Professional Documents

Culture Documents

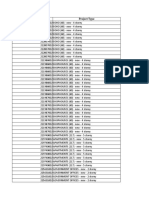

Sloss Industries 1062235 M2234300 EX351 V 2

Sloss Industries 1062235 M2234300 EX351 V 2

Uploaded by

DanielDeFrancescoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sloss Industries 1062235 M2234300 EX351 V 2

Sloss Industries 1062235 M2234300 EX351 V 2

Uploaded by

DanielDeFrancescoCopyright:

Available Formats

P R O J E C T P R O F I L E

NovoRez® Acid Resistant coating used CUSTOMER

Sloss Industries

for secondary containment of up to Birmingham, Alabama

98% sulfuric acid. PROJECT TEAM

Contractor: G & S, LLC. – Jemison, Alabama

PROJECT OVERVIEW

Sloss Industries Corporation is one of the nation’s leading

manufacturers of coke for iron and steel production. The

coke division produces approximately 460,000 tons of

coke annually for the blast furnace market and foundry

industry. www.sloss.com

The growth of the steel industry and rise in production

created a need for additional storage of sulfuric acid at the

Birmingham Plant. When choosing a contractor, Sloss

Industries chose G & S, LLC because of their experience

and ability to meet the plant’s high safety and insurance

requirements. In addition, PolySpec® was chosen to

provide the material because of our long history of success

in the chemical industry, breadth of chemical coatings and

linings product line, and local technical representation.

KEY CONSIDERATIONS

Crack Repair: After the concrete was poured for the new

containment area, an enormous amount of hairline cracks

developed in both the walls and floor. These cracks had to

be filled and reinforced with a flexible system to insure the

integrity of the containment area over time.

Chemical Resistance: The system had to be resistant to up

to 98% sulfuric acid at temperatures of up to 120 deg F.

SYSTEM PRODUCTS

• RezRok® 106:

Epoxy Patching Compound, Fast Cure

• PolySpec® 300EX Primer:

Epoxy Performance Primer for Concrete

• Thiokol® 2235M:

Industrial Polysulfide Joint Sealant, Non-sag

• Thiokol® FEC 2234:

Concrete & Steel Coating/Membrane, Flexible Epoxy

• NovoRez® 351:

Concrete Coating, Acid Resistant

WWW.POLYSPEC.COM • Tel: 281-397-0033 • Fax: 281-397-6512 • 6614 Gant Road • Houston, Texas 77066

© Copyright 2004 PolySpec. PROFILE-PENSKE206-0405. All rights reserved.

You might also like

- Psychdoc's Credit Repair For BeginnersDocument69 pagesPsychdoc's Credit Repair For BeginnersTomek Dzido100% (2)

- VZ-30 Service ManualDocument32 pagesVZ-30 Service ManualJimmy Mayta100% (1)

- CB To Fill Up Items 1,2 & 4 and Col 3 of The Checklist NABCB AT To Fill The RestDocument75 pagesCB To Fill Up Items 1,2 & 4 and Col 3 of The Checklist NABCB AT To Fill The RestBS AnilKumarNo ratings yet

- Anti-Corrosion Methods and MaterialsDocument1 pageAnti-Corrosion Methods and MaterialsVinh Do ThanhNo ratings yet

- Zecor PDFDocument7 pagesZecor PDFjavoidea696526100% (1)

- Sika CaseStudy CPD 6thStPkingGarage UsDocument2 pagesSika CaseStudy CPD 6thStPkingGarage UsTom HartnabbNo ratings yet

- Profile BFL (NEW)Document18 pagesProfile BFL (NEW)Nurhasan TalukdarNo ratings yet

- Intergard 343 Universal PrimerDocument9 pagesIntergard 343 Universal PrimerAndri AjaNo ratings yet

- Cs CPD 6thStPkingGarage UsDocument2 pagesCs CPD 6thStPkingGarage Uschinzorig khurelsukhNo ratings yet

- Brochure Grouting BFLDocument11 pagesBrochure Grouting BFLAndhika eka satryaNo ratings yet

- Our Coating Is After 5 Years Still Effective and Intact! A Major Project From 2008: Internal and External Coating of 2 Bioethanol Storage TanksDocument2 pagesOur Coating Is After 5 Years Still Effective and Intact! A Major Project From 2008: Internal and External Coating of 2 Bioethanol Storage TanksSergio MarchettiNo ratings yet

- RAZON - Admixtures Company ProfileDocument17 pagesRAZON - Admixtures Company Profileshrikrishna rathodNo ratings yet

- Intergard 343 - Marine CoatingsDocument9 pagesIntergard 343 - Marine CoatingsSerggie TabanaoNo ratings yet

- Proctor VCL Technical GuideDocument16 pagesProctor VCL Technical GuideRaduAxinteNo ratings yet

- Corrosion Performance of Epoxy Coated Reinforcing Steel - North America ExperienceDocument17 pagesCorrosion Performance of Epoxy Coated Reinforcing Steel - North America ExperiencebrahmabulNo ratings yet

- Method Statement For RoofDocument22 pagesMethod Statement For Roofahmed samirNo ratings yet

- Sipor X: Siporex Manufacturing Plant in Riyadh, Saudi ArabiaDocument10 pagesSipor X: Siporex Manufacturing Plant in Riyadh, Saudi ArabiaJacob AbrahamNo ratings yet

- Launch EpoxyDocument5 pagesLaunch EpoxyRana MahatoNo ratings yet

- Epoxy Grout PDFDocument4 pagesEpoxy Grout PDFamirthraj74No ratings yet

- 832 00003Document2 pages832 00003Nikesh ShahNo ratings yet

- Procuct Data Guide (Five Star Products)Document192 pagesProcuct Data Guide (Five Star Products)ccorp0089No ratings yet

- BASF Grout Presentation 2018 V1 - TunisiaDocument39 pagesBASF Grout Presentation 2018 V1 - TunisiatchabgoumartinNo ratings yet

- Sigmacover™: Recoatable Epoxy SystemsDocument8 pagesSigmacover™: Recoatable Epoxy SystemsRasheedNo ratings yet

- Burried Piping SpecDocument9 pagesBurried Piping Specsada sivaNo ratings yet

- Bredero Shaw PDFDocument54 pagesBredero Shaw PDFAndersson Benito Herrera100% (1)

- KCH Surface LiningDocument12 pagesKCH Surface LiningicingrockNo ratings yet

- Launch Anticarbonation CoatingDocument4 pagesLaunch Anticarbonation CoatingRana MahatoNo ratings yet

- E 1605 SikaCor 255 277Document5 pagesE 1605 SikaCor 255 277manoj_sitecNo ratings yet

- The Cunard Building, LiverpoolDocument2 pagesThe Cunard Building, LiverpoolIbrahim FawwazNo ratings yet

- Car Park Specified Solutions: From Sika UKDocument4 pagesCar Park Specified Solutions: From Sika UKbeck.26No ratings yet

- Cat EpoxyDocument12 pagesCat Epoxymohamed Salah klaiNo ratings yet

- COM600 Coating ConcreteDocument25 pagesCOM600 Coating ConcreteVicente RegulezNo ratings yet

- Offshore Eng PDFDocument8 pagesOffshore Eng PDFClintonDestinyNo ratings yet

- Protective Epoxy Coatings For Oil and Gas PipelinesDocument2 pagesProtective Epoxy Coatings For Oil and Gas PipelinessiswoutNo ratings yet

- Amercoat 253 FlyerDocument1 pageAmercoat 253 FlyerSherif AbdelhameedNo ratings yet

- Novel Refractory Materials For High-Temperature, High-Alkaline EnvironmentsDocument2 pagesNovel Refractory Materials For High-Temperature, High-Alkaline EnvironmentsAbdul SabirNo ratings yet

- Brochure - CEMTOPDocument20 pagesBrochure - CEMTOPMANISHA SURVENo ratings yet

- Concrete CoatingDocument26 pagesConcrete CoatingHerlys Pereira100% (1)

- ErgonArmor PDFDocument6 pagesErgonArmor PDFChinthamani PandiNo ratings yet

- Fosroc: Grouting SolutionsDocument11 pagesFosroc: Grouting SolutionsShridhar VaidyaNo ratings yet

- Epoxy Coated 123Document4 pagesEpoxy Coated 123alammasoodNo ratings yet

- Chemcrete Profile 18072022Document25 pagesChemcrete Profile 18072022muhammad naumanNo ratings yet

- Siporex BLOCKS Brochure 2 v08092021 enDocument12 pagesSiporex BLOCKS Brochure 2 v08092021 enjcunha4740No ratings yet

- Sika-Trocal Single Ply RoofingDocument12 pagesSika-Trocal Single Ply Roofingp2pnow2005No ratings yet

- Contech ChemicalsDocument8 pagesContech ChemicalskiNo ratings yet

- K450 Plus Updated PDFDocument138 pagesK450 Plus Updated PDFCongson JeffNo ratings yet

- Cold Bonding LNG TanksDocument4 pagesCold Bonding LNG TankskaybeeNo ratings yet

- Hepha Vibes For Maghreb Middle East (2023)Document10 pagesHepha Vibes For Maghreb Middle East (2023)engr kazamNo ratings yet

- EcoCast BrochureDocument4 pagesEcoCast BrochurePeterLOW0218No ratings yet

- Nassco - Manhole Rehabilitation Uisng Cement System-2Document7 pagesNassco - Manhole Rehabilitation Uisng Cement System-2gorinikNo ratings yet

- New Polymer Technology Improves Durability and Constructability of Coatingfor Steel StructuresDocument4 pagesNew Polymer Technology Improves Durability and Constructability of Coatingfor Steel StructuresUsama Awad100% (1)

- Epoxy Coating Guide For ConcreteDocument8 pagesEpoxy Coating Guide For ConcreteShepherd NhangaNo ratings yet

- ESPAC Brochure1Document25 pagesESPAC Brochure1aseem krishnaNo ratings yet

- PolykenDocument8 pagesPolykenVictor Hugo Bustos BeltranNo ratings yet

- Brochure - Valves For Autoclave Processes (EN) .Document20 pagesBrochure - Valves For Autoclave Processes (EN) .Valmet Flow WANo ratings yet

- kINGSPAN METAL DECK DRAMIXDocument16 pageskINGSPAN METAL DECK DRAMIXHeri SiswantoNo ratings yet

- Solarspan Commercial BrochureDocument12 pagesSolarspan Commercial BrochureambienceaNo ratings yet

- Brochure Polyflex Advanced Pu CH enDocument8 pagesBrochure Polyflex Advanced Pu CH enqsdpfyb2c5No ratings yet

- COM900 Pipeline CoatingsDocument61 pagesCOM900 Pipeline CoatingsVicente RegulezNo ratings yet

- Brochure MarineDocument16 pagesBrochure MarineKriz Hor Jiunn ShyangNo ratings yet

- Foundry Practice: The Authoritative Magazine For Foundry Engineers The Authoritative Magazine For Foundry EngineersDocument36 pagesFoundry Practice: The Authoritative Magazine For Foundry Engineers The Authoritative Magazine For Foundry Engineerspatrones. valerio cNo ratings yet

- Epoxy Safety 101: Properly Storing and Mixing Industrial Epoxy ResinsFrom EverandEpoxy Safety 101: Properly Storing and Mixing Industrial Epoxy ResinsRating: 1 out of 5 stars1/5 (1)

- Rav M05 0001Document40 pagesRav M05 0001DanielDeFrancescoNo ratings yet

- FLT M02 0004Document44 pagesFLT M02 0004DanielDeFrancescoNo ratings yet

- Apu M01 0002Document36 pagesApu M01 0002DanielDeFrancescoNo ratings yet

- Pneumatic Hump Separator User Manual - English-PorglobalDocument23 pagesPneumatic Hump Separator User Manual - English-PorglobalDanielDeFrancescoNo ratings yet

- SWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDocument65 pagesSWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDanielDeFrancescoNo ratings yet

- TWLY - ZD Series Automatic Feeder: Operation ManualDocument68 pagesTWLY - ZD Series Automatic Feeder: Operation ManualDanielDeFrancescoNo ratings yet

- Catalogo MadlerDocument1 pageCatalogo MadlerDanielDeFrancescoNo ratings yet

- Torque EspiraladasDocument7 pagesTorque EspiraladasDanielDeFrancescoNo ratings yet

- Screening Tank - GeneralDocument2 pagesScreening Tank - GeneralDanielDeFrancescoNo ratings yet

- MAC Bagfilter ManualDocument93 pagesMAC Bagfilter ManualDanielDeFrancescoNo ratings yet

- Oldelval - 2235SLDocument1 pageOldelval - 2235SLDanielDeFrancescoNo ratings yet

- Graded Quesions Complete Book0Document344 pagesGraded Quesions Complete Book0Irimia Mihai Adrian100% (1)

- Confirmation For Booking ID # 843643049Document1 pageConfirmation For Booking ID # 843643049cindy brigitaNo ratings yet

- Media Preparation and Uses in Medical MicrobiologyDocument20 pagesMedia Preparation and Uses in Medical MicrobiologyPrincewill SeiyefaNo ratings yet

- AVCN1 Full BDocument395 pagesAVCN1 Full BPhương TrungNo ratings yet

- Srikanth ImJDocument2 pagesSrikanth ImJTEJA unixNo ratings yet

- Open Gapps LogDocument2 pagesOpen Gapps LogDaniswara SaktiNo ratings yet

- BUSETH - Ethical Issues in EntrepreneurshipDocument4 pagesBUSETH - Ethical Issues in EntrepreneurshipAngelicaHermoParasNo ratings yet

- Compressor Control, Load Sharing and Anti-SurgeDocument6 pagesCompressor Control, Load Sharing and Anti-SurgeJason Thomas100% (1)

- Coldharbour/Wrotham Road GravesendDocument28 pagesColdharbour/Wrotham Road GravesendWessex ArchaeologyNo ratings yet

- Ibps RRB Clerk Prelims Model Paper PDF Set 9Document29 pagesIbps RRB Clerk Prelims Model Paper PDF Set 9Raj KNo ratings yet

- MBA Interviews (Undergraduation Questions)Document14 pagesMBA Interviews (Undergraduation Questions)anshshah1310No ratings yet

- Mechanism of Titanium Sponge Formation in The Kroll Reduction ReactorDocument11 pagesMechanism of Titanium Sponge Formation in The Kroll Reduction ReactorSrinivasulu PuduNo ratings yet

- Bài tập sự hòa hợp giữa các thìDocument12 pagesBài tập sự hòa hợp giữa các thìLăng BằngNo ratings yet

- Whole Systems Thinking As A Basis For Paradigm Change in EducationDocument477 pagesWhole Systems Thinking As A Basis For Paradigm Change in EducationMaría Teresa Muñoz QuezadaNo ratings yet

- Power Bank ppt-3-3Document20 pagesPower Bank ppt-3-3Apoorva RNo ratings yet

- Homework Punch CardsDocument5 pagesHomework Punch Cardsafetynbpy100% (1)

- Career Summary Recruitment (BFSI, Analytics, IT & Non-IT), Leadership Hiring, Training &Document2 pagesCareer Summary Recruitment (BFSI, Analytics, IT & Non-IT), Leadership Hiring, Training &VipinNo ratings yet

- ReederresumeDocument2 pagesReederresumeapi-425284294No ratings yet

- John Hopkins IbdDocument38 pagesJohn Hopkins IbdNovita ApramadhaNo ratings yet

- A Study of Ratio Analysis ofDocument57 pagesA Study of Ratio Analysis ofAditya KadamNo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet

- Reading Comprehension 2 (Teamwork & Competition)Document16 pagesReading Comprehension 2 (Teamwork & Competition)Ibtisam alanaziNo ratings yet

- CV TemplatesDocument3 pagesCV TemplatesMd Shohag AliNo ratings yet

- Ce - HydrologyDocument9 pagesCe - HydrologyMadelyn MorilloNo ratings yet

- COT-Router Configuration - Docx - Republic of The Philippines DEPARTMENT OF EDUCATION Division of Sultan Kudarat BAI SARIPINANG - College SidekickDocument10 pagesCOT-Router Configuration - Docx - Republic of The Philippines DEPARTMENT OF EDUCATION Division of Sultan Kudarat BAI SARIPINANG - College Sidekickmarivic itongNo ratings yet

- Dhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsDocument8 pagesDhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsHasibul Hassan ShantoNo ratings yet

- The 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, CODocument17 pagesThe 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, COzhikNo ratings yet