Professional Documents

Culture Documents

MAINCOTE HG-54C Acrylic Resin

MAINCOTE HG-54C Acrylic Resin

Uploaded by

Long An DoCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebDocument64 pagesAW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebLong An DoNo ratings yet

- Cellosize QP 100mhDocument2 pagesCellosize QP 100mhca_rl_4No ratings yet

- FUN2799 ISS2 OCT17 MAY17 CI Fact SheetDocument3 pagesFUN2799 ISS2 OCT17 MAY17 CI Fact SheetLong An DoNo ratings yet

- 24315CE r4 1-synchronyImplantFS WEBDocument4 pages24315CE r4 1-synchronyImplantFS WEBLong An DoNo ratings yet

- Cochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesDocument9 pagesCochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesLong An DoNo ratings yet

- Summary of Safety and Effectiveness Data (Ssed) : I. General InformationDocument36 pagesSummary of Safety and Effectiveness Data (Ssed) : I. General InformationLong An DoNo ratings yet

- Rondo 2: Quick GuideDocument32 pagesRondo 2: Quick GuideLong An DoNo ratings yet

- RONDO 2 Audio Processor: Product CatalogueDocument24 pagesRONDO 2 Audio Processor: Product CatalogueLong An DoNo ratings yet

- Aw31902 - 10 - Sonnet User Manual en English UsDocument76 pagesAw31902 - 10 - Sonnet User Manual en English UsLong An DoNo ratings yet

- Rondo 2: It's Never Been EasierDocument4 pagesRondo 2: It's Never Been EasierLong An DoNo ratings yet

- 003244v3 FullDocument91 pages003244v3 FullLong An DoNo ratings yet

- ANSD Guidelines V 2-2 0608131Document29 pagesANSD Guidelines V 2-2 0608131Long An DoNo ratings yet

- 6 Mertens Thursday July 11 1Document16 pages6 Mertens Thursday July 11 1Long An DoNo ratings yet

- BASF Dura-Color Technology Brochure enDocument5 pagesBASF Dura-Color Technology Brochure enLong An DoNo ratings yet

- Cells 10 02400Document16 pagesCells 10 02400Long An DoNo ratings yet

- 2016 BASF ArchitecturalCoatingsBrochure ELDocument64 pages2016 BASF ArchitecturalCoatingsBrochure ELLong An DoNo ratings yet

- Encor 446Document2 pagesEncor 446Long An DoNo ratings yet

- Cancers 13 02731Document17 pagesCancers 13 02731Long An DoNo ratings yet

- Defoamers. Dispersions & Pigments Division Formulation AdditivesDocument51 pagesDefoamers. Dispersions & Pigments Division Formulation AdditivesLong An DoNo ratings yet

- PRIMAL™ HG-1000 Binder: Technical Data SheetDocument9 pagesPRIMAL™ HG-1000 Binder: Technical Data SheetLong An DoNo ratings yet

- Desmodur L 75 - en - 82358391 12978387 13422316Document3 pagesDesmodur L 75 - en - 82358391 12978387 13422316Long An DoNo ratings yet

- كيمياء رابع علمي متميزينDocument132 pagesكيمياء رابع علمي متميزينalmuhndsNo ratings yet

- Development and Validation of Equation of State Fluid Descriptions For C02/Reservoir Oil SystemsDocument6 pagesDevelopment and Validation of Equation of State Fluid Descriptions For C02/Reservoir Oil Systemsoppai.gaijinNo ratings yet

- Chapter 17 - Rev PDFDocument13 pagesChapter 17 - Rev PDFalaa al sahmaraniNo ratings yet

- All Stoichiometry Review (Dec 2020)Document16 pagesAll Stoichiometry Review (Dec 2020)ocNo ratings yet

- Sanray Laboratories PVT LTD.: Sample ResultsDocument1 pageSanray Laboratories PVT LTD.: Sample ResultsSai dineshNo ratings yet

- Small Molecule Tools To ModulaDocument329 pagesSmall Molecule Tools To Modula吴善统No ratings yet

- BISMUTODocument2 pagesBISMUTOLuis Castro HermozaNo ratings yet

- Collagen - Biomaterial For Drug Delivery PDFDocument24 pagesCollagen - Biomaterial For Drug Delivery PDFMichael PradoNo ratings yet

- Oil Additives BrochureDocument12 pagesOil Additives BrochureGray WangNo ratings yet

- 1972 - Bazaral, Hamburger - Standardization and Stability of Immunoglobulin E (IgE)Document3 pages1972 - Bazaral, Hamburger - Standardization and Stability of Immunoglobulin E (IgE)pond_1993No ratings yet

- Solutions: © 2011 Mark H. Rosengarten AE 1Document21 pagesSolutions: © 2011 Mark H. Rosengarten AE 1Yustinus ErickoNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Solved Topical and Yearly (READANDWRITE PDFDocument275 pagesSolved Topical and Yearly (READANDWRITE PDFabdul majeed100% (3)

- Corrosion of Metallic Biomaterials A ReviewDocument92 pagesCorrosion of Metallic Biomaterials A ReviewSabrina RosoiuNo ratings yet

- Che553 - Group - Assignment 2 - 20232Document8 pagesChe553 - Group - Assignment 2 - 20232Arfa Zulkifli01No ratings yet

- Electrolysis of WaterDocument6 pagesElectrolysis of WaterAJ SiosonNo ratings yet

- Gilson Product GuideDocument39 pagesGilson Product Guidewwl1981No ratings yet

- A Study On Compatibility of Concrete Repair MaterialsDocument21 pagesA Study On Compatibility of Concrete Repair MaterialsMahmoud HakimNo ratings yet

- Ultrasound: Ultrasound Is Sound Waves WithDocument80 pagesUltrasound: Ultrasound Is Sound Waves WithPalwan SaryNo ratings yet

- ChemistryDocument1 pageChemistryfiston ishimweNo ratings yet

- Use of Chitosan in Mosquito Repellent Finishing For Cotton Textiles 2165 8064.1000162Document3 pagesUse of Chitosan in Mosquito Repellent Finishing For Cotton Textiles 2165 8064.1000162leesamgyupNo ratings yet

- Chem Kinet Meeting 2Document27 pagesChem Kinet Meeting 2Nuril AzmiNo ratings yet

- Threaded Fasteners With Applied Medium or High Strength Threadlockers - Effect of Different Tightening Procedures On The Tribologial ResponseDocument27 pagesThreaded Fasteners With Applied Medium or High Strength Threadlockers - Effect of Different Tightening Procedures On The Tribologial ResponseLucas InacioNo ratings yet

- BASIS F15 Technical Data SheetDocument1 pageBASIS F15 Technical Data SheetVaittianathan MahavapillaiNo ratings yet

- Disha 3550 Class 10 Science and Mathematics Question BankDocument296 pagesDisha 3550 Class 10 Science and Mathematics Question BankDhruv Jain100% (1)

- 650d4cf65709d80018c3c617 - ## - Ionic Equilibrium DPP 04 (Extra)Document3 pages650d4cf65709d80018c3c617 - ## - Ionic Equilibrium DPP 04 (Extra)Brijesh MishraNo ratings yet

- Quality & Process Control in Textile ProcessingDocument56 pagesQuality & Process Control in Textile ProcessingKeshav Dhawan100% (3)

- Science1001albe 0 PDFDocument10 pagesScience1001albe 0 PDFChunLiNo ratings yet

- 3 Wang2006Document7 pages3 Wang2006senthilNo ratings yet

- Problem Set 6 Fall 2018 With SolutionsDocument5 pagesProblem Set 6 Fall 2018 With SolutionsrickNo ratings yet

MAINCOTE HG-54C Acrylic Resin

MAINCOTE HG-54C Acrylic Resin

Uploaded by

Long An DoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAINCOTE HG-54C Acrylic Resin

MAINCOTE HG-54C Acrylic Resin

Uploaded by

Long An DoCopyright:

Available Formats

Formulation Guidelines

MAINCOTE™ HG-54C Acrylic Resin

Waterborne Acrylic Resin for Corrosion Resistant Primers and High Gloss Topcoats

Regional Product Asia-Pacific

Availability

Description MAINCOTE™ HG-54C Acrylic Resin offers excellent performance standards for acrylic

waterborne maintenance paint vehicles. It can be formulated into primers and gloss topcoats

which are designed for commercial, institutional, and industrial maintenance markets. The

full gloss capability, corrosion resistance, flow, hardness, and chemical resistance

characteristics imparted by MAINCOTE HG-54C Acrylic Resin in a waterborne finish are

typical of those associated with conventional solvent-based maintenance systems. Primer

formulations offer stability with commonly used corrosion-inhibiting pigments.

Formulation The formulation methodology is a major contributor to the performance of MAINCOTE™ HG-

Guidelines 54C Acrylic Resin in paint. The choice of paint ingredients determines the protective as well

as the application properties. The choice and amount of each ingredient in the formulations

offered is significant to the performance. Substitutes should be carefully evaluated.

Coalescent and The type and level of coalescent in the formulation is critical to the balance of properties.

Co-solvent Effects Hydrophobic coalescents that partition to the polymer phase are recommended as opposed

to water-soluble coalescents. Texanol at 15% on polymer solids is optimum for gloss.

Formulations HB-54C-2, G-54C-6, and G-54C-7 illustrate starting-point formulations for

Topcoat/Direct to metal (DTM) applications using different types of coalescent packages.

Both HB-54C-2 and G-54C-6 are recommended high-gloss formulations. Formulation G-

54C-7 contains Dipropylene glycol n-butyl ether (DPnB) / Dibutyl phthalate (DBP) which is a

coalescent package giving good early water resistance properties. This coalescent package

will not yield the high gloss of formulations HB-54C-2 and G-54C-6, but it will show better

early water resistance and corrosion properties. DPnB/DBP is also the coalescent package

for our starting point primer formulation P-54C-9

Dispersing and Like coalescents, the type and level of dispersant will influence the property balance of

Wetting Agents paints based on MAINCOTE™ HG-54C Acrylic Resin. OROTAN™ 165A and OROTAN 681

Dispersants at 1.0% and 1.5% on pigment (solids/solids), respectively, are recommended

starting points. OROTAN 165A Dispersant will give maximum corrosion protection. OROTAN

681 Dispersant will provide higher gloss and will suppress low shear viscosities (Kreb Units),

which is an added feature when using this dispersant. Surfynol 104DPM surfactant is the

wetting aid of choice because it has the least effect on corrosion resistance. It is

advantageous to corrosion resistance to minimize the use of these materials as long as

other properties, like paint stability, are not compromised.

Rheology Nonionic urethane rheology modifiers such as ACRYSOL™ RM-2020NPR, ACRYSOL RM-

Modifiers 8W, and ACRYSOL RM-12W Rheology Modifiers are key to the performance of

MAINCOTE™ HG-54C Acrylic Resin. The use of cellulosic or alkali-soluble thickeners

significantly downgrades its performance, especially corrosion resistance.

UNRESTRICTED – May be shared with anyone

®TM Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 883-00189-0215-APC-EN

Page 1 of 7 MAINCOTE™ HG-54C Acrylic Resin / Dow Coating Materials 02/2015, Rev. 1

Formulation Guidelines

Expected method of application is significant to the selection of rheology control agents.

Brushing formulations require higher viscosity under high shear conditions for best brush

drag. On the other hand, lower high shear viscosity is desired for ease of atomization during

spraying. High shear viscosity is measured by the ICI Viscometer (cone and plate) with units

in poise. The viscosity range suitable for brushing is 1.5 to 2.0 poise, while 0.5 poise is

characteristic of a paint with good atomization.

Low shear viscosity is measured with the Stormer Viscometer with units in Krebs. The

viscosity range best for airless spray is 95-105 Kreb Units to minimize sagging tendencies.

For brushing, formulate to lower values of approximately 85 KU so that brush marks flow out.

ACRYSOL™ RM-2020NPR Rheology Modifier is the choice for brush or roller application.

ACRYSOL RM-8W and ACRYSOL RM-12W Rheology Modifiers are more suitable in paints

designed for spray application. ACRYSOL RM-12Wi Rheology Modifier is excellent for spray

application where flow/sag balance is critical. Having a paint that provides optimum viscosity

for both brush and spray application is difficult and having a viscosity of 90 Kreb Units/1.0

poise (low shear/high shear viscosity) is a compromise. To attain this rheology profile, it

would be necessary to use both rheology modifiers.

Wet Edge and The most effective additives to extend the wet edge time and to inhibit freezing of aqueous

Freeze-thaw paints are propylene glycol and ethylene glycol, but they are hygroscopic and can present

Agents film-formation problems, especially at high humidity. As such, these materials have a

detrimental effect on corrosion resistance, especially early rusting. The starting point

formulations optimized for corrosion resistance tend to have marginal freeze-thaw stability.

Paints with improved freeze-thaw stability can be formulated but with some sacrifice in

corrosion resistance.

Flash Rust In waterborne paints for steel, the water phase must be inhibited or flash rusting will occur.

Inhibitors The recommended additive is sodium nitrite, which is very effective at very low use levels.

Raybo 60 inhibitor or ammonium benzoate are alternatives.

Defoamers Foam control is a major concern in waterborne paint formulation design. Additives are

necessary to eliminate foam during manufacture and on application. The choice of defoamer

type and level will depend primarily on the formulation and mode of application. Deeptone

formulations for airless spray application, which use predispersed colorants, will require the

most potent defoamer package. Brushing formulations with in-house, factory-dispersed dry

pigments will require less.

A good start in choosing the right defoamer package is to have a silicone type in the grind

followed by a non-silicone in the letdown. Effectiveness of the defoamer can be screened by

the shaker test, but the best candidates should be checked by actual application.

Drawdowns should also be done to check for surface defects and impact on gloss.

Defoamer persistence should be checked by oven aging and retesting the defoaming

capabilities.

UNRESTRICTED – May be shared with anyone

®TM Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 883-00189-0215-APC-EN

Page 2 of 7 MAINCOTE™ HG-54C Acrylic Resin / Dow Coating Materials 02/2015, Rev. 1

Formulation Guidelines

Colorants Colorant addition to waterborne maintenance paints generally lowers corrosion resistance

due to the high level of surfactants or additives used to disperse and stabilize the colored

pigments. Colorants recommended for industrial applications, such as Huls America,

AquaChem 896 colorant, have minimal effect as opposed to the universal colorants

commonly used in architectural paints.

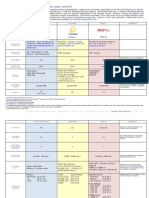

Starting-Point Formulation

High-build Gloss White Topcoat for Airless Spray Application

Based on MAINCOTE™ HG-54C Acrylic Resin

Formulation HB-54C-2

Material Name

Grind Kg

Grind in a Cowles Dissolver to 7+ Hegman, then let down at slower speed

MAINCOTE™ HG-54C Acrylic Resin 400.0

Surfynol CT-151 dispersant 8.5

Ammonia (28%) (pH control) 1.0

Surfynol DF-210 defoamer 2.4

Ti-Pure R-900HG titanium dioxide 127.6

Allow pigment to wet thoroughly, the add:

ACRYSOL™ RM-8W Rheology Modifier 1.2

Grind sub-total 540.7

LetDown

MAINCOTE HG-54C Acrylic Resin 318.5

Texanol coalescent 44.7

Surfynol DF-210 defoamer 2.4

Surfynol 104 DPM wetting agent 10.0

Ammonia (28%) (pH control) 4.0

Sodium nitrite (15% aqueous) (rust inhibitor) 8.2

Water (diluent) 28.0

ACRYSOL RM-8W Rheology Modifier 0.8

Total 957.3

Expected Formulation Constants

PVC, % 10.0

Volume Solids, % 36.5

Weight Solids, % 44.4

Initial viscosity, Krebs 95

pH 9.3

VOC 119.8

Grind, Hegman 7+

UNRESTRICTED – May be shared with anyone

®TM Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 883-00189-0215-APC-EN

Page 3 of 7 MAINCOTE™ HG-54C Acrylic Resin / Dow Coating Materials 02/2015, Rev. 1

Formulation Guidelines

Starting-Point Formulation

High Gloss, Fast-dry DTM Topcoat for Airless Spray Application

Based on MAINCOTE™ HG-54C Acrylic Resin

Formulation G-54C-6

Material Name

Grind Kg

Dipropylene glycol methyl ether (coalescent)1 18.0

Water (diluent) 35.0

OROTAN™ 165A Dispersant 9.5

Ammonia (28%) (pH control) 1.0

TRITON™ CF-10 Surfactant 1.5

Tego Foamex 1488 defoamer 1.5

Ti-Pure R-706 titanium dioxide 195.0

Cowles grind to 7+ Hegman, then add at low speed:

Water (diluent) 5.0

Grind sub-total 266.5

LetDown

MAINCOTE™ HG-54C Acrylic Resin 660.0

Ammonia (28%) (pH control) 4.0

Ethylene glycol monobutyl ether (coalescent) 2 110.0

Tego Foamex 1488 defoamer 2.5

Sodium nitrite (15% aqueous) (rust inhibitor) 9.0

Total 1052.0

Expected Formulation Constants

PVC, % 16.0

Volume Solids, % 33.7

Weight Solids, % 44.6

Initial viscosity, Krebs 95

pH 8.5

VOC 281.6

Grind, Hegman 7+

1. Dipropylene glycol methyl ether. For example DOWANOL™ DPM Coalescent

2. Ethylene glycol monobutyl ether. For example Butyl CELLOSOLVE™ Coalescent

UNRESTRICTED – May be shared with anyone

®TM Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 883-00189-0215-APC-EN

Page 4 of 7 MAINCOTE™ HG-54C Acrylic Resin / Dow Coating Materials 02/2015, Rev. 1

Formulation Guidelines

Starting-Point Formulation

Mid Gloss, Fast-dry DTM Topcoat with Early Water Resistance for

Airless Spray Application based on MAINCOTE™ HG-54C Acrylic Resin

Formulation G-54C-7

Material Name

Grind Kg

Dipropylene glycol methyl ether (coalescent)1 18.0

Water (diluent) 35.0

OROTAN™ 165A Dispersant 9.5

Ammonia (28%) (pH control) 1.0

TRITON™ CF-10 Surfactant 1.5

Tego Foamex 1488 defoamer 1.5

Ti-Pure R-706 titanium dioxide 195.0

Cowles grind to 7+ Hegman, then add at low speed:

Water (diluent) 5.0

Grind sub-total 266.5

LetDown

MAINCOTE™ HG-54C Acrylic Resin 660.0

Ammonia (28%) (pH control) 4.0

Dipropylene glycol n-butyl ether (coalescent) 2 55.0

Dibutyl phthalate (coalescent) 14.0

Tego Foamex 1488 defoamer 2.5

Sodium nitrite (15% aqueous) (rust inhibitor) 9.0

ACRYSOL™ RM-8W Rheology Modifier 4.5

Total 1015.5

Expected Formulation Constants

PVC, % 16.0

Volume Solids, % 35.5

Weight Solids, % 46.2

Initial viscosity, Krebs 97

pH 8.5

VOC 179.5

Grind, Hegman 7+

1. Dipropylene glycol methyl ether. For example DOWANOL™ DPM Coalescent

2. Dipropylene glycol n-butyl ether . For example DOWANOL DPnB Coalescent

UNRESTRICTED – May be shared with anyone

®TM Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 883-00189-0215-APC-EN

Page 5 of 7 MAINCOTE™ HG-54C Acrylic Resin / Dow Coating Materials 02/2015, Rev. 1

Formulation Guidelines

Starting-Point Formulation

Red Primer Paint for Airless Spray Application

Based on MAINCOTE™ HG-54C Acrylic Resin

Formulation P-54C-9

Material Name

Grind Kg

Dipropylene glycol methyl ether (coalescent)1 20.0

Water (diluent) 60.0

OROTAN™ 165A Dispersant 13.0

Ammonia (28%) (pH control) 1.0

TRITON™ CF-10 Surfactant 1.6

Tego Foamex 1488 defoamer 2.0

Bayferrox 120NM red iron oxide 50.0

Atomite calcium carbonate 100.0

Heucophos ZMP anti-corrosive pigment 2 50.0

Shieldex anti-corrosive pigment 26.0

Aerosil R-972 fumed silica 5.0

Cowles grind to 5+ Hegman.

Grind sub-total 328.6

LetDown

MAINCOTE™ HG-54C Acrylic Resin 563.0

Ammonia (28%) (pH control) 3.2

Premix:

Water (diluent) 20.0

Dipropylene glycol n-butyl ether (coalescent) 3 30.0

Dibutyl phthalate (coalescent) 15.0

Tego Foamex 1488 defoamer 4.0

Sodium nitrite (15% aqueous) (rust inhibitor) 9.0

Premix, then add:

ACRYSOL™ RM-8W Rheology Modifier 4.0

Water (diluent) 4.0

Total 980.0

Expected Formulation Constants

PVC, % 26.2

Volume Solids, % 36.2

Weight Solids, % 47.3

Initial viscosity, Krebs 97

pH 8.5

VOC 133.7

Grind, Hegman 5+

1. Dipropylene glycol methyl ether. For example DOWANOL™ DPM Coalescent

2. Heucophos ZMP = basic zinc molybdenum orthophosphate hydrate

3. Dipropylene glycol n-butyl ether. For example DOWANOL DPnB Coalescent

UNRESTRICTED – May be shared with anyone

®TM Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 883-00189-0215-APC-EN

Page 6 of 7 MAINCOTE™ HG-54C Acrylic Resin / Dow Coating Materials 02/2015, Rev. 1

Handling Before using this product, consult the Material Safety Data Sheet (MSDS)/Safety Data

Precautions Sheet (SDS) for details on product hazards, recommended handling precautions and

product storage.

Storage Store products in tightly closed original containers at temperatures recommended on the

product label.

Disposal Dispose in accordance with all local, state (provincial) and federal regulations. Empty

Considerations containers may contain hazardous residues. This material and its container must be

disposed in a safe and legal manner.

It is the user's responsibility to verify that treatment and disposal procedures comply with

local, state (provincial) and federal regulations. Contact your Dow Technical Representative

for more information.

Chemical Many countries within the Asia-Pacific require the registration of chemicals, either imported

Registration or produced locally, prior to their commercial use. Violation of these regulations may lead to

substantial penalties imposed upon the user, the importer or manufacturer, and/or cessation

of supply. It is in your interests to ensure that all chemicals used by you are registered.

Dow does not supply unregistered products unless permitted under limited sampling

procedures as a precursor to registration.

Note on Product availability and grades vary throughout the countries in Asia-Pacific. Please contact

Asia-Pacific your local Dow Coating Materials representative for further information and samples.

Product Line

Product Dow has a fundamental concern for all who make, distribute, and use its products, and for

Stewardship the environment in which we live. This concern is the basis for our product stewardship

philosophy by which we assess the safety, health, and environmental information on our

products and then take appropriate steps to protect employee and public health and our

environment. The success of our product stewardship program rests with each and every

individual involved with Dow products - from the initial concept and research, to manufacture,

use, sale, disposal, and recycle of each product.

Customer Notice Dow strongly encourages its customers to review both their manufacturing processes and

their applications of Dow products from the standpoint of human health and environmental

quality to ensure that Dow products are not used in ways for which they are not intended or

tested. Dow personnel are available to answer your questions and to provide reasonable

technical support. Dow product literature, including safety data sheets, should be consulted

prior to use of Dow products. Current safety data sheets are available from Dow.

Contact: NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and

Australia / NZ +61-3-9956-7500 applicable laws may differ from one location to another and may change with time, Customer is responsible for determining

South East Asia +65-6861-1077 whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's

Greater China +86-21-3851-1000 workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown

Japan +81-3-5460-2150 in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made

Korea +82-10-5265-3736 may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document.

India +91-22-6602-8888 References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly

http://www.dow.com/coating

noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

UNRESTRICTED – May be shared with anyone

®TM Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 883-00189-0215-APC-EN

Page 7 of 7 MAINCOTE™ HG-54C Acrylic Resin / Dow Coating Materials 02/2015, Rev. 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebDocument64 pagesAW32150 - 30 - Surgical Guideline SYNCHRONY PIN - EN English - WebLong An DoNo ratings yet

- Cellosize QP 100mhDocument2 pagesCellosize QP 100mhca_rl_4No ratings yet

- FUN2799 ISS2 OCT17 MAY17 CI Fact SheetDocument3 pagesFUN2799 ISS2 OCT17 MAY17 CI Fact SheetLong An DoNo ratings yet

- 24315CE r4 1-synchronyImplantFS WEBDocument4 pages24315CE r4 1-synchronyImplantFS WEBLong An DoNo ratings yet

- Cochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesDocument9 pagesCochlear Implant Comparison Chart: 16 CFR Part 255 Revised Endorsement GuidesLong An DoNo ratings yet

- Summary of Safety and Effectiveness Data (Ssed) : I. General InformationDocument36 pagesSummary of Safety and Effectiveness Data (Ssed) : I. General InformationLong An DoNo ratings yet

- Rondo 2: Quick GuideDocument32 pagesRondo 2: Quick GuideLong An DoNo ratings yet

- RONDO 2 Audio Processor: Product CatalogueDocument24 pagesRONDO 2 Audio Processor: Product CatalogueLong An DoNo ratings yet

- Aw31902 - 10 - Sonnet User Manual en English UsDocument76 pagesAw31902 - 10 - Sonnet User Manual en English UsLong An DoNo ratings yet

- Rondo 2: It's Never Been EasierDocument4 pagesRondo 2: It's Never Been EasierLong An DoNo ratings yet

- 003244v3 FullDocument91 pages003244v3 FullLong An DoNo ratings yet

- ANSD Guidelines V 2-2 0608131Document29 pagesANSD Guidelines V 2-2 0608131Long An DoNo ratings yet

- 6 Mertens Thursday July 11 1Document16 pages6 Mertens Thursday July 11 1Long An DoNo ratings yet

- BASF Dura-Color Technology Brochure enDocument5 pagesBASF Dura-Color Technology Brochure enLong An DoNo ratings yet

- Cells 10 02400Document16 pagesCells 10 02400Long An DoNo ratings yet

- 2016 BASF ArchitecturalCoatingsBrochure ELDocument64 pages2016 BASF ArchitecturalCoatingsBrochure ELLong An DoNo ratings yet

- Encor 446Document2 pagesEncor 446Long An DoNo ratings yet

- Cancers 13 02731Document17 pagesCancers 13 02731Long An DoNo ratings yet

- Defoamers. Dispersions & Pigments Division Formulation AdditivesDocument51 pagesDefoamers. Dispersions & Pigments Division Formulation AdditivesLong An DoNo ratings yet

- PRIMAL™ HG-1000 Binder: Technical Data SheetDocument9 pagesPRIMAL™ HG-1000 Binder: Technical Data SheetLong An DoNo ratings yet

- Desmodur L 75 - en - 82358391 12978387 13422316Document3 pagesDesmodur L 75 - en - 82358391 12978387 13422316Long An DoNo ratings yet

- كيمياء رابع علمي متميزينDocument132 pagesكيمياء رابع علمي متميزينalmuhndsNo ratings yet

- Development and Validation of Equation of State Fluid Descriptions For C02/Reservoir Oil SystemsDocument6 pagesDevelopment and Validation of Equation of State Fluid Descriptions For C02/Reservoir Oil Systemsoppai.gaijinNo ratings yet

- Chapter 17 - Rev PDFDocument13 pagesChapter 17 - Rev PDFalaa al sahmaraniNo ratings yet

- All Stoichiometry Review (Dec 2020)Document16 pagesAll Stoichiometry Review (Dec 2020)ocNo ratings yet

- Sanray Laboratories PVT LTD.: Sample ResultsDocument1 pageSanray Laboratories PVT LTD.: Sample ResultsSai dineshNo ratings yet

- Small Molecule Tools To ModulaDocument329 pagesSmall Molecule Tools To Modula吴善统No ratings yet

- BISMUTODocument2 pagesBISMUTOLuis Castro HermozaNo ratings yet

- Collagen - Biomaterial For Drug Delivery PDFDocument24 pagesCollagen - Biomaterial For Drug Delivery PDFMichael PradoNo ratings yet

- Oil Additives BrochureDocument12 pagesOil Additives BrochureGray WangNo ratings yet

- 1972 - Bazaral, Hamburger - Standardization and Stability of Immunoglobulin E (IgE)Document3 pages1972 - Bazaral, Hamburger - Standardization and Stability of Immunoglobulin E (IgE)pond_1993No ratings yet

- Solutions: © 2011 Mark H. Rosengarten AE 1Document21 pagesSolutions: © 2011 Mark H. Rosengarten AE 1Yustinus ErickoNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Solved Topical and Yearly (READANDWRITE PDFDocument275 pagesSolved Topical and Yearly (READANDWRITE PDFabdul majeed100% (3)

- Corrosion of Metallic Biomaterials A ReviewDocument92 pagesCorrosion of Metallic Biomaterials A ReviewSabrina RosoiuNo ratings yet

- Che553 - Group - Assignment 2 - 20232Document8 pagesChe553 - Group - Assignment 2 - 20232Arfa Zulkifli01No ratings yet

- Electrolysis of WaterDocument6 pagesElectrolysis of WaterAJ SiosonNo ratings yet

- Gilson Product GuideDocument39 pagesGilson Product Guidewwl1981No ratings yet

- A Study On Compatibility of Concrete Repair MaterialsDocument21 pagesA Study On Compatibility of Concrete Repair MaterialsMahmoud HakimNo ratings yet

- Ultrasound: Ultrasound Is Sound Waves WithDocument80 pagesUltrasound: Ultrasound Is Sound Waves WithPalwan SaryNo ratings yet

- ChemistryDocument1 pageChemistryfiston ishimweNo ratings yet

- Use of Chitosan in Mosquito Repellent Finishing For Cotton Textiles 2165 8064.1000162Document3 pagesUse of Chitosan in Mosquito Repellent Finishing For Cotton Textiles 2165 8064.1000162leesamgyupNo ratings yet

- Chem Kinet Meeting 2Document27 pagesChem Kinet Meeting 2Nuril AzmiNo ratings yet

- Threaded Fasteners With Applied Medium or High Strength Threadlockers - Effect of Different Tightening Procedures On The Tribologial ResponseDocument27 pagesThreaded Fasteners With Applied Medium or High Strength Threadlockers - Effect of Different Tightening Procedures On The Tribologial ResponseLucas InacioNo ratings yet

- BASIS F15 Technical Data SheetDocument1 pageBASIS F15 Technical Data SheetVaittianathan MahavapillaiNo ratings yet

- Disha 3550 Class 10 Science and Mathematics Question BankDocument296 pagesDisha 3550 Class 10 Science and Mathematics Question BankDhruv Jain100% (1)

- 650d4cf65709d80018c3c617 - ## - Ionic Equilibrium DPP 04 (Extra)Document3 pages650d4cf65709d80018c3c617 - ## - Ionic Equilibrium DPP 04 (Extra)Brijesh MishraNo ratings yet

- Quality & Process Control in Textile ProcessingDocument56 pagesQuality & Process Control in Textile ProcessingKeshav Dhawan100% (3)

- Science1001albe 0 PDFDocument10 pagesScience1001albe 0 PDFChunLiNo ratings yet

- 3 Wang2006Document7 pages3 Wang2006senthilNo ratings yet

- Problem Set 6 Fall 2018 With SolutionsDocument5 pagesProblem Set 6 Fall 2018 With SolutionsrickNo ratings yet