Professional Documents

Culture Documents

SB 53-3513r1 Aft Pressure Bulkhead Inspection

SB 53-3513r1 Aft Pressure Bulkhead Inspection

Uploaded by

Garrett ReeveCopyright:

Available Formats

You might also like

- Project-Charter (Mohammad Adnan)Document4 pagesProject-Charter (Mohammad Adnan)Mohammad Adnan80% (5)

- MSB 32-2102r7 NLG Shock InspectionDocument17 pagesMSB 32-2102r7 NLG Shock InspectionGarrett ReeveNo ratings yet

- Vespel Using AdhesivesDocument2 pagesVespel Using AdhesivesVinaya Almane Dattathreya100% (1)

- LISI AEROSPACE - New Generation HI-LITE™ PinsDocument6 pagesLISI AEROSPACE - New Generation HI-LITE™ PinsLeandro González De CeccoNo ratings yet

- 407 MM CH11Document7 pages407 MM CH11Ricardo zafraNo ratings yet

- CH20Document14 pagesCH20Juan pablo Valencia jaramilloNo ratings yet

- Providing Standards To The Aerospace and Defense Industries Since 1941Document2 pagesProviding Standards To The Aerospace and Defense Industries Since 1941sriyan vNo ratings yet

- Dokumen - Tips Marine Engine Selection GuideDocument128 pagesDokumen - Tips Marine Engine Selection GuideAli EndrisNo ratings yet

- Fasteners Manufacturer's Identification Mil-Hdbk-57eDocument240 pagesFasteners Manufacturer's Identification Mil-Hdbk-57eelias100% (1)

- Installation Report No. 08052 Serial Number: Pulselite Starlight Installation Manual MODEL 2401Document30 pagesInstallation Report No. 08052 Serial Number: Pulselite Starlight Installation Manual MODEL 2401locoboeingNo ratings yet

- 28-20-14 Thermal Relief Valve.Document31 pages28-20-14 Thermal Relief Valve.amir ghaznaviNo ratings yet

- BS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteDocument14 pagesBS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteTom YeeNo ratings yet

- Addendum 5. December 2019 Changed Pages OnlyDocument210 pagesAddendum 5. December 2019 Changed Pages OnlyMelele MuNo ratings yet

- Nas1921 AiaDocument4 pagesNas1921 AiaGrandiosNo ratings yet

- Manual Title Manual Number - Paper Copy Temporary Revision NumberDocument106 pagesManual Title Manual Number - Paper Copy Temporary Revision NumberMijahil Yllescas MarquezNo ratings yet

- Tribolube 64Document2 pagesTribolube 64JasonNo ratings yet

- Fuel Cells in Aeronautical Applications Need of Dedicated Balance of PlantDocument13 pagesFuel Cells in Aeronautical Applications Need of Dedicated Balance of PlantpippoNo ratings yet

- Revision Level For CustomerDocument700 pagesRevision Level For Customerfaisal jawadNo ratings yet

- 3589 2001 Reff2022Document29 pages3589 2001 Reff2022raviteja036No ratings yet

- Sae As 5202a 2005-05-25Document3 pagesSae As 5202a 2005-05-25Andr EkmeNo ratings yet

- GTN 6XX Xi Flight Manual SupplementDocument36 pagesGTN 6XX Xi Flight Manual SupplementNicolás MaggiNo ratings yet

- PREN6114Document19 pagesPREN6114malotNo ratings yet

- Dgca Approved Labs IndiaDocument17 pagesDgca Approved Labs IndiaSandeep ReddyNo ratings yet

- Airbus Approved Suppliers ListDocument382 pagesAirbus Approved Suppliers ListHarith AnehNo ratings yet

- Lesson 1 - NASA CompositesDocument11 pagesLesson 1 - NASA CompositesAbdelaziz AbdoNo ratings yet

- Hosking PDFDocument10 pagesHosking PDFDimitra Eirini DiamantidouNo ratings yet

- GSE Reverse Eng Whitepaper 20201112Document5 pagesGSE Reverse Eng Whitepaper 20201112Misno100% (1)

- Mil HDBK 695DDocument45 pagesMil HDBK 695Dfrank_jr_2No ratings yet

- Owner's Manual Talon LC Hydraulic Cargo Hook Kit Airbus Helicopters AS350Document49 pagesOwner's Manual Talon LC Hydraulic Cargo Hook Kit Airbus Helicopters AS350이영모No ratings yet

- Vamsi 305Document2 pagesVamsi 305Shankar BabluNo ratings yet

- 5978357233e09 - Zodiac Aerospace - SB MXH-35-240 R7Document45 pages5978357233e09 - Zodiac Aerospace - SB MXH-35-240 R7Cpatrick DeLyonNo ratings yet

- Mil PRF 85285FDocument26 pagesMil PRF 85285Fchampyjm6532No ratings yet

- Emb145 1Document16 pagesEmb145 1Emme PrabhudasNo ratings yet

- A591A591MDocument4 pagesA591A591MErnesto SanzNo ratings yet

- DEF STAN 61-12 Part 4Document32 pagesDEF STAN 61-12 Part 4YASHASHWYNo ratings yet

- Bell206L4 MM CH64Document36 pagesBell206L4 MM CH64ame.venkyNo ratings yet

- UNF Vs BSFDocument18 pagesUNF Vs BSFJonathan GentNo ratings yet

- En 573-3-2009Document36 pagesEn 573-3-2009akifNo ratings yet

- Movable BridgeDocument263 pagesMovable BridgeCharbel Ghanem100% (1)

- Moog Power and Data Motor and Resolver CatalogDocument112 pagesMoog Power and Data Motor and Resolver CatalogwaqargilllNo ratings yet

- F 428 - 03 - RjqyoaDocument4 pagesF 428 - 03 - Rjqyoamohan chand mulpuriNo ratings yet

- Engineering Deisgn With PolymersDocument39 pagesEngineering Deisgn With Polymerschristopher_kephart1100% (1)

- FAA Capabilities List QAP 2003 2 Rev M Jan 6 2020Document35 pagesFAA Capabilities List QAP 2003 2 Rev M Jan 6 2020Luis Antonio HermozaNo ratings yet

- Mil PRF 32239Document36 pagesMil PRF 32239Guritno GustiantoNo ratings yet

- Dart Bell Catalog-2013Document372 pagesDart Bell Catalog-2013CLAUDIANo ratings yet

- Metco 54NS-1 (Aluminum Seal Coat) PDFDocument3 pagesMetco 54NS-1 (Aluminum Seal Coat) PDFJ. BangjakNo ratings yet

- E243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesDocument6 pagesE243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesudomNo ratings yet

- Topcoat F69: Coatings For Aircraft Structure ProtectionDocument4 pagesTopcoat F69: Coatings For Aircraft Structure Protection김도균No ratings yet

- DRDO RustomDocument6 pagesDRDO RustomPrabhu Mani RathinamNo ratings yet

- 49-00023 E - Coat SpecDocument16 pages49-00023 E - Coat SpecandyNo ratings yet

- Identifi Ation: National Aerospace StandardDocument7 pagesIdentifi Ation: National Aerospace StandardGrandiosNo ratings yet

- Aau AbDocument100 pagesAau AbLuis Eduardo dos SantosNo ratings yet

- ORCONDocument2 pagesORCONKarinaNo ratings yet

- F1472Document5 pagesF1472Antonio JNo ratings yet

- LMM 72-00-00, STORAGE 001 PreservationDocument45 pagesLMM 72-00-00, STORAGE 001 PreservationKarinaNo ratings yet

- Abs 5057Document9 pagesAbs 5057Gael CadenaNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part2Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part2David WongNo ratings yet

- R172 SM D202716Document31 pagesR172 SM D202716Luz Analía Valdez CandiaNo ratings yet

- prEN 4172Document6 pagesprEN 4172malotNo ratings yet

- C35 MANUAL - CNX80 Pilot Friendly GuideDocument47 pagesC35 MANUAL - CNX80 Pilot Friendly GuideblipNo ratings yet

- MX385 OwnersManualDocument12 pagesMX385 OwnersManualzubaedNo ratings yet

- SB 28-3401 Fuel Cell Cover and Gasket InstallationDocument8 pagesSB 28-3401 Fuel Cell Cover and Gasket InstallationGarrett ReeveNo ratings yet

- MTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementDocument10 pagesMTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementGarrett ReeveNo ratings yet

- SB 27-3459r2 Gust Lock InspectionDocument12 pagesSB 27-3459r2 Gust Lock InspectionGarrett ReeveNo ratings yet

- MSB 2718r2 Replace Buckeye Fuel HoseDocument22 pagesMSB 2718r2 Replace Buckeye Fuel HoseGarrett ReeveNo ratings yet

- SB 30-3143 Engine Inlet Anti-Ice Line InspectionDocument6 pagesSB 30-3143 Engine Inlet Anti-Ice Line InspectionGarrett ReeveNo ratings yet

- SB 28-3401 Fuel Cell Cover and Gasket InstallationDocument8 pagesSB 28-3401 Fuel Cell Cover and Gasket InstallationGarrett ReeveNo ratings yet

- SB 24-3181 GCU InspectionDocument7 pagesSB 24-3181 GCU InspectionGarrett ReeveNo ratings yet

- HCI 2008 Promo W SolutionDocument12 pagesHCI 2008 Promo W SolutionMichael CheeNo ratings yet

- Kalsi® Building Board Cladding: Kalsi® Clad Standard DimensionsDocument1 pageKalsi® Building Board Cladding: Kalsi® Clad Standard DimensionsDenis AkingbasoNo ratings yet

- Testing ChecklistDocument3 pagesTesting ChecklistAnurag YadavNo ratings yet

- Title of Project:-Military Hospital Report Management SystemDocument4 pagesTitle of Project:-Military Hospital Report Management SystemAkbar AliNo ratings yet

- Getting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFDocument7 pagesGetting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFoktaNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Case 4.2 Comptronic CorporationDocument2 pagesCase 4.2 Comptronic CorporationThao NguyenNo ratings yet

- Philippine Air Force CAS Aircraft Bidding DocumentsDocument151 pagesPhilippine Air Force CAS Aircraft Bidding DocumentsfuccioniNo ratings yet

- Glumac Shanghai Office Fall 2016Document4 pagesGlumac Shanghai Office Fall 2016NagaraniNo ratings yet

- Lancaster University Dissertation HandbookDocument5 pagesLancaster University Dissertation HandbookPaperWritingServiceCheapAnnArbor100% (1)

- PR m1Document15 pagesPR m1Jazmyn BulusanNo ratings yet

- Project Closing - Post Implementation SurveyDocument7 pagesProject Closing - Post Implementation SurveyMegat Zainurul Anuar bin Megat Johari100% (1)

- Commerce EMDocument344 pagesCommerce EMSTAR E WORLDNo ratings yet

- API BasicsDocument6 pagesAPI BasicsSrinivas BathulaNo ratings yet

- Borneo Sporenburg Final-Ilovepdf-CompressedDocument55 pagesBorneo Sporenburg Final-Ilovepdf-Compressedapi-417024359No ratings yet

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFDocument83 pagesVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaNo ratings yet

- Genuine Eaton Vicker HidrauDocument28 pagesGenuine Eaton Vicker HidrauJenner Volnney Quispe ChataNo ratings yet

- Remarks:: Republic of The Philippines City of General SantosDocument1 pageRemarks:: Republic of The Philippines City of General SantosThe MatrixNo ratings yet

- EDU CAT EN DF1 FI V5R19 Toprint PDFDocument14 pagesEDU CAT EN DF1 FI V5R19 Toprint PDF3pherNo ratings yet

- Checkpoint Enterprise Security Framework Whitepaper v2Document34 pagesCheckpoint Enterprise Security Framework Whitepaper v2hoangtruc.ptitNo ratings yet

- Agile TestingDocument5 pagesAgile TestingAman YadavNo ratings yet

- OrganoLithium ReagentDocument6 pagesOrganoLithium ReagentizaowsikNo ratings yet

- Pre-Lab: Microscopes II: Plant Cells and OsmosisDocument2 pagesPre-Lab: Microscopes II: Plant Cells and Osmosisapi-234540318No ratings yet

- Springer Nature Latex TemplateDocument13 pagesSpringer Nature Latex TemplateAndres FloresNo ratings yet

- IEC Download LinkDocument11 pagesIEC Download LinkMultitech InternationalNo ratings yet

- Bolting Chart For Industrial FlangesDocument6 pagesBolting Chart For Industrial FlangesPritam JadhavNo ratings yet

- Presentation - Pragati MaidanDocument22 pagesPresentation - Pragati MaidanMohamed Anas100% (4)

- B.inggris-Daily ActivitiesDocument11 pagesB.inggris-Daily ActivitiesDadang SopianNo ratings yet

- English For ITDocument276 pagesEnglish For ITBao Tram100% (1)

SB 53-3513r1 Aft Pressure Bulkhead Inspection

SB 53-3513r1 Aft Pressure Bulkhead Inspection

Uploaded by

Garrett ReeveOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SB 53-3513r1 Aft Pressure Bulkhead Inspection

SB 53-3513r1 Aft Pressure Bulkhead Inspection

Uploaded by

Garrett ReeveCopyright:

Available Formats

MANDATORY

SERVICE BULLETIN

Beech

TITLE: FUSELAGE - AFT PRESSURE BULKHEAD WEB INSPECTION/REPAIR

SYNOPSIS OF CHANGE

This Service Bulletin has been revised to correct Model and Airplane Serial Effectivity and part numbers. Relevant

technical changes are marked with change bars in the outside margins.

1. Planning Information

A. Effectivity

(1) Airplanes

(a) Civil

Beech Model 90 King Air Series, Serials LJ-1 through LJ-1287, LJ-1289 through LJ-1294, LJ-

1296 through LJ-1299;

Beech Model E90 King Air, Serials LW-1 through LW-347;

Beech Model F90 King Air, Serials LA-2 through LA-236;

Beech Model 100/A100 King Air, Serials B-2 through B-89, B-93, B-100 through B-247;

Beech Model B100 King Air, Serials BE-1 through BE-137;

Beech Model 200 Super King Air, Serials BB-2, BB-6 through BB-185, BB-187 through BB-202,

BB-204 through BB-269, BB-271 through BB-407, BB-409 through BB-468, BB-470 through BB-

488, BB-490 through BB-509, BB-511 through BB-529, BB-531 through BB-550, BB-552

through BB-562, BB-564 through BB-572, BB-574 through BB-590, BB-592 through BB-608,

BB-610 through BB-626, BB-628 through BB-646, BB-648 through BB-664, BB-666 through BB-

694, BB-696 through BB-733, BB-735 through BB-792, BB-794 through BB-797, BB-799

through BB-822, BB-825 through BB-828, BB-830 through BB-853, BB-872, BB-873, BB-892,

BB-893, and BB-912;

Beech Model B200 Super King Air, Serials BB-734, BB-793, BB-829, BB-854 through BB-870,

BB-874 through BB-891, BB-894, BB-896 through BB-911, BB-913 through BB-990, BB-992

through BB-1051, BB-1053 through BB-1092, BB-1094, BB-1099 through BB-1104, BB-1106

through BB-1116, BB-1118 through BB-1184, BB-1186 through BB-1263, BB-1265 through BB-

Exported under the authority of license exception: TSU. "These commodities, technology or (a) RAC Authorized Service Centers.

software were exported from the United States in accordance with Export Administration (b) Owners of record on the FAA Aircraft Registration Branch List and the RAC

Regulations. Diversion contrary to U.S. law prohibited."

International Owner Notification/Registration Service List.

Raytheon Aircraft Company (RAC) issues Service Information for the benefit of owners and (c) Those having a publications subscription.

fixed base operators in the form of two classes of Service Bulletins. The first class, Mandatory Information on Owner Notification Service or subscription can be obtained through any RAC

Service Bulletins (red border) includes changes, inspections and modifications that could Authorized Service Center. As Mandatory Service Bulletins and Service Bulletins are issued,

affect safety or crashworthiness. RAC also issues Service Bulletins with no red border which temporary notification in the Service Bulletin Master Index should be made until the index is

are designated as either recommended or optional in the compliance section within the revised. Warranty will be allowed only when specifically defined in the Service Bulletin and in

bulletin. In the case of recommended Service Bulletins, RAC feels the changes, accordance with the RAC Warranty Policy.

modifications, improvements or inspections will benefit the owner/operator and although

highly recommended, Recommended Service Bulletins are not considered mandatory at the Unless otherwise designated, RAC Mandatory Service Bulletins, Service Bulletins and RAC

time of issuance. In the case of Optional Service Bulletins, compliance with the changes, Kits are approved for installation on RAC airplanes in original or RAC modified configurations

modifications, improvements or inspections is at the owner/operator’s discretion. Both only. RAC Mandatory Service Bulletins, Service Bulletins and Kits may not be compatible with

classes are mailed to: airplanes modified by STC installations or modifications other than RAC approved kits.

Issued: May, 2002

Revised: October, 2002

SB 53-3513, Rev. 1

1 of 12

MANDATORY

SERVICE BULLETIN

1288, BB-1290 through BB-1300, BB-1302 through BB-1313, BB-1315 through BB-1384, BB-

1389 through BB-1425, BB-1427 through BB-1438, BB-1440 through BB-1443;

Beech Model 200T Super King Air, Serials BT-1 through BT-22, and BT-28;

Beech Model B200T Super King Air, Serials BT-23 through BT-27, BT-29 through BT-34, and

BB-1314;

Beech Model 200C Super King Air, Serials BL-1 through BL-23, BL-26 through BL-36;

Beech Model B200C Super King Air, Serials BL-37 through BL-57, BL-61 through BL-72, BL-

124 through BL-138;

Beech Model 200CT Super King Air, Serials BN-1;

Beech Model B200CT Super King Air, Serials BN-2 through BN-4.

(b) Military

H90 (T-44A), Serials LL-1 through LL-61;

A100 (U-21F), Serials B-1, B-90 through B-92, B-94 through B-99;

A100-1 (U-21J), Serials BB-3 through BB-5;

A200 (C12A), Serials BC-1 through BC-61; BD-1 through BD-30;

A200 (C-12C), Serials BC-1 through BC-75; BD-1 through BD-30 (when modified per Beech SI

C-12-0076);

A200C (UC-12B), Serials BJ-1 through BJ-66;

A200CT (C-12D), Serials BP-1, BP-19, BP-24 through BP-51;

A200CT (C-12F), Serials BP-52 through BP-63;

A200CT (FWC-12D), Serials BP-7 through BP-11;

A200CT (RC-12D), Serials GR-1 through GR-12;

A200CT (RC-12G), Serials FC-1 through FC-3;

A200CT (RC-12H), Serials GR-14 through GR-19;

A200CT (RC-12K), Serials FE-1 through FE-9;

A200CT (RC-12P), Serials FE-25 through FE-31, FE-33 and FE-35;

A200CT (RC-12Q), Serials FE-32, FE-34 and FE-36;

B200C (C-12F), Serials BP-64 through BP-71, BL-73 through BL-112, BL-118 through BL-123;

B200C (UC-12M), Serials BV-1 through BV-10;

B200C (C-12R), Serials BW-1 through BW-29;

B200C (UC-12F), Serials BU-1 through BU-10.

Issued: May, 2002 SB 53-3513, Rev. 1

Revised: October, 2002 2 of 12

MANDATORY

SERVICE BULLETIN

(c) Airplane Serials not FAA certified

Beech Model A200CT King Air, Serials FE-10 through FE-24;

Beech Model B200 King Air, Serials BB-1385 through BB-1388;

Beech Model B200C King Air (RC-12M), Serials BV-11 and BV-12;

Beech Model B200C King Air (RC-12F), Serials BU-11 and BU-12;

Beech Model B200CT King Air (FWC-II), Serials FG-1 and FG-2;

If you are no longer in possession of the airplane, please forward this information to the present

owner.

(2) Spares

None.

B. Reason

This Service Bulletin is being issued to inspect and repair (if required) the forward side of the aft pressure

bulkhead for score marks. These score marks appear to have been caused by the use of a sharp device

while trimming the insulation or other interior material during installation. These discontinuities could

potentially result in a fracture of the bulkhead web along the mark. Local separation at the fracture would

cause a corresponding loss of cabin pressurization. The bulkhead would remain capable of reacting flight

loads and no loss of structural integrity would result.

C. Description

This Service Bulletin is being issued to provide inspection/repair procedures for score marks on the

forward side of the aft pressure bulkhead. The inspection process requires removal of the interior

furnishing and insulation from the aft pressure bulkhead to detect potential score marks in the web areas.

D. Compliance

An Airworthiness Directive has been requested on the matter covered by this Service Bulletin.

(1) Civil Airplanes

Raytheon Aircraft Company considers this to be a Mandatory Service Bulletin. It must be

accomplished no later than 600 flight hours or 24 months after receipt of this Service Bulletin,

whichever occurs first.

(2) Military Airplanes

For compliance information on military airplanes affected by this Service Bulletin, contact the

appropriate headquarters.

E. Approval

The engineering data contained in this Service Bulletin is FAA approved.

Issued: May, 2002 SB 53-3513. Rev. 1

Revised: October, 2002 3 of 12

MANDATORY

SERVICE BULLETIN

F. Manpower

The following information is for planning purposes only:

Estimated man-hours for inspection: 4 hours to gain access, remove the insulation and glue, inspect the

bulkhead and reassemble with new insulation.

Suggested number of men: 1 man.

Estimated man-hours to remove and install the oxygen bottle (if required): 2 hours.

Suggested number of men: 1 man.

Estimated man-hours for blending the score marks: 4 hours.

Suggested number of men: 1 man.

Estimated man-hours to fabricate and install doubler: 10 hours.

Suggested number of men: 1 man.

Estimated man-hours to remove the pressure bulkhead: 8 hours.

Suggested number of men: 1 man.

Estimated man-hours to fabricate the pressure bulkhead: 6 hours.

Suggested number of men: 1 man.

Estimated man-hours to replace the pressure bulkhead: 16 hours.

Suggested number of men: 2 men.

The above is an estimate based on experienced, properly equipped personnel complying with this Service

Bulletin. Occasionally, after work has started, conditions may be found which could result in additional

man-hours. Additional time required for airplanes equipped with avionic shelves.

G. Weight and Balance

None.

H. Electrical Load Data

Not changed.

I. Software Accomplishment Summary

Not applicable.

J. References

Appropriate Chapter of the applicable Maintenance Manual;

Appropriate Chapter of the applicable Illustrated Parts Catalog.

K. Publications Affected

None.

Issued: May, 2002 SB 53-3513, Rev. 1

Revised: October, 2002 4 of 12

MANDATORY

SERVICE BULLETIN

L. Interchangeability of Parts

Not applicable.

M. Warranty Credit

(1) Civil and Non FAA Certified Civil Airplanes

No warranty credit is allowed for the inspection portion of this Service Bulletin.

Warranty credit for labor and parts to the extent noted under MANPOWER and MATERIAL will be

allowed on all affected airplanes.

Warranty coverage offered in this Service Bulletin will expire 24 months from the last day of the

month the original Service Bulletin was issued. After that date, the owner/operator assumes the

responsibility for compliance cost. Raytheon Aircraft Company reserves the right to void warranty

coverage in the area affected by this Service Bulletin until the date the Service Bulletin is

accomplished by a Raytheon Aircraft Company Authorized Service Center.

All warranty work must be accomplished by a Raytheon Aircraft Authorized Service Center rated to

perform maintenance on the specific model of Beech Airplane.

All warranty reimbursements are handled through Raytheon Aircraft Company Authorized Service

Centers. The owner/operator should arrange for an Authorized Service Center to perform the work

and the Authorized Service Center must submit the standard Raytheon Aircraft Company warranty

claim.

(2) Military and Non FAA Certified Military Airplanes

For warranty information on military airplanes affected by this Service Bulletin, contact the

appropriate headquarters.

2. Material Information

A. Materials - Price and Availability

Contact a Raytheon Aircraft Authorized Service Center for information.

B. Industry Support

Not applicable.

C. Airplanes

The following parts required for this modification may be ordered through a Raytheon Aircraft Authorized

Service Center, RAPID or obtained locally:

Quantity Per

Part Number Description

Airplane

MS20470AD4 Rivet, Universal Head As Required

Issued: May, 2002 SB 53-3513. Rev. 1

Revised: October, 2002 5 of 12

MANDATORY

SERVICE BULLETIN

Quantity Per

Part Number Description

Airplane

QQ-A-250/5 2024-T3 Aluminum Sheet Alclad, 0.032 or 0.040 As Required

thickness

MIL-C-5541 Alodine 200, 1200S, 1201 As Required

MIL-P23377, Type 1 Primer As Required

PR1221B Sealant As Required

C3201-25ALPSA or Soundproofing for Aft Surface of Bulkhead 0.25 As Required

ADC-124 Inch Self Adhesive

BS272-WW36X72 Soundproofing for Forward Surface of Bulkhead As Required

One (1) inch Sheet Fiberglass

EC 1300L Adhesive As Required

EA9309NA Adhesive As Required

AF3306 Fabric, Positioning, Scrim cloth As Required

TT-N-95, Type II Solvent, Aliphatic Naphtha As Required

D. Spares

Not applicable.

E. Reidentified Parts

None.

F. Tooling - Price and Availability

Not applicable.

3. Accomplishment Instructions

NOTE

Should any difficulty be encountered in accomplishing this Service Bulletin,

contact Raytheon Aircraft Company at 1-800-429-5372 or 316-676-3140 for

commercial aircraft, and appropriate headquarters for military aircraft.

A. Airplane

Observe all Warnings and Cautions contained in the aircraft manuals

referred to in this Service Bulletin.

Issued: May, 2002 SB 53-3513, Rev. 1

Revised: October, 2002 6 of 12

MANDATORY

SERVICE BULLETIN

Whenever any part of this system is dismantled, adjusted, repaired or

renewed, detailed investigation must be made on completion to make sure

that distortion, tools, rags or any other loose articles or foreign matter that

could impede the free movement and safe operation of the system are not

present, and that the systems and installations in the work area are clean.

(1) Remove all power from the airplane and disconnect the battery. Display warning notices prohibiting

reconnection of airplane electrical power.

(2) Remove all interior furnishings and insulation from the forward side of the aft pressure bulkhead web

to perform the inspection.

(3) Remove sealant from the inside flange of the "U" channel area with (non-metallic) wood or plastic

scraper.

(4) Completely inspect the entire forward side of the aft pressure bulkhead for score marks.

(5) All score marks must be blended and polished to a 125 RMS finish or smoother.

NOTE

For airplanes (BB-2 through BB-669, BT-1 through BT-16) equipped with P/N 50-

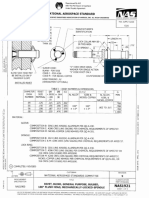

440041 bulkhead with strap that have scores within the area as shown in Figure 1,

remove the strap and blend, and install repair doubler using the existing strap rivet

holes across the entire bulkhead as shown in Figure 3.

(6) After blending, use a fluorescent penetrant or eddy current NDT technique to ensure no cracks have

formed.

(a) If no cracks are found, measure the depth of the blended area(s). if the depth is less than 10% of

the thickness of the web, no further action is required other than reapplying the protective

finishes.

(b) Apply alodine 1200, 1200S, 1201 (obtain locally). Allow the alodine to dwell for approximately

five (5) minutes. After the dwell time has elapsed, wash the treated areas with water and blow

dry (do not wipe dry).

(c) Paint the treated area with epoxy polyamide primer (MIL-P-23377). Proceed to Step (9).

(d) If cracks are found, contact Raytheon Aircraft Company at 1-800-429-5372 or 316-676-3140 for

repair procedures.

(e) Record the depth and location of the blended area(s) on Table 1 for Warranty Claims.

Maintain proper edge distance on the zee (radius) during the back drilling

process.

Issued: May, 2002 SB 53-3513. Rev. 1

Revised: October, 2002 7 of 12

MANDATORY

SERVICE BULLETIN

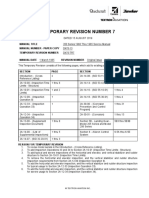

(7) If scoring is greater than 10% but less than 50% of the web thickness (0.032 inch) and within the

area shown in Figure 1, fabricate a doubler to extend from the lap joint (zee) to the zee (W.L. 116.68

to W.L. 122.59). See Figure 2 for airplanes without the strap, and Figure 3 for airplanes with the

strap.

(a) Fabricate the repair doubler from 2024-T3 per QQ-A-250/5 0.032 or 0.040 material.

(b) Drill all holes 0.128 to 0.131 inch diameter, to match existing positions and in new positions.

Maintain a minimum of 2 times rivet diameter edge distance on all fasteners and 4 to 6 times

diameter pitch on all new fasteners.

(c) Fabricate tapered shims from 2024-T3 per QQ-A-250/5 0.032 inch thick material, and taper

shims to a minimum of 0.010 inch thick. See Figure 2.

(d) Deburr all sharp edges of the doublers and shims.

(e) Apply alodine 1200, 1200S, 1201 (obtain locally). Allow the alodine to dwell for approximately

five (5) minutes. After the dwell time has elapsed, wash the treated areas with water and blow

dry (do not wipe dry).

(f) Cold bond repair doubler and tapered shims to bulkhead web using EA9309NA adhesive and

one layer of scrim cloth. Use a small brush, tongue depressor, or similar tool to apply EA9309NA

adhesive to the faying surface of the shim. Apply AF3306 or equivalent scrim cloth to the mating

area to maintain proper bond line. Squeeze out is allowable. Wipe up excess adhesive and fair

edges using clean cheesecloth moistened with TT-N-95, Type II aliphatic naphtha or equivalent

solvent.

(g) Attach the doubler to the web using MS20470AD4 rivets (install wet with sealant).

(h) Paint the treated area with epoxy polyamide primer (MIL-P-23377).

(8) If scoring is greater than 50% of the web thickness or the score is in any location other than

shown in Figure 1, contact Raytheon Aircraft Company at 1-800-429-5372 or 316-676-3140 for

repair procedures.

(9) Reseal the "U" channel area where sealant was removed for inspection.

(10) Install the insulation and interior furnishings removed to perform inspection.

NOTE

Trim insulation prior to installation.

(11) Reconnect the airplane battery, remove warning notices and restore power.

(12) Ensure all work areas are clean and clear of tools and miscellaneous items of equipment.

(13) Return airplane to service.

B. Spares

Not applicable.

C. Record of Compliance

Upon completion of this Service Bulletin, make an appropriate maintenance record entry.

Issued: May, 2002 SB 53-3513, Rev. 1

Revised: October, 2002 8 of 12

MANDATORY

SERVICE BULLETIN

Table 1

Record Depth and Location of Score(s)

Issued: May, 2002 SB 53-3513. Rev. 1

Revised: October, 2002 9 of 12

MANDATORY

SERVICE BULLETIN

Maximum Area of Damage for Repair Doubler

Figure 1

Issued: May, 2002 SB 53-3513, Rev. 1

Revised: October, 2002 10 of 12

MANDATORY

SERVICE BULLETIN

UP

REPAIR

R /H

DOUBLER ZEE (REF)

FRAME

BULKHEAD WEB

W .L. 122.59

W .L. 116.78

MS20470AD4 RIVETS, SCORE MARK (REF)

EXISTING POSITIONS

TAPERED SHIM

ZEE (REF) (4 PLACES)

VIEW LOOKING AFT

B351303.AI

Repair Doubler for Bulkhead without Strap

Figure 2

Issued: May, 2002 SB 53-3513. Rev. 1

Revised: October, 2002 11 of 12

MANDATORY

SERVICE BULLETIN

UP

R/H

FRAME

ZEE (REF)

REPAIR BULKHEAD WEB

DOUBLER

W .L. 116.78

MS20470AD4 RIVETS, SCORE MARK (REF)

EXISTING POSITIONS

TAPERED SHIM

ZEE (REF) (4 PLACES)

VIEW LOOKING AFT

B351304.AI

Repair Doubler for Bulkhead with Strap

Figure 3

Issued: May, 2002 SB 53-3513, Rev. 1

Revised: October, 2002 12 of 12

You might also like

- Project-Charter (Mohammad Adnan)Document4 pagesProject-Charter (Mohammad Adnan)Mohammad Adnan80% (5)

- MSB 32-2102r7 NLG Shock InspectionDocument17 pagesMSB 32-2102r7 NLG Shock InspectionGarrett ReeveNo ratings yet

- Vespel Using AdhesivesDocument2 pagesVespel Using AdhesivesVinaya Almane Dattathreya100% (1)

- LISI AEROSPACE - New Generation HI-LITE™ PinsDocument6 pagesLISI AEROSPACE - New Generation HI-LITE™ PinsLeandro González De CeccoNo ratings yet

- 407 MM CH11Document7 pages407 MM CH11Ricardo zafraNo ratings yet

- CH20Document14 pagesCH20Juan pablo Valencia jaramilloNo ratings yet

- Providing Standards To The Aerospace and Defense Industries Since 1941Document2 pagesProviding Standards To The Aerospace and Defense Industries Since 1941sriyan vNo ratings yet

- Dokumen - Tips Marine Engine Selection GuideDocument128 pagesDokumen - Tips Marine Engine Selection GuideAli EndrisNo ratings yet

- Fasteners Manufacturer's Identification Mil-Hdbk-57eDocument240 pagesFasteners Manufacturer's Identification Mil-Hdbk-57eelias100% (1)

- Installation Report No. 08052 Serial Number: Pulselite Starlight Installation Manual MODEL 2401Document30 pagesInstallation Report No. 08052 Serial Number: Pulselite Starlight Installation Manual MODEL 2401locoboeingNo ratings yet

- 28-20-14 Thermal Relief Valve.Document31 pages28-20-14 Thermal Relief Valve.amir ghaznaviNo ratings yet

- BS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteDocument14 pagesBS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteTom YeeNo ratings yet

- Addendum 5. December 2019 Changed Pages OnlyDocument210 pagesAddendum 5. December 2019 Changed Pages OnlyMelele MuNo ratings yet

- Nas1921 AiaDocument4 pagesNas1921 AiaGrandiosNo ratings yet

- Manual Title Manual Number - Paper Copy Temporary Revision NumberDocument106 pagesManual Title Manual Number - Paper Copy Temporary Revision NumberMijahil Yllescas MarquezNo ratings yet

- Tribolube 64Document2 pagesTribolube 64JasonNo ratings yet

- Fuel Cells in Aeronautical Applications Need of Dedicated Balance of PlantDocument13 pagesFuel Cells in Aeronautical Applications Need of Dedicated Balance of PlantpippoNo ratings yet

- Revision Level For CustomerDocument700 pagesRevision Level For Customerfaisal jawadNo ratings yet

- 3589 2001 Reff2022Document29 pages3589 2001 Reff2022raviteja036No ratings yet

- Sae As 5202a 2005-05-25Document3 pagesSae As 5202a 2005-05-25Andr EkmeNo ratings yet

- GTN 6XX Xi Flight Manual SupplementDocument36 pagesGTN 6XX Xi Flight Manual SupplementNicolás MaggiNo ratings yet

- PREN6114Document19 pagesPREN6114malotNo ratings yet

- Dgca Approved Labs IndiaDocument17 pagesDgca Approved Labs IndiaSandeep ReddyNo ratings yet

- Airbus Approved Suppliers ListDocument382 pagesAirbus Approved Suppliers ListHarith AnehNo ratings yet

- Lesson 1 - NASA CompositesDocument11 pagesLesson 1 - NASA CompositesAbdelaziz AbdoNo ratings yet

- Hosking PDFDocument10 pagesHosking PDFDimitra Eirini DiamantidouNo ratings yet

- GSE Reverse Eng Whitepaper 20201112Document5 pagesGSE Reverse Eng Whitepaper 20201112Misno100% (1)

- Mil HDBK 695DDocument45 pagesMil HDBK 695Dfrank_jr_2No ratings yet

- Owner's Manual Talon LC Hydraulic Cargo Hook Kit Airbus Helicopters AS350Document49 pagesOwner's Manual Talon LC Hydraulic Cargo Hook Kit Airbus Helicopters AS350이영모No ratings yet

- Vamsi 305Document2 pagesVamsi 305Shankar BabluNo ratings yet

- 5978357233e09 - Zodiac Aerospace - SB MXH-35-240 R7Document45 pages5978357233e09 - Zodiac Aerospace - SB MXH-35-240 R7Cpatrick DeLyonNo ratings yet

- Mil PRF 85285FDocument26 pagesMil PRF 85285Fchampyjm6532No ratings yet

- Emb145 1Document16 pagesEmb145 1Emme PrabhudasNo ratings yet

- A591A591MDocument4 pagesA591A591MErnesto SanzNo ratings yet

- DEF STAN 61-12 Part 4Document32 pagesDEF STAN 61-12 Part 4YASHASHWYNo ratings yet

- Bell206L4 MM CH64Document36 pagesBell206L4 MM CH64ame.venkyNo ratings yet

- UNF Vs BSFDocument18 pagesUNF Vs BSFJonathan GentNo ratings yet

- En 573-3-2009Document36 pagesEn 573-3-2009akifNo ratings yet

- Movable BridgeDocument263 pagesMovable BridgeCharbel Ghanem100% (1)

- Moog Power and Data Motor and Resolver CatalogDocument112 pagesMoog Power and Data Motor and Resolver CatalogwaqargilllNo ratings yet

- F 428 - 03 - RjqyoaDocument4 pagesF 428 - 03 - Rjqyoamohan chand mulpuriNo ratings yet

- Engineering Deisgn With PolymersDocument39 pagesEngineering Deisgn With Polymerschristopher_kephart1100% (1)

- FAA Capabilities List QAP 2003 2 Rev M Jan 6 2020Document35 pagesFAA Capabilities List QAP 2003 2 Rev M Jan 6 2020Luis Antonio HermozaNo ratings yet

- Mil PRF 32239Document36 pagesMil PRF 32239Guritno GustiantoNo ratings yet

- Dart Bell Catalog-2013Document372 pagesDart Bell Catalog-2013CLAUDIANo ratings yet

- Metco 54NS-1 (Aluminum Seal Coat) PDFDocument3 pagesMetco 54NS-1 (Aluminum Seal Coat) PDFJ. BangjakNo ratings yet

- E243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesDocument6 pagesE243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesudomNo ratings yet

- Topcoat F69: Coatings For Aircraft Structure ProtectionDocument4 pagesTopcoat F69: Coatings For Aircraft Structure Protection김도균No ratings yet

- DRDO RustomDocument6 pagesDRDO RustomPrabhu Mani RathinamNo ratings yet

- 49-00023 E - Coat SpecDocument16 pages49-00023 E - Coat SpecandyNo ratings yet

- Identifi Ation: National Aerospace StandardDocument7 pagesIdentifi Ation: National Aerospace StandardGrandiosNo ratings yet

- Aau AbDocument100 pagesAau AbLuis Eduardo dos SantosNo ratings yet

- ORCONDocument2 pagesORCONKarinaNo ratings yet

- F1472Document5 pagesF1472Antonio JNo ratings yet

- LMM 72-00-00, STORAGE 001 PreservationDocument45 pagesLMM 72-00-00, STORAGE 001 PreservationKarinaNo ratings yet

- Abs 5057Document9 pagesAbs 5057Gael CadenaNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part2Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part2David WongNo ratings yet

- R172 SM D202716Document31 pagesR172 SM D202716Luz Analía Valdez CandiaNo ratings yet

- prEN 4172Document6 pagesprEN 4172malotNo ratings yet

- C35 MANUAL - CNX80 Pilot Friendly GuideDocument47 pagesC35 MANUAL - CNX80 Pilot Friendly GuideblipNo ratings yet

- MX385 OwnersManualDocument12 pagesMX385 OwnersManualzubaedNo ratings yet

- SB 28-3401 Fuel Cell Cover and Gasket InstallationDocument8 pagesSB 28-3401 Fuel Cell Cover and Gasket InstallationGarrett ReeveNo ratings yet

- MTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementDocument10 pagesMTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementGarrett ReeveNo ratings yet

- SB 27-3459r2 Gust Lock InspectionDocument12 pagesSB 27-3459r2 Gust Lock InspectionGarrett ReeveNo ratings yet

- MSB 2718r2 Replace Buckeye Fuel HoseDocument22 pagesMSB 2718r2 Replace Buckeye Fuel HoseGarrett ReeveNo ratings yet

- SB 30-3143 Engine Inlet Anti-Ice Line InspectionDocument6 pagesSB 30-3143 Engine Inlet Anti-Ice Line InspectionGarrett ReeveNo ratings yet

- SB 28-3401 Fuel Cell Cover and Gasket InstallationDocument8 pagesSB 28-3401 Fuel Cell Cover and Gasket InstallationGarrett ReeveNo ratings yet

- SB 24-3181 GCU InspectionDocument7 pagesSB 24-3181 GCU InspectionGarrett ReeveNo ratings yet

- HCI 2008 Promo W SolutionDocument12 pagesHCI 2008 Promo W SolutionMichael CheeNo ratings yet

- Kalsi® Building Board Cladding: Kalsi® Clad Standard DimensionsDocument1 pageKalsi® Building Board Cladding: Kalsi® Clad Standard DimensionsDenis AkingbasoNo ratings yet

- Testing ChecklistDocument3 pagesTesting ChecklistAnurag YadavNo ratings yet

- Title of Project:-Military Hospital Report Management SystemDocument4 pagesTitle of Project:-Military Hospital Report Management SystemAkbar AliNo ratings yet

- Getting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFDocument7 pagesGetting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFoktaNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Case 4.2 Comptronic CorporationDocument2 pagesCase 4.2 Comptronic CorporationThao NguyenNo ratings yet

- Philippine Air Force CAS Aircraft Bidding DocumentsDocument151 pagesPhilippine Air Force CAS Aircraft Bidding DocumentsfuccioniNo ratings yet

- Glumac Shanghai Office Fall 2016Document4 pagesGlumac Shanghai Office Fall 2016NagaraniNo ratings yet

- Lancaster University Dissertation HandbookDocument5 pagesLancaster University Dissertation HandbookPaperWritingServiceCheapAnnArbor100% (1)

- PR m1Document15 pagesPR m1Jazmyn BulusanNo ratings yet

- Project Closing - Post Implementation SurveyDocument7 pagesProject Closing - Post Implementation SurveyMegat Zainurul Anuar bin Megat Johari100% (1)

- Commerce EMDocument344 pagesCommerce EMSTAR E WORLDNo ratings yet

- API BasicsDocument6 pagesAPI BasicsSrinivas BathulaNo ratings yet

- Borneo Sporenburg Final-Ilovepdf-CompressedDocument55 pagesBorneo Sporenburg Final-Ilovepdf-Compressedapi-417024359No ratings yet

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFDocument83 pagesVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaNo ratings yet

- Genuine Eaton Vicker HidrauDocument28 pagesGenuine Eaton Vicker HidrauJenner Volnney Quispe ChataNo ratings yet

- Remarks:: Republic of The Philippines City of General SantosDocument1 pageRemarks:: Republic of The Philippines City of General SantosThe MatrixNo ratings yet

- EDU CAT EN DF1 FI V5R19 Toprint PDFDocument14 pagesEDU CAT EN DF1 FI V5R19 Toprint PDF3pherNo ratings yet

- Checkpoint Enterprise Security Framework Whitepaper v2Document34 pagesCheckpoint Enterprise Security Framework Whitepaper v2hoangtruc.ptitNo ratings yet

- Agile TestingDocument5 pagesAgile TestingAman YadavNo ratings yet

- OrganoLithium ReagentDocument6 pagesOrganoLithium ReagentizaowsikNo ratings yet

- Pre-Lab: Microscopes II: Plant Cells and OsmosisDocument2 pagesPre-Lab: Microscopes II: Plant Cells and Osmosisapi-234540318No ratings yet

- Springer Nature Latex TemplateDocument13 pagesSpringer Nature Latex TemplateAndres FloresNo ratings yet

- IEC Download LinkDocument11 pagesIEC Download LinkMultitech InternationalNo ratings yet

- Bolting Chart For Industrial FlangesDocument6 pagesBolting Chart For Industrial FlangesPritam JadhavNo ratings yet

- Presentation - Pragati MaidanDocument22 pagesPresentation - Pragati MaidanMohamed Anas100% (4)

- B.inggris-Daily ActivitiesDocument11 pagesB.inggris-Daily ActivitiesDadang SopianNo ratings yet

- English For ITDocument276 pagesEnglish For ITBao Tram100% (1)