Professional Documents

Culture Documents

Warner Electric: Bronco II 160 Series DC Drives

Warner Electric: Bronco II 160 Series DC Drives

Uploaded by

IDIMAFRE SADECVOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warner Electric: Bronco II 160 Series DC Drives

Warner Electric: Bronco II 160 Series DC Drives

Uploaded by

IDIMAFRE SADECVCopyright:

Available Formats

SUPPORTED BY DANA CORPORATION

WARNER ELECTRIC

The Warner Electric Motors and Controls Division of Dana Corporation is a global leader in the engineer-

ing and manufacturing of motor and control products for industrial applications. All Warner Electric

products and services are backed by highly specialized engineers and service people who can help solve

your production challenges. Warner Electric’s capabilities and products have improved operations for

hundreds of companies around the world.

Warner Electric® stepper motors and controls, servo motors and controls, voltage conditioning products,

engineered systems, and AC/DC drives are available worldwide through an extensive authorized distribu-

tor network. These distributors provide convenient service by offering technical support, replacement

Bronco II

parts, and literature, as well as an extensive inventory of off-the-shelf models for the fastest possible 160 Series DC Drives

delivery and service. Call your nearest distributor for ordering and application information.

IN U.S.A. AND CANADA

WARNER ELECTRIC MOTORS AND CONTROLS DIVISION

◆ Sales: 734-669-4700

◆ Customer Service: 800-787-3532

◆ Product Application: 800-787-3532

◆ Product Literature Request: 800-787-3532

◆ Fax: 800-766-6366 or 860-589-2136

◆ Web Site: www.warnernet.com

SERVO CONTROLS STEPPER CONTROLS VOLTAGE CONDITIONING ENGINEERED SYSTEMS AC/DC DRIVES

WARNER ELECTRIC MOTORS AND CONTROLS DIVISION

Division Office Bristol Plant Systems Center International - Europe

640 Avis Drive, Suite 200 383 Middle Street 13500-J South Point Blvd. Lausanne, Switzerland

Ann Arbor, MI 48108 Bristol, CT 06010 Charlotte, NC 28273 La Pierreire

CH-1029 Villars-Ste-Croix,

Switzerland

©1999 Warner Electric Division

C3004 9/99 Printed in U.S.A.

Bronco II Coverall 1 10/21/99, 18.47

ADDITIONAL WARNER ELECTRIC DC DRIVES & CONTROLS

A Total Commitment Through

Distribution

• Throughout the North American Conti- • An extention of the commitment to product

nent distributors provide one stop product service is carried to each and every customer

availability and expertise through the dedicated distributor network.

• Each Distributor is a Market specialist • A carefully oriented plan is made with each

to meet local and immediate needs. distrubutor to insure optimum coverage and

service for each market area.

SE2000 DC Drives QUADRALINE 7000 DC Drives

• Literally thousands of sales and service

This non-regenerative DC drive is designed to control Designed for full wave, regenerative applications, the

personnel form the total team commitment for

shunt wound or permanent magnetic field DC motors Quadraline 7000 is designed for either permanent magnet

from ¼ to 5 HP. It offers isolated 4-20mA or 0-10 VDC or wound feild DC motors from ¼ to 5 HP. It features product and sales assurance.

control signal, tachometer generator feedback, circuit fullwave 4-quadrant operation, seven selectable perfor-

protection, diagnostic capabilities, control relay, torque mance features, electronic reversing and seven control

and slope control, and overcurrent protection. Jumper adjustments, positioning accuracy. Chassis or NEMA 4/12

selectable to program drives for specified motor or enclosures available and UL listed.

application. Horsepower range 115 VAC to 230 VAC.

Open chassis available and UL listed.

M4000 Digital 3-Phase DC Drives DS9000 Digital Drive Speed Controller

The M4000 Series Digital 3-Phase DC Drive is a The DS9000 Digital Speed Controller features long term

programmable, microprocessor based variable speed DC speed accuracy, control and stability. It offers 16-bit

drive. It allows keypad control of each parameter. Digital microprocessor based, AC or DC drive control, ± .01% YOUR DISTRIBUTOR IS:

readout provides on-line monitoring of drive operation. accuracy, digital master or follower, analog or digital

Ideal for many drive applications including wire and input, and two selectable sets of programmable param-

cable, packaging/converting, machinery and material eters. Front panel controls include a 4-digit LED readout,

handling. Improved circuit board technology has added keypad controls and four LED status indicators.

standard features, including serial communications and a

field-weakening controller for constant power and

extended speed range applications.

*Contact Warner Electric for information on our complete line of AC drives

Bronco II Coverall 2 10/21/99, 18.49

Bronco II Bronco II

Contents

Contents

Features and Benefits . . . . . . . 2

Applications . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . 6

How to Order . . . . . . . . . . . . . . 9

Selection Information . . . . . . 10

Options . . . . . . . . . . . . . . . . . 11

Remote Operator

Stations . . . . . . . . . . . . . . . . . 12

Isolation Transformers . . . . . 12

Standard DC Motors . . . . . . . 13

Washdown Duty

DC Motors . . . . . . . . . . . . . . . 16

Dimensions . . . . . . . . . . . . . . 17

Connection Diagrams . . . . . . 18

Recommended Spare

Parts . . . . . . . . . . . . . . . . . . . 19

Service . . . . . . . . . . . . . . . . . 19

Bronco II Bronco II

20 1

Bronco Spreads 1 10/21/99, 18.51

Bronco II Bronco II

Replacement parts list for all models

Features Check out these outstanding standard features Recommended

of the Bronco II 160 Series from Warner Electric Motors and Controls...

and Warner Electric

Spare Parts

Benefits Description Old

Part Number

New

Speed/Torque Adjust Pot. 2K APT2026–00 224552-000

Start/Run/Stop Switch ASW3010–00 224554-000

Forward/Reverse Switch ASW1051–01 224579-001

Auto/Manual or Run/Jog Switch ASW1079–00 224551-000

Water Tight Boot (For all Switches) HMI 1103-00 224639-000

Water Tight Nut (For all Pots) HMI1012–00 224638-000

Fuse, 20 Amp PFU1010–07 104364-025

Isolation Follower Card BWC36015–00 –

Power Module ATY4001–03 224544-001

PC Board Assembly SPD36006–00 –

Service Service

It is intended that the Bronco II

should be serviced by replacing

Listed Field programmable jumpers Jog at potentiometer speed

major sub-assemblies. The

Allow the Bronco II to be quickly Set your Bronco II speed Replacement Parts List lists all of

Listed for use in Canada modified to match available plant potentiometer at the desired the sub-assemblies required to

line voltage, select motor HP, and speed and you can jog the motor service Bronco II drives. It is

Speed regulation to select the feedback signal allowing easy set up of your recommended that users keep

Regulation by armature voltage required. machine process. these parts readily available to

feedback or tachometer support the drive’s critical

generator feedback (non- AC line protection fuse Field supply for shunt wound

field motors applications.

reversing models only). Fault protection...eliminates a For additional assistance or the

costly replacement. Permanent magnet field or shunt name of your closest authorized

Dual voltage input wound field motors...Bronco II is

(115/230 VAC) Full wave power conversion service center, contact Warner

the right one. Electric Motors and Controls

Each model can be connected to circuit with 2 SCR’s and 3

diodes providing NEMA Totally enclosed, cast customer service at

either of two line voltages 1/4, 1/2, 800-787-3532.

3/4 and 1HP motors @115VAC Code K, DC armature supply aluminum enclosure meets

input or 1, 1-1/2 and 2 HP motors Insures optimum motor NEMA 4, NEMA 12 and

@ 230VAC. performance, cooler motor NEMA 4X standards

operation and longer life. Incredibly rugged DC drives for

Circuit protection the most critical industrial

Transient voltage protection by IR compensation adjustment environment–dust tight, oil tight

MOV. Improves speed regulation in and water resistant.

armature voltage feedback mode.

Torque control Maximum and minimum

Controls motor armature current Control relay with 3-wire speed adjustments

for applications requiring torque start/stop circuit Establishes minimum and

or tension control. Prevents automatic restart after maximum speeds.

power outage for increased

Local or remote operator safety. (May be reconnected for Adjustable acceleration

control line start operation if required.) (1 to 5 seconds)

Flexible, compact...fits where you Easy-to-set for smooth, linear

want it. speed control.

Open chassis unit availability

For convenient mounting of one

or several drives in your

enclosure.

Bronco II Bronco II

2 19

Bronco Spreads 2 10/21/99, 18.52

Bronco II Bronco II

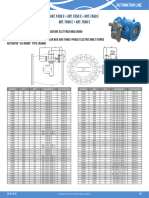

Models B160, B163 & B165 Washdown Duty

Connection Models B168 & B169

Features

Diagrams Jumper location

for model 165

A new standard in and

adjustable speed

Jumper location DC Drives. Benefits

for models

160 & 163 1 2 3 1 2 Specifically designed for food

Process – Common processing and other industries

1 2 3 4 5 6 7 8 9 10 TB5 TB4

Follower + Current Input where the motor and control are

TB2 Signal

+ – Input + Volts Input constantly exposed to high

*Optional

Tachometer 1 2 3 4 5 6 7 8 9 10 pressure washdown to maintain

+ – TB2

cleanliness.

+ –

7V/1000 RPM Optional • Rugged

Tachometer • Reliable

*Model

160 Only

– + • Versatile

7V/1000 RPM • Accurate

TB1 TB1

• Economically priced

7 6 5 4 3 2 1 7 6 5 4 3 2 1

• Listed

F2 F1 A2 A1 L1 L2 Gnd F2 F1 A2 A1 L1 L2 Gnd

F2 – A2 – F2 – A2 – • Listed for use in Canada

F1 + A1 + F1 + A1 + The Bronco II Washdown Duty

DC Drives convert single phase

115 or 230 VAC 115 or 230 VAC AC line voltages of either 115 of

50/60 Hz 50/60 Hz

230 VAC to variable DC for

armature voltage speed control

of permanent magnet or shunt

wound DC motors from 1/4 to

2 HP.

Models B161S & B162

Jumper Location for Jumper Location for

Torque Control Operation Speed Control Operation

Totally enclosed cast aluminum epoxy coated FDA

approved white enclosure with gasketed cover and

stainless steel captive screws meets NEMA 4X.

1 2 3 6 9 10

Optional Stop

2-Wire Start

Start + –

TB2 Optional Proven Warner Electric Dependability

Tachometer

• Full Wave power conversion circuit with 2 SCR’s and 3

+ –

Stop diodes with NEMA K configuration allows cooler motor

7V/1000 RPM operation.

Start CW

• IR compensation improves speed regulation in armature

W Torque Control

Speed CW Adjust

voltage feedback mode.

Control W 2K, 2W, 5%

Adjust CCW

• Control relay with 3-wire start/stop circuit prevents

2K, 2W, 5% automatic restart after power outage for increased safety.

CCW TB1 (May be reconnected for line start operation if required.)

7 6 5 4 3 2 1

• Full two year warranty.

F2 F1 A2 A1 L1 L2 Gnd

F2 – A2 –

F1 + A1 +

115 or 230 VAC

50/60 Hz

Bronco II Bronco II

18 3

Bronco Spreads 3 10/21/99, 18.52

Bronco II Bronco II

Applications Enclosed Models B160, B162, B163, B165, B168 & B169

Dimensions

Conveyors Conduit Knockout

1.500 2.000

Ø .875 2 Places

• Simple, variable speed control

• Forward or reverse direction

• Compact and rugged for on

machine mounting 8.125

8.875

9.500

5.625

4.625

3.250

.250

2.500 .688 .313

5.000

.250 W x .375 L Slot

2 Places

Take-up

• Simple center winders

Chassis Model B161S

• Constant Torque Ø .250 4 Places

5.000 7.000

1.000

1.000 .313 .452

5.000 3.000

Mixers

• Variable speed

• Rugged and industrially tough Dimensions are listed in inches

• NEMA 4/12 enclosures

Bronco II Bronco II

4 17

Bronco Spreads 4 10/21/99, 18.52

Bronco II Bronco II

Washdown The Washdown Duty DC Motors

are specifically suited for tough Food Processing Applications

Duty DC environments where washdown is

essential to maintain cleanliness. • Washdown is frequent

Motors These motors are selected to • Cleanliness is critical

function as a companion with the • Rugged, tough environment

appropriate WASHDOWN DUTY

BRONCO II D.C. Drive Controller.

Features

8 standard Washdown Duty DC

Motors

• Epoxy Finished - FDA

approved

• Moisture Resistant Wire

• 90 or 180 VDC Armature

• Permanent Magnet Field

• 1750 RPM

• Totally Enclosed

• Sealed and corrosion protected

to meet the environments

found in food and other

industries demanding high

levels of cleanliness.

DC Motors – Washdown Duty

1/4 to 3/4 Horsepower 90 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed

NEMA Model Number

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC Chemical Processing

Type Size Face without 7 VDC/1000 RPM Tachometer

Tachometer Tachometer Kit • Corrosive atmosphere

(mounted) • Frequently wet

• Simple mounting

1/4 M 4622 NV 56C MOD6112010 N/A N/A

1/2 M 4660 NV 56C MOF6112010 N/A N/A

3/4 M 4680 NV 56C MOG6112010 N/A N/A

Note: All motors are capable of 20:1 constant torque speed range.

DC Motors – Washdown Duty

1/2 to 2 Horsepower 180 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed

NEMA Model Number

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC

Type Size Face without 7 VDC/1000 RPM Tachometer

Tachometer Tachometer Kit Waste Water Treatment

(mounted)

• Wet environment

1/2 M 4660 NV 56C MOF7112010 N/A N/A • Compact size

3/4 M 4680 NV 56C MOG7112010 N/A N/A • Minimal maintenance

1 B 435P FC 56C MOH7211300 N/A N/A

1-1/2 B 536P FC 145C MOI7211300 N/A N/A

2 B 548P FC 145C MOJ7211300 N/A N/A

Bronco II Note: All motors are capable of 20:1 constant torque speed range. Bronco II

16 5

Bronco Spreads 5 10/21/99, 18.52

Bronco II Bronco II

Specifications Versatility DC Motors Standard

7 Standard Models 1/4 to 1 Horsepower 90 VDC Armature – 100/50 VDC SHUNT WOUND FIELD – 1750 RPM – Totally Enclosed DC Motors

Model B160 NEMA Model Number

NEMA 4/12 enclosure with Start/ HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC

Stop, Run/Jog switches and Type Size Face without 7 VDC/1000 RPM Tachometer

Speed potentiometer mounted on Tachometer Tachometer Kit

enclosure front cover (mounted)

Model B161S 1/4 B 413D FC 56C MOD1211700 MOD1211731 TAC 4001–00

Chassis for mounting in customer 1/2 B 420D FC 56C MOF1211700 MOF1211731 TAC 4001–00

supplied enclosure 3/4 B 428D FC 56C MOG1211700 MOG1211731 TAC 4001–00

Model B162 1 B 535D FC 56C MOH1211700 MOH1211731 TAC 4007–00

NEMA 4/12 enclosure for use

with a remote operator control Note: All motors are capable of 20:1 constant torque speed range.

Model B163

NEMA 4/12 enclosure with Start/

Stop, Run/Jog, Forward/Reverse

switches and Speed Potentio-

meter on enclosure front cover

Model B165

NEMA 4/12 enclosure with torque

control. Start/Stop and Forward/

Reverse switches and Torque

Potentiometer on enclosure front DC Motors

cover

1/2 to 2 Horsepower 180 VDC Armature – 200/100 VDC SHUNT WOUND FIELD – 1750 RPM – Totally Enclosed

Model B168

Same features as Model 169 NEMA Model Number

described below except the front HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC

panel mounted Speed Potentio- Type Size Face without 7 VDC/1000 RPM Tachometer

meter trims the speed signal Tachometer Tachometer Kit

when operated in the automatic (mounted)

mode.

1/2 B 420D FC 56C MOF2211700 MOF2211731 TAC 4001–00

Model B169 3/4 B 428D FC 56C MOG2211700 MOG2211731 TAC 4001–00

External isolated signal follower 1 G 146ATC FC 140TC MOH2210800 MOH2210831 TAC 4001–02

in NEMA 4/12 enclosure with B 535D FC 56C MOH2211800 MOH2211831 TAC 4007–01

Start/Stop and Auto/Manual

G L182ACY NV 180C MOH2110100 MOH2110131 TAC 4002–03

switches mounted on enclosure

front. Controls motor speed from 1-1/2 G 148ATC FC 140TC MOI2210800 MOI12210831 TAC 4004–02

either a grounded or ungrounded G L186ACY NV 180C MOI2110100 MOI2110131 TAC 4002–03

signal—4–20mA, 1–5mA, 0–10 B 636D FC 180C MOI2211400 MOI2211431 TAC 4001–15

VDC, 0–14 VDC, 0–100 VDC in

auto mode, or from the speed 2 G 149ATC FC 140TC MOJ2210800 MOJ12210831 TAC 4004–02

potentiometer in manual mode. B 646D FC 180C MOJ2211400 MOJ2211431 TAC 4001–15

G L186ACY NV 180C MOJ2110100 MOJ2110131 TAC 4002–03

Note: All motors are capable of 20:1 constant torque speed range.

Bronco II Bronco II

6 15

Bronco Spreads 6 10/21/99, 18.53

Bronco II Bronco II

Standard DC Motors Washdown Duty Specifications

6 Standard Models

DC Motors 1/4 to 1 Horsepower 90 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed

Model B160WD

NEMA Model Number

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC NEMA 4X enclosure with Start/

Type Size Face without 7 VDC/1000 RPM Tachometer Stop, Run/Jog switches and

Tachometer Tachometer Kit Speed potentiometer mounted on

(mounted) enclosure front cover

1/4 G 56HAA NV 56C MOD6110210 N/A N/A Model B162WD

B 320P NV 56C MOD6211200 MOD6211231 TAC 4001–13 NEMA 4X enclosure for use with

a remote operator control

1/2 G 56KAA FC 56C MOF6210210 N/A N/A

B 336P NV 56C MOF6211200 MOF6211231 TAC 4001–13 Model B163WD

NEMA 4X enclosure with Start/

3/4 G 56PAA FC 56C MOG6210210 N/A N/A

Stop, Run/Jog, Forward/Reverse

B 428P FC 56C MOG6211100 MOG6211131 TAC 4001–00 switches and Speed Potentio-

1 G 56SAA FC 56C MOH6210210 N/A N/A meter on enclosure front cover

B 435P FC 56C MOH6211100 MOH6211131 TAC 4001–00 Model B165WD

NEMA 4X enclosure with torque

Note: All motors are capable of 20:1 constant torque speed range. control. Start/Stop and Forward/

Reverse switches and Torque

Potentiometer on enclosure front

cover

Model B168WD

DC Motors Same features as Model 169

described below except the front

1/2 to 2 Horsepower 180 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed panel mounted Speed Potentio-

meter trims the speed signal

NEMA Model Number when operated in the automatic

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC mode.

Type Size Face without 7 VDC/1000 RPM Tachometer

Tachometer Tachometer Kit Model 169WD

(mounted) External isolated signal follower

in NEMA 4X enclosure with Start/

1/2 G 56KAA FC 56C MOF7210210 N/A N/A Stop and Auto/Manual switches

B 336P NV 56C MOF7111100 MOF7111131 TAC 4001–13 mounted on enclosure front.

3/4 G 56PAA FC 56C MOG7210210 N/A N/A Controls motor speed from either

a grounded or ungrounded

B 336P NV 56C MOG7211100 MOG7211131 TAC 4001–10 signal—4–20mA, 1–5mA, 0–10

1 G 146ATC FC 140TC MOH7210800 MOH7210831 TAC 4004–02 VDC, 0–14 VDC, 0–100 VDC in

G 56SAA FC 56C MOH7210210 N/A N/A auto mode, or from the speed

potentiometer in manual mode.

B 435P FC 56C MOH7211100 MOH7211131 TAC 4001–00

1-1/2 B 536P FC 140TC MOI7211100 MOI7211131 TAC 4007–01

G 148ATC FC 140TC MOI7210800 MOI7210831 TAC 4004–02

2 B 548P FC 140TC MOJ7211100 MOJ7211131 TAC 4007–01

G 149ATC FC 140TC MOJ7210800 MOJ7210831 TAC 4004–02

Note: All motors are capable of 20:1 constant torque speed range.

Bronco II Bronco II

14 7

Bronco Spreads 7 10/21/99, 18.53

Bronco II Bronco II

Specifications Ratings How to Order Motor chart specify:

Horsepower

Non-Listed Motors

Non-listed motors are available,

Standard

Horsepower Range 115 VAC 1/4–1 HP

230 VAC 1/2–2 HP

Selection charts for DC motors,

available from Warner Electric

Motor Type (Manufacturer) but specific information is DC Motors

AC Line Input Voltage 115 or 230 VAC ±10% Motors and Controls, are listed on

B=Baldor required.

AC Line Frequency 50/60 Hz ± 2 Hz the following pages. For more

G=General Electric 1. Motor horsepower

115 VAC Supply M=Indiana General 2. RPM

complete specifications and

Armature Voltage 0–90 VDC Frame Size 3. Frame size

dimensional information, contact

Field Voltage 50/100 VDC Motor Enclosure 4. Volts, armature

Warner Electric Motors and

230 VAC Supply TE=Totally Enclosed 5. Volts, field or PM

Controls customer service.

Armature Voltage 0–180 VDC TEFC=Fan Cooled 6. Enclosure

Field Voltage 100/200 VDC TENV=Non Ventilated 7. Conduit location, F1, F2 etc.

Service Factor 1.0 ‘C’ Face Size 8. Thermostat

Duty Continuous (For use with Single Phase 9. Accessory endshield

Maximum Load Capacity 150% for 1 minute Controllers only) 10. ‘C’ face

Line Protection Fuse Armature Voltage 11. Delivery requirements

Model Number 12. Special application or

Motor with Tachometer environmental considerations

Operating Conditions (mounted) and other important

Motor without Tachometer information.

Ambient Temperature Tachometer Kit

Chassis Model 0–55°C

Enclosed Models 0–40°C

Relative Humidity 5–95% non-condensing

Altitude To 3300 feet (1000m)

Performance Characteristics

Speed Range 30:1 with armature voltage

feedback

50:1 with tach-generator

feedback

Speed Regulation (As % of motor

base speed) for 95% load change

Armature Voltage Feedback ± 2%

Tachometer Feedback 1/2–1%

Adjustments

Current Range 2.5, 5, 7.5, 10 Amps DC

Nominal

(Adjustable to 150% of each

range)

Maximum Speed 75–110% of motor base speed

Minimum Speed 0–30% of motor base speed

IR Compensation Adjustable

Acceleration 1–5 seconds (Linear, 0 to top

speed)

Options

• External Signal Isolation Follower For installation on chassis or

Kit remote (Standard on Models enclosed units. Allows motor

B168 and B169) Model BWC 36015 speed to be controlled from

• For use with Bronco II M/N B162 a grounded or ungrounded

when required. external signal—4–20mA,

1–5mA, 0–10 VDC, 0–14 VDC,

or 0–100 VDC. There is a

provision for auto/manual

operation if required.

Bronco II Bronco II

8 13

Bronco Spreads 8 10/21/99, 18.53

Bronco II Bronco II

Remote Remote Operator Stations (ROS) In determining the components

that comprise a drive system, the

How to Order

Operator Function Model Model Number Suffix

following selections must be

made for features and options.

Stations Number for 10 Turn Speed Pot

Start Pushbutton (1) (3) 1. DC Motor Controller 4. Isolation Transformer

Stop Pushbutton R8005 -10 Select HP and AC input voltage. Select KVA of transformer when

Single Turn Speed Pot The AC input voltage will required by adding the total HP of

Start Pushbutton (1) (3) determine motor armature and all drives to be connected to the

Stop Pushbutton field voltage. transformer. Then select model

Single Turn Speed Pot R8011 -10 number by primary input voltage

AC Input Motor Voltage and secondary output voltage.

Auto-Manual Speed

Voltage Arm/Field

Start-Stop Switch (2) (3)

Run-Jog Switch 115V 90V Arm 5. Options/Accessories

Auto-Man Switch R1001 N/A 50V/100V Field

Single Turn Speed Pot 230V 180V Arm A. The Bronco II provides only

100V/200V Field one option; i.e. the process

Note: follower applicable only to

(1) NEMA 12 Enclosed with wiring to operators B161S or B162 models.

Now select drive configuration,

(2) NEMA 4 Enclosed with wiring to terminal strips B. The isolated follower is factory

chassis or enclosure. If enclo-

(3) Applies to Models B161S and B162 only. installed in the B168 and B169

sure, do you want a blank front

models or field installed in

cover or operators controls.

B161S or B162 models.

Determine which operators are

required (i.e., run/jog, auto/

manual) and whether they will be Example 1

on a remote operators station or A conveyer requires a 1 HP DC

on the drive enclosure. From the motor, 1750 RPM, shunt wound

list of standard option boards, field, TEFC enclosure and a

select those required for your 7V/1000RPM tachometer. The

application. DC drive will be chassis mount,

230 VAC single phase input, to

2. DC Motor be operated from a ROS. ROS to

include start/stop and a speed

With the motor voltage specified potentiometer. Isolation trans-

by the AC input voltage selected former from a 230 VAC input is

above, now determine permanent required.

Isolation Isolation Transformers magnet or shunt wound, frame

Item Qty Part No.

Transformers size, enclosure type (TEFC or

TENV), C face, and whether a 1 1 B161S

tachometer will be required. 2 1 MOH2210831

Single phase NEMA I Enclosed, Dry Type, No Taps, 60 Hz, Type G

3 1 R1001

4 1 TRS21–020

HP KVA Primary Secondary Model Number 5 0 Not Required

Voltage Voltage

1/4 1/2 120/240 120/240 TRS21-005

Example 2

A Food Processing Conveyor

1/2 1 120/240 120/240 TRS21-010 requires a 1 HP DC Motor, 1750

RPM. The operation requires the

3/4 11/2 120/240 120/240 TRS21-015 3. Remote (ROS) Operator selection of start, stop, run or jog,

1 2 120/240 120/240 TRS21-020

Station forward and reverse as well as

speed adjustment. The plant

If a remote operators station will supply voltage is single phase,

11/2 3 240/480 120/240 TRS42-030 be used, select which operators 60 hertz, 230 VAC.

will be used, and the NEMA

2 5 240/480 120/240 TRS42-050 rating required. These apply to Item Qty Part No.

the chassis model B161S or

1 1 B163WD

Model B162. If the application

2 1 MOH7211300

requires reversing a model B163

3 0 Not Required

Bronco II must be selected as

4 0 Not Required

Bronco II models cannot provide

reversing with a remote operator

station.

Bronco II For dimensions and connection information, contact Warner Electric Motors and Controls customer service. Bronco II

12 9

Bronco Spreads 9 10/21/99, 18.53

Bronco II Bronco II

Selection BRONCO II

Options

Select the model that best fits your application needs.

Information Run-Jog Torque External Signal External Signal

Model BWC 36015 Process

Run/Stop

Input HP

Fwd-Rev Control Local Isolation Process Follower Board 0 – 100V

P1

Follower

▲

0 – 14V

Line Remote Local Local Operator w/ Follower J6 0 – 10V

Standard on Models B168 and B169.

Voltage Chassis Enclosed Operator Local Operator Operator Speed Trim Option Kit

Optional for customer installation on

4 – 20mA

1 – 5mA Board

115 VAC 1/4–1 models B161S or B162. 1 1

R27

Min

Spd

R28

Max

Spd

Replacement

Single B161S B162 B160 B163 B165 B169 B168 BWC36015

Phase TB3 TB4 Parts

230 VAC 1/2–2

P1

WASHDOWN DUTY BRONCO II(1)

External Signal R26 R43

Run–Jog Stop Run-Jog Torque External Signal IR Comp Accel

Input HP

Fwd-Rev Control Local Isolation

Line Remote Local Local Operator w/ Follower 2.5A

5A R27

J1 Max Spd

Voltage Enclosed Operator Local Operator Operator Speed Trim Option Kit 7.5A

10A

ARM

R29

115 VAC 1/4–1 SW1 Torque

R28

Single B162WD B160WD B163WD B165WDB B169WD B168WD BWC36015 Tach T1

Phase Min Spd

1 2 3 4 5 6 7 8 9 10

230 VAC 1/2–2 TB2

(1)

Note: J4 230V 230V J5

(+) (G2) (AC2)

Washdown Duty Broncos provide the same features as non washdown models with the exception of the epoxy finish and 115V 115V

stainless exterior hardware. 21

J3

PC Board Assembly 90V 180V

▲

(Standard on all Bronco II models) (–) (G1) (AC1) RC1 F1

D19

Model B160 and B160 WD Model B168 and B168 WD Option P2 P3

NEMA 4/12 enclosure with Start/ Same features as Model 169 External Signal Islolation Follower D20

Stop, Run/Jog switches and described below except the front Kit (Standard on Models B168 P4 P5 TB1

Speed Potentiometer mounted on panel mounted Speed and B169) Model BWC 36015 7 6 5 4 3 2 1

enclosure front cover Potentiometer trims the speed For installation on chassis or

signal when operated in the remote enclosed units. Allows

Model B161S automatic mode. motor speed to be controlled form F2 F1 A2 A1 L2 L1 Gnd

Chassis for mounting in customer a grounded or ungrounded

supplied enclosure Model B169 and B169 WD external signal—4-20mA, 1-5mA,

External isolated signal follower 0-10VDC, 0-14VDC, or 0-

Model B162 and B162 WD in NEMA 4/12 enclosure with 100VDC. There is a provision for

NEMA 4/12 enclosure for use Start/Stop and Auto/Manual auto/manual operation if required.

with a remote operator control switches and Speed

Potentiometer mounted on

Model B163 and B163 WD

enclosure front. Controls motor

NEMA 4/12 enclosure with Start/ speed from either a grounded or

Stop, Run/Jog, Forward/Reverse ungrounded signal—4-20ma,

switches and Speed 1-5ma, 0-10VDC, 0-14VDC,

Potentiometer on enclosure front 0-100VDC in auto mode, or from

cover the speed potentiometer in

Model B165 and B165 WD manual mode.

NEMA 4/12 enclosure with torque

control. Start/Stop and Forward/

Reverse switches and Torque

Potentiometer on enclosure front

cover

Bronco II Bronco II

10 11

Bronco Spreads 10 10/21/99, 18.53

Bronco II Bronco II

Selection BRONCO II

Options

Select the model that best fits your application needs.

Information Run-Jog Torque External Signal External Signal

Model BWC 36015 Process

Run/Stop

Input HP

Fwd-Rev Control Local Isolation Process Follower Board 0 – 100V

P1

Follower

▲

0 – 14V

Line Remote Local Local Operator w/ Follower J6 0 – 10V

Standard on Models B168 and B169.

Voltage Chassis Enclosed Operator Local Operator Operator Speed Trim Option Kit

Optional for customer installation on

4 – 20mA

1 – 5mA Board

115 VAC 1/4–1 models B161S or B162. 1 1

R27

Min

Spd

R28

Max

Spd

Replacement

Single B161S B162 B160 B163 B165 B169 B168 BWC36015

Phase TB3 TB4 Parts

230 VAC 1/2–2

P1

WASHDOWN DUTY BRONCO II(1)

External Signal R26 R43

Run–Jog Stop Run-Jog Torque External Signal IR Comp Accel

Input HP

Fwd-Rev Control Local Isolation

Line Remote Local Local Operator w/ Follower 2.5A

5A R27

J1 Max Spd

Voltage Enclosed Operator Local Operator Operator Speed Trim Option Kit 7.5A

10A

ARM

R29

115 VAC 1/4–1 SW1 Torque

R28

Single B162WD B160WD B163WD B165WDB B169WD B168WD BWC36015 Tach T1

Phase Min Spd

1 2 3 4 5 6 7 8 9 10

230 VAC 1/2–2 TB2

(1)

Note: J4 230V 230V J5

(+) (G2) (AC2)

Washdown Duty Broncos provide the same features as non washdown models with the exception of the epoxy finish and 115V 115V

stainless exterior hardware. 21

J3

PC Board Assembly 90V 180V

▲

(Standard on all Bronco II models) (–) (G1) (AC1) RC1 F1

D19

Model B160 and B160 WD Model B168 and B168 WD Option P2 P3

NEMA 4/12 enclosure with Start/ Same features as Model 169 External Signal Islolation Follower D20

Stop, Run/Jog switches and described below except the front Kit (Standard on Models B168 P4 P5 TB1

Speed Potentiometer mounted on panel mounted Speed and B169) Model BWC 36015 7 6 5 4 3 2 1

enclosure front cover Potentiometer trims the speed For installation on chassis or

signal when operated in the remote enclosed units. Allows

Model B161S automatic mode. motor speed to be controlled form F2 F1 A2 A1 L2 L1 Gnd

Chassis for mounting in customer a grounded or ungrounded

supplied enclosure Model B169 and B169 WD external signal—4-20mA, 1-5mA,

External isolated signal follower 0-10VDC, 0-14VDC, or 0-

Model B162 and B162 WD in NEMA 4/12 enclosure with 100VDC. There is a provision for

NEMA 4/12 enclosure for use Start/Stop and Auto/Manual auto/manual operation if required.

with a remote operator control switches and Speed

Potentiometer mounted on

Model B163 and B163 WD

enclosure front. Controls motor

NEMA 4/12 enclosure with Start/ speed from either a grounded or

Stop, Run/Jog, Forward/Reverse ungrounded signal—4-20ma,

switches and Speed 1-5ma, 0-10VDC, 0-14VDC,

Potentiometer on enclosure front 0-100VDC in auto mode, or from

cover the speed potentiometer in

Model B165 and B165 WD manual mode.

NEMA 4/12 enclosure with torque

control. Start/Stop and Forward/

Reverse switches and Torque

Potentiometer on enclosure front

cover

Bronco II Bronco II

10 11

Bronco Spreads 10 10/21/99, 18.53

Bronco II Bronco II

Remote Remote Operator Stations (ROS) In determining the components

that comprise a drive system, the

How to Order

Operator Function Model Model Number Suffix

following selections must be

made for features and options.

Stations Number for 10 Turn Speed Pot

Start Pushbutton (1) (3) 1. DC Motor Controller 4. Isolation Transformer

Stop Pushbutton R8005 -10 Select HP and AC input voltage. Select KVA of transformer when

Single Turn Speed Pot The AC input voltage will required by adding the total HP of

Start Pushbutton (1) (3) determine motor armature and all drives to be connected to the

Stop Pushbutton field voltage. transformer. Then select model

Single Turn Speed Pot R8011 -10 number by primary input voltage

AC Input Motor Voltage and secondary output voltage.

Auto-Manual Speed

Voltage Arm/Field

Start-Stop Switch (2) (3)

Run-Jog Switch 115V 90V Arm 5. Options/Accessories

Auto-Man Switch R1001 N/A 50V/100V Field

Single Turn Speed Pot 230V 180V Arm A. The Bronco II provides only

100V/200V Field one option; i.e. the process

Note: follower applicable only to

(1) NEMA 12 Enclosed with wiring to operators B161S or B162 models.

Now select drive configuration,

(2) NEMA 4 Enclosed with wiring to terminal strips B. The isolated follower is factory

chassis or enclosure. If enclo-

(3) Applies to Models B161S and B162 only. installed in the B168 and B169

sure, do you want a blank front

models or field installed in

cover or operators controls.

B161S or B162 models.

Determine which operators are

required (i.e., run/jog, auto/

manual) and whether they will be Example 1

on a remote operators station or A conveyer requires a 1 HP DC

on the drive enclosure. From the motor, 1750 RPM, shunt wound

list of standard option boards, field, TEFC enclosure and a

select those required for your 7V/1000RPM tachometer. The

application. DC drive will be chassis mount,

230 VAC single phase input, to

2. DC Motor be operated from a ROS. ROS to

include start/stop and a speed

With the motor voltage specified potentiometer. Isolation trans-

by the AC input voltage selected former from a 230 VAC input is

above, now determine permanent required.

Isolation Isolation Transformers magnet or shunt wound, frame

Item Qty Part No.

Transformers size, enclosure type (TEFC or

TENV), C face, and whether a 1 1 B161S

tachometer will be required. 2 1 MOH2210831

Single phase NEMA I Enclosed, Dry Type, No Taps, 60 Hz, Type G

3 1 R1001

4 1 TRS21–020

HP KVA Primary Secondary Model Number 5 0 Not Required

Voltage Voltage

1/4 1/2 120/240 120/240 TRS21-005

Example 2

A Food Processing Conveyor

1/2 1 120/240 120/240 TRS21-010 requires a 1 HP DC Motor, 1750

RPM. The operation requires the

3/4 11/2 120/240 120/240 TRS21-015 3. Remote (ROS) Operator selection of start, stop, run or jog,

1 2 120/240 120/240 TRS21-020

Station forward and reverse as well as

speed adjustment. The plant

If a remote operators station will supply voltage is single phase,

11/2 3 240/480 120/240 TRS42-030 be used, select which operators 60 hertz, 230 VAC.

will be used, and the NEMA

2 5 240/480 120/240 TRS42-050 rating required. These apply to Item Qty Part No.

the chassis model B161S or

1 1 B163WD

Model B162. If the application

2 1 MOH7211300

requires reversing a model B163

3 0 Not Required

Bronco II must be selected as

4 0 Not Required

Bronco II models cannot provide

reversing with a remote operator

station.

Bronco II For dimensions and connection information, contact Warner Electric Motors and Controls customer service. Bronco II

12 9

Bronco Spreads 9 10/21/99, 18.53

Bronco II Bronco II

Specifications Ratings How to Order Motor chart specify:

Horsepower

Non-Listed Motors

Non-listed motors are available,

Standard

Horsepower Range 115 VAC 1/4–1 HP

230 VAC 1/2–2 HP

Selection charts for DC motors,

available from Warner Electric

Motor Type (Manufacturer) but specific information is DC Motors

AC Line Input Voltage 115 or 230 VAC ±10% Motors and Controls, are listed on

B=Baldor required.

AC Line Frequency 50/60 Hz ± 2 Hz the following pages. For more

G=General Electric 1. Motor horsepower

115 VAC Supply M=Indiana General 2. RPM

complete specifications and

Armature Voltage 0–90 VDC Frame Size 3. Frame size

dimensional information, contact

Field Voltage 50/100 VDC Motor Enclosure 4. Volts, armature

Warner Electric Motors and

230 VAC Supply TE=Totally Enclosed 5. Volts, field or PM

Controls customer service.

Armature Voltage 0–180 VDC TEFC=Fan Cooled 6. Enclosure

Field Voltage 100/200 VDC TENV=Non Ventilated 7. Conduit location, F1, F2 etc.

Service Factor 1.0 ‘C’ Face Size 8. Thermostat

Duty Continuous (For use with Single Phase 9. Accessory endshield

Maximum Load Capacity 150% for 1 minute Controllers only) 10. ‘C’ face

Line Protection Fuse Armature Voltage 11. Delivery requirements

Model Number 12. Special application or

Motor with Tachometer environmental considerations

Operating Conditions (mounted) and other important

Motor without Tachometer information.

Ambient Temperature Tachometer Kit

Chassis Model 0–55°C

Enclosed Models 0–40°C

Relative Humidity 5–95% non-condensing

Altitude To 3300 feet (1000m)

Performance Characteristics

Speed Range 30:1 with armature voltage

feedback

50:1 with tach-generator

feedback

Speed Regulation (As % of motor

base speed) for 95% load change

Armature Voltage Feedback ± 2%

Tachometer Feedback 1/2–1%

Adjustments

Current Range 2.5, 5, 7.5, 10 Amps DC

Nominal

(Adjustable to 150% of each

range)

Maximum Speed 75–110% of motor base speed

Minimum Speed 0–30% of motor base speed

IR Compensation Adjustable

Acceleration 1–5 seconds (Linear, 0 to top

speed)

Options

• External Signal Isolation Follower For installation on chassis or

Kit remote (Standard on Models enclosed units. Allows motor

B168 and B169) Model BWC 36015 speed to be controlled from

• For use with Bronco II M/N B162 a grounded or ungrounded

when required. external signal—4–20mA,

1–5mA, 0–10 VDC, 0–14 VDC,

or 0–100 VDC. There is a

provision for auto/manual

operation if required.

Bronco II Bronco II

8 13

Bronco Spreads 8 10/21/99, 18.53

Bronco II Bronco II

Standard DC Motors Washdown Duty Specifications

6 Standard Models

DC Motors 1/4 to 1 Horsepower 90 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed

Model B160WD

NEMA Model Number

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC NEMA 4X enclosure with Start/

Type Size Face without 7 VDC/1000 RPM Tachometer Stop, Run/Jog switches and

Tachometer Tachometer Kit Speed potentiometer mounted on

(mounted) enclosure front cover

1/4 G 56HAA NV 56C MOD6110210 N/A N/A Model B162WD

B 320P NV 56C MOD6211200 MOD6211231 TAC 4001–13 NEMA 4X enclosure for use with

a remote operator control

1/2 G 56KAA FC 56C MOF6210210 N/A N/A

B 336P NV 56C MOF6211200 MOF6211231 TAC 4001–13 Model B163WD

NEMA 4X enclosure with Start/

3/4 G 56PAA FC 56C MOG6210210 N/A N/A

Stop, Run/Jog, Forward/Reverse

B 428P FC 56C MOG6211100 MOG6211131 TAC 4001–00 switches and Speed Potentio-

1 G 56SAA FC 56C MOH6210210 N/A N/A meter on enclosure front cover

B 435P FC 56C MOH6211100 MOH6211131 TAC 4001–00 Model B165WD

NEMA 4X enclosure with torque

Note: All motors are capable of 20:1 constant torque speed range. control. Start/Stop and Forward/

Reverse switches and Torque

Potentiometer on enclosure front

cover

Model B168WD

DC Motors Same features as Model 169

described below except the front

1/2 to 2 Horsepower 180 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed panel mounted Speed Potentio-

meter trims the speed signal

NEMA Model Number when operated in the automatic

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC mode.

Type Size Face without 7 VDC/1000 RPM Tachometer

Tachometer Tachometer Kit Model 169WD

(mounted) External isolated signal follower

in NEMA 4X enclosure with Start/

1/2 G 56KAA FC 56C MOF7210210 N/A N/A Stop and Auto/Manual switches

B 336P NV 56C MOF7111100 MOF7111131 TAC 4001–13 mounted on enclosure front.

3/4 G 56PAA FC 56C MOG7210210 N/A N/A Controls motor speed from either

a grounded or ungrounded

B 336P NV 56C MOG7211100 MOG7211131 TAC 4001–10 signal—4–20mA, 1–5mA, 0–10

1 G 146ATC FC 140TC MOH7210800 MOH7210831 TAC 4004–02 VDC, 0–14 VDC, 0–100 VDC in

G 56SAA FC 56C MOH7210210 N/A N/A auto mode, or from the speed

potentiometer in manual mode.

B 435P FC 56C MOH7211100 MOH7211131 TAC 4001–00

1-1/2 B 536P FC 140TC MOI7211100 MOI7211131 TAC 4007–01

G 148ATC FC 140TC MOI7210800 MOI7210831 TAC 4004–02

2 B 548P FC 140TC MOJ7211100 MOJ7211131 TAC 4007–01

G 149ATC FC 140TC MOJ7210800 MOJ7210831 TAC 4004–02

Note: All motors are capable of 20:1 constant torque speed range.

Bronco II Bronco II

14 7

Bronco Spreads 7 10/21/99, 18.53

Bronco II Bronco II

Specifications Versatility DC Motors Standard

7 Standard Models 1/4 to 1 Horsepower 90 VDC Armature – 100/50 VDC SHUNT WOUND FIELD – 1750 RPM – Totally Enclosed DC Motors

Model B160 NEMA Model Number

NEMA 4/12 enclosure with Start/ HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC

Stop, Run/Jog switches and Type Size Face without 7 VDC/1000 RPM Tachometer

Speed potentiometer mounted on Tachometer Tachometer Kit

enclosure front cover (mounted)

Model B161S 1/4 B 413D FC 56C MOD1211700 MOD1211731 TAC 4001–00

Chassis for mounting in customer 1/2 B 420D FC 56C MOF1211700 MOF1211731 TAC 4001–00

supplied enclosure 3/4 B 428D FC 56C MOG1211700 MOG1211731 TAC 4001–00

Model B162 1 B 535D FC 56C MOH1211700 MOH1211731 TAC 4007–00

NEMA 4/12 enclosure for use

with a remote operator control Note: All motors are capable of 20:1 constant torque speed range.

Model B163

NEMA 4/12 enclosure with Start/

Stop, Run/Jog, Forward/Reverse

switches and Speed Potentio-

meter on enclosure front cover

Model B165

NEMA 4/12 enclosure with torque

control. Start/Stop and Forward/

Reverse switches and Torque

Potentiometer on enclosure front DC Motors

cover

1/2 to 2 Horsepower 180 VDC Armature – 200/100 VDC SHUNT WOUND FIELD – 1750 RPM – Totally Enclosed

Model B168

Same features as Model 169 NEMA Model Number

described below except the front HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC

panel mounted Speed Potentio- Type Size Face without 7 VDC/1000 RPM Tachometer

meter trims the speed signal Tachometer Tachometer Kit

when operated in the automatic (mounted)

mode.

1/2 B 420D FC 56C MOF2211700 MOF2211731 TAC 4001–00

Model B169 3/4 B 428D FC 56C MOG2211700 MOG2211731 TAC 4001–00

External isolated signal follower 1 G 146ATC FC 140TC MOH2210800 MOH2210831 TAC 4001–02

in NEMA 4/12 enclosure with B 535D FC 56C MOH2211800 MOH2211831 TAC 4007–01

Start/Stop and Auto/Manual

G L182ACY NV 180C MOH2110100 MOH2110131 TAC 4002–03

switches mounted on enclosure

front. Controls motor speed from 1-1/2 G 148ATC FC 140TC MOI2210800 MOI12210831 TAC 4004–02

either a grounded or ungrounded G L186ACY NV 180C MOI2110100 MOI2110131 TAC 4002–03

signal—4–20mA, 1–5mA, 0–10 B 636D FC 180C MOI2211400 MOI2211431 TAC 4001–15

VDC, 0–14 VDC, 0–100 VDC in

auto mode, or from the speed 2 G 149ATC FC 140TC MOJ2210800 MOJ12210831 TAC 4004–02

potentiometer in manual mode. B 646D FC 180C MOJ2211400 MOJ2211431 TAC 4001–15

G L186ACY NV 180C MOJ2110100 MOJ2110131 TAC 4002–03

Note: All motors are capable of 20:1 constant torque speed range.

Bronco II Bronco II

6 15

Bronco Spreads 6 10/21/99, 18.53

Bronco II Bronco II

Washdown The Washdown Duty DC Motors

are specifically suited for tough Food Processing Applications

Duty DC environments where washdown is

essential to maintain cleanliness. • Washdown is frequent

Motors These motors are selected to • Cleanliness is critical

function as a companion with the • Rugged, tough environment

appropriate WASHDOWN DUTY

BRONCO II D.C. Drive Controller.

Features

8 standard Washdown Duty DC

Motors

• Epoxy Finished - FDA

approved

• Moisture Resistant Wire

• 90 or 180 VDC Armature

• Permanent Magnet Field

• 1750 RPM

• Totally Enclosed

• Sealed and corrosion protected

to meet the environments

found in food and other

industries demanding high

levels of cleanliness.

DC Motors – Washdown Duty

1/4 to 3/4 Horsepower 90 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed

NEMA Model Number

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC Chemical Processing

Type Size Face without 7 VDC/1000 RPM Tachometer

Tachometer Tachometer Kit • Corrosive atmosphere

(mounted) • Frequently wet

• Simple mounting

1/4 M 4622 NV 56C MOD6112010 N/A N/A

1/2 M 4660 NV 56C MOF6112010 N/A N/A

3/4 M 4680 NV 56C MOG6112010 N/A N/A

Note: All motors are capable of 20:1 constant torque speed range.

DC Motors – Washdown Duty

1/2 to 2 Horsepower 180 VDC Armature – PERMANENT MAGNET FIELD – 1750 RPM – Totally Enclosed

NEMA Model Number

HP Motor Frame Enclosure ‘C’ Motor Motor with 7 VDC

Type Size Face without 7 VDC/1000 RPM Tachometer

Tachometer Tachometer Kit Waste Water Treatment

(mounted)

• Wet environment

1/2 M 4660 NV 56C MOF7112010 N/A N/A • Compact size

3/4 M 4680 NV 56C MOG7112010 N/A N/A • Minimal maintenance

1 B 435P FC 56C MOH7211300 N/A N/A

1-1/2 B 536P FC 145C MOI7211300 N/A N/A

2 B 548P FC 145C MOJ7211300 N/A N/A

Bronco II Note: All motors are capable of 20:1 constant torque speed range. Bronco II

16 5

Bronco Spreads 5 10/21/99, 18.52

Bronco II Bronco II

Applications Enclosed Models B160, B162, B163, B165, B168 & B169

Dimensions

Conveyors Conduit Knockout

1.500 2.000

Ø .875 2 Places

• Simple, variable speed control

• Forward or reverse direction

• Compact and rugged for on

machine mounting 8.125

8.875

9.500

5.625

4.625

3.250

.250

2.500 .688 .313

5.000

.250 W x .375 L Slot

2 Places

Take-up

• Simple center winders

Chassis Model B161S

• Constant Torque Ø .250 4 Places

5.000 7.000

1.000

1.000 .313 .452

5.000 3.000

Mixers

• Variable speed

• Rugged and industrially tough Dimensions are listed in inches

• NEMA 4/12 enclosures

Bronco II Bronco II

4 17

Bronco Spreads 4 10/21/99, 18.52

Bronco II Bronco II

Models B160, B163 & B165 Washdown Duty

Connection Models B168 & B169

Features

Diagrams Jumper location

for model 165

A new standard in and

adjustable speed

Jumper location DC Drives. Benefits

for models

160 & 163 1 2 3 1 2 Specifically designed for food

Process – Common processing and other industries

1 2 3 4 5 6 7 8 9 10 TB5 TB4

Follower + Current Input where the motor and control are

TB2 Signal

+ – Input + Volts Input constantly exposed to high

*Optional

Tachometer 1 2 3 4 5 6 7 8 9 10 pressure washdown to maintain

+ – TB2

cleanliness.

+ –

7V/1000 RPM Optional • Rugged

Tachometer • Reliable

*Model

160 Only

– + • Versatile

7V/1000 RPM • Accurate

TB1 TB1

• Economically priced

7 6 5 4 3 2 1 7 6 5 4 3 2 1

• Listed

F2 F1 A2 A1 L1 L2 Gnd F2 F1 A2 A1 L1 L2 Gnd

F2 – A2 – F2 – A2 – • Listed for use in Canada

F1 + A1 + F1 + A1 + The Bronco II Washdown Duty

DC Drives convert single phase

115 or 230 VAC 115 or 230 VAC AC line voltages of either 115 of

50/60 Hz 50/60 Hz

230 VAC to variable DC for

armature voltage speed control

of permanent magnet or shunt

wound DC motors from 1/4 to

2 HP.

Models B161S & B162

Jumper Location for Jumper Location for

Torque Control Operation Speed Control Operation

Totally enclosed cast aluminum epoxy coated FDA

approved white enclosure with gasketed cover and

stainless steel captive screws meets NEMA 4X.

1 2 3 6 9 10

Optional Stop

2-Wire Start

Start + –

TB2 Optional Proven Warner Electric Dependability

Tachometer

• Full Wave power conversion circuit with 2 SCR’s and 3

+ –

Stop diodes with NEMA K configuration allows cooler motor

7V/1000 RPM operation.

Start CW

• IR compensation improves speed regulation in armature

W Torque Control

Speed CW Adjust

voltage feedback mode.

Control W 2K, 2W, 5%

Adjust CCW

• Control relay with 3-wire start/stop circuit prevents

2K, 2W, 5% automatic restart after power outage for increased safety.

CCW TB1 (May be reconnected for line start operation if required.)

7 6 5 4 3 2 1

• Full two year warranty.

F2 F1 A2 A1 L1 L2 Gnd

F2 – A2 –

F1 + A1 +

115 or 230 VAC

50/60 Hz

Bronco II Bronco II

18 3

Bronco Spreads 3 10/21/99, 18.52

Bronco II Bronco II

Replacement parts list for all models

Features Check out these outstanding standard features Recommended

of the Bronco II 160 Series from Warner Electric Motors and Controls...

and Warner Electric

Spare Parts

Benefits Description Old

Part Number

New

Speed/Torque Adjust Pot. 2K APT2026–00 224552-000

Start/Run/Stop Switch ASW3010–00 224554-000

Forward/Reverse Switch ASW1051–01 224579-001

Auto/Manual or Run/Jog Switch ASW1079–00 224551-000

Water Tight Boot (For all Switches) HMI 1103-00 224639-000

Water Tight Nut (For all Pots) HMI1012–00 224638-000

Fuse, 20 Amp PFU1010–07 104364-025

Isolation Follower Card BWC36015–00 –

Power Module ATY4001–03 224544-001

PC Board Assembly SPD36006–00 –

Service Service

It is intended that the Bronco II

should be serviced by replacing

Listed Field programmable jumpers Jog at potentiometer speed

major sub-assemblies. The

Allow the Bronco II to be quickly Set your Bronco II speed Replacement Parts List lists all of

Listed for use in Canada modified to match available plant potentiometer at the desired the sub-assemblies required to

line voltage, select motor HP, and speed and you can jog the motor service Bronco II drives. It is

Speed regulation to select the feedback signal allowing easy set up of your recommended that users keep

Regulation by armature voltage required. machine process. these parts readily available to

feedback or tachometer support the drive’s critical

generator feedback (non- AC line protection fuse Field supply for shunt wound

field motors applications.

reversing models only). Fault protection...eliminates a For additional assistance or the

costly replacement. Permanent magnet field or shunt name of your closest authorized

Dual voltage input wound field motors...Bronco II is

(115/230 VAC) Full wave power conversion service center, contact Warner

the right one. Electric Motors and Controls

Each model can be connected to circuit with 2 SCR’s and 3

diodes providing NEMA Totally enclosed, cast customer service at

either of two line voltages 1/4, 1/2, 800-787-3532.

3/4 and 1HP motors @115VAC Code K, DC armature supply aluminum enclosure meets

input or 1, 1-1/2 and 2 HP motors Insures optimum motor NEMA 4, NEMA 12 and

@ 230VAC. performance, cooler motor NEMA 4X standards

operation and longer life. Incredibly rugged DC drives for

Circuit protection the most critical industrial

Transient voltage protection by IR compensation adjustment environment–dust tight, oil tight

MOV. Improves speed regulation in and water resistant.

armature voltage feedback mode.

Torque control Maximum and minimum

Controls motor armature current Control relay with 3-wire speed adjustments

for applications requiring torque start/stop circuit Establishes minimum and

or tension control. Prevents automatic restart after maximum speeds.

power outage for increased

Local or remote operator safety. (May be reconnected for Adjustable acceleration

control line start operation if required.) (1 to 5 seconds)

Flexible, compact...fits where you Easy-to-set for smooth, linear

want it. speed control.

Open chassis unit availability

For convenient mounting of one

or several drives in your

enclosure.

Bronco II Bronco II

2 19

Bronco Spreads 2 10/21/99, 18.52

Bronco II Bronco II

Contents

Contents

Features and Benefits . . . . . . . 2

Applications . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . 6

How to Order . . . . . . . . . . . . . . 9

Selection Information . . . . . . 10

Options . . . . . . . . . . . . . . . . . 11

Remote Operator

Stations . . . . . . . . . . . . . . . . . 12

Isolation Transformers . . . . . 12

Standard DC Motors . . . . . . . 13

Washdown Duty

DC Motors . . . . . . . . . . . . . . . 16

Dimensions . . . . . . . . . . . . . . 17

Connection Diagrams . . . . . . 18

Recommended Spare

Parts . . . . . . . . . . . . . . . . . . . 19

Service . . . . . . . . . . . . . . . . . 19

Bronco II Bronco II

20 1

Bronco Spreads 1 10/21/99, 18.51

ADDITIONAL WARNER ELECTRIC DC DRIVES & CONTROLS

A Total Commitment Through

Distribution

• Throughout the North American Conti- • An extention of the commitment to product

nent distributors provide one stop product service is carried to each and every customer

availability and expertise through the dedicated distributor network.

• Each Distributor is a Market specialist • A carefully oriented plan is made with each

to meet local and immediate needs. distrubutor to insure optimum coverage and

service for each market area.

SE2000 DC Drives QUADRALINE 7000 DC Drives

• Literally thousands of sales and service

This non-regenerative DC drive is designed to control Designed for full wave, regenerative applications, the

personnel form the total team commitment for

shunt wound or permanent magnetic field DC motors Quadraline 7000 is designed for either permanent magnet

from ¼ to 5 HP. It offers isolated 4-20mA or 0-10 VDC or wound feild DC motors from ¼ to 5 HP. It features product and sales assurance.

control signal, tachometer generator feedback, circuit fullwave 4-quadrant operation, seven selectable perfor-

protection, diagnostic capabilities, control relay, torque mance features, electronic reversing and seven control

and slope control, and overcurrent protection. Jumper adjustments, positioning accuracy. Chassis or NEMA 4/12

selectable to program drives for specified motor or enclosures available and UL listed.

application. Horsepower range 115 VAC to 230 VAC.

Open chassis available and UL listed.

M4000 Digital 3-Phase DC Drives DS9000 Digital Drive Speed Controller

The M4000 Series Digital 3-Phase DC Drive is a The DS9000 Digital Speed Controller features long term

programmable, microprocessor based variable speed DC speed accuracy, control and stability. It offers 16-bit

drive. It allows keypad control of each parameter. Digital microprocessor based, AC or DC drive control, ± .01% YOUR DISTRIBUTOR IS:

readout provides on-line monitoring of drive operation. accuracy, digital master or follower, analog or digital

Ideal for many drive applications including wire and input, and two selectable sets of programmable param-

cable, packaging/converting, machinery and material eters. Front panel controls include a 4-digit LED readout,

handling. Improved circuit board technology has added keypad controls and four LED status indicators.

standard features, including serial communications and a

field-weakening controller for constant power and

extended speed range applications.

*Contact Warner Electric for information on our complete line of AC drives

Bronco II Coverall 2 10/21/99, 18.49

SUPPORTED BY DANA CORPORATION

WARNER ELECTRIC

The Warner Electric Motors and Controls Division of Dana Corporation is a global leader in the engineer-

ing and manufacturing of motor and control products for industrial applications. All Warner Electric

products and services are backed by highly specialized engineers and service people who can help solve

your production challenges. Warner Electric’s capabilities and products have improved operations for

hundreds of companies around the world.

Warner Electric® stepper motors and controls, servo motors and controls, voltage conditioning products,

engineered systems, and AC/DC drives are available worldwide through an extensive authorized distribu-

tor network. These distributors provide convenient service by offering technical support, replacement

Bronco II

parts, and literature, as well as an extensive inventory of off-the-shelf models for the fastest possible 160 Series DC Drives

delivery and service. Call your nearest distributor for ordering and application information.

IN U.S.A. AND CANADA

WARNER ELECTRIC MOTORS AND CONTROLS DIVISION

◆ Sales: 734-669-4700

◆ Customer Service: 800-787-3532

◆ Product Application: 800-787-3532

◆ Product Literature Request: 800-787-3532

◆ Fax: 800-766-6366 or 860-589-2136

◆ Web Site: www.warnernet.com

SERVO CONTROLS STEPPER CONTROLS VOLTAGE CONDITIONING ENGINEERED SYSTEMS AC/DC DRIVES

WARNER ELECTRIC MOTORS AND CONTROLS DIVISION

Division Office Bristol Plant Systems Center International - Europe

640 Avis Drive, Suite 200 383 Middle Street 13500-J South Point Blvd. Lausanne, Switzerland

Ann Arbor, MI 48108 Bristol, CT 06010 Charlotte, NC 28273 La Pierreire

CH-1029 Villars-Ste-Croix,

Switzerland

©1999 Warner Electric Division

C3004 9/99 Printed in U.S.A.

Bronco II Coverall 1 10/21/99, 18.47

You might also like

- Secadora Electrolux Manual de ServicioDocument8 pagesSecadora Electrolux Manual de Servicioorkys Tenorio100% (1)

- Hyundai Tucson Quick Reference GuideDocument17 pagesHyundai Tucson Quick Reference Guidewreckedweasel50% (2)

- Irelay 60 & Irelay 50-P (AD20190618)Document22 pagesIrelay 60 & Irelay 50-P (AD20190618)flyngdance100% (1)

- DC60D MK2 Genset Controller User Manual V1.1Document49 pagesDC60D MK2 Genset Controller User Manual V1.1Mauricio Olaya100% (1)

- Volantex ESC Manual PDFDocument8 pagesVolantex ESC Manual PDFCameron Clarke0% (1)

- OSC48xx Series: USB Oscilloscope/Data Logger Device Family FeaturesDocument20 pagesOSC48xx Series: USB Oscilloscope/Data Logger Device Family FeaturesArturo EspinoNo ratings yet

- Pioneer 202 Metal DetectorDocument20 pagesPioneer 202 Metal Detectorp_romero_cNo ratings yet

- Emerson Commander SK Getting Started Guide Size A-DDocument52 pagesEmerson Commander SK Getting Started Guide Size A-DGorbaniRanderesNo ratings yet

- EMC StandardsDocument19 pagesEMC StandardsDHARMENDRA100% (1)

- A SeriesDocument337 pagesA SeriesLuis Alonso Morales EsquivelNo ratings yet

- Kingroon ConfiguracoesDocument3 pagesKingroon ConfiguracoesanafrancaNo ratings yet

- Siemens - Sirius 3rt1026-1aDocument2 pagesSiemens - Sirius 3rt1026-1aJose GallardoNo ratings yet

- Midiverb Iv Stereo Effects Processor Service Manual V 1.00 6/13/95Document29 pagesMidiverb Iv Stereo Effects Processor Service Manual V 1.00 6/13/95Everardo Pineda ParraNo ratings yet

- Pioneer GM 3000TDocument19 pagesPioneer GM 3000TBorcan CristiNo ratings yet

- 258 Copeland CF and CS Compressor CatalogueDocument88 pages258 Copeland CF and CS Compressor Cataloguevacosteles100% (1)

- Manual TVDocument64 pagesManual TVpatricioNo ratings yet

- Denon AVR-1906Document70 pagesDenon AVR-1906bsambNo ratings yet

- SB 10059670 2273Document10 pagesSB 10059670 2273benjaminNo ratings yet

- RAS 1215 DatasheetDocument4 pagesRAS 1215 Datasheetnandosinternet100% (1)

- 32LC818 Lcd26v88amDocument53 pages32LC818 Lcd26v88amDaniel AvecillaNo ratings yet

- Led TV: Service ManualDocument47 pagesLed TV: Service ManualGiancarloRichardRivadeneyraMirandaNo ratings yet

- PS 850 Treadmill Owner's Manual: Downloaded From Manuals Search EngineDocument40 pagesPS 850 Treadmill Owner's Manual: Downloaded From Manuals Search EngineKamal ImouzarNo ratings yet

- Manual de Servicio Radio Base Kenwood Modelo TK-7102H-InglésDocument43 pagesManual de Servicio Radio Base Kenwood Modelo TK-7102H-InglésJorge Alvaro Lopez CervantesNo ratings yet

- Hisense 39ldafaft Pld3913ft Lt39dr530 Lt39da530 Tds1339ft Ldf39ilo2 39dr530 (Chassis Msd309px) Manual de Servicio LCDDocument45 pagesHisense 39ldafaft Pld3913ft Lt39dr530 Lt39da530 Tds1339ft Ldf39ilo2 39dr530 (Chassis Msd309px) Manual de Servicio LCDAlexis ColmenaresNo ratings yet

- LG lm-w5040Document58 pagesLG lm-w5040supermax900No ratings yet

- All About 2n2222 Transistor and Its Circuit DiagramsDocument5 pagesAll About 2n2222 Transistor and Its Circuit DiagramsSai KiranNo ratings yet

- 4600cl StepperDocument37 pages4600cl StepperJEREMEE MICHAEL TYLERNo ratings yet

- Haier Ht1006txve Service ManualDocument23 pagesHaier Ht1006txve Service ManualDoru RazvanNo ratings yet

- Error Code Troubleshooting Guide: Revised 2/2015Document47 pagesError Code Troubleshooting Guide: Revised 2/2015Mohammed ShabanNo ratings yet

- Alternistor Triacs (6-40 Amps)Document10 pagesAlternistor Triacs (6-40 Amps)David Lovato100% (1)

- Switch Mode Power Supply 12V-35VDocument13 pagesSwitch Mode Power Supply 12V-35VRgcp RgcpNo ratings yet

- Processor Setting FundamentalsDocument14 pagesProcessor Setting Fundamentalsta dang hung100% (1)

- JULIE CAR EMULATOR User Manual ImmoDocument1 pageJULIE CAR EMULATOR User Manual ImmoJozefNo ratings yet

- Manual Telefono Siemens Euroset - 3005Document16 pagesManual Telefono Siemens Euroset - 3005Marcelo FanjulNo ratings yet

- LC240CP, LC340CP - Service Manual (3828A20911A) - 122206Document61 pagesLC240CP, LC340CP - Service Manual (3828A20911A) - 122206Lim JohnvynNo ratings yet

- Catalog PDFDocument312 pagesCatalog PDFnolasco100% (1)

- SYLVANIA W6413tc - SMDocument46 pagesSYLVANIA W6413tc - SMdreamyson1983100% (1)

- Manual TV-Monitor LG 22MA33DDocument42 pagesManual TV-Monitor LG 22MA33DDragos DragoshNo ratings yet

- Manual Equipo AUG 25-30 ELBWDocument26 pagesManual Equipo AUG 25-30 ELBWShadow50_4No ratings yet

- Concert Series Bass Maximizer Owners Enjoyment ManualDocument16 pagesConcert Series Bass Maximizer Owners Enjoyment ManualEduardo AmezcuaNo ratings yet

- Manual Sa Akx95lm KDocument150 pagesManual Sa Akx95lm KFernando SotoNo ratings yet

- AIWA 4ZG-1 (Chipset SONY) SvcMnlsDocument18 pagesAIWA 4ZG-1 (Chipset SONY) SvcMnlsavrelecNo ratings yet

- Pioneer DEH-P4700MP User ManualDocument46 pagesPioneer DEH-P4700MP User ManualViki Kis100% (1)

- Samsung Galaxy J7 Neo SM-J701MDocument131 pagesSamsung Galaxy J7 Neo SM-J701MAndres Felipe G100% (1)

- Kenmore 41742042100 Washer PDFDocument24 pagesKenmore 41742042100 Washer PDFsloth185No ratings yet

- 1 GIGRAC 300/600 Technical ManualDocument97 pages1 GIGRAC 300/600 Technical ManualJose Luthier De Amplis Guitarreros100% (1)

- Laundry Top LoadDocument440 pagesLaundry Top LoaddivyeshethNo ratings yet

- Ecm HV-240Document12 pagesEcm HV-240Tanya Piriyabunharn100% (1)

- Zapi h2 Pump Controller 969Document3 pagesZapi h2 Pump Controller 969SaveliyGovorkovNo ratings yet

- MTX-L PlusDocument14 pagesMTX-L Plusjuanlasserre9444No ratings yet

- EnglishDocument210 pagesEnglishNicanor Herrera WallsNo ratings yet

- Transformer Brochure Minera - SchneiderDocument4 pagesTransformer Brochure Minera - SchneiderTino HardikaNo ratings yet

- ConnectivityDocument64 pagesConnectivitymike mikeNo ratings yet

- DS - Calatogue PDFDocument8 pagesDS - Calatogue PDFPritam SinghNo ratings yet

- Seco-DC-Drives Catalog en-US Rev2005Document40 pagesSeco-DC-Drives Catalog en-US Rev2005milacronNo ratings yet

- Magna Plus Generators Brochure PDFDocument6 pagesMagna Plus Generators Brochure PDFPaul Peraza0% (1)

- Sirco Mot DC - DC Ess - Catalogue - Pages - 2023 08 - DCG - en UsDocument4 pagesSirco Mot DC - DC Ess - Catalogue - Pages - 2023 08 - DCG - en UsANDRE CHEZSANo ratings yet

- 08GPCat SinglePhaseDCDocument22 pages08GPCat SinglePhaseDCSAMO SAMARANo ratings yet

- Inequalities A Mathematical Olympiad ApproachDocument84 pagesInequalities A Mathematical Olympiad ApproachsaiNo ratings yet

- K-Line Mini - Contactors, Overload Relays and Accessories: Class 8502Document48 pagesK-Line Mini - Contactors, Overload Relays and Accessories: Class 8502hassan karimiNo ratings yet

- Performance, Efficiency, Versatility: Powering GenerationsDocument8 pagesPerformance, Efficiency, Versatility: Powering Generationsrofano aswanNo ratings yet

- Demand More: Eaton's Complete Line of Variable Frequency DrivesDocument8 pagesDemand More: Eaton's Complete Line of Variable Frequency DrivesChen LiNo ratings yet

- TV Manual 32SF560Document54 pagesTV Manual 32SF560Joy Howden-EllisNo ratings yet

- FSP Group FSP350 60APN 350W Technische Details 234f55Document1 pageFSP Group FSP350 60APN 350W Technische Details 234f55EdipoNo ratings yet

- Ad231 Parts & Service ManualsDocument36 pagesAd231 Parts & Service Manualsminoltaep4050No ratings yet

- GE Incandescent Flair Decorative Lamps Brochure 1972Document4 pagesGE Incandescent Flair Decorative Lamps Brochure 1972Alan MastersNo ratings yet

- Datasheet L4909 PDFDocument7 pagesDatasheet L4909 PDFRICHIHOTS2No ratings yet

- Amt R04423-00 PDFDocument21 pagesAmt R04423-00 PDFYudhika CibroNo ratings yet

- Reduction of Voltage Spike in The Isolated Bi-Directional Converter With Flyback SnubberDocument10 pagesReduction of Voltage Spike in The Isolated Bi-Directional Converter With Flyback SnubberVenkatesan SwamyNo ratings yet

- Fakoor Sanat Tehran: 1. General Data & InformationDocument6 pagesFakoor Sanat Tehran: 1. General Data & Informationkarimi-15No ratings yet

- Power Quality Issues: EE4161 Unit: 4 Long-Duration Voltage VariationsDocument35 pagesPower Quality Issues: EE4161 Unit: 4 Long-Duration Voltage VariationsSrikanth IslavatuNo ratings yet

- QBCR.E85310 - Outlet and Junction Boxes For Use in Hazardous Locations - UL Product IqDocument4 pagesQBCR.E85310 - Outlet and Junction Boxes For Use in Hazardous Locations - UL Product Iqjuan palominoNo ratings yet

- Mechanical Design of Overhead Transmission Line: Assignment-Module 3 Transmission and DistributionDocument2 pagesMechanical Design of Overhead Transmission Line: Assignment-Module 3 Transmission and DistributionsmitajanaNo ratings yet

- Changeover & by Pass SwitchesDocument12 pagesChangeover & by Pass Switcheshemant kumarNo ratings yet

- DigSilent Training ModuleDocument18 pagesDigSilent Training Moduletosikur rahmanNo ratings yet

- Oc SC TestDocument14 pagesOc SC Testraghu_chandra_3No ratings yet

- Art. F500 E - Art. F550 E - Art. F560 E Art. F600 E - Art. F650 EDocument3 pagesArt. F500 E - Art. F550 E - Art. F560 E Art. F600 E - Art. F650 Eilusion alusionNo ratings yet

- 1785613820Document469 pages1785613820Anonymous wwmxD7No ratings yet

- 77-Club Car Presedent EXCEL (1515) Install Sheet-370Document4 pages77-Club Car Presedent EXCEL (1515) Install Sheet-370info.wenamericaNo ratings yet

- How To Check Basic Electronic Components Using A MultiDocument7 pagesHow To Check Basic Electronic Components Using A MultiHumayaunNo ratings yet

- Wind EnergyDocument21 pagesWind EnergyAnonymous 800E9bNo ratings yet

- Electrovalvula DKI, DKU y DKORDocument4 pagesElectrovalvula DKI, DKU y DKORJuan Carlos Bermudez Cardenas100% (1)

- 9.0 Electric MotorDocument20 pages9.0 Electric MotorZwe1991No ratings yet

- Battery Installation and OperationDocument38 pagesBattery Installation and OperationZay Yar100% (1)

- UNO DM 3.3 4.0 4.6 5.0 TL PLUS - BCD.00680 - Revb - EN PDFDocument4 pagesUNO DM 3.3 4.0 4.6 5.0 TL PLUS - BCD.00680 - Revb - EN PDFTiago Michel HoffmannNo ratings yet

- Modicon TM3 - TM3DI16Document8 pagesModicon TM3 - TM3DI16Abdan SyakuraNo ratings yet

- Smart Energy ConsumptionDocument15 pagesSmart Energy ConsumptionKristyadi Daripada PaidiNo ratings yet

- Smart Grid Technology - Implementation & Benefit For PLNDocument16 pagesSmart Grid Technology - Implementation & Benefit For PLNrendroyoko100% (1)

- Vendor ListDocument1 pageVendor ListpeeramohamedNo ratings yet

- Battery Storage in JapanDocument3 pagesBattery Storage in Japanaryaman chakrabortyNo ratings yet