Professional Documents

Culture Documents

Caterpillar Performance Handbook 49 62020 - Partie32

Caterpillar Performance Handbook 49 62020 - Partie32

Uploaded by

ali alilouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caterpillar Performance Handbook 49 62020 - Partie32

Caterpillar Performance Handbook 49 62020 - Partie32

Uploaded by

ali alilouCopyright:

Available Formats

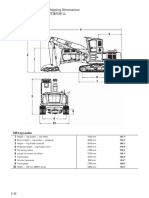

Notes —

2-78

PHB-Sec02-18.indd 78 6/21/18 12:01 PM

DRILLS

3

CONTENTS

ROTARY DRILLS

Product Line Description . . . . . . . . . . . . . . . . . . .3-2

Applications/Industries Served . . . . . . . . . . . . . . .3-2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Key Specifications . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Throughout this document, references to Tier 4 Interim/Stage IIIB/Japan 2011 (Tier 4 Interim) include U.S. EPA

Tier 4 Interim, EU Stage IIIB, and Japan 2011 (Tier 4 Interim) equivalent emission standards. References to

Tier 4 Final/Stage IV/Japan 2014 (Tier 4 Final) include U.S. EPA Tier 4 Final, EU Stage IV, and Japan 2014

(Tier 4 Final) emission standards.

Throughout this document, references to Tier 1/Stage I include U.S. EPA Tier 1 and EU Stage I equivalent emission

standards. References to Tier 2/Stage II/Japan 2001 (Tier 2) equivalent include U.S. EPA Tier 2, EU Stage II, and

Japan 2001 (Tier 2) equivalent emission standards. References to Tier 3/Stage IIIA/Japan 2006 (Tier 3) equivalent

include U.S. EPA Tier 3, EU Stage IIIA, and Japan 2006 (Tier 3) equivalent emission standards.

Updated June/2019 3-1

PHB-Sec03-19.indd 1 6/25/19 9:05 AM

Rotary Drills Product Line Description

Applications/Industries Served

PRODUCT LINE DESCRIPTION

Cat® Rotary Drills are available with a maximum

bit load range of up to 63 975 kg (141,000 lb), to suit a

wide variety of applications. They’re proven to deliver

efficiency, high productivity and low cost, as well as

provide a comfortable environment for the operator.

A synergy of robust structures, long-lasting systems

and innovative technology, the Cat line of rotary drills

have demonstrated their effectiveness and longevity in

a variety of mining environments, including both soft-

and hard-rock applications, as well as extreme tempera-

ture and high-altitude locations.

Equipped to power rotary tricone bits of various sizes

and configurations, the diesel powered drills can be

configured with high pressure compressors for DTH

(down-the-hole) hammer drilling. Caterpillar has the drill

that delivers the optimal combination of bit load, rotary

torque and onboard air to ensure maximum productiv-

ity in a wide range of applications.

PRIMARY APPLICATIONS FOR ROTARY BLASTHOLE DRILLS

Bench Cast Blast Presplit Grade Control Over Burden

MODEL Drilling Drilling Drilling Drilling Drilling

MD6200* x x x x

MD6250 x x x x x

MD6310 x x x x x

MD6380 x x x x

MD6640 x x x

*Primary production blasthole drill, with the ability to do limited presplit drilling.

3-2 Updated June/2019

PHB-Sec03-19.indd 2 6/25/19 9:05 AM

Features Rotary Drills

CAT ROTARY DRILL FEATURES HOBO Wrench

The variable grip Hydraulically Operated Break Out

Solid Structures 3

wrench is part of a highly efficient breakout system

Box section frame rail construction with optimized, that increases speed of pipe changing operations, con-

profiled transititions in all high stress areas provides excep- sequently increasing productivity.

tional structural durability. Caterpillar undercarriages The hydraulic break out wrench is operated from the

with three-point oscillating suspension, GLT (grease cab thus protecting the operator.

lubricated tracks, double post upper carrier rollers). It also reduces impact loading to the mast and rotary

Sturdy Mast head during pipe changes, further increasing drill mechan-

ical availability.

Each model can be configured with various mast lengths

to suit specific application requirements for single pass

or multi pass drilling. Power Group

Designed with double-cut lacing in all joints to assure Fast cycle times are achieved through top of class bit

long life, mast structures are made of rectangular load, rotary head horsepower, bailing air and a multi-

ASTM 500 Grade B steel tubing for all main chords, tude of time-saving systems for maximum efficiency.

cross members and lacing.

Ergonomic Cab

This design ensures a torsionally strong mast struc-

ture and reduces deflection and material fatigue. Cab rubber shock-mounts absorb mechanical vibra-

Machined frame/mast interfaces eliminate custom tion and restrict exterior noise. The operator station

fitment and allow for easy mast replacement or swap- design integrates an ergonomic seat, joystick controls

ping of masts between drills without cutting or welding. with full instrumentation, and dual 254 mm (10 in) color

displays, high definition touchscreen and 12 volt power

Jack System port. There is an additional display screen for cc cameras

Jack casing assemblies are integrally welded to the which is color, high-definition and 254 mm (10 in).

main frame providing structural strength and durability

and reduce torsional flexing of the main frame.

The leveling jacks are positioned to provide excellent

stability and weight over the hole.

Updated June/2019 3-3

PHB-Sec03-19.indd 3 6/25/19 9:05 AM

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Introduction To Super Single - 1200 HPDocument41 pagesIntroduction To Super Single - 1200 HPmozhi.sh100% (3)

- Yamaha Banshee Parts Manual 5FK6 - 2000Document55 pagesYamaha Banshee Parts Manual 5FK6 - 2000Felipe Antonio Pinto VillarroelNo ratings yet

- Centrifugal Pump Test Set: Screenshot of The Optional VDAS® SoftwareDocument3 pagesCentrifugal Pump Test Set: Screenshot of The Optional VDAS® SoftwareSyafiq Sabran HasnanNo ratings yet

- D6G2 XL Product PresentationDocument51 pagesD6G2 XL Product Presentationfirman manalu100% (1)

- Catalogo McGUILLDocument16 pagesCatalogo McGUILLJHON FERNEY BOHORQUEZ SALDARRIAGANo ratings yet

- Packer Retrievable GT DualDocument24 pagesPacker Retrievable GT DualRodolfo RiderNo ratings yet

- Tabla de Conversión de GasesDocument2 pagesTabla de Conversión de GasesGiulianno Alv MayNo ratings yet

- Trituradora Eagle 1200 25 CCDocument2 pagesTrituradora Eagle 1200 25 CCRodrigo MartinezNo ratings yet

- SAEPL Catalog 2018Document8 pagesSAEPL Catalog 2018Sanjoy SanyalNo ratings yet

- Dual Chamfered CutterDocument16 pagesDual Chamfered CutterAzri HamimNo ratings yet

- Torno YcmDocument32 pagesTorno Ycmcarlos mesa100% (1)

- De 20220812162629y1ee0Document4 pagesDe 20220812162629y1ee0Raiyre RolandNo ratings yet

- Hydraulic Rock Breaker MontabertDocument4 pagesHydraulic Rock Breaker MontabertSam ManutençãoNo ratings yet

- D8T, D9T, D10T: Waste HandlerDocument16 pagesD8T, D9T, D10T: Waste HandlerJuan Alfredo ValdésNo ratings yet

- Brochure Rotostar Small Plansifter MPAR en LowDocument4 pagesBrochure Rotostar Small Plansifter MPAR en LowGonzalo MuleroNo ratings yet

- Ignite Carbon 29": Frame PassportDocument7 pagesIgnite Carbon 29": Frame PassportvictorNo ratings yet

- 416E Vs 580M Product Buletin (TEJB9166)Document56 pages416E Vs 580M Product Buletin (TEJB9166)firman manaluNo ratings yet

- Collet Chuck Catalog 2007 PDFDocument28 pagesCollet Chuck Catalog 2007 PDFAlexandru Marius-catalinNo ratings yet

- Rigid Stranders - NEWDocument8 pagesRigid Stranders - NEWAbdul HarisNo ratings yet

- Berco BROCHURE PDFDocument3 pagesBerco BROCHURE PDFJohn Gonzalez100% (1)

- Tunneling Excavator: Cat C7 Diesel Engine With ACERT™ TechnologyDocument16 pagesTunneling Excavator: Cat C7 Diesel Engine With ACERT™ TechnologyImran HasicNo ratings yet

- Cb22B, Cb24B, Cb24B XT Cb32B, Cc24B: Tility OmpactorsDocument2 pagesCb22B, Cb24B, Cb24B XT Cb32B, Cc24B: Tility OmpactorsMarco Antonio Gutierrez PulchaNo ratings yet

- Waste HandlerDocument8 pagesWaste HandlerDharmesh patelNo ratings yet

- Naramada Method Statement - R0Document16 pagesNaramada Method Statement - R0Indra Nath MishraNo ratings yet

- Bomag 40 PDFDocument20 pagesBomag 40 PDFIGNACIONo ratings yet

- Surface Belt Structure: Cema C & D SeriesDocument8 pagesSurface Belt Structure: Cema C & D SeriesSari Ully Sibarani100% (1)

- DCP Product DatasheetDocument16 pagesDCP Product Datasheetsandip0002No ratings yet

- Workover Bops PDFDocument5 pagesWorkover Bops PDFBeni N SoloNo ratings yet

- Tri Cone BitsDocument16 pagesTri Cone BitsPeter ForrestNo ratings yet

- Catlogo Motorreductores Boston Gears AlimenticioDocument72 pagesCatlogo Motorreductores Boston Gears Alimenticiometalcernaw rodriguezNo ratings yet

- Catlogo Motorreductores Boston Gears AlimenticioDocument72 pagesCatlogo Motorreductores Boston Gears Alimenticiometalcernaw rodriguezNo ratings yet

- Brushcutters AEHQ5847 01 08 08Document2 pagesBrushcutters AEHQ5847 01 08 08Carlo PoliNo ratings yet

- FX 45a 55a SSDocument2 pagesFX 45a 55a SSAlvin SmithNo ratings yet

- PEBJ0011 Cutter Bit Reference Guide Puntas Cat Micro FresadoDocument20 pagesPEBJ0011 Cutter Bit Reference Guide Puntas Cat Micro FresadoHECTOR ESCALLONNo ratings yet

- SSL AttachmentDocument22 pagesSSL AttachmentFulkan HadiyanNo ratings yet

- Dressta 534e La Ms 4029 Dss11Document8 pagesDressta 534e La Ms 4029 Dss11YakupovmmNo ratings yet

- SR Catalog of WBCUDocument23 pagesSR Catalog of WBCUEdgar GomezNo ratings yet

- BRANDT VSM Multi Sizer Separator Flyer ENDocument2 pagesBRANDT VSM Multi Sizer Separator Flyer ENCrudeMan FangNo ratings yet

- LF 230 Core Drill: Technical Data SheetDocument7 pagesLF 230 Core Drill: Technical Data SheetLuis Aparcana100% (1)

- GTDocument30 pagesGTAbhishek VelagaNo ratings yet

- 1986 National Waste Processing Conference 28Document10 pages1986 National Waste Processing Conference 28Eduardo LopesNo ratings yet

- Mill Lines by FlSmidthDocument4 pagesMill Lines by FlSmidthIrving Dirzo CarrilloNo ratings yet

- Atlas Copco Dsyndr 20110103043229dDocument4 pagesAtlas Copco Dsyndr 20110103043229dAntónio Pedro TavaresNo ratings yet

- SmartROC T35 T40Document8 pagesSmartROC T35 T40Giulio BelmondoNo ratings yet

- Doble Reduccion 70-380Document2 pagesDoble Reduccion 70-380Zamir Andres SencioNo ratings yet

- December 1998 Bucket Catalog UpdateDocument336 pagesDecember 1998 Bucket Catalog Updatetommy lanyonNo ratings yet

- Waste and Recycling: Industry SolutionsDocument24 pagesWaste and Recycling: Industry SolutionsIan WoodsNo ratings yet

- Dressta Loaders Spec 57b493Document8 pagesDressta Loaders Spec 57b493Dan Patch100% (1)

- EZG Series Slurry Pump: Excellence Pump Industry Co., LTDDocument6 pagesEZG Series Slurry Pump: Excellence Pump Industry Co., LTDCristobal BernalNo ratings yet

- Bobcat 463Document4 pagesBobcat 463Elvis Eberth Huanca MachacaNo ratings yet

- Risk AssessmentDocument16 pagesRisk AssessmentengrmcabNo ratings yet

- Recloser ABBDocument24 pagesRecloser ABBFranca MenteNo ratings yet

- Serie 2Document36 pagesSerie 2camiloNo ratings yet

- Mobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 SeriesDocument4 pagesMobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 Series Mobil DTE™ 700 SeriesAbu AlbumNo ratings yet

- BTA2 Technical SheetDocument2 pagesBTA2 Technical SheetOnie Hammamz OylNo ratings yet

- Shear & Moment TableDocument12 pagesShear & Moment TableRaja RajanNo ratings yet

- Tds Mibil DTE 732Document4 pagesTds Mibil DTE 732mahirtanjim50No ratings yet

- Krebs Products For The Coal IndustryDocument20 pagesKrebs Products For The Coal IndustryANo ratings yet

- 380LCDocument34 pages380LCGervann KempNo ratings yet

- Front Shovels: Digging Envelopes 385C FSDocument4 pagesFront Shovels: Digging Envelopes 385C FSali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie86Document4 pagesCaterpillar Performance Handbook 49 62020 Partie86ali alilouNo ratings yet

- Processing/Loading Forest Machines: Shipping Dimensions 320D Series 2 FMDocument4 pagesProcessing/Loading Forest Machines: Shipping Dimensions 320D Series 2 FMali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie85Document4 pagesCaterpillar Performance Handbook 49 62020 Partie85ali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie80Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie80ali alilouNo ratings yet

- Hw300 Highwall Mining System SpecificationsDocument4 pagesHw300 Highwall Mining System Specificationsali alilouNo ratings yet

- Forest Products Work Tools: Logging Forks SpecificationsDocument4 pagesForest Products Work Tools: Logging Forks Specificationsali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie589Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie589ali alilouNo ratings yet

- Processing/Loading Forest Machines: Shipping Dimensions 558 LLDocument4 pagesProcessing/Loading Forest Machines: Shipping Dimensions 558 LLali alilouNo ratings yet

- Highwall Mining System: Hw300 Optional EquipmentDocument4 pagesHighwall Mining System: Hw300 Optional Equipmentali alilouNo ratings yet

- Processing/Loading Forest Machines: Working Ranges 320D Series 2 FMDocument4 pagesProcessing/Loading Forest Machines: Working Ranges 320D Series 2 FMali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie84Document4 pagesCaterpillar Performance Handbook 49 62020 Partie84ali alilouNo ratings yet

- Processing/Loading Forest Machines: Shipping Dimensions 538/538 LLDocument4 pagesProcessing/Loading Forest Machines: Shipping Dimensions 538/538 LLali alilouNo ratings yet

- Notes - : PHB-Sec05-18.indd 126Document4 pagesNotes - : PHB-Sec05-18.indd 126ali alilouNo ratings yet

- Mining and Earthmoving: Estimating Production Off-the-Job Example Problem (English) Example Problem (Metric)Document4 pagesMining and Earthmoving: Estimating Production Off-the-Job Example Problem (English) Example Problem (Metric)ali alilouNo ratings yet

- Land Clearing: Equipment Selection TableDocument4 pagesLand Clearing: Equipment Selection Tableali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie588Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie588ali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie1Document4 pagesCaterpillar Performance Handbook 49 62020 Partie1ali alilouNo ratings yet

- Processing/Loading Forest Machines: Working Ranges 324D FMDocument4 pagesProcessing/Loading Forest Machines: Working Ranges 324D FMali alilouNo ratings yet

- Mining and Earthmoving: Estimating Production Off-the-Job Grade Resistance Total Resistance TractionDocument4 pagesMining and Earthmoving: Estimating Production Off-the-Job Grade Resistance Total Resistance Tractionali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie590Document4 pagesCaterpillar Performance Handbook 49 62020 Partie590ali alilouNo ratings yet

- Tires: TKPH Rating Michelin TiresDocument4 pagesTires: TKPH Rating Michelin Tiresali alilouNo ratings yet

- Tables: Engine/Machine Cross ReferenceDocument4 pagesTables: Engine/Machine Cross Referenceali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie595Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie595ali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie586Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie586ali alilouNo ratings yet

- Tires: Ton-Kilometer Per Hour Rating SystemDocument4 pagesTires: Ton-Kilometer Per Hour Rating Systemali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie587Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie587ali alilouNo ratings yet

- Caterpillar Performance Handbook 49 62020 - Partie596Document4 pagesCaterpillar Performance Handbook 49 62020 - Partie596ali alilouNo ratings yet

- Tires: TKPH Rating Goodyear TiresDocument4 pagesTires: TKPH Rating Goodyear Tiresali alilouNo ratings yet

- Tires: TKPH Rating Goodyear TiresDocument4 pagesTires: TKPH Rating Goodyear Tiresali alilouNo ratings yet

- Ex Drive PDFDocument252 pagesEx Drive PDFmishka123No ratings yet

- HSE MATERIAL LIST - Faisal Palace Project # J 1014Document6 pagesHSE MATERIAL LIST - Faisal Palace Project # J 1014Gopal RaiNo ratings yet

- RS9110 - Install Manual - FinalDocument28 pagesRS9110 - Install Manual - FinaljcarlosaguiarNo ratings yet

- Chery A21 Service Manual Mechanism of 2.0nalc EngineDocument45 pagesChery A21 Service Manual Mechanism of 2.0nalc Enginehusnihameed74No ratings yet

- Manual de Operacion y Mantenimiento de Motor DT 530 y HT 530Document107 pagesManual de Operacion y Mantenimiento de Motor DT 530 y HT 530Fernando100% (2)

- Telemecanique XMPA12B2131 DatasheetDocument3 pagesTelemecanique XMPA12B2131 DatasheetMathiasNo ratings yet

- Electrical Design Manual For HospitalsDocument14 pagesElectrical Design Manual For HospitalsfisplNo ratings yet

- What Is A Battery Holder?Document4 pagesWhat Is A Battery Holder?Raviteja bukkaipalliNo ratings yet

- Price List SPC 2021Document15 pagesPrice List SPC 2021Nesa DjuricNo ratings yet

- Tender Schedule For Electrical Work PDFDocument6 pagesTender Schedule For Electrical Work PDFnakul4491_88890127No ratings yet

- Smartline Pressure Transmitters ST 700 User'S Manual: Honeywell Process SolutionsDocument167 pagesSmartline Pressure Transmitters ST 700 User'S Manual: Honeywell Process SolutionsAbdulaziz K AlbnyanNo ratings yet

- NK Cables Antenna Line ProductsDocument52 pagesNK Cables Antenna Line ProductsAndreyNo ratings yet

- 29F010Document21 pages29F010Dario GomezNo ratings yet

- Eluxa Horns Strobes Data Sheet TD450157ENDocument4 pagesEluxa Horns Strobes Data Sheet TD450157ENRícardoNo ratings yet

- L01 2aabDocument72 pagesL01 2aab111sNo ratings yet

- Auxiliary Blower Fans TYPE DM-51-76B: Technical ManualDocument11 pagesAuxiliary Blower Fans TYPE DM-51-76B: Technical ManualDragonta GontaNo ratings yet

- LTX1046VT Cub Cadet Lawn TractorDocument40 pagesLTX1046VT Cub Cadet Lawn TractorKevin WilsonNo ratings yet

- T400 Cone CrusherDocument2 pagesT400 Cone CrushergugiNo ratings yet

- Pilz RelayDocument11 pagesPilz RelayRavi SankarNo ratings yet

- Catalogo de Accesorios Marine 2021 LowDocument180 pagesCatalogo de Accesorios Marine 2021 LowFilipe PratasNo ratings yet

- OWON XDM3041 Bench-Type Digital Multimeter Technical Spec.sDocument2 pagesOWON XDM3041 Bench-Type Digital Multimeter Technical Spec.sAndres LaiNo ratings yet

- Alarma Ungo Ms8200 InstallDocument30 pagesAlarma Ungo Ms8200 InstallvalyexNo ratings yet

- Instruction Manual: Compact InverterDocument192 pagesInstruction Manual: Compact Invertersunhuynh100% (1)

- Max 253Document18 pagesMax 253sergey39123No ratings yet

- Solar Wireless Electric Vehicle Charging SystemDocument7 pagesSolar Wireless Electric Vehicle Charging SystemMANISH KUMARNo ratings yet

- Penawaran HPI 14 10 2016Document8 pagesPenawaran HPI 14 10 2016acongNo ratings yet

- Urban Altoids Survival Tin - 2.0Document2 pagesUrban Altoids Survival Tin - 2.0n8356No ratings yet

- SL-25230 Rev5 NXa30-200kVA UserManualDocument132 pagesSL-25230 Rev5 NXa30-200kVA UserManualstasNo ratings yet