Professional Documents

Culture Documents

Sop 091-12

Sop 091-12

Uploaded by

m_armoutiCopyright:

Available Formats

You might also like

- Troubleshooting Guide For GL Cranes With Control System CC2000 or CC3000 - MacGREGORDocument6 pagesTroubleshooting Guide For GL Cranes With Control System CC2000 or CC3000 - MacGREGORAllen Anyayahan50% (2)

- Hydrostatic Test ProcedureDocument9 pagesHydrostatic Test ProcedureMohammed Kamal86% (14)

- D3148Document6 pagesD3148Jan0% (1)

- Aashto T 322 - 07Document11 pagesAashto T 322 - 07amin13177No ratings yet

- 22A105CDocument12 pages22A105CDuram_Han_2546No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Universal Testing MachineDocument28 pagesUniversal Testing MachineMarc Anthony de VillaNo ratings yet

- Mos Lab Manul by Abhidhesh YadavDocument45 pagesMos Lab Manul by Abhidhesh YadavabhiNo ratings yet

- Materials Testing Laboratory Laboratory Exercise No. 1 Inspection of The Materials & Testing LaboratoryDocument10 pagesMaterials Testing Laboratory Laboratory Exercise No. 1 Inspection of The Materials & Testing LaboratoryRejoice SamboNo ratings yet

- M0627Document24 pagesM0627subhransubaral1No ratings yet

- Exp 1 Introduction UTMDocument6 pagesExp 1 Introduction UTMSusmit AloneNo ratings yet

- 1.Strength-of-Materials V+Document36 pages1.Strength-of-Materials V+sriramNo ratings yet

- Mos Lab ManualDocument71 pagesMos Lab ManualAtul GaurNo ratings yet

- Diploma 3 Strength - of - MaterialsDocument26 pagesDiploma 3 Strength - of - MaterialsKumar SubramanianNo ratings yet

- Sir J C Bose School of Engineering (Diploma: Adv Strength of Materials Lab ManualDocument47 pagesSir J C Bose School of Engineering (Diploma: Adv Strength of Materials Lab ManualdibyenindusNo ratings yet

- Hydrotest ProcedureDocument6 pagesHydrotest ProcedureIkhsan Hj SiratNo ratings yet

- Final SOM ManualDocument52 pagesFinal SOM Manualharsh patelNo ratings yet

- Section 28 - Deadweight TesterDocument22 pagesSection 28 - Deadweight TesterhammamiNo ratings yet

- OBJECT: - To Study The Various Component Parts of The Universal TestingDocument8 pagesOBJECT: - To Study The Various Component Parts of The Universal TestingDream CafeNo ratings yet

- D6723.1203165 1 DirectTensionTesterDocument13 pagesD6723.1203165 1 DirectTensionTesterAnantNo ratings yet

- Sae Arp 5483-8 2002 (En) PDFDocument9 pagesSae Arp 5483-8 2002 (En) PDFWilliam LooNo ratings yet

- D 4405Document5 pagesD 4405mohsenNo ratings yet

- Parts of Universal Testing MachineDocument5 pagesParts of Universal Testing MachineFaisal NaeemNo ratings yet

- Astm D2290-00Document5 pagesAstm D2290-00T Mathew TholoorNo ratings yet

- T22Document13 pagesT22Juan Daniel Rojas PalmaNo ratings yet

- Installation / Operation / Maintenance Instructions Magnetic Level GaugeDocument6 pagesInstallation / Operation / Maintenance Instructions Magnetic Level GaugeHumayun NawazNo ratings yet

- Barkatullah University Institute of Technology: Presentation OnDocument20 pagesBarkatullah University Institute of Technology: Presentation OnSalman KhanNo ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- ASTM D 2290Document5 pagesASTM D 2290Pablo AlcázarNo ratings yet

- CMT Chapter7 UTMDocument9 pagesCMT Chapter7 UTMAidan Paul Arlanza EscotoNo ratings yet

- Plint Tribological MachineDocument13 pagesPlint Tribological MachineAndy Z del PieroNo ratings yet

- Utm PDFDocument5 pagesUtm PDFFaisal NaeemNo ratings yet

- Charpy & Izod Metals Impact TestingDocument2 pagesCharpy & Izod Metals Impact TestingFarhanah OnnNo ratings yet

- Pressure Gauge Technical InformationsDocument4 pagesPressure Gauge Technical Informationssahayaraaj100% (1)

- Aashto T-22-90Document2 pagesAashto T-22-90Putu Agus Santosa100% (1)

- Micro-Project Report To Study of Compression Testing MachineDocument15 pagesMicro-Project Report To Study of Compression Testing MachineAkash BhorNo ratings yet

- SOM Write Up1Document34 pagesSOM Write Up1KUNKRINo ratings yet

- Strength of Material LabDocument44 pagesStrength of Material LabDeepak SahNo ratings yet

- Strength of MaterialsDocument24 pagesStrength of Materialsmech bhabhaNo ratings yet

- 17CVL37 - BMT Lab PDFDocument47 pages17CVL37 - BMT Lab PDFkamalnitrrNo ratings yet

- FlowmwterDocument68 pagesFlowmwterjimmjim100% (1)

- Unit 1 CMTDocument25 pagesUnit 1 CMTMelvin BulosNo ratings yet

- Dead Weight Tester InfoDocument6 pagesDead Weight Tester InfoElias Kapa100% (1)

- Experiment # 2 Tension Testing of MetalsDocument3 pagesExperiment # 2 Tension Testing of MetalsJ. Fabián MenaNo ratings yet

- 08 Hydrostatic Test Procedure Section I OKDocument9 pages08 Hydrostatic Test Procedure Section I OKEduardo GarciaNo ratings yet

- SAE J343-2001 Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesDocument9 pagesSAE J343-2001 Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesMiguel GalindoNo ratings yet

- Ots80Pb & Ots60Pb Oil Test Set: User GuideDocument22 pagesOts80Pb & Ots60Pb Oil Test Set: User GuidehailstormNo ratings yet

- Subject: Moee: Sanjaybhai Rajguru College of Diploma Eng., RDocument4 pagesSubject: Moee: Sanjaybhai Rajguru College of Diploma Eng., RshivamNo ratings yet

- Voltage Withstand TestDocument4 pagesVoltage Withstand Testmshahidshaukat100% (1)

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- MTG 7.20.1 CapacitorsDocument7 pagesMTG 7.20.1 CapacitorsmayberurenaNo ratings yet

- OKITP01 - PruebaPresión Rev.1Document13 pagesOKITP01 - PruebaPresión Rev.1Hugo Fiusa AlvarezNo ratings yet

- Lab Report 2Document5 pagesLab Report 221pwind0685No ratings yet

- D 2938 - 95 R02 PDFDocument3 pagesD 2938 - 95 R02 PDFJosephNo ratings yet

- Astm C1201 C1201M 15Document2 pagesAstm C1201 C1201M 15Bajid Ali KhanNo ratings yet

- Tensile TestDocument6 pagesTensile TestMohamed EmadNo ratings yet

- Motor Life Evaluation of An Upright Vacuum Cleaner: Standard Test Method ForDocument7 pagesMotor Life Evaluation of An Upright Vacuum Cleaner: Standard Test Method ForDylkanWingsNo ratings yet

- Tns Dw2 ManualDocument6 pagesTns Dw2 Manualyeison11No ratings yet

- Hydro Test Key PointsDocument16 pagesHydro Test Key PointsRahulNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Arithmetic Sequences and Series-BogerDocument34 pagesArithmetic Sequences and Series-Bogerm_armoutiNo ratings yet

- Sop 091-15Document2 pagesSop 091-15m_armoutiNo ratings yet

- Warm Up Lesson Presentation Lesson QuizDocument34 pagesWarm Up Lesson Presentation Lesson Quizm_armoutiNo ratings yet

- 3.3 Linear FunctionsDocument28 pages3.3 Linear Functionsm_armoutiNo ratings yet

- Q.Tech-QC-NDT-021-PROCEDURE TOFD-01Document18 pagesQ.Tech-QC-NDT-021-PROCEDURE TOFD-01m_armoutiNo ratings yet

- Sop 091-13Document2 pagesSop 091-13m_armoutiNo ratings yet

- Document # WI 091-15 Page 1 / 2 Approved By:: NDT & Corrosion Control ServicesDocument2 pagesDocument # WI 091-15 Page 1 / 2 Approved By:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Sop 091-14Document2 pagesSop 091-14m_armoutiNo ratings yet

- Document # WI 091-14 Page 1 / 2 Approved By:: NDT & Corrosion Control ServicesDocument2 pagesDocument # WI 091-14 Page 1 / 2 Approved By:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Sop 091-09Document3 pagesSop 091-09m_armoutiNo ratings yet

- Sop 091-08Document2 pagesSop 091-08m_armoutiNo ratings yet

- 1.0 Scope:: NDT & Corrosion Control ServicesDocument1 page1.0 Scope:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Sop 091-07Document2 pagesSop 091-07m_armoutiNo ratings yet

- NDT & Corrosion Control Services: Standard Operating ProcedureDocument6 pagesNDT & Corrosion Control Services: Standard Operating Procedurem_armoutiNo ratings yet

- Sop 151-1Document4 pagesSop 151-1m_armoutiNo ratings yet

- Title:: NDT & Corrosion Control ServicesDocument1 pageTitle:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Title:: NDT & Corrosion Control ServicesDocument1 pageTitle:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Drawing OHB 5000033109Document11 pagesDrawing OHB 5000033109rola76No ratings yet

- HSK DIN 69893 enDocument29 pagesHSK DIN 69893 enalphatoolsNo ratings yet

- Llustrated Arts Anual: 600-Series Snow ThrowersDocument44 pagesLlustrated Arts Anual: 600-Series Snow ThrowersDaryl MasonNo ratings yet

- Catalog English 2018 - RobotsDocument320 pagesCatalog English 2018 - RobotsRobertoAlexandreSchöpfNo ratings yet

- 924 Spare Parts ManualDocument322 pages924 Spare Parts ManualSamy QuilumbangoNo ratings yet

- Giddings & Lewis Sect08 HydDocument24 pagesGiddings & Lewis Sect08 HydAngel AdautaNo ratings yet

- Tle7 Ia Carpentry M3 V2-1 PDFDocument28 pagesTle7 Ia Carpentry M3 V2-1 PDFMichelle DaurogNo ratings yet

- Eje/F: Chapter 28 - Fuel SystemDocument46 pagesEje/F: Chapter 28 - Fuel SystemJose danielNo ratings yet

- GB Exp Glass Mode 2023 (Tumbal) .MCRDocument16 pagesGB Exp Glass Mode 2023 (Tumbal) .MCRMeldi Fajar MutaqinNo ratings yet

- Fluid Power Design Data SheetDocument2 pagesFluid Power Design Data SheetHamza ChenakerNo ratings yet

- 3 Jaws Punch FormerDocument1 page3 Jaws Punch FormerAku AdjunNo ratings yet

- Katalog Lakoni Pro 2020Document88 pagesKatalog Lakoni Pro 2020Asdar AsdarNo ratings yet

- HL 510B Omsu80Document11 pagesHL 510B Omsu80onur tezman100% (1)

- DLL Tle-H.e. 6 q1 w7Document6 pagesDLL Tle-H.e. 6 q1 w7Melanie DucalangNo ratings yet

- Machining Process Used To Produce Various ShapesDocument33 pagesMachining Process Used To Produce Various ShapesMuhammad ArifNo ratings yet

- CX7P9 Calefaccion PDFDocument92 pagesCX7P9 Calefaccion PDFJuan IdrovoNo ratings yet

- Weld Test Stand Assembly ManualDocument9 pagesWeld Test Stand Assembly ManualLUIS CORDOVA ZANCHESNo ratings yet

- Aitt Feb 2017 TH Sem IIIDocument6 pagesAitt Feb 2017 TH Sem IIIMadhu KumarNo ratings yet

- GunneryDocument31 pagesGunneryStukaNo ratings yet

- Out MCC 400Document49 pagesOut MCC 400Fatholla SalehiNo ratings yet

- Fits and Clearances - Contents: Propeller Maintenance Manual 132ADocument8 pagesFits and Clearances - Contents: Propeller Maintenance Manual 132AAlexis KidemaNo ratings yet

- Things in The School Bag (Barang-Barang Yang Ada Di Dalam Tas Sekolah)Document2 pagesThings in The School Bag (Barang-Barang Yang Ada Di Dalam Tas Sekolah)Sary SalutNo ratings yet

- User'S Manual: Pneumatic Positioner YT-1200 SeriesDocument22 pagesUser'S Manual: Pneumatic Positioner YT-1200 SeriescesarNo ratings yet

- I Year Manual BookDocument69 pagesI Year Manual BookBalram RajputNo ratings yet

- Consumable Stock June 2021Document497 pagesConsumable Stock June 2021isser150No ratings yet

- Examen LevasDocument5 pagesExamen LevasEduardo SolisNo ratings yet

- Electronics Products Assembly (EPAS) : Presented By: Alex D. Bedaña TLE TeacherDocument24 pagesElectronics Products Assembly (EPAS) : Presented By: Alex D. Bedaña TLE TeacherAxelJohnBedanaNo ratings yet

- 2 JOB SHEET-Elecro-Pneumatics 2Document26 pages2 JOB SHEET-Elecro-Pneumatics 2ardiyantoNo ratings yet

- Manual Trans Overhaul - Type 02A Article TextDocument20 pagesManual Trans Overhaul - Type 02A Article TextHakim Ben Abdeljelil100% (1)

Sop 091-12

Sop 091-12

Uploaded by

m_armoutiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop 091-12

Sop 091-12

Uploaded by

m_armoutiCopyright:

Available Formats

NDT & Corrosion Control Services Standard Operating Procedure

Document # SOP 091-12 Page 1 / 2

Approved By: Issue: 1/1 Date: 20 / 4 / 2000

Title: Tensile Testing of Steel Specimens.

1.0 SCOPE

This procedure specifies the general requirements of tensile testing of metallic

materials at room temperature using Universal Testing Machine.

2.0 REFERENCES

1. ASTM E8M Standard test method for tension testing of metallic materials.

2. ASME SEC IX Welding and brazing qualifications.

3. ASTM E6 Standard Terminology relating to methods of mechanical testing.

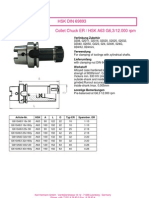

3.0 EQUIPMENT

Universal testing machine (Type UTE-60) comprises of loading unit, hydraulic

system and electronic control unit shall be used for conducting tension test.

The loading unit consists of two cross heads and lower table. Center cross head is

adjustable by means of gear motor and the test is carried-out between the center and

upper cross heads. Sensing of load is by means of a precession pressure transducer of

strain gauge type. Gripping devices (jaws) inserted for tensile test specimen along

with the rack jaws slide in the lower and upper cross heads. This sliding motion of

the rack jaw is achieved by rotating the helical toothed penion, by operating the hand

wheel.

A positive displacement type piston pump is used to produce continuous, non-

pulsating, high-pressure oil current for smooth application of the load on the

specimen. A pressure compensated flow control valve with integral safety relief

valve (on left side) and a return valve (on right side) is provided on the control panel.

An Electrical panel with push buttons for the motors with overload protection and

limit switch interlock for safe operation is provided.

4.0 TESTING PERSONNEL

Qualified personnel with sufficient working experience shall conduct the test and

record the results as per the requirements.

5.0 TEST SPECIMEN

Test specimens shall be either substantially full size or machined as per the product

specification for the materials being tested. It is desirable to have the cross sectional

area of the specimen, smallest at the center of the reduced section to ensure fracture

within the gauge length. The shape of the ends of specimen shall be suitable to fit the

grips of the testing machine so that the force may be applied axially.

NDT & Corrosion Control Services Standard Operating Procedure

Document # SOP 091-12 Page 2 / 2

Approved By: Issue: 1/1 Date: 20 / 4 / 2000

Title: Tensile Testing of Steel Specimens.

For small tubular products, particularly sizes 25 mm and under in nominal outside

diameter and frequently for large sizes, except as limited by the testing equipment, it

is standard practice to use tension test specimens of full size tubular section (see

attachment # 01). The reduced section specimens for plates and large diameter pipes

also shown in the attachments #02 and #03.

6.0 CALIBRATION

Universal Testing machine shall be calibrated at time intervals not exceeding 12

months and spot checks shall be conducted on monthly basis to ensure that the

machine is operating within the calibration range.

7.0 METHOD OF TESTING

The measuring range shall be adjusted according to the capacity of the test piece.

Proper jaw inserts shall be selected for upper and lower chuck assemblies. Upper end

of the test piece shall be gripped using the operation handle for the upper cross head.

By keeping the left valve fully closed, open the right valve until the lower table is

slightly lifted and close it to adjust the load to zero by TARE push button.

By operating the lower grip operation handle, lift the lower cross head to grip the

lower part of the specimen. The jaws shall be locked in position by operating the

jaw-locking handle. Control valve shall be opened slowly to get the desired loading

rate. The locking handle shall be unclamped and go on increasing the load until the

test piece is broken.

8.0 DOCUMENTATION

Test information shall be reported with the details of material and sample

identification, specimen type, tensile strength and the method used for rounding of

test results (attachment F#01).

You might also like

- Troubleshooting Guide For GL Cranes With Control System CC2000 or CC3000 - MacGREGORDocument6 pagesTroubleshooting Guide For GL Cranes With Control System CC2000 or CC3000 - MacGREGORAllen Anyayahan50% (2)

- Hydrostatic Test ProcedureDocument9 pagesHydrostatic Test ProcedureMohammed Kamal86% (14)

- D3148Document6 pagesD3148Jan0% (1)

- Aashto T 322 - 07Document11 pagesAashto T 322 - 07amin13177No ratings yet

- 22A105CDocument12 pages22A105CDuram_Han_2546No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Universal Testing MachineDocument28 pagesUniversal Testing MachineMarc Anthony de VillaNo ratings yet

- Mos Lab Manul by Abhidhesh YadavDocument45 pagesMos Lab Manul by Abhidhesh YadavabhiNo ratings yet

- Materials Testing Laboratory Laboratory Exercise No. 1 Inspection of The Materials & Testing LaboratoryDocument10 pagesMaterials Testing Laboratory Laboratory Exercise No. 1 Inspection of The Materials & Testing LaboratoryRejoice SamboNo ratings yet

- M0627Document24 pagesM0627subhransubaral1No ratings yet

- Exp 1 Introduction UTMDocument6 pagesExp 1 Introduction UTMSusmit AloneNo ratings yet

- 1.Strength-of-Materials V+Document36 pages1.Strength-of-Materials V+sriramNo ratings yet

- Mos Lab ManualDocument71 pagesMos Lab ManualAtul GaurNo ratings yet

- Diploma 3 Strength - of - MaterialsDocument26 pagesDiploma 3 Strength - of - MaterialsKumar SubramanianNo ratings yet

- Sir J C Bose School of Engineering (Diploma: Adv Strength of Materials Lab ManualDocument47 pagesSir J C Bose School of Engineering (Diploma: Adv Strength of Materials Lab ManualdibyenindusNo ratings yet

- Hydrotest ProcedureDocument6 pagesHydrotest ProcedureIkhsan Hj SiratNo ratings yet

- Final SOM ManualDocument52 pagesFinal SOM Manualharsh patelNo ratings yet

- Section 28 - Deadweight TesterDocument22 pagesSection 28 - Deadweight TesterhammamiNo ratings yet

- OBJECT: - To Study The Various Component Parts of The Universal TestingDocument8 pagesOBJECT: - To Study The Various Component Parts of The Universal TestingDream CafeNo ratings yet

- D6723.1203165 1 DirectTensionTesterDocument13 pagesD6723.1203165 1 DirectTensionTesterAnantNo ratings yet

- Sae Arp 5483-8 2002 (En) PDFDocument9 pagesSae Arp 5483-8 2002 (En) PDFWilliam LooNo ratings yet

- D 4405Document5 pagesD 4405mohsenNo ratings yet

- Parts of Universal Testing MachineDocument5 pagesParts of Universal Testing MachineFaisal NaeemNo ratings yet

- Astm D2290-00Document5 pagesAstm D2290-00T Mathew TholoorNo ratings yet

- T22Document13 pagesT22Juan Daniel Rojas PalmaNo ratings yet

- Installation / Operation / Maintenance Instructions Magnetic Level GaugeDocument6 pagesInstallation / Operation / Maintenance Instructions Magnetic Level GaugeHumayun NawazNo ratings yet

- Barkatullah University Institute of Technology: Presentation OnDocument20 pagesBarkatullah University Institute of Technology: Presentation OnSalman KhanNo ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- ASTM D 2290Document5 pagesASTM D 2290Pablo AlcázarNo ratings yet

- CMT Chapter7 UTMDocument9 pagesCMT Chapter7 UTMAidan Paul Arlanza EscotoNo ratings yet

- Plint Tribological MachineDocument13 pagesPlint Tribological MachineAndy Z del PieroNo ratings yet

- Utm PDFDocument5 pagesUtm PDFFaisal NaeemNo ratings yet

- Charpy & Izod Metals Impact TestingDocument2 pagesCharpy & Izod Metals Impact TestingFarhanah OnnNo ratings yet

- Pressure Gauge Technical InformationsDocument4 pagesPressure Gauge Technical Informationssahayaraaj100% (1)

- Aashto T-22-90Document2 pagesAashto T-22-90Putu Agus Santosa100% (1)

- Micro-Project Report To Study of Compression Testing MachineDocument15 pagesMicro-Project Report To Study of Compression Testing MachineAkash BhorNo ratings yet

- SOM Write Up1Document34 pagesSOM Write Up1KUNKRINo ratings yet

- Strength of Material LabDocument44 pagesStrength of Material LabDeepak SahNo ratings yet

- Strength of MaterialsDocument24 pagesStrength of Materialsmech bhabhaNo ratings yet

- 17CVL37 - BMT Lab PDFDocument47 pages17CVL37 - BMT Lab PDFkamalnitrrNo ratings yet

- FlowmwterDocument68 pagesFlowmwterjimmjim100% (1)

- Unit 1 CMTDocument25 pagesUnit 1 CMTMelvin BulosNo ratings yet

- Dead Weight Tester InfoDocument6 pagesDead Weight Tester InfoElias Kapa100% (1)

- Experiment # 2 Tension Testing of MetalsDocument3 pagesExperiment # 2 Tension Testing of MetalsJ. Fabián MenaNo ratings yet

- 08 Hydrostatic Test Procedure Section I OKDocument9 pages08 Hydrostatic Test Procedure Section I OKEduardo GarciaNo ratings yet

- SAE J343-2001 Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesDocument9 pagesSAE J343-2001 Test and Test Procedures For SAE 100R Series Hydraulic Hose and Hose AssembliesMiguel GalindoNo ratings yet

- Ots80Pb & Ots60Pb Oil Test Set: User GuideDocument22 pagesOts80Pb & Ots60Pb Oil Test Set: User GuidehailstormNo ratings yet

- Subject: Moee: Sanjaybhai Rajguru College of Diploma Eng., RDocument4 pagesSubject: Moee: Sanjaybhai Rajguru College of Diploma Eng., RshivamNo ratings yet

- Voltage Withstand TestDocument4 pagesVoltage Withstand Testmshahidshaukat100% (1)

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- MTG 7.20.1 CapacitorsDocument7 pagesMTG 7.20.1 CapacitorsmayberurenaNo ratings yet

- OKITP01 - PruebaPresión Rev.1Document13 pagesOKITP01 - PruebaPresión Rev.1Hugo Fiusa AlvarezNo ratings yet

- Lab Report 2Document5 pagesLab Report 221pwind0685No ratings yet

- D 2938 - 95 R02 PDFDocument3 pagesD 2938 - 95 R02 PDFJosephNo ratings yet

- Astm C1201 C1201M 15Document2 pagesAstm C1201 C1201M 15Bajid Ali KhanNo ratings yet

- Tensile TestDocument6 pagesTensile TestMohamed EmadNo ratings yet

- Motor Life Evaluation of An Upright Vacuum Cleaner: Standard Test Method ForDocument7 pagesMotor Life Evaluation of An Upright Vacuum Cleaner: Standard Test Method ForDylkanWingsNo ratings yet

- Tns Dw2 ManualDocument6 pagesTns Dw2 Manualyeison11No ratings yet

- Hydro Test Key PointsDocument16 pagesHydro Test Key PointsRahulNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Arithmetic Sequences and Series-BogerDocument34 pagesArithmetic Sequences and Series-Bogerm_armoutiNo ratings yet

- Sop 091-15Document2 pagesSop 091-15m_armoutiNo ratings yet

- Warm Up Lesson Presentation Lesson QuizDocument34 pagesWarm Up Lesson Presentation Lesson Quizm_armoutiNo ratings yet

- 3.3 Linear FunctionsDocument28 pages3.3 Linear Functionsm_armoutiNo ratings yet

- Q.Tech-QC-NDT-021-PROCEDURE TOFD-01Document18 pagesQ.Tech-QC-NDT-021-PROCEDURE TOFD-01m_armoutiNo ratings yet

- Sop 091-13Document2 pagesSop 091-13m_armoutiNo ratings yet

- Document # WI 091-15 Page 1 / 2 Approved By:: NDT & Corrosion Control ServicesDocument2 pagesDocument # WI 091-15 Page 1 / 2 Approved By:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Sop 091-14Document2 pagesSop 091-14m_armoutiNo ratings yet

- Document # WI 091-14 Page 1 / 2 Approved By:: NDT & Corrosion Control ServicesDocument2 pagesDocument # WI 091-14 Page 1 / 2 Approved By:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Sop 091-09Document3 pagesSop 091-09m_armoutiNo ratings yet

- Sop 091-08Document2 pagesSop 091-08m_armoutiNo ratings yet

- 1.0 Scope:: NDT & Corrosion Control ServicesDocument1 page1.0 Scope:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Sop 091-07Document2 pagesSop 091-07m_armoutiNo ratings yet

- NDT & Corrosion Control Services: Standard Operating ProcedureDocument6 pagesNDT & Corrosion Control Services: Standard Operating Procedurem_armoutiNo ratings yet

- Sop 151-1Document4 pagesSop 151-1m_armoutiNo ratings yet

- Title:: NDT & Corrosion Control ServicesDocument1 pageTitle:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Title:: NDT & Corrosion Control ServicesDocument1 pageTitle:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Drawing OHB 5000033109Document11 pagesDrawing OHB 5000033109rola76No ratings yet

- HSK DIN 69893 enDocument29 pagesHSK DIN 69893 enalphatoolsNo ratings yet

- Llustrated Arts Anual: 600-Series Snow ThrowersDocument44 pagesLlustrated Arts Anual: 600-Series Snow ThrowersDaryl MasonNo ratings yet

- Catalog English 2018 - RobotsDocument320 pagesCatalog English 2018 - RobotsRobertoAlexandreSchöpfNo ratings yet

- 924 Spare Parts ManualDocument322 pages924 Spare Parts ManualSamy QuilumbangoNo ratings yet

- Giddings & Lewis Sect08 HydDocument24 pagesGiddings & Lewis Sect08 HydAngel AdautaNo ratings yet

- Tle7 Ia Carpentry M3 V2-1 PDFDocument28 pagesTle7 Ia Carpentry M3 V2-1 PDFMichelle DaurogNo ratings yet

- Eje/F: Chapter 28 - Fuel SystemDocument46 pagesEje/F: Chapter 28 - Fuel SystemJose danielNo ratings yet

- GB Exp Glass Mode 2023 (Tumbal) .MCRDocument16 pagesGB Exp Glass Mode 2023 (Tumbal) .MCRMeldi Fajar MutaqinNo ratings yet

- Fluid Power Design Data SheetDocument2 pagesFluid Power Design Data SheetHamza ChenakerNo ratings yet

- 3 Jaws Punch FormerDocument1 page3 Jaws Punch FormerAku AdjunNo ratings yet

- Katalog Lakoni Pro 2020Document88 pagesKatalog Lakoni Pro 2020Asdar AsdarNo ratings yet

- HL 510B Omsu80Document11 pagesHL 510B Omsu80onur tezman100% (1)

- DLL Tle-H.e. 6 q1 w7Document6 pagesDLL Tle-H.e. 6 q1 w7Melanie DucalangNo ratings yet

- Machining Process Used To Produce Various ShapesDocument33 pagesMachining Process Used To Produce Various ShapesMuhammad ArifNo ratings yet

- CX7P9 Calefaccion PDFDocument92 pagesCX7P9 Calefaccion PDFJuan IdrovoNo ratings yet

- Weld Test Stand Assembly ManualDocument9 pagesWeld Test Stand Assembly ManualLUIS CORDOVA ZANCHESNo ratings yet

- Aitt Feb 2017 TH Sem IIIDocument6 pagesAitt Feb 2017 TH Sem IIIMadhu KumarNo ratings yet

- GunneryDocument31 pagesGunneryStukaNo ratings yet

- Out MCC 400Document49 pagesOut MCC 400Fatholla SalehiNo ratings yet

- Fits and Clearances - Contents: Propeller Maintenance Manual 132ADocument8 pagesFits and Clearances - Contents: Propeller Maintenance Manual 132AAlexis KidemaNo ratings yet

- Things in The School Bag (Barang-Barang Yang Ada Di Dalam Tas Sekolah)Document2 pagesThings in The School Bag (Barang-Barang Yang Ada Di Dalam Tas Sekolah)Sary SalutNo ratings yet

- User'S Manual: Pneumatic Positioner YT-1200 SeriesDocument22 pagesUser'S Manual: Pneumatic Positioner YT-1200 SeriescesarNo ratings yet

- I Year Manual BookDocument69 pagesI Year Manual BookBalram RajputNo ratings yet

- Consumable Stock June 2021Document497 pagesConsumable Stock June 2021isser150No ratings yet

- Examen LevasDocument5 pagesExamen LevasEduardo SolisNo ratings yet

- Electronics Products Assembly (EPAS) : Presented By: Alex D. Bedaña TLE TeacherDocument24 pagesElectronics Products Assembly (EPAS) : Presented By: Alex D. Bedaña TLE TeacherAxelJohnBedanaNo ratings yet

- 2 JOB SHEET-Elecro-Pneumatics 2Document26 pages2 JOB SHEET-Elecro-Pneumatics 2ardiyantoNo ratings yet

- Manual Trans Overhaul - Type 02A Article TextDocument20 pagesManual Trans Overhaul - Type 02A Article TextHakim Ben Abdeljelil100% (1)