Professional Documents

Culture Documents

PSV Report Blocked

PSV Report Blocked

Uploaded by

Elias EliasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSV Report Blocked

PSV Report Blocked

Uploaded by

Elias EliasCopyright:

Available Formats

ENERGY EQUITY EPIC

DOC. NO. REV.

EE-PR-CAL-004 A

Calculation

DATE: August 31, 2021 SHEET: 1 OF 5

PSV SIZING

REPORT

(BLOCKED OUTLET CASE)

ENERGY EQUITY EPIC (SENGKANG) Pty. Ltd.

CPP & PMS PLANT MODIFICATION PROJECT

RE DATE PAGE DESCRIPTION PREP’ CHK’D APP’D COMP

A 31-Aug-21 5 ISSUED FOR REVIEW AHS DNS

ENERGY EQUITY EPIC CPP & PMS Plant Modification Project

TABLE OF CONTENT

Page

1. INTRODUCTION.......................................................................................................2

2. DESIGN BASIS......................................................................................................... 3

3. DESIGN METHOD.....................................................................................................3

4. SUMMARY OF RESULT...........................................................................................4

5. REFERENCE............................................................................................................. 4

ATTACHMENT:

A. PSV-10310 CALCULATION SHEET

B. PSV-10311 CALCULATION SHEET

C. PSV-1223 CALCULATION SHEET

PSV SIZING REPORT (Blocked Discharge) Page 2 of 5

ENERGY EQUITY EPIC CPP & PMS Plant Modification Project

1.0 INTRODUCTION

The aims of this calculation are determine the recommended Pressure Relief Valves

(PSV) size for inlet separator (V-103) at Central Processing Plant (CPP) and inlet

separator (V-122) Patila Metering System (PMS).

2.0 DESIGN BASIS

The following basis was applied:

1. PSV loads for blocked outlet case were based on rates as shown on Process Flow

Diagrams.

2. PSV-1223 load (instrument failure case) were based on restriction orifice calculation.

3. PSV load for PSV 10310 and PSV-10311 is 49505 lb/hr.

4. PSV load for PSV-1223 is 71 mmscfd or 132226 lb/hr

3.0 DESIGN METHOD

Orifice Size calculation

The following formula will be used for blocked outlet case.

W Z T

a

C P1 Kd Kb M

Where:

W = Relief Load, Lb/hr

P1 = Relieving pressure, psia

C = Coefficient, Table. 9 API 520

Kd = constant, 0.975 per API 520

Kb = constant, 1 per API 520

Z = Compressibility factor

T = relieving temperature

M = molecular weight

a = orifice area, in2

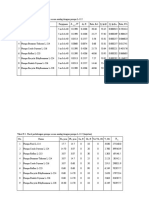

4.0 SUMMARY OF THE CALCULATION RESULT

PSV SIZING REPORT (Blocked Discharge) Page 3 of 5

ENERGY EQUITY EPIC CPP & PMS Plant Modification Project

Refer to Attachment for Calculation of Design Result

Vessel “Full-open” PSV Orifice Orifice Lead and Tail

PSV No. Case

No. Relief Rate Area Designation Pipe Size

LB/HR IN2 IN

Blocked

V-103 PSV-10310 64123 0.785 H 2-600# X 3-150#

Discharge

Blocked

V-103 PSV-10311 64123 0.785 H 2-600# X 3-150#

Discharge

Instrument

V-122 PSV-1223 140471 2.853 L 4-300# X 6-150#

Failure

The Complete calculation result is provided in Attachment Calculation Sheet

5.0 REFERENCE

1. Perry, Robert. H, "Perry's Chemical Engineering Handbooks", 5 th edition.

2. Gas Processors Supplier Association “Engineering Data Book”, Vol. 1.

3. API Recommended Practice 520, 4th edition

PSV SIZING REPORT (Blocked Discharge) Page 4 of 5

ENERGY EQUITY EPIC CPP & PMS Plant Modification Project

Attachment Calculation Sheet

PSV-10310 Calculation Sheet

PSV-10311 Calculation Sheet

PSV-1223 Calculation Sheet

PSV SIZING REPORT (Blocked Discharge) Page 5 of 5

You might also like

- Cable Adequacy Check ReportDocument21 pagesCable Adequacy Check ReportJayce PinedaNo ratings yet

- SP-OS-PL-CAL-0003 Rev. 0 Pipeline Stress AnalysisDocument19 pagesSP-OS-PL-CAL-0003 Rev. 0 Pipeline Stress AnalysisElias EliasNo ratings yet

- Line Sizing Design Basis - General Specification PDFDocument11 pagesLine Sizing Design Basis - General Specification PDFSaiKumarNo ratings yet

- Fluid Mechanics - UnlockedDocument115 pagesFluid Mechanics - UnlockedAbhigyaSingh100% (3)

- Lead Sheet 716-X000Document1 pageLead Sheet 716-X000Chandhu Kurian ThampiNo ratings yet

- Nitrogen Blanketing For Storage and TransportationDocument5 pagesNitrogen Blanketing For Storage and Transportationwferry27100% (2)

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 pagesN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridNo ratings yet

- PSV Sizing2Document3 pagesPSV Sizing2pavanNo ratings yet

- 140 V 023Document4 pages140 V 023Goutam GiriNo ratings yet

- Jihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191Document2 pagesJihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191HarryBouterNo ratings yet

- Overview of PV EliteDocument35 pagesOverview of PV EliteVishaka ThekkedathNo ratings yet

- NKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)Document15 pagesNKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)ahmad santoso100% (1)

- WI-SSA-ENGBID-004-E - 1 - Engineering Design Review in Tendering PhaseDocument8 pagesWI-SSA-ENGBID-004-E - 1 - Engineering Design Review in Tendering Phaseanghel_florin82No ratings yet

- Specification For Air Compressors and Air Dryer PackagesDocument21 pagesSpecification For Air Compressors and Air Dryer PackagesSudjono BroNo ratings yet

- Hydraulic Report - 23th MarchDocument51 pagesHydraulic Report - 23th MarchGoutam GiriNo ratings yet

- RTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVDocument15 pagesRTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVroronoa_zorro11No ratings yet

- 5639-72-PP-031 - RB-PSV Sizing Report-PSV203A&BDocument9 pages5639-72-PP-031 - RB-PSV Sizing Report-PSV203A&BpavanNo ratings yet

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 pagesNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNo ratings yet

- Pump SizeDocument9 pagesPump SizedkumarNo ratings yet

- Input From Simulation Result From Table or Chart AssumptionDocument31 pagesInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- TBA - Vessel InternalsDocument5 pagesTBA - Vessel InternalsTifano KhristiyantoNo ratings yet

- DatasheetDocument1 pageDatasheetDeni HermawanNo ratings yet

- Blowdown Calculation Inventory-TopsideDocument16 pagesBlowdown Calculation Inventory-TopsideNK100% (1)

- Process Design Basis Unit 107: NGL FractionationDocument17 pagesProcess Design Basis Unit 107: NGL Fractionationmohsen ranjbarNo ratings yet

- Line SizingDocument14 pagesLine SizingSaif MujawarNo ratings yet

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanNo ratings yet

- De MisterDocument2 pagesDe MisterLaxman G GalipelliNo ratings yet

- Oil and Natural Gas Corporation Limited: HP/LP Flare Tip and Flare Ignition System DatasheetDocument16 pagesOil and Natural Gas Corporation Limited: HP/LP Flare Tip and Flare Ignition System DatasheetHafiz AbubakarNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias Elias100% (1)

- TetraSentry SIL Verification Report PDFDocument19 pagesTetraSentry SIL Verification Report PDFHassan ManzarNo ratings yet

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Separator All Oil and Gas SpreadsheetDocument22 pagesSeparator All Oil and Gas SpreadsheetSatria 'igin' Girindra Nugraha100% (1)

- T-0702 - P&idDocument2 pagesT-0702 - P&idPriyam KmNo ratings yet

- HSR 1.63 (For HYSYS V10.0)Document4 pagesHSR 1.63 (For HYSYS V10.0)Ba Jun Thối0% (1)

- DJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDocument6 pagesDJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDIANTORONo ratings yet

- PSV Force Rev0bDocument1 pagePSV Force Rev0bdumbledoreaaaaNo ratings yet

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasNo ratings yet

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNo ratings yet

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaiseNo ratings yet

- BVBVDocument67 pagesBVBVHoàng Minh ÁiNo ratings yet

- DsdsDocument10 pagesDsdsLinh GiangNo ratings yet

- Inputs Required For FIV & AIV StudyDocument1 pageInputs Required For FIV & AIV StudyRonak MotaNo ratings yet

- Data Sheet For Magnetic Flowmeters Rev5Document3 pagesData Sheet For Magnetic Flowmeters Rev5Kandula RajuNo ratings yet

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiNo ratings yet

- PSV Sizing Tool - API BasedDocument11 pagesPSV Sizing Tool - API BasedJoseph Paul Ilagan0% (1)

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Gas Pipeline Blowdown TimeDocument6 pagesGas Pipeline Blowdown TimeWalid Ben HuseinNo ratings yet

- Settle Out Pressure Calculations PDFDocument4 pagesSettle Out Pressure Calculations PDFAlvin SmithNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- 1 PipelineStudio Gas Simulator Module Tuning - English - Rev421Document28 pages1 PipelineStudio Gas Simulator Module Tuning - English - Rev421sushilNo ratings yet

- 20120507091359 (1)Document6 pages20120507091359 (1)Noman Abu-FarhaNo ratings yet

- JS1034-XX-F06-0001. A1Document107 pagesJS1034-XX-F06-0001. A1Pawan Gosavi100% (1)

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- FlareTot - Total Flare AnalysisDocument8 pagesFlareTot - Total Flare AnalysisArjun KapoorNo ratings yet

- PSV Reation Force - Two Phase - Assumption Close SytemDocument4 pagesPSV Reation Force - Two Phase - Assumption Close SytemNesrine MhedhbiNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28From EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28No ratings yet

- DH PEP PPS PR 001 Process DescriptionDocument6 pagesDH PEP PPS PR 001 Process Descriptionfadli arsyadaNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- API520 RVsizingDocument6 pagesAPI520 RVsizingDarshan PatelNo ratings yet

- RPT-1000483-PL-000-00-00-010 - Rev 1Document65 pagesRPT-1000483-PL-000-00-00-010 - Rev 1process1plecoNo ratings yet

- CA-4010GS-CC-001 Rev BDocument21 pagesCA-4010GS-CC-001 Rev BCharles HutabaratNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Data sheetCExlsDocument1 pageData sheetCExlsElias Elias100% (1)

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Specific Project SpecificationDocument5 pagesSpecific Project SpecificationElias EliasNo ratings yet

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasNo ratings yet

- Cover Coalescing Filter (F-9000)Document1 pageCover Coalescing Filter (F-9000)Elias EliasNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias Elias100% (1)

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Project Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateDocument3 pagesProject Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateElias EliasNo ratings yet

- Singgar Mulia Engineering: Vertical Separator Design BasisDocument2 pagesSinggar Mulia Engineering: Vertical Separator Design BasisElias EliasNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Attachment For FireDocument8 pagesAttachment For FireElias EliasNo ratings yet

- UICAFE12815-ENG-CAL-XXXX Rev ADocument23 pagesUICAFE12815-ENG-CAL-XXXX Rev AElias EliasNo ratings yet

- Production Pump Sizing P. 0920 A, B, C: CalculationDocument5 pagesProduction Pump Sizing P. 0920 A, B, C: CalculationElias EliasNo ratings yet

- Cost Breakdown-Sent To Contractors (ESA Process Review)Document6 pagesCost Breakdown-Sent To Contractors (ESA Process Review)Elias EliasNo ratings yet

- Hazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesDocument12 pagesHazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesElias EliasNo ratings yet

- Appendix BDocument66 pagesAppendix BElias EliasNo ratings yet

- Hazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesDocument13 pagesHazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesElias EliasNo ratings yet

- Piping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaDocument3 pagesPiping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaElias EliasNo ratings yet

- Appendix ADocument16 pagesAppendix AElias EliasNo ratings yet

- 0708-L-CC-002 Pipeline Stress Calculation From GRF Keramasan To AKE Rev BDocument10 pages0708-L-CC-002 Pipeline Stress Calculation From GRF Keramasan To AKE Rev BElias EliasNo ratings yet

- Appendix ADocument38 pagesAppendix AElias EliasNo ratings yet

- 0708-Q-CC-001 Pipe Stress Calculation From Pipeline To Gas Scrubber Rev BDocument11 pages0708-Q-CC-001 Pipe Stress Calculation From Pipeline To Gas Scrubber Rev BElias EliasNo ratings yet

- Gas Liquid Separation Technology PDFDocument24 pagesGas Liquid Separation Technology PDFnodyyyNo ratings yet

- Exercise 7 ChemistryDocument31 pagesExercise 7 Chemistryapi-533545229No ratings yet

- Saes L 131Document10 pagesSaes L 131samsurendran_mech4020No ratings yet

- Sedimentation Tank DesignDocument23 pagesSedimentation Tank Designyash_btech100% (1)

- Lab Report 8Document4 pagesLab Report 8mamoona noreenNo ratings yet

- Wastewater Treatment Plant WWTP2Document9 pagesWastewater Treatment Plant WWTP2اسومي الوكحNo ratings yet

- Fluid Pressure Measuring DevicesDocument31 pagesFluid Pressure Measuring DevicesM Kafeel Khan100% (1)

- HVAC LAB ReportDocument47 pagesHVAC LAB ReportMuhammad Abubakar Muhammad ShoaibNo ratings yet

- Model Testing of Francis-Type Hydraulic TurbinesDocument4 pagesModel Testing of Francis-Type Hydraulic TurbinesAjay KumarNo ratings yet

- Applied Hydrology AssignmentDocument39 pagesApplied Hydrology AssignmentAbdusalam IdirisNo ratings yet

- Air System DesignDocument50 pagesAir System DesignratheeshNo ratings yet

- Water Responsive Initiative For Urban Planning:: Anupama .K #13 S-8 B-ArchDocument11 pagesWater Responsive Initiative For Urban Planning:: Anupama .K #13 S-8 B-ArchkukucuckooNo ratings yet

- Task 1: - A) It's Required To Describe With A Schematic Representation The Main Turbomachines Classifications According To: - 1) Energy TransferDocument14 pagesTask 1: - A) It's Required To Describe With A Schematic Representation The Main Turbomachines Classifications According To: - 1) Energy TransferAbd El-Rahman NasserNo ratings yet

- Fans, Blowers and Compressors: Used To Move and Compress The GasDocument37 pagesFans, Blowers and Compressors: Used To Move and Compress The GasAteeq Ul RehmanNo ratings yet

- Water Treatment Lecture 4 EENVDocument35 pagesWater Treatment Lecture 4 EENVEllina TehNo ratings yet

- Welder HandbookDocument7 pagesWelder Handbooksandeepkumar63No ratings yet

- SEJ446 Final Report 2014Document81 pagesSEJ446 Final Report 2014Busiku SilengaNo ratings yet

- Separator Sizing - Part-4 by Anand PatelDocument8 pagesSeparator Sizing - Part-4 by Anand PatelHarish KumarNo ratings yet

- Primary Chilled Water Pump Head Loss CalculationDocument6 pagesPrimary Chilled Water Pump Head Loss Calculationsatish HiremathNo ratings yet

- CIVE2304 C5 Subsurface WaterDocument60 pagesCIVE2304 C5 Subsurface WaternaserNo ratings yet

- Fluid Statics - Part 1 (Hydrostatics) : Ioan NistorDocument8 pagesFluid Statics - Part 1 (Hydrostatics) : Ioan NistorJohn Lloyd SantosNo ratings yet

- Rotating Equipment Snøhvit LNG Theory and Main Boosting TEP10Document35 pagesRotating Equipment Snøhvit LNG Theory and Main Boosting TEP10Jicheng PiaoNo ratings yet

- Venturi Orifice Rota MeterDocument15 pagesVenturi Orifice Rota MeterRajuKumarNo ratings yet

- Rainwater HarvestingDocument8 pagesRainwater HarvestingjasonwongqooyNo ratings yet

- DEARATOR Post Manual FR (R)Document138 pagesDEARATOR Post Manual FR (R)Ehtisham ul haqNo ratings yet

- Belajar KaznaeDocument277 pagesBelajar KaznaewahyuNo ratings yet

- PLP P-2-2003, Glycol Dehydration-2nd Ed-RosenDocument41 pagesPLP P-2-2003, Glycol Dehydration-2nd Ed-Rosenivanov5559100% (1)