Professional Documents

Culture Documents

Food Standards Code (The Code) With Respect To The Extension of Use of

Food Standards Code (The Code) With Respect To The Extension of Use of

Uploaded by

STEVANYYLNDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Food Standards Code (The Code) With Respect To The Extension of Use of

Food Standards Code (The Code) With Respect To The Extension of Use of

Uploaded by

STEVANYYLNDCopyright:

Available Formats

Executive summary (FSANZ item 3.1.

1)

With this application DSM Food Specialties B.V. (DFS) requests a variation of

Standard 1.3.1 “Food Additives”, Schedule 1 of the Australia New Zealand

Food Standards Code (the Code) with respect to the extension of use of

natamycin as a natural preservative in fermented milk products and

rennetted milk products of Food categories 1.2.2 and 20.2. The maximum

level of use is 5 mg/kg.

The dossier is written according the FSANZ Application Handbook, edition

dated 1 September 2013.

Food spoilage through microbial contamination is a common occurrence

resulting in significant losses in manufacturing, in the food supply chain and

at home. Spoiled foods will be discarded resulting in significant economic

cost to the food industry, retailers and consumers. According to the FAO

report from 2011 on “Global food losses and food waste”, food security is a

major concern. In medium and high-income countries, food is to a

significant extent wasted at the consumption stage, meaning that it is

discarded even if it is still suitable for human consumption. Food losses in

industrialized countries are as high as in developing countries with more

than 40% of the food losses occurring at retail and consumer levels. It

represents a waste of resources used in the production and food that will

not be consumed leads to unnecessary CO2 emissions in addition to loss of

economic value of the food produced.

Yeast and moulds are known microorganisms that could cause spoilage of

yogurt. Also in Australia the food spoilage caused by fungi is high, and

estimated to be in the range of $10.000.000 value wasted per annum.

Natamycin is a natural yeast and mould inhibitor produced by submerged

aerobic fermentation of Streptomyces natalensis. It has a broad spectrum

activity against all moulds and yeasts known as contaminants of food

products and is active at very low concentrations. Natamycin is extensively

used worldwide, especially in the cheese and sausage industries. It is active

only against yeasts and moulds, therefore will not interact with viable

bacteria and will improve the quality and shelf life of (non-pasteurized)

fermented milk products

A complete safety evaluation was published in the WHO Food Additives

Series No. 48: Safety Evaluation of Certain Food Additives and

Contaminants: Natamycin (Pimaricin) in 2002. The European Food Safety

Authority (EFSA) confirmed the safety of natamycin in their latest re-

evaluation in 2009.

REG#56361 Page 5 of 45 DSM 1443-001

Anti-microbial resistance as a consequence of the use of natamycin was and

is extensively evaluated not only by International Safety Authorities e.g.

EFSA and JECFA but also by DSM Food Specialties.

The EFSA in 2009 concluded with respect to antimicrobial resistance that

“…, induction of natamycin resistant mutants in yeast is reported to be

difficult. The Panel concluded that there was no concern for the induction

of antimicrobial resistance.”

This confirmed the conclusions from JECFA at their 20th meeting in 1976 and

their 57th meeting in 2002: “Cross-resistance between antifungal polyenes is

relatively infrequent. In particular, resistance to natamycin seldom implies

resistance to related polyenes. Although cross-resistance with nystatin and

amphotericin has been observed, selection of natamycin-resistant strains in

vitro has never been accompanied by such cross-resistance. Transferable

resistance between bacterial cells depends on the transfer of DNA and does

not occur with yeast and fungi, which have a different cell-wall barrier.”.

To substantiate these conclusions further with the latest scientific

information, DSM Food Specialties had an independent literature review on

natamycin resistance performed and had challenge tests executed to

investigate the possible development of natamycin tolerance.

The independent literature review was performed by TNO, the Netherlands

organisation for applied scientific research (www.tno.nl ).

Based on this literature review, it is concluded that:

Natamycin resistance is mainly due to natural resistance;

No reports have been published claiming acquired natamycin resistance

in fungi due to horizontal gene transfer;

Experimental evidence of fungi acquiring resistance to natamycin is not

encountered so far.

The independent challenge tests were performed by the Centraalbureau

voor Schimmelcultures (CBS) in the Netherlands (www.cbs.knaw.nl). CBS -

Fungal Biodiversity Centre is an institute of the Royal Netherlands Academy

of Arts and Sciences (KNAW).

Based on these challenge tests, it is concluded that:

An intensive program aimed at inducing tolerance towards natamycin has

resulted in an increase in tolerance of a few individual strains, but did

not alter the range of natural variation of sensitivities;

Resistance to natamycin was not developed;

One of the strains showed an increased tolerance for amphotericin B and

nystatin after training with natamycin: Aspergillus ochraceus. The

sensitivity towards all three polyene antifungals decreased

approximately 3-fold. In contrast, two Fusarium strains trained for

natamycin tolerance showed an increased sensitivity for the other two

antimycotics.

The selection regime used was much more severe than would be

encountered during the use of natamycin as a food preservative.

REG#56361 Page 6 of 45 DSM 1443-001

The overall conclusion based on efficacy, stability and safety data is that

natamycin is a safe, suitable and effective natural yeast and mould inhibitor

at a low dosage level (i.e. ≤ 5 ppm).

Natamycin will increase the shelf life of yogurt without influencing the

organoleptic characteristics of yogurt and contributes simultaneously to

economic sustainability through less wastage of food at the manufacturer,

retailer and consumer level.

REG#56361 Page 7 of 45 DSM 1443-001

You might also like

- 0052-0054 (51) Antimicrobial Effectiveness TestingDocument4 pages0052-0054 (51) Antimicrobial Effectiveness TestingDr usama El ShafeyNo ratings yet

- Should The United States Have Annexed The Philippines?Document3 pagesShould The United States Have Annexed The Philippines?John Cramerus100% (3)

- LV Ph2020 - Bid Set - ArchitecturalDocument30 pagesLV Ph2020 - Bid Set - Architecturalart cafeNo ratings yet

- Penicillium 8 Pag.Document11 pagesPenicillium 8 Pag.Jorge Raul VilcaNo ratings yet

- Meat Haccp 2Document9 pagesMeat Haccp 2parithyi murali tharanNo ratings yet

- Listeria Monocytogenes Isolated FromDocument7 pagesListeria Monocytogenes Isolated FromSidah BensefiaNo ratings yet

- Scientific Opinion On The Use of Natamycin (E 235) As A Food AdditiveDocument25 pagesScientific Opinion On The Use of Natamycin (E 235) As A Food AdditiveΕυαγγελία ΘεοχάρηNo ratings yet

- Judicious Use of Antimicrobials For Poultry VeterinariansDocument16 pagesJudicious Use of Antimicrobials For Poultry VeterinariansJuan Pablo EspinalNo ratings yet

- Y4722e00 PDFDocument22 pagesY4722e00 PDFJuan AndreoliNo ratings yet

- Nutfruit March 2016 IvarssonDocument3 pagesNutfruit March 2016 IvarssonFred EricNo ratings yet

- Fermented Foods and Food Safety: ArticleDocument9 pagesFermented Foods and Food Safety: ArticlesimurabiyeNo ratings yet

- Journal of Dairy Science Volume Issue 2017 (Doi 10.3168 - jds.2017-12660) Kaczorek, E. Małaczewska, J. Wójcik, R. Rękawek, W. Siwic - Phenotypic and Genotypic Antimicrobial Susceptibility PatternDocument12 pagesJournal of Dairy Science Volume Issue 2017 (Doi 10.3168 - jds.2017-12660) Kaczorek, E. Małaczewska, J. Wójcik, R. Rękawek, W. Siwic - Phenotypic and Genotypic Antimicrobial Susceptibility Patternyudi poponNo ratings yet

- Efficacy of Natamycin For Control of Growth and Ochratoxin A Production by Aspergillus Carbonarius Strains Under Different Environmental ConditionsDocument6 pagesEfficacy of Natamycin For Control of Growth and Ochratoxin A Production by Aspergillus Carbonarius Strains Under Different Environmental ConditionsDrAmit VermaNo ratings yet

- Publications ScientifiquesDocument103 pagesPublications ScientifiquesBrowndonNo ratings yet

- Optimization of The Cultivation Medium For Natamycin Production by Streptomyces NatalensisDocument10 pagesOptimization of The Cultivation Medium For Natamycin Production by Streptomyces Natalensissebastianscribd2014No ratings yet

- Assessment of Total Aflatoxin Content in Dry Fruits Samples Collected From Local Markets of Lahore, Pakistan Aflatoxins in Dry FruitsDocument16 pagesAssessment of Total Aflatoxin Content in Dry Fruits Samples Collected From Local Markets of Lahore, Pakistan Aflatoxins in Dry FruitssirNo ratings yet

- Determination of Antibiotic Residues in Honey: - Zaneta Bargan Ska, Marek S Lebioda, Jacek Namies NikDocument7 pagesDetermination of Antibiotic Residues in Honey: - Zaneta Bargan Ska, Marek S Lebioda, Jacek Namies NikJelena S NikolicNo ratings yet

- Animal-Feed Additives Rules Scan-Old Report Out108 PDFDocument21 pagesAnimal-Feed Additives Rules Scan-Old Report Out108 PDFGatoNo ratings yet

- HAMLET - Human Alpha-Lactalbumin Made LEthal To Tumor Cells. Fraser2014Document7 pagesHAMLET - Human Alpha-Lactalbumin Made LEthal To Tumor Cells. Fraser2014orlandom61No ratings yet

- BIOHAZ PiensosSalmonella08Document84 pagesBIOHAZ PiensosSalmonella08amamùra maamarNo ratings yet

- 2022 Investigation of Mobile Colistin ResistanceDocument6 pages2022 Investigation of Mobile Colistin ResistanceHimen SalimizandNo ratings yet

- MycotoxinsDocument7 pagesMycotoxinsJohn WaweruNo ratings yet

- Occurrence of Aflatoxin in FoodDocument8 pagesOccurrence of Aflatoxin in Foodfarkad rawiNo ratings yet

- Exposure Assessment of Multiple Mycotoxins in Black and White Sesame Seeds Consumed in ThailandDocument10 pagesExposure Assessment of Multiple Mycotoxins in Black and White Sesame Seeds Consumed in ThailandwaelNo ratings yet

- Shrimp - Antimicrobial Residue - 2020Document14 pagesShrimp - Antimicrobial Residue - 2020yen nguyenNo ratings yet

- The Unseen EnemyDocument5 pagesThe Unseen EnemyInternational Aquafeed magazineNo ratings yet

- The Informative Value of An Overview On Antibiotic Consumption, Treatment Efficacy and Cost of Clinical Mastitis at Farm LevelDocument8 pagesThe Informative Value of An Overview On Antibiotic Consumption, Treatment Efficacy and Cost of Clinical Mastitis at Farm LeveljsolvarelaNo ratings yet

- Test Procedures For Insecticide Resistance Monitoring in Malaria Vector MosquitoesDocument40 pagesTest Procedures For Insecticide Resistance Monitoring in Malaria Vector MosquitoesΧαράλαμποςΧατζηκανέλλουNo ratings yet

- Cereal Foods World 2018Document3 pagesCereal Foods World 2018SQF PractitionerNo ratings yet

- Antibiotic and Bacteriocin Sensitivity of Listeria PDFDocument6 pagesAntibiotic and Bacteriocin Sensitivity of Listeria PDFVincent ReyesNo ratings yet

- Comparison of In-Vitro Efficacy of Vanc, LNZ and Dapto Angainst MRSA.Document6 pagesComparison of In-Vitro Efficacy of Vanc, LNZ and Dapto Angainst MRSA.Nawwal NaeemNo ratings yet

- Reducing Antimicrobial Use in Food AnimalsDocument4 pagesReducing Antimicrobial Use in Food AnimalsAli RazaNo ratings yet

- Animals: Epidemiology and Classification of MastitisDocument17 pagesAnimals: Epidemiology and Classification of Mastitisarini nashirahNo ratings yet

- Antibiotic Susceptibility Test and Mic DeterminationDocument12 pagesAntibiotic Susceptibility Test and Mic DeterminationankitapearlNo ratings yet

- The Benefits of Biosecurity in Poultry FarmingDocument3 pagesThe Benefits of Biosecurity in Poultry FarmingsudheerpulaNo ratings yet

- Antimicrobial Resistance of Salmonella From Poultry Meat in Brazil Results of A Nationwide SurveyDocument8 pagesAntimicrobial Resistance of Salmonella From Poultry Meat in Brazil Results of A Nationwide SurveyMatheus SouzaNo ratings yet

- Case Study About 3 Hazard in Dairy Products: Submitted By: Group 4Document17 pagesCase Study About 3 Hazard in Dairy Products: Submitted By: Group 4Monaliza SalibioNo ratings yet

- Case Study About 3 Hazard in Dairy Products: Submitted By: Group 4Document17 pagesCase Study About 3 Hazard in Dairy Products: Submitted By: Group 4Monaliza SalibioNo ratings yet

- Dnevni Unos - EnglDocument22 pagesDnevni Unos - EnglMarija PavlovicNo ratings yet

- Decision - PC 051102 - 14 May 12Document29 pagesDecision - PC 051102 - 14 May 12Mehrad KarimiNo ratings yet

- Determination of Microbiological Quality of IcDocument8 pagesDetermination of Microbiological Quality of IcnawresnoussaNo ratings yet

- Shelf Life Extension of CheeseDocument18 pagesShelf Life Extension of Cheesenils2484100% (1)

- Pharmacy Daily For Fri 04 Jul 2014 - Vaccination Consultation, Fourth Term For Kardachi, MA Warns On Investment, MIMS Updates and Much MoreDocument3 pagesPharmacy Daily For Fri 04 Jul 2014 - Vaccination Consultation, Fourth Term For Kardachi, MA Warns On Investment, MIMS Updates and Much MorepharmacydailyNo ratings yet

- NatamycinDocument10 pagesNatamycinedwarhannaNo ratings yet

- Chapter OneDocument17 pagesChapter OneBrix RosalijosNo ratings yet

- Jurnal Reading AMRDocument49 pagesJurnal Reading AMRLoudry Amsal EGNo ratings yet

- Sandspilgerammethods2009 PDFDocument8 pagesSandspilgerammethods2009 PDFBharti ChauhanNo ratings yet

- Listeria Monocytogenes: Antimicrobial Activity of Chitosan Films With Essential Oils Against On CabbageDocument6 pagesListeria Monocytogenes: Antimicrobial Activity of Chitosan Films With Essential Oils Against On CabbageGabyFasciglioneNo ratings yet

- 4 Salmonella in Eggs From Shopping To Consumption A Review Providing An An Evidence-Based Analysis of Risk FactorsDocument26 pages4 Salmonella in Eggs From Shopping To Consumption A Review Providing An An Evidence-Based Analysis of Risk FactorsWalton Science Research LabNo ratings yet

- Morkbak Et Al EAAE 2008Document8 pagesMorkbak Et Al EAAE 2008Nguyen Minh TrongNo ratings yet

- Candida Albicans Biofilm InhibitorsDocument7 pagesCandida Albicans Biofilm InhibitorsSenuke TestNo ratings yet

- Parasite Control in Pasture-Grazed Dairy Cattle: Are We at The Edge of A Precipice?Document7 pagesParasite Control in Pasture-Grazed Dairy Cattle: Are We at The Edge of A Precipice?Oktrestu Dwi PutraNo ratings yet

- Meeting Report Artemisinin-Resistant Malaria: Research Challenges, Opportunities, and Public Health ImplicationsDocument11 pagesMeeting Report Artemisinin-Resistant Malaria: Research Challenges, Opportunities, and Public Health ImplicationsDiah AlyaNo ratings yet

- AmikacinDocument2 pagesAmikacinnajwa zinaouiNo ratings yet

- Development of Practical Risk Management Strategies Based On Microbiological Risk Assessment Outputs Kiel, Germany, 3-7 April 2006Document31 pagesDevelopment of Practical Risk Management Strategies Based On Microbiological Risk Assessment Outputs Kiel, Germany, 3-7 April 2006bhaleshNo ratings yet

- 513EPDocument2 pages513EPVioleta GrigorasNo ratings yet

- US Rare Earth Minerals, Inc. - AquacultureDocument5 pagesUS Rare Earth Minerals, Inc. - AquacultureUSREMNo ratings yet

- Risk Based Control of Biogenic Amine Formation inDocument93 pagesRisk Based Control of Biogenic Amine Formation inoffice8187No ratings yet

- Trematerraet FFL2015Document8 pagesTrematerraet FFL2015Nidhi TiwariNo ratings yet

- In Vivo Ameliorative Effects of Methanol Leaf Extract of Lawsonia Inermis Linn On Experimental Trypanosoma Congolense Infection in Wistar RatsDocument8 pagesIn Vivo Ameliorative Effects of Methanol Leaf Extract of Lawsonia Inermis Linn On Experimental Trypanosoma Congolense Infection in Wistar RatsYulanda SinnenNo ratings yet

- Fnut 09 944856Document13 pagesFnut 09 944856Benni IskandarNo ratings yet

- Plant Disease Management Strategies for Sustainable Agriculture through Traditional and Modern ApproachesFrom EverandPlant Disease Management Strategies for Sustainable Agriculture through Traditional and Modern ApproachesImran Ul HaqNo ratings yet

- Service Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemDocument343 pagesService Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemUNNI VENUGOPAL67% (3)

- Luces International InstalacionDocument157 pagesLuces International InstalaciondanflocaNo ratings yet

- Industrial Seminar ReportDocument1 pageIndustrial Seminar ReportAkul Sirohi ce22m104No ratings yet

- CERTIFICATE AcknowlgementDocument8 pagesCERTIFICATE Acknowlgementprakhar raghuvanshiNo ratings yet

- Module No 1 :automobile Engineering (Mumbai University)Document78 pagesModule No 1 :automobile Engineering (Mumbai University)Vaibhav Vithoba Naik100% (4)

- Multi Step NotesDocument8 pagesMulti Step Notesapi-310503032No ratings yet

- PDF Adapted Physical Education National Standards Third Edition Kelly Ebook Full ChapterDocument53 pagesPDF Adapted Physical Education National Standards Third Edition Kelly Ebook Full Chapteranne.oconnor830100% (4)

- Alfred Jarry and PostmodernismDocument48 pagesAlfred Jarry and PostmodernismSonnyDysNo ratings yet

- Scientix4 New Ambassadors T&C-Feb-23Document4 pagesScientix4 New Ambassadors T&C-Feb-23dada_dadyNo ratings yet

- Daftar PustakaDocument4 pagesDaftar PustakaInilah Aqku Appha AdhanyaNo ratings yet

- Literature Review On Alcohol Abuse in KenyaDocument5 pagesLiterature Review On Alcohol Abuse in Kenyagw0ttn7j100% (1)

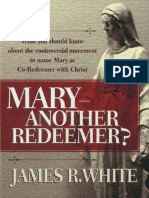

- Mary Another RedeemerDocument87 pagesMary Another RedeemernadabeleandroNo ratings yet

- Organizational Culture ReviewDocument6 pagesOrganizational Culture ReviewLeafar VerdantNo ratings yet

- Individual Assignment For MGT162Document9 pagesIndividual Assignment For MGT162Iyad AmeenNo ratings yet

- Marketing - Chapter 17Document53 pagesMarketing - Chapter 17denixngNo ratings yet

- Audit Information System Using Cobit 5: January 2020Document9 pagesAudit Information System Using Cobit 5: January 2020biruk eduNo ratings yet

- Thomas L. Pazdernik, Laszlo Kerecsen-Rapid Review Pharmacology, 3rd Edition-Mosby (2010)Document784 pagesThomas L. Pazdernik, Laszlo Kerecsen-Rapid Review Pharmacology, 3rd Edition-Mosby (2010)dtech2No ratings yet

- Dissertation Dedication ExamplesDocument7 pagesDissertation Dedication ExamplesWhereCanYouBuyResumePaperSouthBend100% (1)

- Dissertation RJM Pijpers September 2011Document294 pagesDissertation RJM Pijpers September 2011MarkoNo ratings yet

- Manchester University Press: de Stijl and Dutch ModernismDocument1 pageManchester University Press: de Stijl and Dutch ModernismHoàng YếnNo ratings yet

- How To Produce Your Book With Scribus.: Make The Front MatterDocument3 pagesHow To Produce Your Book With Scribus.: Make The Front MattersudyNo ratings yet

- Spices 1 Spices 2 MergedDocument41 pagesSpices 1 Spices 2 Mergedmralone3107No ratings yet

- Amphibious VehiclesDocument11 pagesAmphibious Vehiclesk2gadu7457No ratings yet

- 3.pyrogen & DepyrogenationDocument16 pages3.pyrogen & DepyrogenationHujjat UllahNo ratings yet

- UPSC-CSE-Yogesh-Kumbhejkar-8-2015 Exam View PDFDocument11 pagesUPSC-CSE-Yogesh-Kumbhejkar-8-2015 Exam View PDFB AspirantNo ratings yet

- Psychological StatisticsDocument6 pagesPsychological StatisticsMarielle Francisco0% (1)

- 4l60e Manual Shift ConversionDocument10 pages4l60e Manual Shift ConversionSalvador PinedaNo ratings yet

- Law of Motion Final PDFDocument32 pagesLaw of Motion Final PDFMark RosalesNo ratings yet