Professional Documents

Culture Documents

Niras: DESIGN CRITERIA For Induction Bending On

Niras: DESIGN CRITERIA For Induction Bending On

Uploaded by

Enrico Manfrinato0 ratings0% found this document useful (0 votes)

7 views2 pagesThe document provides design criteria for induction bending of stainless steel and carbon-manganese steel pipes. It includes tables with minimum dimensions for pipe diameter, wall thickness, bend radius, and distances between the front clamp, bends, and rear push for the bending process. Notes indicate that values in grey areas are for extra thick-walled pipes and that the tables provide general guidelines that can be optimized for specific requests.

Original Description:

Original Title

Design-Criteria-13.02.2020

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides design criteria for induction bending of stainless steel and carbon-manganese steel pipes. It includes tables with minimum dimensions for pipe diameter, wall thickness, bend radius, and distances between the front clamp, bends, and rear push for the bending process. Notes indicate that values in grey areas are for extra thick-walled pipes and that the tables provide general guidelines that can be optimized for specific requests.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views2 pagesNiras: DESIGN CRITERIA For Induction Bending On

Niras: DESIGN CRITERIA For Induction Bending On

Uploaded by

Enrico ManfrinatoThe document provides design criteria for induction bending of stainless steel and carbon-manganese steel pipes. It includes tables with minimum dimensions for pipe diameter, wall thickness, bend radius, and distances between the front clamp, bends, and rear push for the bending process. Notes indicate that values in grey areas are for extra thick-walled pipes and that the tables provide general guidelines that can be optimized for specific requests.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

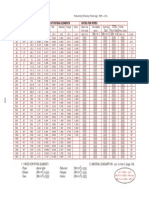

Rev. 12.02.

2020 # 11 SS (Corrosion Resistant Alloy (CRA) STEEL

niras

DESIGN CRITERIA for Induction bending on: Stainless Steel

Pipe Radius Wall "A1" “A2” “B1” “B2” “C1” “C2”

Front between Rear

OD Minimum WT

Clamp bends push

nominal (mm) x OD (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

½” 21,3 3,2 67 >3 140 207 150 274 450 517

¾” 26,7 2,6 67 >3 140 207 150 274 450 517

1” 33,4 2 67 >4 140 207 150 274 450 517

1 ¼” 42,2 2 84 >4 140 224 150 309 450 534

1 ½” 48,3 2 97 >4 140 237 150 333 450 547

2” 60,3 2 121 > 4,5 140 261 150 381 450 571

2 ½” 73,0 2 146 >5 140 286 150 432 450 596

3” 88,9 2 178 > 5,5 260 438 180 616 450 628

4” 114,3 2 229 >6 260 489 180 717 450 679

5” 141,3 3 424 7 to 35 260 684 260 1108 600 1024

5” 141,3 2 283 15 to 35 460 743 460 1025 1150 1433

6” 168,3 3 505 11 to 40 260 765 300 1270 1150 1655

6” 168,3 2 337 18 to 40 460 797 460 1133 1150 1487

8” 219,1 3 657 11 to 50 460 1117 460 1775 1150 1807

8” 219,1 2 438 20 to 50 460 898 460 1336 1150 1588

10” 273,0 3 819 15 to 50 460 1279 460 2098 1150 1969

10” 273,0 2 546 20 to 50 460 1006 460 1552 1150 1696

12” 323,8 2 648 18 to 50 460 1108 460 1755 1150 1798

12” 323,8 3 971 15 to 50 460 1431 460 2403 1150 2121

14” 355,6 2 711 21 to 45 460 1171 460 1882 1150 1861

14” 355,6 3 1067 18 to 45 460 1527 460 2594 1150 2217

16” 406,4 2 813 20 to 40 460 1273 460 2086 1150 1963

16” 406,4 3,0 1219 18 to 40 460 1679 460 2898 1150 2369

18” 457 2 914 25 to 40 460 1374 460 2288 1150 2064

18” 457 3,0 1371 18 to 40 460 1831 460 3202 1150 2521

20” 508 3 1524 20 to 25 460 1984 460 3508 1150 2674

20” 508 4,5 2286 35 460 2746 460 5032 1150 3436

Values in grey areas meant for pipes with extra thick wall.

This table is for general information and guidelines. We can improve and optimize after

N.B.: request. We will, if necessary, attach (weld) extra pipe length needed for the bending

operation.

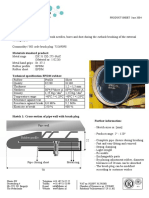

stop (rear push)

start (front clamp)

Rev. 12.02.2020 # 11 CS (CARBON-Manganese STEEL)

niras

DESIGN CRITERIA for Induction bending on: Carbon Steel

Pipe Radius Wall "A1" “A2” “B1” “B2” “C1” “C2”

Front between Rear

OD Minimum WT

Clamp bends push

nominal (mm) x OD (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

½” 21,3 3,2 67 >3 140 207 150 274 450 517

¾” 26,7 2,6 67 >3 140 207 150 274 450 517

1” 33,4 2 67 > 3,5 140 207 150 274 450 517

1 ¼” 42,2 2 84 >4 140 224 150 309 450 534

1 ½” 48,3 2 97 >4 140 237 150 333 450 547

2” 60,3 2 121 > 4,5 140 261 150 381 450 571

2 ½” 73,0 2 146 >5 140 286 150 432 450 596

3” 88,9 2 178 > 5,5 260 438 180 616 450 628

4” 114,3 2 229 >6 260 489 180 717 450 679

5” 141,3 3 424 7 to 35 260 684 260 1108 600 1024

5” 141,3 2 283 15 to 35 460 743 460 1025 1150 1433

6” 168,3 2 337 11 to 40 260 597 300 933 1150 1487

6” 168,3 2 337 18 to 40 460 797 460 1133 1150 1487

8” 219,1 2 438 11 to 50 460 898 460 1336 1150 1588

8” 219,1 3 657 20 to 50 460 1117 460 1775 1150 1807

10” 273,0 2 546 15 to 50 460 1006 460 1552 1150 1696

10” 273,0 3 819 20 to 50 460 1279 460 2098 1150 1969

12” 323,8 2 648 18 to 50 460 1108 460 1755 1150 1798

12” 323,8 3 971 15 to 50 460 1431 460 2403 1150 2121

14” 355,6 2 711 21 to 45 460 1171 460 1882 1150 1861

14” 355,6 3 1067 18 to 45 460 1527 460 2594 1150 2217

16” 406,4 1,7 691 20 to 40 460 1151 460 1842 1150 1841

16” 406 3 1219 18 to 40 460 1679 460 2898 1150 2369

18” 457 2 914 25 to 40 460 1374 460 2288 1150 2064

18” 457 3 1371 18 to 40 460 1831 460 3202 1150 2521

20” 508 3 1524 20 to 25 460 1984 460 3508 1150 2674

20” 508 4,5 2286 35 460 2746 460 5032 1150 3436

Values in grey areas meant for pipes with extra thick wall.

This table is for general information and guidelines. We can improve and optimize after

N.B.: request. We will, if necessary, attach (weld) extra pipe length needed for the bending

operation.

stop (rear push)

start (front clamp)

You might also like

- Pipe Fittings Surface AreaDocument1 pagePipe Fittings Surface AreaB Girish82% (57)

- Pipe Fittings Surface Area PDFDocument1 pagePipe Fittings Surface Area PDFIqra Angels100% (2)

- Pipe Fittings Surface Area PDFDocument1 pagePipe Fittings Surface Area PDFIqra Angels88% (8)

- ASME PCC-1 Bolted Flange Joint AssemblyDocument1 pageASME PCC-1 Bolted Flange Joint Assemblykhaireddin75% (4)

- The Effects of Hydrogen Injection in Natural Gas Networks For The Dutch Underground StoragesDocument74 pagesThe Effects of Hydrogen Injection in Natural Gas Networks For The Dutch Underground StoragesEnrico ManfrinatoNo ratings yet

- Pressure Equipment Workshop 20201116Document96 pagesPressure Equipment Workshop 20201116Enrico ManfrinatoNo ratings yet

- IGEM - TD - 1 - Introduction & ScopeDocument18 pagesIGEM - TD - 1 - Introduction & ScopeEnrico ManfrinatoNo ratings yet

- Materials Science and Engineering Unit 1 PDFDocument19 pagesMaterials Science and Engineering Unit 1 PDFParis100% (1)

- Design Criteria 13.02.2020Document2 pagesDesign Criteria 13.02.2020Enrico ManfrinatoNo ratings yet

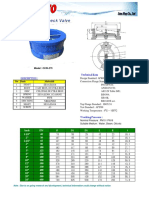

- Check Valve - Wafer TypeDocument2 pagesCheck Valve - Wafer Typehuudung87No ratings yet

- TecDataPressClasDIPipeR 9Document1 pageTecDataPressClasDIPipeR 9Eduardo Jr Bueno ReyesNo ratings yet

- Valve ASME B1610 Face To FaceDocument2 pagesValve ASME B1610 Face To Facemarutitarke00No ratings yet

- ASME B16.10 RTJ FtoF Dims Ball GGC PlugDocument1 pageASME B16.10 RTJ FtoF Dims Ball GGC Plugrupeshp1989No ratings yet

- Especificaciones para Tubos Según Astm F714: Presion de TrabajoDocument2 pagesEspecificaciones para Tubos Según Astm F714: Presion de TrabajoJohanNo ratings yet

- Price List Pipa Hitam Dan Galvanis: Pt. Golden Piping IndonesiaDocument1 pagePrice List Pipa Hitam Dan Galvanis: Pt. Golden Piping IndonesiailhamNo ratings yet

- AEA-Pipe FitingDocument10 pagesAEA-Pipe Fitingdechi MartinezNo ratings yet

- Hunter Actualizado PDFDocument2 pagesHunter Actualizado PDFBryan VillalobosNo ratings yet

- Dimensions of Raised Flanges: As Per Is: 1538 (Part IV) - 1976Document7 pagesDimensions of Raised Flanges: As Per Is: 1538 (Part IV) - 1976Nikhil GoyalNo ratings yet

- ASME B16.10 RF/BWE Valve Face To Face Dimension Ball/GGC/PlugDocument1 pageASME B16.10 RF/BWE Valve Face To Face Dimension Ball/GGC/PlugRAVIKIRAN BARDENo ratings yet

- Model BVBS Vertical In-Line Strainers: DescriptionDocument4 pagesModel BVBS Vertical In-Line Strainers: Descriptionwalter ruizNo ratings yet

- Spiral Wound Gaskets Data TableDocument42 pagesSpiral Wound Gaskets Data TableCharles OnyechereNo ratings yet

- Expansion Joints SheetDocument34 pagesExpansion Joints SheetHumaid ShaikhNo ratings yet

- Bondstrand Product Dimension - Series 2420 Conductive: PIPE (Taper Joint Data) Socket DepthDocument22 pagesBondstrand Product Dimension - Series 2420 Conductive: PIPE (Taper Joint Data) Socket DepthABDUL KADHAR100% (1)

- Cutting and Dimensioning Pipe at Odd AnglesDocument2 pagesCutting and Dimensioning Pipe at Odd AnglesTheVirus PapaNo ratings yet

- Areas - Tabla Unificada REV 1 TCDocument467 pagesAreas - Tabla Unificada REV 1 TCAdrian TocaNo ratings yet

- PERHITUNGANtderi9xryx6 STR BAJADocument110 pagesPERHITUNGANtderi9xryx6 STR BAJAYasinta Rizka FNo ratings yet

- Idoc - Pub - Pipe Fittings Surface Area PDFDocument1 pageIdoc - Pub - Pipe Fittings Surface Area PDFkiller shaNo ratings yet

- Pipe Fittings Surface Area PDFDocument1 pagePipe Fittings Surface Area PDFberktor100% (3)

- AWWA C207: Dimensional Table For Steel-Ring FlangesDocument10 pagesAWWA C207: Dimensional Table For Steel-Ring FlangesBrian GalindezNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- ASME Boiler and Pressure Vessels Code - bpvc13Document1 pageASME Boiler and Pressure Vessels Code - bpvc13cristinelbNo ratings yet

- ASME PCC-1-2013 Table For Pressure Boundary Bolted Flange Joint AssemblyDocument1 pageASME PCC-1-2013 Table For Pressure Boundary Bolted Flange Joint AssemblykhaireddinNo ratings yet

- Mod. XXXXX Cast Iron A126 200 PSIG: Note: Dimensions, Design and Materials Are Subject To Change Without NoticeDocument2 pagesMod. XXXXX Cast Iron A126 200 PSIG: Note: Dimensions, Design and Materials Are Subject To Change Without NoticeHenry CruzNo ratings yet

- CI Wafer Check Valve IkonoDocument1 pageCI Wafer Check Valve IkonoĐdt BìnhNo ratings yet

- Fitting DimensionsDocument243 pagesFitting DimensionsgirgintasNo ratings yet

- Raccordi A "T" Saldati in Acciaio Inox Cod. RFW1620 A Norme Ansi B 31Document1 pageRaccordi A "T" Saldati in Acciaio Inox Cod. RFW1620 A Norme Ansi B 31AHMED AMIRANo ratings yet

- Carbon Steel: 90 Long Radius Seamless Weld Elbows Center To End Dimensions, Weights and VolumesDocument21 pagesCarbon Steel: 90 Long Radius Seamless Weld Elbows Center To End Dimensions, Weights and VolumesEdward Jr ChapetonNo ratings yet

- Ms Pipe Weight Chart: Sl. No. Odinmm Idinmm Pipe Size in NB Pipe Size in Inch Thickness in MM Unit Pipe Weight (KG/M)Document32 pagesMs Pipe Weight Chart: Sl. No. Odinmm Idinmm Pipe Size in NB Pipe Size in Inch Thickness in MM Unit Pipe Weight (KG/M)Prashant33% (3)

- Tabel Profil Baja Gissa PDFDocument67 pagesTabel Profil Baja Gissa PDFrea reoNo ratings yet

- SignpostS FormattedDocument34 pagesSignpostS FormattedpraveenNo ratings yet

- Untitled-2 Merged PDFDocument5 pagesUntitled-2 Merged PDFKazekage MinatoNo ratings yet

- Untitled-2 Merged PDFDocument5 pagesUntitled-2 Merged PDFKazekage MinatoNo ratings yet

- Filtro WaterMistDocument2 pagesFiltro WaterMisthuiryk goncalvesNo ratings yet

- Tabel PipaDocument10 pagesTabel PipadediNo ratings yet

- dp90 3Document5 pagesdp90 3Jorge CalcaneoNo ratings yet

- Stainless Steel Seamless PipesDocument14 pagesStainless Steel Seamless PipesRajendra FittingsNo ratings yet

- Maximum Recommended Flow Through Compressed Air PipeDocument3 pagesMaximum Recommended Flow Through Compressed Air PipehanshanantaNo ratings yet

- Codo 90º Radio Largo Astm A-234 WPB Ansi B 16.9: Standard XSDocument1 pageCodo 90º Radio Largo Astm A-234 WPB Ansi B 16.9: Standard XSNelson Alexander Aponte SimbronNo ratings yet

- Elbow Centre To FaceDocument2 pagesElbow Centre To FaceRNo ratings yet

- Duplex Pipes Exporter Repute Stel 2205Document1 pageDuplex Pipes Exporter Repute Stel 2205PRAVINNo ratings yet

- pipe-fittings-surface-areaDocument1 pagepipe-fittings-surface-areaAbdul RafiNo ratings yet

- Pipe%ScheduleDocument5 pagesPipe%Schedule9033301054No ratings yet

- Catalogue DARCO Arbrés ENDocument28 pagesCatalogue DARCO Arbrés ENScipp ZengNo ratings yet

- Inquiries Data-KkDocument44 pagesInquiries Data-KkSunil RahangdaleNo ratings yet

- Flange Ss316 Price List: PN-10 PN-16 PN-40Document2 pagesFlange Ss316 Price List: PN-10 PN-16 PN-40NoviNo ratings yet

- E-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFDocument4 pagesE-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFAnand GNo ratings yet

- Pipe Bends Specification PDFDocument4 pagesPipe Bends Specification PDFToniNo ratings yet

- 5d Bend-Dimensions - E-17 Model l60-6d Wrought 6d 60o ElbowDocument4 pages5d Bend-Dimensions - E-17 Model l60-6d Wrought 6d 60o Elbowjacob thangamNo ratings yet

- E-17 Model l60-6d Wrought 6d 60o ElbowDocument4 pagesE-17 Model l60-6d Wrought 6d 60o ElbowAdil AlaliNo ratings yet

- E-17 Model l60-6d Wrought 6d 60o ElbowDocument4 pagesE-17 Model l60-6d Wrought 6d 60o ElbowmohdNo ratings yet

- E-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFDocument4 pagesE-17 MODEL L60-6D WROUGHT 6D 60o ELBOW PDFKikist ErsNo ratings yet

- Elbows - Long Radius, 3D, 5D, 6D PDFDocument4 pagesElbows - Long Radius, 3D, 5D, 6D PDFzinha_al100% (1)

- Fig. 1 Mid-Section With 8 Mounted Blocks: Type C: Product Sheet June 2007Document1 pageFig. 1 Mid-Section With 8 Mounted Blocks: Type C: Product Sheet June 2007Enrico ManfrinatoNo ratings yet

- GPT 1-6 VCS-VCFS 10.2020-Lowres PDFDocument12 pagesGPT 1-6 VCS-VCFS 10.2020-Lowres PDFEnrico ManfrinatoNo ratings yet

- PS English Plastic Bevel ProtectorDocument1 pagePS English Plastic Bevel ProtectorEnrico ManfrinatoNo ratings yet

- Masking Ring Use: Materials Standard ProductDocument1 pageMasking Ring Use: Materials Standard ProductEnrico ManfrinatoNo ratings yet

- PS English Cross BracingDocument1 pagePS English Cross BracingEnrico ManfrinatoNo ratings yet

- Plastic Plug Use:: PRODUCT SHEET January 2003Document1 pagePlastic Plug Use:: PRODUCT SHEET January 2003Enrico ManfrinatoNo ratings yet

- PS English Reusable Bevel ProtectorDocument1 pagePS English Reusable Bevel ProtectorEnrico ManfrinatoNo ratings yet

- Pipe Cover Model A Use:: PRODUCT SHEET January 2003Document1 pagePipe Cover Model A Use:: PRODUCT SHEET January 2003Enrico ManfrinatoNo ratings yet

- Brush Plug Use:: Product Sheet June 2004Document1 pageBrush Plug Use:: Product Sheet June 2004Enrico ManfrinatoNo ratings yet

- Design Criteria 13.02.2020Document2 pagesDesign Criteria 13.02.2020Enrico ManfrinatoNo ratings yet

- Product Sheet June 2004: Rubber ProfileDocument1 pageProduct Sheet June 2004: Rubber ProfileEnrico ManfrinatoNo ratings yet

- The Key To Successful Bending PracticesDocument5 pagesThe Key To Successful Bending PracticesEnrico ManfrinatoNo ratings yet

- Predicting Corrosion in Pipelines Oil Wells and Gas Wells. A Computer Model Approach PDFDocument21 pagesPredicting Corrosion in Pipelines Oil Wells and Gas Wells. A Computer Model Approach PDFEnrico ManfrinatoNo ratings yet

- PTC 2020 AssiDocument14 pagesPTC 2020 AssiEnrico Manfrinato100% (1)

- Algorithm For Determining The Corrosion Rate of Oil Pipelines Using Modified Norsok M-506 Model: A Case StudyDocument14 pagesAlgorithm For Determining The Corrosion Rate of Oil Pipelines Using Modified Norsok M-506 Model: A Case StudyEnrico ManfrinatoNo ratings yet

- UK Experience - European Standards ImplementationDocument266 pagesUK Experience - European Standards ImplementationEnrico ManfrinatoNo ratings yet

- Analytical Methods To Calculate Water Content in Natural GasDocument16 pagesAnalytical Methods To Calculate Water Content in Natural GasEnrico ManfrinatoNo ratings yet

- 3.7.25July2014-NZGA-HERA-Geothermal-materials-selection-Quest Integrity-GroupDocument28 pages3.7.25July2014-NZGA-HERA-Geothermal-materials-selection-Quest Integrity-GroupEnrico ManfrinatoNo ratings yet

- Sobinox Door HandlesDocument4 pagesSobinox Door HandlesFORLINE nuiNo ratings yet

- FORMWORK - Docx Notes PDFDocument14 pagesFORMWORK - Docx Notes PDFsalo maloNo ratings yet

- Specification Part 2 Specs - 2 Civil WorksDocument72 pagesSpecification Part 2 Specs - 2 Civil WorksMaulid100% (1)

- Equivalent Interface Properties To Model Soil-Facing Interactions With Zero-Thickness and Continuum Element MethodologiesDocument9 pagesEquivalent Interface Properties To Model Soil-Facing Interactions With Zero-Thickness and Continuum Element MethodologiesHamzah Al-HashemiNo ratings yet

- Contact Session Slides Rubber Manufacture, Processing and Value Addition - 2015Document27 pagesContact Session Slides Rubber Manufacture, Processing and Value Addition - 2015Chathura Thennakoon100% (1)

- Chapter 3 Part 1 Pavement Materials: BY: Mohamad Shahrizal Bin AliasDocument27 pagesChapter 3 Part 1 Pavement Materials: BY: Mohamad Shahrizal Bin AliasMohamad Shahrizal AliasNo ratings yet

- Mud Hands: Earth Architects, BangaloreDocument43 pagesMud Hands: Earth Architects, BangaloreNamitha PraveenNo ratings yet

- Pigging Training Course Mod 5 Rev 1Document46 pagesPigging Training Course Mod 5 Rev 1Suparerk SirivedinNo ratings yet

- FAQ Levelplast 02122010Document4 pagesFAQ Levelplast 02122010Rajiv ShahNo ratings yet

- Boilers and Steam Systems ..BoeDocument151 pagesBoilers and Steam Systems ..BoeMV AmohanAKarthicK100% (2)

- SOAL 01 Material Safety Data Sheet (MSDS) Lembar Tanya Jawab FGDDocument3 pagesSOAL 01 Material Safety Data Sheet (MSDS) Lembar Tanya Jawab FGDAzil SuardhyNo ratings yet

- Vanguard Electric 2022Document24 pagesVanguard Electric 2022Frederick GuerreroNo ratings yet

- STD PPT-M-TechDocument23 pagesSTD PPT-M-TechTeju TejuNo ratings yet

- General Chemistry 2 Quarter 2-Week 1 (Module 2) Types of Intermolecular Forces Pre-TestDocument4 pagesGeneral Chemistry 2 Quarter 2-Week 1 (Module 2) Types of Intermolecular Forces Pre-TestDexter John Delos SantosNo ratings yet

- Sika Injection 304 PDS PDFDocument4 pagesSika Injection 304 PDS PDFslantsyhimNo ratings yet

- Guidelines For Source ApprovalDocument24 pagesGuidelines For Source ApprovalvamsiNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyRanielNo ratings yet

- Estofill PDFDocument2 pagesEstofill PDFKaren MiradNo ratings yet

- Engineering Chemistry Refractories and NanomaterialsDocument14 pagesEngineering Chemistry Refractories and NanomaterialsSiddharth Singh100% (1)

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Document1 pageA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Vivek MishraNo ratings yet

- User Manual HYCD-282-282ADocument16 pagesUser Manual HYCD-282-282ALuis GutierrezNo ratings yet

- Thermal-Stress Analysis Theory and Practices - Predictive Engineering White PaperDocument24 pagesThermal-Stress Analysis Theory and Practices - Predictive Engineering White PaperL.a. MayorNo ratings yet

- Spira Trol TI S24 70 ENDocument18 pagesSpira Trol TI S24 70 ENQuyết Bạch ĐìnhNo ratings yet

- Reinforced Concrete Frank ColumbusDocument194 pagesReinforced Concrete Frank ColumbusKamilly100% (3)

- Spiral Weld Calculation Using Electrode E90Xx: BAUER Foundations Philippines, IncDocument1 pageSpiral Weld Calculation Using Electrode E90Xx: BAUER Foundations Philippines, IncMac-Ross CordovaNo ratings yet

- Buerkle Catalogue 2020 English PricesDocument276 pagesBuerkle Catalogue 2020 English PricesJacekNo ratings yet

- Failure Composite 1Document7 pagesFailure Composite 1puskesmas ngancarNo ratings yet

- Energy Harvesting From Piezoelectric Material As An Eenvironmental FriendlyDocument4 pagesEnergy Harvesting From Piezoelectric Material As An Eenvironmental FriendlyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- General Catalog Rev. 2Document40 pagesGeneral Catalog Rev. 2alidonmezNo ratings yet