Professional Documents

Culture Documents

Karumel Ex4412: KCC Corporation

Karumel Ex4412: KCC Corporation

Uploaded by

ABAID ULLAHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Karumel Ex4412: KCC Corporation

Karumel Ex4412: KCC Corporation

Uploaded by

ABAID ULLAHCopyright:

Available Formats

KCC Corporation

Head Office: 1301-4, Seocho-Dong, Seocho-Ku, Seoul, Korea

TEL: +82 2 3480 5712~4 FAX: +82 2 3480 5436

KARUMEL EX4412

FUSION BONDED EPOXY POWDER COATING

KARUMEL EX4412 is an epoxy based powder coating, designed for corrosion protection of water pipeline.

It has been tested and certified to meet the requirements of Water Regulation Advisory Scheme (United

Kingdom) for use as a coating in contact with potable water and also meets the requirements of AWWA

standard C213, and BS 6920 listed under WRAS (Cold & Hot water use up to 85℃)

1. POWDER PROPERTIES

Property Test Description Results

Color Standard Color Blue, Grey

CSA Z245.20-14 Clause 12.2

Gel Time* 100~150 seconds (Line Pipe)

(at 205±3℃)

Moisture Content CSA Z245.20-14 Clause 12.4 ≤ 0.50% (at time of manufacture)

Density CSA Z245.20-14 Clause 12.6 1,400 ± 50 g/L

0.71 ㎡/kg/㎜

Theoretical Coverage 2

138 ft /lb/mil

Thermal Tg1 = 62 ~ 72℃

CSA Z245.20-14 Clause 12.7

Characteristics Tg2 = 93 ~ 108℃

Below 25℃ with relative humidity 65% sealed

Shelf Life Max. 18 months

state ( 77℉)

* Gel time values depend on operator’s technique and test condition.

2. GENERAL APPLICATION

• A heavy duty coating on valve, fitting, and water pipe.

• No primer required.

• Remove oil, grease and loosely adhering deposits.

• Remove surface dust using a vacuum or a dry, oil-free of air.

• Clean the surface to Near-White blast (SSPC-SP10, Swedish Standard Sa 2.5, NACE No.2, BS Second

Quality) and profile between 2 and 4mils.

• After blasting, remove contaminants or defects like dust & metallic bur through the specified procedure.

• Preheat the pipe to 177 ~ 232℃ (350~450℉).

(The optimum temperature can vary according to the condition of coating facilities and coating system)

• Apply KARUMEL EX4412 in accordance with the specification.

(Film thickness can be chosen by specification)

• Follow recommended cure schedule indicated in Section 3. CURE SCHEDULE.

All data are based on laboratory testing and practical experience.

The information is believed to be accurate without any obligation to KCC.

KCC Corporation

Head Office: 1301-4, Seocho-Dong, Seocho-Ku, Seoul, Korea

TEL: +82 2 3480 5712~4 FAX: +82 2 3480 5436

KARUMEL EX4412

FUSION BONDED EPOXY POWDER COATING

3. CURE SCHEDULE

The following theoretical curing schedules are recommended to achieve the best performance properties.

Pipe Temperature* Cure Time(Line Pipe)

450 ℉ (232 ℃) 15 min.

350 ℉ (177 ℃) 30 min.

* Cure can be affected by coating line condition and pipe size hence degree of cure should be checked by

appropriate method such as DSC.

4. FILM PROPERTIES

Property Test Description Criteria Results

CSA Z245.20-14 Clause 12.8

Cathodic Disbondment 3.5V*65℃*24h ≤6.5 mm Avg. 3 mm

1.5V*20℃*28d ≤8.5 mm Avg. 5 mm

CSA Z245.20-14 Clause 12.10

Porosity Cross-Section Rating of 1~4 ≤Rating 2

Interface Rating of 1~4 ≤Rating 2

ARAMCO 09-SAMSS-091

5.5˚/PD at 25℃ No Cracking No Cracking

ARAMCO 09-SAMSS-091

Flexibility

3.75˚/PD at 10℃ No Cracking No Cracking

ARAMCO 09-SAMSS-091

3.0˚/PD at 5℃ No Cracking No Cracking

CSA Z245.20-14 Clause 12.12

1.5J at -30℃ No Holidays No Holidays

Impact Resistance

AWWA C213-07

100in-lbs (11.3J) at 23℃ No Holidays No Holidays

CSA Z245.20-14 Clause 12.14

Adhesion

75℃*24h Rating of 1~3 Rating 1~2

AWWA C213-07

Abrasion Resistance

1kg,5000 cycles, CS-17 wheels ≤0.3 g < 0.18g loss

ASTM D2240

Hardness

Shore D 82

ASTM B117 No Blistering

Salt Fog

No Loss of Adhesion

AWWA C213-07

Volume Resistivity 15 15

ASTM D257 1.1 × 10 1.5 × 10 ohm-cm

AWWA C213-07

Dielectric Strength

ASTM D149 1,000 V/mil 1,450 V/mil

AWWA C213-07

Penetration

60℃ ≤10% 0.7%

All data are based on laboratory testing and practical experience.

The information is believed to be accurate without any obligation to KCC.

KCC Corporation

Head Office: 1301-4, Seocho-Dong, Seocho-Ku, Seoul, Korea

TEL: +82 2 3480 5712~4 FAX: +82 2 3480 5436

KARUMEL EX4412

FUSION BONDED EPOXY POWDER COATING

Property Test Description Criteria Results

ASTM D870

Hot Water Immersion No visual defects

1000hrs @85℃

Tensile Strength ASTM D2370 7,760 psi

CSA Z245.20-02 No Blistering,

90 days at 23℃ No Swelling,

- Hydrochloric acid in distilled water No Cracks &

- 10% sodium chloride and sulphuric No Loss of adhesion

acid in distilled water

Chemical Resistance - 10% sodium chloride in distilled water

- Distilled water

- 5% sodium hydroxide in distilled water

- Saturated solution mixture of equal

parts by mass of magnesium carbonate

and calcium carbonate in distilled water

5. APPROVAL

WRAS (Water Regulation Advisory Scheme) – U.K.

Standard – BS6920 (Non-metallic materials for use with drinking water)

Approval Number - 1701541

6. REPAIRS

KOPATCH PC300 is recommended to use in case of repairing the area coated with KARUMEL EX4412.

KOPATCH PC300 is WRAS approved 2-component liquid epoxy material.

Approval Number - 1410505

7. APPLICATION DETAILS

Property Details

18 months at 25℃ cool and dry place (Cooler temperature and lower humidity are

Storage

recommended)

Packing 20 kg / 130kg / 1 ton big bag

Do not mix with any other type of powder or the reduction of gloss and defect of

physical properties may occur. Incorporate reclaim powder with virgin powder for

Remarks re-use, only after sieving and at a Recommended maximum of 10%.

The use of recycled powder shall be only permitted when proper screening

equipment is installed and gel time, moisture is within range.

All data are based on laboratory testing and practical experience.

The information is believed to be accurate without any obligation to KCC.

KCC Corporation

Head Office: 1301-4, Seocho-Dong, Seocho-Ku, Seoul, Korea

TEL: +82 2 3480 5712~4 FAX: +82 2 3480 5436

KARUMEL EX4412

FUSION BONDED EPOXY POWDER COATING

8. NOTICE

• Read Material Safety Data Sheet for complete hazard and safety information.

• All data are based on laboratory testing and practical experience.

• The information is believed to be accurate, however without any obligation.

• Contact your KCC sales representative for more information.

ISSUED April 2019

All data are based on laboratory testing and practical experience.

The information is believed to be accurate without any obligation to KCC.

You might also like

- Astm A1078 PDFDocument5 pagesAstm A1078 PDFmmendez113100% (1)

- SATIP SAIC SATR IndexDocument87 pagesSATIP SAIC SATR Indexlhanx2100% (9)

- Technical Procedure - Pipeline Preservation PDFDocument85 pagesTechnical Procedure - Pipeline Preservation PDFFarhan Hanafi100% (4)

- BS en 12502-3Document18 pagesBS en 12502-3laboratorium logamNo ratings yet

- FT-IR Fingerprinting of A Non-Aqueous Liquid Paint As Supplied in The Manufacturer's ContainerDocument6 pagesFT-IR Fingerprinting of A Non-Aqueous Liquid Paint As Supplied in The Manufacturer's ContainerJuan F Alvarez100% (2)

- Quality Procedure For Dual FBE Coating Rev.01Document39 pagesQuality Procedure For Dual FBE Coating Rev.01Nebu Mathew100% (1)

- P&Id Reverse Osmosis: Shuqaiq 3 Independent Water ProjectDocument20 pagesP&Id Reverse Osmosis: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Section 5.0 - Epoxy Coatin SystemsDocument36 pagesSection 5.0 - Epoxy Coatin SystemsgemotorresNo ratings yet

- Com Su 4042 IDocument38 pagesCom Su 4042 Iolalekan100% (1)

- Ductile Iron Pipes and Fittings - Electrosteel Casting LTD PDFDocument44 pagesDuctile Iron Pipes and Fittings - Electrosteel Casting LTD PDFSmith780512No ratings yet

- Soluble Salts and CoatingsDocument11 pagesSoluble Salts and CoatingsDale Wade100% (1)

- Technical Data - JotunDocument2 pagesTechnical Data - JotunWajid ZiaNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- ASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsDocument6 pagesASTM D6392-12 Det The Integrity of Nonreinforced Geomembrane Seams Using Thermo-Fusion MethodsMoeketsi KhubeluNo ratings yet

- Astm D2621 2005Document26 pagesAstm D2621 2005Marc Padu100% (1)

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- Beginners Guide To CorrosionDocument10 pagesBeginners Guide To Corrosionshamu081No ratings yet

- 3LPE Coating Performance in IranDocument3 pages3LPE Coating Performance in IranJorge Suarez100% (1)

- OTS60PBDocument4 pagesOTS60PBLiza Taguines VillegasNo ratings yet

- NACE TR21473-2024 In-Situ Coating of Steel Pipelines Via PiggingDocument16 pagesNACE TR21473-2024 In-Situ Coating of Steel Pipelines Via Piggingahugandkiss77071No ratings yet

- ASTM A123 and G90 Specifications - American Galvanizers AssociationDocument3 pagesASTM A123 and G90 Specifications - American Galvanizers AssociationwinarnobNo ratings yet

- Sigmashield 880 GF - ISO 23040-1Document1 pageSigmashield 880 GF - ISO 23040-1Saravan KumarNo ratings yet

- Mar Resistance of Organic Coatings: Standard Test Method ForDocument3 pagesMar Resistance of Organic Coatings: Standard Test Method Formit uotNo ratings yet

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseEngTamerNo ratings yet

- Mil PRF 85285eDocument24 pagesMil PRF 85285emurphygtNo ratings yet

- Data Sheet Proguard CN 200 A.SDocument3 pagesData Sheet Proguard CN 200 A.SAlexir Thatayaone NdovieNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- NACE Coating Inspector's Logbook, Fifth Edition: Arthur K. MarshallDocument1 pageNACE Coating Inspector's Logbook, Fifth Edition: Arthur K. MarshallGouse PashaNo ratings yet

- ASTM E1132-99aDocument27 pagesASTM E1132-99aOmar Bellido ValenciaNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqNo ratings yet

- Astm and Iso Vocs in Coatings - Method Comparison MatrixDocument2 pagesAstm and Iso Vocs in Coatings - Method Comparison MatrixShaik ShahNo ratings yet

- Astm D4228 05R17Document3 pagesAstm D4228 05R17Johana Rivadeneira100% (1)

- Esd Floor Coating Certificate Iso Goldmin Detail 1Document11 pagesEsd Floor Coating Certificate Iso Goldmin Detail 1laiju cs100% (1)

- Surface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningDocument2 pagesSurface Preparation Standard No. 1: SSPC: The Society For Protective Coatings Solvent CleaningKrishna VachaNo ratings yet

- Iso 11126 7 2018Document9 pagesIso 11126 7 2018Ludwig Datuk JiangNo ratings yet

- Guida Coprax Eng 2015 LightDocument82 pagesGuida Coprax Eng 2015 Lightairsys7projec100% (1)

- NORSOK R-004 2005 (Draft) Piping and Equipment InsulationDocument30 pagesNORSOK R-004 2005 (Draft) Piping and Equipment InsulationWHWENNo ratings yet

- 3 6077 RTVDocument2 pages3 6077 RTVgkretroNo ratings yet

- Conder Separator Brochure NewDocument8 pagesConder Separator Brochure Newednavilod100% (1)

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- POLYPOXY-NF Technical Data SheetDocument2 pagesPOLYPOXY-NF Technical Data SheetCommando crawlerNo ratings yet

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDocument46 pagesRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesNo ratings yet

- ASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesDocument6 pagesASTM D610 - Standard Practice For Evaluating Degree of Rusting On Painted Steel SurfacesRoger SchvepperNo ratings yet

- Araldite Klad XDocument1 pageAraldite Klad XakhanNo ratings yet

- Basf Masterprotect 1815 TdsDocument3 pagesBasf Masterprotect 1815 TdsEngTamer100% (1)

- ASTM D4541 and ISO 4624: ?/sup InstrumentsDocument2 pagesASTM D4541 and ISO 4624: ?/sup InstrumentsTeguh SilaNo ratings yet

- Exova Coating TestingDocument19 pagesExova Coating TestingMehman Nasibov100% (1)

- Measurements of Dry Film Coating Thickness On SteelDocument2 pagesMeasurements of Dry Film Coating Thickness On SteelKrizia Meiahn Catalon100% (1)

- MSDS Primer S1301-M Parte ADocument2 pagesMSDS Primer S1301-M Parte AMichael Betetta AbadNo ratings yet

- Pa 3 PDFDocument0 pagesPa 3 PDFNageswara Rao BavisettyNo ratings yet

- Is123 1996Document11 pagesIs123 1996Raji Satheesh100% (1)

- ISO 1512-1991 (Partial)Document9 pagesISO 1512-1991 (Partial)smupy_122-1No ratings yet

- Galvosil 15680 Data SheetDocument2 pagesGalvosil 15680 Data Sheetn00b1810No ratings yet

- QC PVC 18373Document4 pagesQC PVC 18373Andrei SimionNo ratings yet

- Irish Standard I.S. EN ISO 11126-3:2018Document14 pagesIrish Standard I.S. EN ISO 11126-3:2018Nitin KawareNo ratings yet

- ASTM D3359 Standard Test Methods For Measuring Adhesion by Tape TestDocument2 pagesASTM D3359 Standard Test Methods For Measuring Adhesion by Tape TestEdgarDavidDiazCamposNo ratings yet

- 05500Document6 pages05500khalid764No ratings yet

- Technical Data Sheet: Stolevell Thinplast FinishDocument3 pagesTechnical Data Sheet: Stolevell Thinplast FinishAnthony Al Lakiss0% (1)

- (201207) (PDS) Ex4700Document3 pages(201207) (PDS) Ex4700Abdelrahman AwadallahNo ratings yet

- 7-2500 FbeDocument3 pages7-2500 FbejleonosNo ratings yet

- Technical Information Sheet: 7-2508 Pipe CoatingDocument3 pagesTechnical Information Sheet: 7-2508 Pipe Coatingreza329329No ratings yet

- Nap-Gard 7-2504 Gold-Dual Powder System: Technical Data SheetDocument3 pagesNap-Gard 7-2504 Gold-Dual Powder System: Technical Data Sheetlong chanNo ratings yet

- GDF057-BR002-SPL-02: Operator WestDocument2 pagesGDF057-BR002-SPL-02: Operator WestABAID ULLAHNo ratings yet

- Tank AlignmentDocument1 pageTank AlignmentABAID ULLAHNo ratings yet

- GDF057-BR001-SPL-01: Field ShopDocument2 pagesGDF057-BR001-SPL-01: Field ShopABAID ULLAHNo ratings yet

- KRO2-WM01-S-0702 - Specific Equipment Dimensional Drawings Rev.6Document55 pagesKRO2-WM01-S-0702 - Specific Equipment Dimensional Drawings Rev.6ABAID ULLAHNo ratings yet

- KRO2-WQ00-M-8038 - Installation, Operating, Maintenance, Commissioning Instructions and Assembling Drawings Rev.0Document126 pagesKRO2-WQ00-M-8038 - Installation, Operating, Maintenance, Commissioning Instructions and Assembling Drawings Rev.0ABAID ULLAHNo ratings yet

- KR02-WQ00-S-8012-Rev D-Air Receiver GAD-Approved (06.05.2021)Document5 pagesKR02-WQ00-S-8012-Rev D-Air Receiver GAD-Approved (06.05.2021)ABAID ULLAHNo ratings yet

- KRO2-WM01-H-0702-Specific Equipment Data Sheet With Its Motor Data Sheet Revd - AADocument46 pagesKRO2-WM01-H-0702-Specific Equipment Data Sheet With Its Motor Data Sheet Revd - AAABAID ULLAHNo ratings yet

- Al-Khobar Seawater Reverse Osmosis 2 Desalination PlantDocument344 pagesAl-Khobar Seawater Reverse Osmosis 2 Desalination PlantABAID ULLAHNo ratings yet

- (SA05C1-WV00-S-0013) Cartridge Filter Dimensional Drawing - REVD (AA)Document5 pages(SA05C1-WV00-S-0013) Cartridge Filter Dimensional Drawing - REVD (AA)ABAID ULLAHNo ratings yet

- SA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointDocument1 pageSA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- Al-Khobar Seawater Reverse Osmosis 2 Desalination PlantDocument4 pagesAl-Khobar Seawater Reverse Osmosis 2 Desalination PlantABAID ULLAHNo ratings yet

- SA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

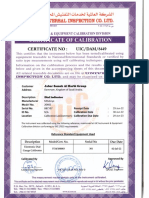

- Calibration CertificatesDocument18 pagesCalibration CertificatesABAID ULLAHNo ratings yet

- SA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- SA04C2-03-WP-D-43101-01-2: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-43101-01-2: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- SA04C2-03-WP-D-42101-01-3: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-42101-01-3: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Sa04c2 03 WP D 42202 0.2Document2 pagesSa04c2 03 WP D 42202 0.2ABAID ULLAHNo ratings yet

- SA04C2-03-WP-D-42103-01-1: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-42103-01-1: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Sa04c2 03 WP D 42102 0.2Document2 pagesSa04c2 03 WP D 42102 0.2ABAID ULLAHNo ratings yet

- SA04C2-03-WP-D-42201-01-3: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-42201-01-3: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- 19pv0379-Bikar ProcedureDocument4 pages19pv0379-Bikar ProcedureABAID ULLAHNo ratings yet

- Manometer MEI 0-25 BAR 19166307122330Document1 pageManometer MEI 0-25 BAR 19166307122330ABAID ULLAHNo ratings yet

- SA04C2-MS-MET-AAG-0009 Rev 01 Method Statement of Pneumatic Test For SS and GRE PipesDocument11 pagesSA04C2-MS-MET-AAG-0009 Rev 01 Method Statement of Pneumatic Test For SS and GRE PipesABAID ULLAHNo ratings yet

- SA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeDocument16 pagesSA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeABAID ULLAHNo ratings yet

- SA04C2-MS-MET-AAG-0014 - REV-00 MS For Loading and Unloading of Ss Pipes and Material Using Over Head CraneDocument9 pagesSA04C2-MS-MET-AAG-0014 - REV-00 MS For Loading and Unloading of Ss Pipes and Material Using Over Head CraneABAID ULLAHNo ratings yet

- Coating Procedure - Shuqaiq Desalination PJT - Rev.2Document19 pagesCoating Procedure - Shuqaiq Desalination PJT - Rev.2ABAID ULLAHNo ratings yet

- SA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesDocument11 pagesSA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesABAID ULLAHNo ratings yet

- 270 S.J. S.J.: ID QTY DN Description Sch/Cla SSDocument2 pages270 S.J. S.J.: ID QTY DN Description Sch/Cla SSABAID ULLAHNo ratings yet

- Manometer MEI 0-25 BAR 19166307122330Document1 pageManometer MEI 0-25 BAR 19166307122330ABAID ULLAHNo ratings yet

- A775 - Standard Specification For Epoxy-Coated Steel Reinforcing BarsDocument11 pagesA775 - Standard Specification For Epoxy-Coated Steel Reinforcing BarsÉrica RodriguesNo ratings yet

- CBT Test PreparationDocument29 pagesCBT Test PreparationAMALENDU PAULNo ratings yet

- Weltech Prequalification - KoreaDocument43 pagesWeltech Prequalification - KoreaCassy AbulenciaNo ratings yet

- 80080-TCH-0000-SP-003 - SIGNED-Coating ProcedureDocument7 pages80080-TCH-0000-SP-003 - SIGNED-Coating ProcedurePaul NieNo ratings yet

- Lecture 4 - Types of RebarsDocument51 pagesLecture 4 - Types of RebarsJagannathan KNo ratings yet

- Coatings For HDDDocument8 pagesCoatings For HDDrenato100% (1)

- Astm A 899 - 91 (R 02)Document3 pagesAstm A 899 - 91 (R 02)Abu Muhammad iftikharNo ratings yet

- Apcs 113 - Inorganic ZincDocument11 pagesApcs 113 - Inorganic ZincMoghal AliNo ratings yet

- PDFDocument24 pagesPDFmika cabelloNo ratings yet

- Com Su 5315 ADocument39 pagesCom Su 5315 AolalekanNo ratings yet

- SP-1246 Part 1 Technical RequirementsDocument27 pagesSP-1246 Part 1 Technical RequirementsBurning TrainNo ratings yet

- Fire Protection Control ValvesDocument20 pagesFire Protection Control ValvesDaniel Eduardo RodriguezNo ratings yet

- Ta-Btv: Butterfly ValvesDocument8 pagesTa-Btv: Butterfly Valvesclan_partijeNo ratings yet

- Material Take-Off List: Saudi Aramco 6228-ENG (11/2010)Document1 pageMaterial Take-Off List: Saudi Aramco 6228-ENG (11/2010)FahadNo ratings yet

- 2012A Functional Spec For 3LPP (3 Layer Poly Propelene) Corrosion Coating For Linepipes) (Rev. 0)Document46 pages2012A Functional Spec For 3LPP (3 Layer Poly Propelene) Corrosion Coating For Linepipes) (Rev. 0)Samuel John100% (1)

- Brederoshaw CC Pds A4 2lppDocument2 pagesBrederoshaw CC Pds A4 2lppabcNo ratings yet

- Water Uptake and Interfacial Delamination of An Epoxy-Coated Galvanized Steel - An Electrochemical Impedance Spectroscopic StudyDocument8 pagesWater Uptake and Interfacial Delamination of An Epoxy-Coated Galvanized Steel - An Electrochemical Impedance Spectroscopic StudyNavid HoseiniNo ratings yet

- Miv Brochure 637b979b5355bDocument28 pagesMiv Brochure 637b979b5355bBassamNo ratings yet

- Final Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Document95 pagesFinal Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Unni CyriacNo ratings yet

- Method Statement For APCS-113A (1) 22-6-2011Document7 pagesMethod Statement For APCS-113A (1) 22-6-2011sharif339No ratings yet

- GS (2006) Vol 2 Rev20 S15 Steel ReinforcementDocument14 pagesGS (2006) Vol 2 Rev20 S15 Steel ReinforcementLap Chun TUNGNo ratings yet

- Inspection HandbookDocument127 pagesInspection HandbookWalter Rueda100% (2)

- BrederoShaw PDS FBE PDFDocument2 pagesBrederoShaw PDS FBE PDFJR RZNo ratings yet