Professional Documents

Culture Documents

(PARKER) Dovetail and Half Dovetail Design Charts

(PARKER) Dovetail and Half Dovetail Design Charts

Uploaded by

Lorena PessanhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(PARKER) Dovetail and Half Dovetail Design Charts

(PARKER) Dovetail and Half Dovetail Design Charts

Uploaded by

Lorena PessanhaCopyright:

Available Formats

Parker O-Ring Handbook

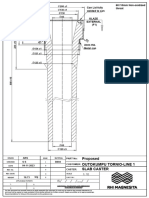

Dovetail Grooves

It is often necessary to provide some mechanical means for holding G

an O-ring in a face seal groove during assembly and maintenance of

equipment. An undercut or dovetail groove has proven beneficial in many

applications to keep the O-ring in place. This is an expensive groove

Static O-Ring Sealing

to machine, however, and thus should be used only when absolutely

necessary.

L R

It should be noted that although this method has been used success-

66°

fully, it is not generally recommended. The inherent characteristics of the

groove design limit the amount of void area. Normally acceptable toler- R1

ance extremes, wide service temperature ranges, and fluid media that

cause high swell of the elastomer are conditions that cannot be tolerated

in this type of groove design. Mean Groove

Diameter Coincides

With Mean

O-ring Diameter. Finishes are RMS values

O-Ring Dovetail Grooves

Radius “R” is CRITICAL. Insufficient radius will potentially cause damage to the O-ring during installation, while excessive radius may contribute to extrusion.

G

O-Ring W L Groove Width

Size Cross Section Gland (To sharp

AS568A- Nominal Actual Depth Squeeze % corner) R R1

004 .053 .057

.070

through 1/16 to 23 to .005 1/64

±.003

050 .055 .061

102 .081 .083

.103

through 3/32 to 21 to .010 1/64

±.003

178 .083 .087

201 .111 .113

.139

through 1/8 to 20 to .010 1/32

±.004

284 .113 .117

309 .171 .171

.210

through 3/16 to 18 to .015 1/32

±.005

395 .173 .175

425 .231 .231

.275

through 1/4 to 16 to .015 1/16

±.006

475 .234 .235

.315 .315

.375

Special 3/8 to 16 to .020 3/32

±.007

.319 .319

NOTE: These design recommendations assume metal-to-metal contact. In special applications, for example in the semiconductor industry, deviation from these

recommendations may be necessary. When designing with Parofluor elastomers, one should take into consideration that perfluorinated elastomers may require

more squeeze than an FKM material to obtain optimum sealing performance. To increase squeeze, modifications of the design recommendations shown above

are necessary.

Design Chart 4-4: Dovetail Grooves

Parker Hannifin Corporation • O-Ring Division 4-19

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 • Fax: (859) 335-5128

www.parkerorings.com

Parker O-Ring Handbook

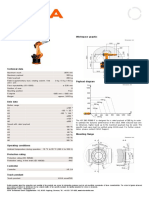

Half Dovetail Grooves

G

Static O-Ring Sealing

R

L

66°

R1

Mean Groove

Diameter Coincides

With Mean

O-ring Diameter. Finishes are RMS values

O-Ring Half Dovetail Grooves

Radius “R” is CRITICAL. Insufficient radius will potentially cause damage to the O-ring during installation, while excessive radius may contribute to extrusion.

G

O-Ring W L Groove Width

Size Cross Section Gland (To sharp

AS568A- Nominal Actual Depth Squeeze % corner) R R1

004 .053 .064

.070

through 1/16 to 23 to .005 1/64

±.003

050 .055 .066

102 .083 .095

.103

through 3/32 to 19 to .010 1/64

±.003

178 .085 .097

201 .113 .124

.139

through 1/8 to 18 to .010 1/32

±.004

284 .115 .128

309 .173 .190

.210

through 3/16 to 17 to .015 1/32

±.005

395 .176 .193

425 .234 .255

.275

through 1/4 to 15 to .015 1/16

±.006

475 .238 .257

.319 .350

.375

Special 3/8 to 14 to .020 3/32

±.007 .323 .358

NOTE: These design recommendations assume metal-to-metal contact. In special applications, for example in the semiconductor industry, deviation from these

recommendations may be necessary. When designing with Parofluor elastomers, one should take into consideration that perfluorinated elastomers may require

more squeeze than an FKM material to obtain optimum sealing performance. To increase squeeze, modifications of the design recommendations shown above

are necessary.

Design Chart 4-5: Half Dovetail Grooves

4-20 Parker Hannifin Corporation • O-Ring Division

2360 Palumbo Drive, Lexington, KY 40509

Phone: (859) 269-2351 • Fax: (859) 335-5128

www.parkerorings.com

You might also like

- OutlookDocument53 pagesOutlookAvi Kense100% (1)

- Dovetail Half Dovetail Page 11 Ref GuideDocument1 pageDovetail Half Dovetail Page 11 Ref GuideOP GAMERNo ratings yet

- O-Ring Static Groove Design: Guide For Table A5 - 1Document3 pagesO-Ring Static Groove Design: Guide For Table A5 - 1Garikai MutongiNo ratings yet

- Ashcroft El Data SheetDocument1 pageAshcroft El Data SheetmisaelzaNo ratings yet

- Proposed LS Line 1Document1 pageProposed LS Line 1AWNISH PRASAD SINGHNo ratings yet

- 800 Series Lock-O-Seals: Fastener and Fitting SealsDocument2 pages800 Series Lock-O-Seals: Fastener and Fitting SealsFernandoNo ratings yet

- Asme Sec 1Document7 pagesAsme Sec 1Md Ashikur RahmanNo ratings yet

- CSink Speed FeedDocument2 pagesCSink Speed FeedBeto CovasNo ratings yet

- Saffire Welding Cutting and Process Nozzles 1Document2 pagesSaffire Welding Cutting and Process Nozzles 1Steve SilverwoodNo ratings yet

- R II Gear Mar09Document7 pagesR II Gear Mar09sujit5584No ratings yet

- Ampacities of Copper Alloy C11000 Busbars (StormPower)Document3 pagesAmpacities of Copper Alloy C11000 Busbars (StormPower)Nathia RoaNo ratings yet

- T 714 PG 187-188 PDFDocument2 pagesT 714 PG 187-188 PDFJossimar PerezNo ratings yet

- 04 Amortiguadores de Rotación ContinuaDocument11 pages04 Amortiguadores de Rotación ContinuajaraozvNo ratings yet

- RJ26RJR26Document2 pagesRJ26RJR26joel alvaradoNo ratings yet

- Countersunk Head Cap ScrewsDocument2 pagesCountersunk Head Cap ScrewsmuathNo ratings yet

- XT Mobile Shear: Reference GuideDocument12 pagesXT Mobile Shear: Reference GuidePrudzNo ratings yet

- O RingDocument89 pagesO RingNikolat84No ratings yet

- Manual de Instalação 442 LargeDocument12 pagesManual de Instalação 442 LargeDanilo D'AmatoNo ratings yet

- 1667400001-1651223101 Proto JSBV8SP CatalogDocument112 pages1667400001-1651223101 Proto JSBV8SP Catalogjean-marc MoralesNo ratings yet

- 890-011-232.09 300-400 Lever Bender Instr1222Document10 pages890-011-232.09 300-400 Lever Bender Instr1222Zts MksNo ratings yet

- Rounded IndicationDocument7 pagesRounded IndicationArul Edwin VijayNo ratings yet

- Capillaries: 1572 & 1572N SeriesDocument1 pageCapillaries: 1572 & 1572N SeriesFlexiblecsiNo ratings yet

- Dobatubos Serie 404Document8 pagesDobatubos Serie 404adrian hernandezNo ratings yet

- Rota Disc OPERATORS MANUALDocument53 pagesRota Disc OPERATORS MANUALCoco BangoNo ratings yet

- Tabla Pines RupturaDocument1 pageTabla Pines RupturaMANUEL ISAZANo ratings yet

- MZE - For Long Clamping Lengths, Manually Actuated: Cartridge MandrelDocument1 pageMZE - For Long Clamping Lengths, Manually Actuated: Cartridge Mandrelr aNo ratings yet

- KR 280 R3080 F: Workspace GraphicDocument1 pageKR 280 R3080 F: Workspace GraphicDorobantu CatalinNo ratings yet

- Data Sheet: E Cores and AccessoriesDocument6 pagesData Sheet: E Cores and AccessoriesCarlos FlorezNo ratings yet

- Timing Belts EngineeringDocument28 pagesTiming Belts EngineeringJoan LamedaNo ratings yet

- Renk Tds Floating Labyrinth Seal enDocument2 pagesRenk Tds Floating Labyrinth Seal enJaime Vanegas IriarteNo ratings yet

- HL 400seriesDocument9 pagesHL 400seriesMuh ImronNo ratings yet

- Dimensions Mechanical & Performance RequirementsDocument7 pagesDimensions Mechanical & Performance RequirementsLorena PessanhaNo ratings yet

- Johnson Power - U. Joint - Installation & MaintenanceDocument4 pagesJohnson Power - U. Joint - Installation & Maintenanceyudiar djamaldilliahNo ratings yet

- 3296 - 3/8 " Square Trimpot Trimming Potentiometer: FeaturesDocument2 pages3296 - 3/8 " Square Trimpot Trimming Potentiometer: FeaturesDaniel RetcelNo ratings yet

- 3296 - 3/8 " Square Trimpot Trimming Potentiometer: FeaturesDocument2 pages3296 - 3/8 " Square Trimpot Trimming Potentiometer: FeaturesSri VidyaNo ratings yet

- BournsDocument2 pagesBournsJesus Ruy SanchezNo ratings yet

- 106 DR Fixit Torchshield AP 3160 - 4160Document3 pages106 DR Fixit Torchshield AP 3160 - 4160I QuNo ratings yet

- Rotalign: Why Not Use A 10" Diameter in The Coupling Mode?Document1 pageRotalign: Why Not Use A 10" Diameter in The Coupling Mode?ZakNo ratings yet

- 716 SPNDocument2 pages716 SPNRPINILLA (EICO S.A.)No ratings yet

- Load-Cells DescriptionDocument13 pagesLoad-Cells DescriptionRinku SatapathyNo ratings yet

- ASG BrochureDocument1 pageASG Brochure江文泽No ratings yet

- Sttype ABDocument1 pageSttype ABSean YangNo ratings yet

- Operating Instructions: Rota - DiscDocument53 pagesOperating Instructions: Rota - DiscArmorNo ratings yet

- Tap SPDOpInstDocument6 pagesTap SPDOpInstjschaudtNo ratings yet

- Coupling Catalog PDFDocument22 pagesCoupling Catalog PDFManick Raj JNo ratings yet

- Airpax Series 5024 Temperature SensorsDocument2 pagesAirpax Series 5024 Temperature SensorsakaNo ratings yet

- Turcon Glyd Ring II: Unrivalled Performance Under PressureDocument2 pagesTurcon Glyd Ring II: Unrivalled Performance Under PressureSharan DaraindharaneNo ratings yet

- Engineering: Timing Belt DrivesDocument34 pagesEngineering: Timing Belt DrivesbennyfergusonNo ratings yet

- VJMillDocument57 pagesVJMillpelowisNo ratings yet

- KR 210 R3100 Ultra: ControllerDocument1 pageKR 210 R3100 Ultra: ControllerJoão AntonioNo ratings yet

- WCC Gear CatalogueDocument17 pagesWCC Gear CatalogueHugo DesputraNo ratings yet

- Main and Connecting Rod Bearing Replacement: Engineering ReferenceDocument10 pagesMain and Connecting Rod Bearing Replacement: Engineering ReferenceAlfredoNo ratings yet

- 42tu011 - 164278 PDFDocument1 page42tu011 - 164278 PDFBruno VianaNo ratings yet

- Atlas RivnutsDocument4 pagesAtlas RivnutsevandropintonetoNo ratings yet

- Making Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyDocument2 pagesMaking Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyCương Phạm NgọcNo ratings yet

- Gear CouplingDocument17 pagesGear CouplingSuresh KavaliNo ratings yet

- Baby Lock Symphony BLSY AddendumDocument56 pagesBaby Lock Symphony BLSY AddendumiliiexpugnansNo ratings yet

- GRINNELL Model B302 and Model BN302 Grooved End Butterfly Valves With Gear Operators or Lever-Lock Operators General DescriptionDocument6 pagesGRINNELL Model B302 and Model BN302 Grooved End Butterfly Valves With Gear Operators or Lever-Lock Operators General DescriptionСергей КолесниковNo ratings yet

- Brother Hi TapDocument6 pagesBrother Hi TapMohd Asri TaipNo ratings yet

- JP150Document2 pagesJP150simeneh demelashNo ratings yet

- 3 Day Course On Project ManagementDocument196 pages3 Day Course On Project ManagementPeyman MznNo ratings yet

- Maria Montessori and Her Educational Philosophy: Breaking Barriers in EducationDocument5 pagesMaria Montessori and Her Educational Philosophy: Breaking Barriers in EducationfreddyNo ratings yet

- Time Cost Trade OffDocument22 pagesTime Cost Trade Offtulsi pokhrelNo ratings yet

- Superman All StarsDocument31 pagesSuperman All StarsDaniel CostaNo ratings yet

- Cat 772g BRDocument28 pagesCat 772g BR111No ratings yet

- EPM Model5014i ManualDocument352 pagesEPM Model5014i ManualJorgeLuisUriarteNo ratings yet

- CT3Document7 pagesCT3Vishy BhatiaNo ratings yet

- RAW Character ActivityDocument2 pagesRAW Character ActivityLisa HulmeNo ratings yet

- API Process PumpsDocument40 pagesAPI Process Pumpsmahi_mNo ratings yet

- Tabel Usia Teknis Peralatan MedisDocument12 pagesTabel Usia Teknis Peralatan MedisAditya PuteraNo ratings yet

- Optigenex v. Jeunesse Global Holdings Et. Al.Document57 pagesOptigenex v. Jeunesse Global Holdings Et. Al.PriorSmartNo ratings yet

- Notes in Criminal SociologyDocument8 pagesNotes in Criminal SociologyWevinneNo ratings yet

- Textbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFDocument53 pagesTextbook A World of Three Cultures Honor Achievement and Joy 1St Edition Miguel E Basanez Ebook All Chapter PDFkatie.martinez610100% (23)

- 4-SSS SAS ASA and AAS Congruence PDFDocument4 pages4-SSS SAS ASA and AAS Congruence PDFAivie Jannelle Columna BejoNo ratings yet

- Water-Treatment (Rhen)Document13 pagesWater-Treatment (Rhen)Mark Anthony ReyesNo ratings yet

- Egurukul OrbitDocument8 pagesEgurukul OrbitbetsyNo ratings yet

- Effects of Covid-19 To Students in The Medical FieldDocument2 pagesEffects of Covid-19 To Students in The Medical FieldAnne RonquilloNo ratings yet

- How To Size A Propeller ShaftDocument2 pagesHow To Size A Propeller ShaftJoão Henrique Volpini MattosNo ratings yet

- Rhine Falls: Palazzos - Lago Di Lugano (Document2 pagesRhine Falls: Palazzos - Lago Di Lugano (Hazel Gwyneth Nate BirondoNo ratings yet

- 2022-23 - Grade IV - Math - Term I - Revision PS 1Document7 pages2022-23 - Grade IV - Math - Term I - Revision PS 1sankar raoNo ratings yet

- RCC 100 Important Questions 39Document33 pagesRCC 100 Important Questions 39Engr Mehdi BugtiNo ratings yet

- Fall 2023 MATH 39100 Final Exam ReviewDocument3 pagesFall 2023 MATH 39100 Final Exam ReviewSimranjit SinghNo ratings yet

- Plu Grid-No.19Document1 pagePlu Grid-No.19BrijeshgevariyaNo ratings yet

- Using RFT Probes With Magnifi 4 v.01Document68 pagesUsing RFT Probes With Magnifi 4 v.01shahid khan100% (1)

- Chapter 7Document15 pagesChapter 7Lowella May Tan ChengNo ratings yet

- Literature Review Ending Violence Against Women and GirlsDocument93 pagesLiterature Review Ending Violence Against Women and GirlsKyteNo ratings yet

- Cross Country - Issue 242, August 2023Document92 pagesCross Country - Issue 242, August 2023ธนวัฒน์ ปิยะวิสุทธิกุลNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 142, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- Increasing Awareness of Future Teachers About Health, Health Preservation and Health Saving Technologies of Preschool ChildrenDocument4 pagesIncreasing Awareness of Future Teachers About Health, Health Preservation and Health Saving Technologies of Preschool ChildrenResearch ParkNo ratings yet