Pipe Stress AnalysisKavin Kumar100% (3)

- Diagrama Flujo-Secador CD550+Document1 pageDiagrama Flujo-Secador CD550+Ricardo Limaymanta TicseNo ratings yet

- Chapter 3 Flow ComputationDocument16 pagesChapter 3 Flow ComputationRefisa Jiru100% (1)

- Flight Dynamics - NotesDocument109 pagesFlight Dynamics - NotesOdhiambo AustinNo ratings yet

- Selecting Right ImpellerDocument7 pagesSelecting Right Impellericingrock100% (2)

- Valves Objective QuestionsDocument4 pagesValves Objective QuestionszhangyiliNo ratings yet

- Pressure Regulators Page 34Document1 pagePressure Regulators Page 34BdyeuNo ratings yet

- Younis CVDocument11 pagesYounis CVMounir GhardaiaNo ratings yet

- Deep Well Turbine and Submersible PumpsDocument16 pagesDeep Well Turbine and Submersible Pumpsahsanul haqueNo ratings yet

- Fluid MechanicsDocument46 pagesFluid MechanicsEr Suraj Hulke100% (1)

- Hydralic Ram: A Minor Project Report OFDocument28 pagesHydralic Ram: A Minor Project Report OFRishabNo ratings yet

- Section 3 Hydraulic SystemDocument3 pagesSection 3 Hydraulic SystemRafał DworakNo ratings yet

- A Computer Program For The Aerodynamic Design of Axisymmetric and Planar Nozzles For Supersonic and Hypersonic Wind TunnelsDocument151 pagesA Computer Program For The Aerodynamic Design of Axisymmetric and Planar Nozzles For Supersonic and Hypersonic Wind TunnelsBlackFootNo ratings yet

- FMM Question Set 1Document16 pagesFMM Question Set 1Abhijit KuchbhilikhtaNo ratings yet

- Orifice Under Constant HeadDocument2 pagesOrifice Under Constant HeadDevansh SharmaNo ratings yet