Professional Documents

Culture Documents

GBU10005 - GBU1010: 10A Glass Passivated Bridge Rectifier

GBU10005 - GBU1010: 10A Glass Passivated Bridge Rectifier

Uploaded by

Mae MegumiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GBU10005 - GBU1010: 10A Glass Passivated Bridge Rectifier

GBU10005 - GBU1010: 10A Glass Passivated Bridge Rectifier

Uploaded by

Mae MegumiCopyright:

Available Formats

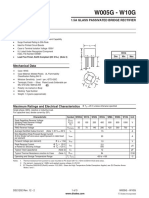

Pb GBU10005 - GBU1010

10A GLASS PASSIVATED BRIDGE RECTIFIER

Features Mechanical Data

• Glass Passivated Die Construction • Case: GBU

• High Case Dielectric Strength of 1500VRMS • Case Material: Molded Plastic. UL Flammability Classification

• Low Reverse Leakage Current Rating 94V-0

• Surge Overload Rating to 220A Peak • Moisture Sensitivity: Level 1 per J-STD-020

• Ideal for Printed Circuit Board Applications • Terminals: Matte Tin Finish. Solderable per MIL-STD 202, Method

• UL Listed Under Recognized Component 208

Index, File Number E94661 • Polarity: Marked on Body

• Lead-Free Finish; RoHS Compliant (Notes 1 & 2) • Mounting: Through Hole for #6 Screw

• Mounting Torque: 5.0 Inch-pounds Maximum

• Marking: Date Code and Type Number

• Weight: 4 grams (approximate)

Ordering Information (Note 3)

Part Number Case Packaging

GBU10005-GBU1010 GBU 20/Tube

Notes: 1. EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant. All applicable RoHS exemptions applied.

2. See http://www.diodes.com for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green" and Lead-free.

3. For packaging details, go to our website at http://www.diodes.com.

Maximum Ratings and Electrical Characteristics (@TA = +25°C, unless otherwise specified.)

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitive load, derate current by 20%.

GBU GBU GBU GBU GBU GBU GBU

Characteristic Symbol Unit

10005 1001 1002 1004 1006 1008 1010

Peak Repetitive Reverse Voltage VRRM

Working Peak Reverse Voltage VRWM 50 100 200 400 600 800 1000 V

DC Blocking Voltage VR

RMS Reverse Voltage VR(RMS) 35 70 140 280 420 560 700 V

Average Forward Rectified Current (Note 4) @ TC = +100°C I(AV) 10 A

Non-Repetitive Peak Forward Surge Current

IFSM 220 A

8.3ms Single Half Sine-Wave Superimposed on Rated Load

Forward Voltage (per element) @ IF = 5.0A VFM 1.0 V

Peak Reverse Current at @ TC = +25°C 5.0

IR μA

Rated DC Blocking Voltage @ TC = +125°C 500

2 2 2

I t Rating for Fusing (Note 5) I t 200 A s

Typical Total Capacitance per Element (Note 6) CT 60 pF

Typical Thermal Resistance Junction to Case (Note 4) RθJC 2.2 °C/W

Operating and Storage Temperature Range TJ, TSTG -55 to +150 °C

Notes: 4. Unit mounted on 100mm x 100mm x 1.6mm copper plate heatsink.

5. Non-repetitive, for t > 1.0ms and < 8.3ms.

6. Measured at 1.0MHz and applied reverse voltage of 4.0V DC.

GBU10005 - GBU1010 1 of 4 November 2012

Document number: DS30052 Rev. 6 - 2 www.diodes.com © Diodes Incorporated

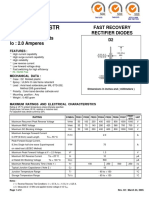

GBU10005 - GBU1010

100

I(AV), AVG FORWARD RECTIFIED CURRENT (A)

10

IF, INSTANTANEOUS FORWARD CURRENT (A)

Resistive or

Inductive Load

8

TJ = 25° C

10

6

4

1.0

0 0.1

0 50 100 150 0 0.2 0.6 1.0 1.4 1.8

TC, CASE TEMPERATURE (° C) VF, INSTANTANEOUS FORWARD VOLTAGE (V)

Figure 1 Forward Current Derating Curve Figure 2 Typical Forward Characteristics, per element

250 1,000

IFSM, PEAK FORWARD SURGE CURRENT (A)

T J = 25° C

f = 1.0MHz

200

CT, TOTAL CAPACITANCE (pF)

Single half-sine wave

150

100

100

50

TJ = 25° C

0 10

1 10 100 0.1 1.0 10 100

NUMBER OF CYCLES AT 60Hz VR, REVERSE VOLTAGE (V)

Figure 3 Maximum Non-Repetitive Surge Current Figure 4 Typical Total Capacitance, per element

GBU10005 - GBU1010 2 of 4 November 2012

Document number: DS30052 Rev. 6 - 2 www.diodes.com © Diodes Incorporated

GBU10005 - GBU1010

Package Outline Dimensions

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

GBU

Dim Min Max

A

K A 21.8 22.3

B M B 3.5 4.1

C 7.4 7.9

C D 1.65 2.16

L E 2.25 2.75

F 1.95 2.35

O D

- ~ ~ +

E

G

H

1.02

4.83

1.27

5.33

J 17.5 18.0

F K 3.2 X 45°

J L 18.3 18.8

N

M 3.30 3.56

G

N 0.46 0.56

O 1.90R

P P 0.76 1.0

H All Dimensions in mm

GBU10005 - GBU1010 3 of 4 November 2012

Document number: DS30052 Rev. 6 - 2 www.diodes.com © Diodes Incorporated

GBU10005 - GBU1010

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

GBU10005 - GBU1010 4 of 4 November 2012

Document number: DS30052 Rev. 6 - 2 www.diodes.com © Diodes Incorporated

You might also like

- Cambridge Studies in International Relations John A. Vasquez The War Puzzle Revisited Cambridge University Press 2009Document507 pagesCambridge Studies in International Relations John A. Vasquez The War Puzzle Revisited Cambridge University Press 2009Isabelle Drăgănescu0% (1)

- OutSystems 10 Professional Developer CertificationDocument4 pagesOutSystems 10 Professional Developer CertificationhanspaulNo ratings yet

- w10g - Passivated Bridge RectifierDocument3 pagesw10g - Passivated Bridge Rectifierrudey18No ratings yet

- 1.5KE6V8 (C) A - 1.5KE400 (C) A: 1500W Transient Voltage SuppressorDocument4 pages1.5KE6V8 (C) A - 1.5KE400 (C) A: 1500W Transient Voltage SuppressorVladv002No ratings yet

- SB380 SB3100Document4 pagesSB380 SB3100jrhappy systemsNo ratings yet

- Gbu10005-Gbu1010 N1770 Rev.aDocument5 pagesGbu10005-Gbu1010 N1770 Rev.aAldy ChesterkunNo ratings yet

- Smbjp6ke6 8 C A Smbjp6ke550 C A Do 214aa - 2511159Document6 pagesSmbjp6ke6 8 C A Smbjp6ke550 C A Do 214aa - 2511159Viola Safa Nur AnnisaNo ratings yet

- Lead-Free Finish Rohs Compliant (Notes 1 & 2) : 35A Glass Passivated Bridge RectifierDocument4 pagesLead-Free Finish Rohs Compliant (Notes 1 & 2) : 35A Glass Passivated Bridge RectifierJomblo NgenesNo ratings yet

- Schrack Power PCB Relay RP II/1Document3 pagesSchrack Power PCB Relay RP II/1IBJSC.comNo ratings yet

- Smbj5.0a Smbj170a DiodesDocument6 pagesSmbj5.0a Smbj170a DiodesAhmed Sherif CupoNo ratings yet

- KBPC600 - KBPC610: FeaturesDocument3 pagesKBPC600 - KBPC610: FeaturesdanielaNo ratings yet

- 1N5391/S - 1N5399/S: Discontinued 08/06/2009Document3 pages1N5391/S - 1N5399/S: Discontinued 08/06/2009fabrizzio asdasdNo ratings yet

- SB160 Schottky Diode 60V 1a PDFDocument3 pagesSB160 Schottky Diode 60V 1a PDFdemostenessNo ratings yet

- SMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFDocument4 pagesSMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFAntoni MonteroNo ratings yet

- GblxxeDocument5 pagesGblxxeJairo Alonso Hernandez GonzalezNo ratings yet

- SMBJ 1Document8 pagesSMBJ 1Omar MelchorNo ratings yet

- SB370 - SB3100: Contact UsDocument3 pagesSB370 - SB3100: Contact UsYoelNo ratings yet

- GPP 20 ADocument5 pagesGPP 20 AJulioCesar MagalhaesNo ratings yet

- Diodesincorporated 2w10g Datasheets 8452Document3 pagesDiodesincorporated 2w10g Datasheets 8452maximiliano gagliardiNo ratings yet

- GBJ15005 PDFDocument2 pagesGBJ15005 PDFsaberNo ratings yet

- RGP10A, RGP10B, RGP10D, RGP10G, RGP10J, RGP10K, RGP10M: Vishay General SemiconductorDocument4 pagesRGP10A, RGP10B, RGP10D, RGP10G, RGP10J, RGP10K, RGP10M: Vishay General SemiconductorDelos Santos JojoNo ratings yet

- Stp10Nk80Zfp Stp10Nk80Z - Stw10Nk80Z: N-Channel 800V - 0.78 - 9A - To-220/Fp-To-247 Zener-Protected Supermesh MosfetDocument15 pagesStp10Nk80Zfp Stp10Nk80Z - Stw10Nk80Z: N-Channel 800V - 0.78 - 9A - To-220/Fp-To-247 Zener-Protected Supermesh MosfetBlakeNo ratings yet

- Data SheetDocument2 pagesData Sheetalain rougetNo ratings yet

- GSIB2020N, GSIB2040N, GSIB2060N, GSIB2080N: Vishay General SemiconductorDocument4 pagesGSIB2020N, GSIB2040N, GSIB2060N, GSIB2080N: Vishay General Semiconductorشعبان العواميNo ratings yet

- Ds 30135Document4 pagesDs 30135Afshin GhafooriNo ratings yet

- GSIB620 Thru GSIB680: Vishay General SemiconductorDocument4 pagesGSIB620 Thru GSIB680: Vishay General SemiconductorCARLOS ALBERTO Ramos UlloaNo ratings yet

- Ug2A, Ug2B, Ug2C, Ug2D: Vishay General SemiconductorDocument5 pagesUg2A, Ug2B, Ug2C, Ug2D: Vishay General SemiconductorKhan SahibNo ratings yet

- SB570 - SB5100: 5.0A Schottky Barrier RectifierDocument3 pagesSB570 - SB5100: 5.0A Schottky Barrier RectifierWalter FabianNo ratings yet

- MBRF10150CT THRU MBRF10200CT: Schottky Barrier RectifierDocument2 pagesMBRF10150CT THRU MBRF10200CT: Schottky Barrier RectifierY. Leonel MolinaNo ratings yet

- P6KE6V8CADocument4 pagesP6KE6V8CASaid BoublehNo ratings yet

- Datasheet Diode IN4002GDocument3 pagesDatasheet Diode IN4002GPoupée De SoieNo ratings yet

- RGP 10 GDocument5 pagesRGP 10 GDirson Volmir WilligNo ratings yet

- Schrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysDocument4 pagesSchrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysWilson Rubiano AlfaroNo ratings yet

- DF005S - DF10S: 1.0A Surface Mount Glass Passivated Bridge Rectifier FeaturesDocument2 pagesDF005S - DF10S: 1.0A Surface Mount Glass Passivated Bridge Rectifier FeaturesClaudiney BricksNo ratings yet

- Mbrf10100ct n0189 Rev.bDocument4 pagesMbrf10100ct n0189 Rev.bEugene FlexNo ratings yet

- Datasheet - Live: Rohs RohsDocument2 pagesDatasheet - Live: Rohs RohsErnesto Raphael Magallanes BorjasNo ratings yet

- Glass Passivated Single-Phase Bridge RectifierDocument4 pagesGlass Passivated Single-Phase Bridge Rectifieretovive1No ratings yet

- SMAJ5.0 (C) A - SMAJ170 (C) A: 400W Surface Mount Transient Voltage Suppressor FeaturesDocument4 pagesSMAJ5.0 (C) A - SMAJ170 (C) A: 400W Surface Mount Transient Voltage Suppressor Featuresedi purwantoNo ratings yet

- GPP20A Thru GPP20M: Vishay General SemiconductorDocument4 pagesGPP20A Thru GPP20M: Vishay General SemiconductorNell CendsNo ratings yet

- D25XB40 ........ D25XB100 25 Amp. Glass Passivated Single Phase in Line Bridge RectifierDocument4 pagesD25XB40 ........ D25XB100 25 Amp. Glass Passivated Single Phase in Line Bridge RectifierAlejandro RomeroNo ratings yet

- Supresor de Pico 1.5kev8CADocument3 pagesSupresor de Pico 1.5kev8CAJoao HerreraNo ratings yet

- 1.5KE6V8 (C) A - 1.5KE400 (C) A: 1500W Transient Voltage SuppressorDocument4 pages1.5KE6V8 (C) A - 1.5KE400 (C) A: 1500W Transient Voltage Suppressorantonp78No ratings yet

- GP15A, GP15B, GP15D, GP15G, GP15J, GP15K, GP15M: Vishay General SemiconductorDocument5 pagesGP15A, GP15B, GP15D, GP15G, GP15J, GP15K, GP15M: Vishay General SemiconductorJuan ChoNo ratings yet

- 1.5KE6V8 (C) A - 1.5KE400 (C) A: 1500W Transient Voltage SuppressorDocument4 pages1.5KE6V8 (C) A - 1.5KE400 (C) A: 1500W Transient Voltage SuppressorHerberth BarriosNo ratings yet

- UF1001 - UF1007: FeaturesDocument4 pagesUF1001 - UF1007: Featuresdrivers automotrizNo ratings yet

- GBU1001 - GBU1007: Taiwan SemiconductorDocument6 pagesGBU1001 - GBU1007: Taiwan SemiconductorDodi ArvaniNo ratings yet

- 3.0A Rectifier: Lead Free Finish, Rohs Compliant (Note 3)Document3 pages3.0A Rectifier: Lead Free Finish, Rohs Compliant (Note 3)Victor SantosNo ratings yet

- 1N5400 THRU 1N5408: FeaturesDocument3 pages1N5400 THRU 1N5408: FeaturesWijaya TeknikNo ratings yet

- Sb3150 and Sb3200: Cystech Electronics CorpDocument6 pagesSb3150 and Sb3200: Cystech Electronics CorpCube7 GeronimoNo ratings yet

- Schrack Miniature Power PCB RYII-AP: General Purpose Relays PCB RelaysDocument3 pagesSchrack Miniature Power PCB RYII-AP: General Purpose Relays PCB RelaysKholilNo ratings yet

- Dfls1200: Powerdi 123Document3 pagesDfls1200: Powerdi 123m3y54mNo ratings yet

- TE Connectivity AMP 4 1393238 7 DatasheetDocument2 pagesTE Connectivity AMP 4 1393238 7 DatasheetastizeNo ratings yet

- Puente Gbu6aDocument4 pagesPuente Gbu6aJESSAMYN GUERRERO MONTOYANo ratings yet

- Rectron: SemiconductorDocument2 pagesRectron: SemiconductorAVRPICNo ratings yet

- 1.5SMC6.8A (CA) - 1.5SMC440A (CA) : Surface Mount Transient Voltage Suppessor DiodeDocument4 pages1.5SMC6.8A (CA) - 1.5SMC440A (CA) : Surface Mount Transient Voltage Suppessor DiodeMohammad AhmadNo ratings yet

- HRSG 21 Sump Pumps 20GMA31AP001, 20GMA32AP002 (Motor Datasheet, Drawing)Document5 pagesHRSG 21 Sump Pumps 20GMA31AP001, 20GMA32AP002 (Motor Datasheet, Drawing)Anibal QuezadaNo ratings yet

- Evc 135Document4 pagesEvc 135Leewwon LeeNo ratings yet

- Features: Surface Mount Glass Passivated Single Phase Bridge Rectifier Reverse Voltage 1400V Ountput Current 2.0ADocument4 pagesFeatures: Surface Mount Glass Passivated Single Phase Bridge Rectifier Reverse Voltage 1400V Ountput Current 2.0ATeudis Naranjo OrtizNo ratings yet

- Datasheet PDFDocument3 pagesDatasheet PDFSamvel KhachatryanNo ratings yet

- AOTF600A70FLDocument6 pagesAOTF600A70FLEliseo SanchezNo ratings yet

- 4 PDFDocument2 pages4 PDFMega GhostNo ratings yet

- PN2222A Silicon NPN Transistor Audio Amplifier, Switch TO 92 Type PackageDocument3 pagesPN2222A Silicon NPN Transistor Audio Amplifier, Switch TO 92 Type PackageMae MegumiNo ratings yet

- High Power Chip Resistors: LTR 1 8 EZP J 1 0 5Document7 pagesHigh Power Chip Resistors: LTR 1 8 EZP J 1 0 5Mae MegumiNo ratings yet

- C10, C11Document52 pagesC10, C11Mae MegumiNo ratings yet

- 1I5400 Thru 1N5408 Axial Lead Standard Recovery Silicon Rectifiers, 3 Amp, DO 201ADDocument2 pages1I5400 Thru 1N5408 Axial Lead Standard Recovery Silicon Rectifiers, 3 Amp, DO 201ADMae MegumiNo ratings yet

- RCS E3: VishayDocument10 pagesRCS E3: VishayMae MegumiNo ratings yet

- Csm-7Xdu SMD Crystal: Operating Conditions / Electrical CharacteristicsDocument2 pagesCsm-7Xdu SMD Crystal: Operating Conditions / Electrical CharacteristicsMae MegumiNo ratings yet

- Data Sheet: Surface-Mount Ceramic Multilayer CapacitorsDocument20 pagesData Sheet: Surface-Mount Ceramic Multilayer CapacitorsMae MegumiNo ratings yet

- Package Power JackDocument5 pagesPackage Power JackMae MegumiNo ratings yet

- Packaging Code: GRM155R71H104KE14 - (0402, X7R:EIA, 0.1uf, DC50V) Reference SheetDocument29 pagesPackaging Code: GRM155R71H104KE14 - (0402, X7R:EIA, 0.1uf, DC50V) Reference SheetMae MegumiNo ratings yet

- Aluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsDocument4 pagesAluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsMae MegumiNo ratings yet

- Chip Type Part Number: Miniaturized Aluminum Electrolytic CapacitorsDocument5 pagesChip Type Part Number: Miniaturized Aluminum Electrolytic CapacitorsMae MegumiNo ratings yet

- 01.inter Com Engg PDFDocument28 pages01.inter Com Engg PDFSanjeevi PrakashNo ratings yet

- Separators of Different GenerationsDocument46 pagesSeparators of Different GenerationsISLAM I. Fekry100% (8)

- Sci 09 Sample QPDocument8 pagesSci 09 Sample QPkvindhraNo ratings yet

- Certiport Exam Administration Policies: Examination SecurityDocument2 pagesCertiport Exam Administration Policies: Examination SecurityrajputamitdNo ratings yet

- Henry The NavigatorDocument2 pagesHenry The Navigatorapi-294843376No ratings yet

- Anh - 10Document50 pagesAnh - 10Hưng PhúNo ratings yet

- Rapid Culture of Pratylenchus Zeae On Carrot DiscsDocument2 pagesRapid Culture of Pratylenchus Zeae On Carrot DiscsFrank KagodaNo ratings yet

- Blasting BrochureDocument8 pagesBlasting BrochureMuhammad SyiardyNo ratings yet

- Uganda GGDS Implementation Roadmap FINALDocument41 pagesUganda GGDS Implementation Roadmap FINALmosesmattekkNo ratings yet

- Not All Mineral Oils Are Equal Exploring The History and Tech Behind Mineral Insulating OilsDocument6 pagesNot All Mineral Oils Are Equal Exploring The History and Tech Behind Mineral Insulating OilsJicheng PiaoNo ratings yet

- Comm 10Document2 pagesComm 10boopNo ratings yet

- An Overview of Function Point AnalysisDocument6 pagesAn Overview of Function Point AnalysisavinashnNo ratings yet

- The SNG Blueprint Part 1 PDFDocument26 pagesThe SNG Blueprint Part 1 PDFAdrian PatrikNo ratings yet

- MCQ IadDocument23 pagesMCQ Iads soyaNo ratings yet

- Notice: Medicare: Emergency Medical Treatment and Labor Act Technical Advisory GroupDocument2 pagesNotice: Medicare: Emergency Medical Treatment and Labor Act Technical Advisory GroupJustia.comNo ratings yet

- PE Curriculum Grade 9-12Document2 pagesPE Curriculum Grade 9-12agungsportnetasNo ratings yet

- Sep2 Meterview: Energy Measurement and ManagementDocument2 pagesSep2 Meterview: Energy Measurement and ManagementAdil HameedNo ratings yet

- AllergyDocument35 pagesAllergyAhmed ImranNo ratings yet

- 5.00 FD An1 s1 CE Chemistry 23-24Document4 pages5.00 FD An1 s1 CE Chemistry 23-24imsNo ratings yet

- The Untouchables and The Pax Britannica Dr. B.R.ambedkarDocument61 pagesThe Untouchables and The Pax Britannica Dr. B.R.ambedkarVeeramani ManiNo ratings yet

- Free Money Making Guide PDF VersionDocument15 pagesFree Money Making Guide PDF VersionboulboutNo ratings yet

- Assessing Speaking SkillsDocument2 pagesAssessing Speaking SkillsDaniel MyoNo ratings yet

- Guidelines and Fundamental Considerations For Axle BalancingDocument40 pagesGuidelines and Fundamental Considerations For Axle BalancingAnonymous PVXBGg9TNo ratings yet

- Econchella PDFDocument2 pagesEconchella PDFSanjana JobiNo ratings yet

- Math Vectors v2Document72 pagesMath Vectors v2Rowanberry11No ratings yet

- IBM Power Facts and FeaturesDocument19 pagesIBM Power Facts and Featuresivan Dario Correa RestrepoNo ratings yet

- Formatted SBI Clerk Mains Previous Year Paper 2021Document78 pagesFormatted SBI Clerk Mains Previous Year Paper 2021shyamveer147No ratings yet

- Multiple IntelligencesDocument3 pagesMultiple IntelligencesRaisa NicoldNo ratings yet