Professional Documents

Culture Documents

Processing and Quality Evaluation of Guava Squash

Processing and Quality Evaluation of Guava Squash

Uploaded by

Shailendra RajanCopyright:

Available Formats

You might also like

- Contingency Measures and ProceduresDocument2 pagesContingency Measures and ProceduresKua Warren Muñez72% (18)

- Effect of Xanthan Gum On Storage Stability and Sensory Attributes of Guava SquashDocument5 pagesEffect of Xanthan Gum On Storage Stability and Sensory Attributes of Guava SquashharshaNo ratings yet

- Buckwheat Flour Proteins Are Safe For Coeliac Patients: Hurdle Technology Preserve Fruit ChunksDocument0 pagesBuckwheat Flour Proteins Are Safe For Coeliac Patients: Hurdle Technology Preserve Fruit ChunksProf C.S.PurushothamanNo ratings yet

- Reaction Kinetics of Physico-Chemical Attributes in Coconut Inflorescence Sap During FermentationDocument9 pagesReaction Kinetics of Physico-Chemical Attributes in Coconut Inflorescence Sap During FermentationElena ContrerasNo ratings yet

- Rheological Characteristics of Arabic Gum Suspension and Plantago Seeds MucilageDocument7 pagesRheological Characteristics of Arabic Gum Suspension and Plantago Seeds MucilageTalha HabibNo ratings yet

- Food Chemistry: A B A ADocument10 pagesFood Chemistry: A B A APaul Jefferson Flores HurtadoNo ratings yet

- Influence of Chemical Preservatives and Pasteurization Temperature On Preservation of Custard Apple Pulp in Deep FreezerDocument6 pagesInfluence of Chemical Preservatives and Pasteurization Temperature On Preservation of Custard Apple Pulp in Deep FreezerTJPRC PublicationsNo ratings yet

- Soursop Efficacy Research For HealthDocument10 pagesSoursop Efficacy Research For HealthDaniel BartoloNo ratings yet

- 1 s2.0 S0960852402000755 MainDocument3 pages1 s2.0 S0960852402000755 MainVinícius BalducoNo ratings yet

- Artikel 3 EngDocument8 pagesArtikel 3 EngAndri PratamaNo ratings yet

- 4 MangopaperDocument5 pages4 MangopaperMunaza Binte ayubNo ratings yet

- Dried Fruit Study N°2Document6 pagesDried Fruit Study N°2minbinlosamoNo ratings yet

- Ijfftv 2 N 2 LDocument5 pagesIjfftv 2 N 2 LHabib BekhchiNo ratings yet

- Studies On The Storage Behaviour of Amla Jam: Esearch AperDocument5 pagesStudies On The Storage Behaviour of Amla Jam: Esearch AperharshaNo ratings yet

- 7 PBDocument7 pages7 PBat6315763No ratings yet

- Physicochemical Analysis of Jam Preparations From Watermelon WasteDocument4 pagesPhysicochemical Analysis of Jam Preparations From Watermelon WasteHamada AhmedNo ratings yet

- Comparative Study of Fruit Bioactivity of SpondiasDocument4 pagesComparative Study of Fruit Bioactivity of SpondiasIJAERS JOURNALNo ratings yet

- Jurnal TIN Fitry Filianty 2010 PDFDocument8 pagesJurnal TIN Fitry Filianty 2010 PDFFitry FiliantyNo ratings yet

- Basundi : Patel and Upadhyay (2003) ConcludedDocument7 pagesBasundi : Patel and Upadhyay (2003) ConcludedAshutosh MasihNo ratings yet

- Media Pertumbuhan MikrobaDocument9 pagesMedia Pertumbuhan MikrobaUmmu AthiyyahNo ratings yet

- SapotamarmaladeDocument9 pagesSapotamarmaladeBob FloresNo ratings yet

- 21501-Texto Del Artículo-70381-2-10-20200204Document7 pages21501-Texto Del Artículo-70381-2-10-20200204Nórida Pájaro GómezNo ratings yet

- Effect of Edible Gum Coating Glycerin and Calcium Lactate Application On The Post Harvest Quality of Guava FruitDocument5 pagesEffect of Edible Gum Coating Glycerin and Calcium Lactate Application On The Post Harvest Quality of Guava FruitIJARP PublicationsNo ratings yet

- Utilization of Fruit WasteDocument11 pagesUtilization of Fruit WasteherondaleNo ratings yet

- 6757-Article Text-21884-1-10-20220412Document9 pages6757-Article Text-21884-1-10-20220412Gabrielle Ann SalazarNo ratings yet

- Preparation of Fruits Candy From Jackfruit and Mango Using A Mechanical DryerDocument11 pagesPreparation of Fruits Candy From Jackfruit and Mango Using A Mechanical DryerKrishna DangiNo ratings yet

- Postharvest Biology and TechnologyDocument6 pagesPostharvest Biology and Technologywell -turnNo ratings yet

- Microbial Diversity and Proximate Composition of Tapai, A Sabah's Fermented BeverageDocument6 pagesMicrobial Diversity and Proximate Composition of Tapai, A Sabah's Fermented BeverageNURUL SHAEERA BINTI SULAIMAN -No ratings yet

- Ginat and Alghamdi, 2013Document5 pagesGinat and Alghamdi, 2013Vy NguyenNo ratings yet

- International Journal of Biological MacromoleculesDocument9 pagesInternational Journal of Biological Macromoleculesfawole olaniyiNo ratings yet

- Antidesma Bunius: Physicochemical Properties of Bignay ( (L.) Spreng.) Wine at Different Stages of ProcessingDocument8 pagesAntidesma Bunius: Physicochemical Properties of Bignay ( (L.) Spreng.) Wine at Different Stages of ProcessingSendo SegundoNo ratings yet

- Dioscorea Hispida DennstDocument7 pagesDioscorea Hispida DennstCicy IrnaNo ratings yet

- L A B TRC Khu MauDocument9 pagesL A B TRC Khu MauHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Rehydration Kinetics and Soluble Solids Lixiviation of Candied Mango Fruit As Affected by Sucrose ConcentrationDocument10 pagesRehydration Kinetics and Soluble Solids Lixiviation of Candied Mango Fruit As Affected by Sucrose ConcentrationMiguel Angel Ramos RuizNo ratings yet

- Pão Clean Label Com Suco de Limão e EnzimasDocument10 pagesPão Clean Label Com Suco de Limão e EnzimasLennon BarrosNo ratings yet

- 2019, Hennessey-Ramos Et Al., Evaluation of A Colorant and Oil Extracted From Avocado Waste As Functional ComponentsDocument8 pages2019, Hennessey-Ramos Et Al., Evaluation of A Colorant and Oil Extracted From Avocado Waste As Functional ComponentsNaitOner 99No ratings yet

- H NG XiêmDocument7 pagesH NG XiêmPham Binh AnNo ratings yet

- Effect of Storage Temperature On Physicochemical and Sensory Evaluation of Kinnow Mandarin Juice Blends 2157 7110.1000361Document4 pagesEffect of Storage Temperature On Physicochemical and Sensory Evaluation of Kinnow Mandarin Juice Blends 2157 7110.1000361Asif MerajNo ratings yet

- Process Standardization, Characterization and Storage Study of A Sweet Potato (Ipomoea Batatas L.) WineDocument8 pagesProcess Standardization, Characterization and Storage Study of A Sweet Potato (Ipomoea Batatas L.) WinePrasanna KumarNo ratings yet

- Akpa 1Document7 pagesAkpa 1Whirl BambiNo ratings yet

- JamunDocument9 pagesJamunSajiv3No ratings yet

- JFBT - Volume 08 - Issue 1 - Pages 35-46Document12 pagesJFBT - Volume 08 - Issue 1 - Pages 35-46Boban ThomasNo ratings yet

- Effects of Sodium Benzoate On Storage Stability of Previously Improved Beverage From Tamarind (Tamarindus Indica L.)Document12 pagesEffects of Sodium Benzoate On Storage Stability of Previously Improved Beverage From Tamarind (Tamarindus Indica L.)Sitar JoshiNo ratings yet

- Food Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen DewettinckDocument8 pagesFood Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen Dewettincklaycang malangNo ratings yet

- Shelf Life Enhancement of Fresh Pears Using Tulsi (Ocimum Sanctum) Herbal Edible CoatingsDocument8 pagesShelf Life Enhancement of Fresh Pears Using Tulsi (Ocimum Sanctum) Herbal Edible CoatingsShailendra RajanNo ratings yet

- Development and Shelf Life Assessment of ADocument8 pagesDevelopment and Shelf Life Assessment of AMarian BelmisNo ratings yet

- Development of A Fruit Bar Using Zapodilla 2015Document7 pagesDevelopment of A Fruit Bar Using Zapodilla 2015subdireccion licenciaturaNo ratings yet

- 1 53696 1 10 20170125Document10 pages1 53696 1 10 20170125iwanNo ratings yet

- Studies On Preparation of Custard Apple VinegarDocument6 pagesStudies On Preparation of Custard Apple VinegarIJAERS JOURNALNo ratings yet

- Effect of Treatments CMC and Storage ConDocument4 pagesEffect of Treatments CMC and Storage Conshreyaspatil954No ratings yet

- Evaluation and Preparation of Guava Jam Stored at Ambient TemperatureDocument10 pagesEvaluation and Preparation of Guava Jam Stored at Ambient Temperatureiftikhar AhmedNo ratings yet

- Recipe Pickled FishDocument5 pagesRecipe Pickled FishRohit MarcNo ratings yet

- Kualitas Asam Cuka Kelapa (Cocos Nucifera L.) Dengan Metode Lambat (Slow Methods)Document13 pagesKualitas Asam Cuka Kelapa (Cocos Nucifera L.) Dengan Metode Lambat (Slow Methods)Anonymous WHaqMRqQNo ratings yet

- Production of Star Fruit Alcoholic Fermented BeverageDocument6 pagesProduction of Star Fruit Alcoholic Fermented Beveragejungkook jeonNo ratings yet

- Utilization of Black Rice (Oryza Sativa L. Indica) Extract in Making Sarabba As Functional DrinkDocument8 pagesUtilization of Black Rice (Oryza Sativa L. Indica) Extract in Making Sarabba As Functional DrinkAr Rahman ArifNo ratings yet

- Cultivo de PitayaDocument7 pagesCultivo de PitayaNando FranklinNo ratings yet

- Amla Candy ResearchDocument3 pagesAmla Candy ResearchYasin AnsariNo ratings yet

- Fermented Guava by L PlantarumDocument3 pagesFermented Guava by L PlantarumUjang KarnaNo ratings yet

- 19 IFRJ 20 (02) 2013 WanDocument6 pages19 IFRJ 20 (02) 2013 WanNguyễn Thành VinhNo ratings yet

- March 2015 1427458365 82Document5 pagesMarch 2015 1427458365 82Kiều ChâuNo ratings yet

- Aquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaFrom EverandAquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaNo ratings yet

- Anti-Stress Effects of Melatonin Pre-Treatment On GerminationDocument6 pagesAnti-Stress Effects of Melatonin Pre-Treatment On GerminationShailendra RajanNo ratings yet

- Effect of Phytosanitary Radiation Treatments On Storage QualityDocument7 pagesEffect of Phytosanitary Radiation Treatments On Storage QualityShailendra RajanNo ratings yet

- A Study On Nutrient Optimization For Enhanced Geranium Oil YieldDocument5 pagesA Study On Nutrient Optimization For Enhanced Geranium Oil YieldShailendra RajanNo ratings yet

- Recent Patents On Intelligent Automated Fruit Harvesting Robots For Sweet Pepper and AppleDocument4 pagesRecent Patents On Intelligent Automated Fruit Harvesting Robots For Sweet Pepper and AppleShailendra RajanNo ratings yet

- The Addition of Glucose in Holding Solution Enhances Vase Life and Inflorescence Quality of Cut Hydrangea Flower Over The Application of Sucrose or MannitolDocument7 pagesThe Addition of Glucose in Holding Solution Enhances Vase Life and Inflorescence Quality of Cut Hydrangea Flower Over The Application of Sucrose or MannitolShailendra RajanNo ratings yet

- Design of Dry Coconut Dehusking and Deshelling Machine Components Using Solidworks SimulationDocument6 pagesDesign of Dry Coconut Dehusking and Deshelling Machine Components Using Solidworks SimulationShailendra RajanNo ratings yet

- Journal of Applied Horticulture 183Document80 pagesJournal of Applied Horticulture 183Shailendra RajanNo ratings yet

- Lactic Acid Production by Immobilized Rhizopus SP IIUM GÛ5 in Air Pulsed ALR Using Agriculture Waste SubstratesDocument6 pagesLactic Acid Production by Immobilized Rhizopus SP IIUM GÛ5 in Air Pulsed ALR Using Agriculture Waste SubstratesShailendra RajanNo ratings yet

- A Comparison of Cabbage Crop Growth Parameters and Harvest Maturity Indices Under Different Planting Methods, With An Emphasis On Mechanical HarvestingDocument5 pagesA Comparison of Cabbage Crop Growth Parameters and Harvest Maturity Indices Under Different Planting Methods, With An Emphasis On Mechanical HarvestingShailendra RajanNo ratings yet

- The Economic and Technical Analysis of Peach GrowingDocument5 pagesThe Economic and Technical Analysis of Peach GrowingShailendra RajanNo ratings yet

- Genetical Studies in Mango (Mangifera Indica L.)Document2 pagesGenetical Studies in Mango (Mangifera Indica L.)Shailendra RajanNo ratings yet

- BSR-1 - A High Yielding, Self-Fruitful Aonla VarietyDocument2 pagesBSR-1 - A High Yielding, Self-Fruitful Aonla VarietyShailendra RajanNo ratings yet

- Relative Uptake of The Fungicide CarbendazimDocument5 pagesRelative Uptake of The Fungicide CarbendazimShailendra RajanNo ratings yet

- NBRI MarigoldDocument2 pagesNBRI MarigoldShailendra RajanNo ratings yet

- In Vitro Establishment of Tolerant Clones of Banana Against Race-1 Fusarium Oxysporum F. Sp. CubenseDocument4 pagesIn Vitro Establishment of Tolerant Clones of Banana Against Race-1 Fusarium Oxysporum F. Sp. CubenseShailendra RajanNo ratings yet

- Control Air DryerDocument23 pagesControl Air DryerGeorgiNo ratings yet

- Quant Question Practice-Test4Document8 pagesQuant Question Practice-Test4Ss AaNo ratings yet

- From Cells To Tissue To Organs To Organ Systems: LS1.A: Structure and FunctionDocument3 pagesFrom Cells To Tissue To Organs To Organ Systems: LS1.A: Structure and FunctionSaleh AlsowayanNo ratings yet

- 1SDA083658R1 t4v Ha 250 Tma 80 800 3p F F 800v AcDocument3 pages1SDA083658R1 t4v Ha 250 Tma 80 800 3p F F 800v AcJuan Esteban Benjumea BenjumeaNo ratings yet

- Pai ToolDocument2 pagesPai TooldjanetNo ratings yet

- 8MAN100072-0001 A en Technical Description Onboard DC Grid™ System Sales PDFDocument30 pages8MAN100072-0001 A en Technical Description Onboard DC Grid™ System Sales PDFStefanitaNo ratings yet

- CE306 Shallow and Deep FoundationsDocument34 pagesCE306 Shallow and Deep FoundationsMustafa LuayNo ratings yet

- S - A - Retailer's Impact Woolworth CaseDocument8 pagesS - A - Retailer's Impact Woolworth CaseKonrad GłowackiNo ratings yet

- Recreational Mathematics. A Scroll Known As The Rhind PapyrusDocument2 pagesRecreational Mathematics. A Scroll Known As The Rhind PapyrusYonas D. EbrenNo ratings yet

- Guelen, Jeanne ThereseDocument2 pagesGuelen, Jeanne ThereseJay GeeNo ratings yet

- Seven, SeeDocument39 pagesSeven, SeeShybe Elrik100% (1)

- Past Paper Compilation - EnzymesDocument36 pagesPast Paper Compilation - Enzymessaim mughalNo ratings yet

- Introduction To Photography: Study Material For StudentsDocument100 pagesIntroduction To Photography: Study Material For Studentsjoe aliaNo ratings yet

- C. v. Raman - WikipediaDocument50 pagesC. v. Raman - Wikipedianagpalhiteshi132No ratings yet

- F 28969256Document254 pagesF 28969256luke7670No ratings yet

- Iso 18254-2015 - ApeoDocument18 pagesIso 18254-2015 - ApeoDoulat RamNo ratings yet

- ISU APC Review - Recommendations ExtractDocument8 pagesISU APC Review - Recommendations ExtractAinobushoborozi AntonyNo ratings yet

- Gen 003 Mod 15Document5 pagesGen 003 Mod 15jhonrievelascoNo ratings yet

- The KybalionDocument165 pagesThe KybalionBig piggyNo ratings yet

- Calculus Based Physics 1 Midterm Quiz 1 by JezzaDocument3 pagesCalculus Based Physics 1 Midterm Quiz 1 by JezzaMichalcova Realisan Jezza100% (1)

- Research Proposal Application Form and Endorsement of Immediate SupervisorDocument2 pagesResearch Proposal Application Form and Endorsement of Immediate SupervisorRommel YabisNo ratings yet

- Class 2 - Kahneman and Tversky - Judgment Under Uncertainty, Heuristic and BiasesDocument9 pagesClass 2 - Kahneman and Tversky - Judgment Under Uncertainty, Heuristic and BiasesSamantha Nicole GuiaoNo ratings yet

- Technical Seminar Report (Word) - 1MJ18AE098Document24 pagesTechnical Seminar Report (Word) - 1MJ18AE098Prasanna Pk0% (1)

- HR Forms HDRDOT Wok RequestDocument1 pageHR Forms HDRDOT Wok RequestZico WooNo ratings yet

- 5 1 Mine Dump Truck Wheel Spindle REMANDocument2 pages5 1 Mine Dump Truck Wheel Spindle REMANSACHIDHANANDHAM ANo ratings yet

- Caffeine Is A Widely UsedDocument5 pagesCaffeine Is A Widely UsedHarry HopeNo ratings yet

- Mercurius Health ENGDocument20 pagesMercurius Health ENGKhải 3A1 Trần QuốcNo ratings yet

- Fruit Fly Lab: A. Observation IDocument3 pagesFruit Fly Lab: A. Observation IDJ ISAACSNo ratings yet

- Klein Educ 723 Final Synthesis Paper Final VersionDocument10 pagesKlein Educ 723 Final Synthesis Paper Final Versionapi-609448544No ratings yet

Processing and Quality Evaluation of Guava Squash

Processing and Quality Evaluation of Guava Squash

Uploaded by

Shailendra RajanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Processing and Quality Evaluation of Guava Squash

Processing and Quality Evaluation of Guava Squash

Uploaded by

Shailendra RajanCopyright:

Available Formats

Journal of Applied Horticulture, 13(1): 82-84, 2011 Journal

Appl

Processing and quality evaluation of guava squash

J. Shankara Swamy* and A.K. Banik

Department of Post Harvest Technology, Bidhan Chandra Krishi Viswa Vidhyalaya Mohanpur, West Bengal-741 252,

India. *E-mail: shankara.swamy@gmail.com

Abstract

Guava (Psidium guajava), called as apple of the tropics, is one of the most common fruits in India. Excellent flavour and nutritive

Complementary Copy-Not for Sale

value aid to its great potential for preparation of beverages like squash and ready to serve (RTS). A study was undertaken to produce a

stable and organolepticaly preferred guava squash with proper suspension of fruit pulp supplementing the squash soluble dietary fibre

with xanthan gum at five different concentrations (0.1 to 0.5%). Bottled guava squash of cv. Allahabad Safeda was prepared with 25%

pulp, 40% total soluble solids (TSS), and 1% acidity with different concentration levels of xanthan gum, an exocellular polysaccharide

produced by obligatory aerobic microorganism, Xanthomonas campestris. The stability of the products was studied by chemical and

sensory evaluation of bottled squash during 180 days of storage. There were little changes in the quality parameters viz., TSS, pH,

titratable acidity and ascorbic acid during storage. Non-enzymatic browning in guava squash increased with prolonged storage. Xanthan

gum (0.5% W/W) gave stability to the product during 180 days of storage. Overall, acceptability was highest in pure guava squash

containing 0.1% of xanthan gum, 40% of TSS and 1% of acidity during the 180 days of storage period.

Key words: Guava squash, xanthan gum, non-enzymatic browning, stability.

Introduction Materials and methods

Guava (Psidium guajava L.), called as apple of the tropics, The present investigation was undertaken at the Department

is one of the most common fruits in India. It is a quite hardy, of Postharvest Technology, Bidhan Chandra Krishi Viswa

prolific bearer, remunerative fruit and thrives well on all types Vidhyalaya, Mohanpur. Guava (cv. Allahabad Safeda) was

of soils from alluvial to lateritic but sensitive to water logging procured from local Barajaguli market. Fruits with the same level

conditions (Bose et al., 2001). It is commercially cultivated in of maturity, ripe and firm, free from blemishes and bruises were

gangetic alluvial zones of north and south Parganas, Nadia and carefully selected for the study.

Murshidabad district and lateritic zones of Paschim, Medinipur

Washed guava fruits were sliced into small pieces (2-2.5 cm)

and Birbhum district, covering an area of nearly 8.27 thousand

with stainless steel knife while immersed in water. Fruit slices

hectares (Anon., 2004). Guava bears fruit twice in a year –in rainy

in water were heated at 74 -75oC for (2 - 5 min). Small pieces

season and in winter. Farmers of West Bengal have developed

were mashed in a grinder with filtered water in proportions of

technology to induce flowering at any time in the year. This

1: 3 by weight (guava slices / water, w/v). Pulp thus obtained

facilitates availability of guava fruits throughout year.

was passed through a muslin cloth. Bottled guava squash was

Guava is plentiful during the rainy season and fruit disposal prepared with 25% pulp adjusted to 40 % TSS and 1% acidity

becomes a serious problem. Its utilization is very little in (as citric acid) with varied levels of xanthan gum (Loha Chemie

processing industry. Only jam and jelly are made from the fruits, Pvt. Ltd. Mumbai, India) 0.1, 0.2, 0.3, 0.4, 0.5%, The hot syrup

but jam and jelly manufactured from guava pulp are not acceptable and fruit pulps / juice having calculated amount of xanthan gum

like other fruit products because of their gritty texture (Ramana were mixed on weight basis as outlined in recipes (Table 1).

Rao et al., 1956). This gritty texture is due to the presence of The guava squash treatments were heated to 850C. For the final

corky cells in the pulp. Hence, big industries do not manufacture product, preservative KMS (Potassium metabisulphite) 350 ppm

it. Excellent flavour and nutritive value of guava offers great was added to prevent spoilage during the storage. The prepared

potential for beverage preparation. The beverages are becoming squash was poured into pre-sterilized bottles of 200 mL capacity

popular in comparison to synthetic or aerated drink thus there is (sterilized at 25 lb/inch for 15 min) and sealed airtight. Then the

a need to develop processing technique for value added products product was sterilized in boiling water for 20 minutes and cooled

such as squash and RTS. immediately. Bottles were stored at room temperature (18-250C)

for further observation.

Keeping the above facts in view, the present study was undertaken

to utilize guava fruit pulp in the production of guava squash Prepared guava squash were analyzed for pH by Toshniwal

which would remain in suspension. To stabilize the product digital pH meter (Model DI 707), total soluble solids by hand

soluble dietary fibre in the form of xanthan gum at different refractometer (Erma hand refractometer) and acidity by titration

concentrations was used and the changes in physico-chemical, method. Ascorbic acid was determined by 2,6-dichlorophenol

sensory and microbiological attributes of the treatments during indophenol titration method (Ranganna, 1986) at every 30 days

storage were evaluated. interval during 180 days of storage. Viscosity, one of the important

Complementary Copy-Not for Sale

Processing and quality evaluation of guava squash 83

rheological characterstics of liquid foods was determined in fresh ascorbic acid content of guava squash was noticed during storage.

guava squash over a wide range of temperature (25-50oC) as well The decline in ascorbic acid concentration could be due to thermal

as at constant concentration (40 oBrix) by using the viscometer degradation during processing and subsequent oxidation in storage

bath (Model No.- SVB, S.L. No.- S/01 Simco Brand, Kolkata, as it is very sensitive to heat, pressure treatment and light (Brock et

West Bengal) and capillary viscometer tube (Cannon Fenske al., 1998). Xanthan gum level and storage days interaction effects

viscometer). Non-enzymatic browning in the guava squash was in changing ascorbic acid content were significant throughout

measured in terms of OD (Optical density) at 440 nm by using storage period. Maximum decrease in ascorbic acid was noticed

a spectrophotometer (UV-VIS Dual beam Spectrophotometer, in the treatment G1D6 (25% of pulp, 40o Brix, 1% acidity, 0% of

UVS-2700, Labomed, Inc.). Guava squash was evaluated at 180 xanthan gum at 180 days of storage period) i.e., from 37.18 to

days of storage for sensory attributes such as appearance, aroma 21.86 mg/100mL.

and flavour, taste and overall acceptability by a panel of 8 judges

Minimum decrease in ascorbic acid was noticed in the treatment

by numerical scoring method (Amerine et al., 1965). The prepared

G6D1 (25% of pulp, 400 Brix, 1% acidity, 0.5% of xanthan gum at

product was observed for mold growth by visual methods at

30 days of storage period) i.e., from 37.18 to 37.17mg/100mL. A

monthly intervals throughout the storage period.

Complementary Copy-Not for Sale

linear increase in non-enzymatic browning of guava squash was

For data analysis, factorial completely randomized design was noticed during the 180 days of storage period. This might be due

used. The data was analyzed and main interaction effects were to non-enzymatic reaction between organic acids and sugars or

presented (Sundararaj et al., 1972). Significance of the treatment oxidization of phenols leading to development of brown pigments

effect was tested using F-test. (Deka et al., 2005). Maximum increase in non-enzymatic browning

(NEB) was noticed in the treatment G1D6 (25% of pulp, 40o Brix,

Results and discussion 1% acidity, 0% of xanthan gum at 180 days of storage period)

i.e., from 0.00 to 0.087 OD. Non- enzymatic browning was not

In general, total soluble solids of guava squash increased during

observed in the treatment G6D1 (25% of pulp, 40o Brix, 1% acidity,

storage (Table 2). This might be due to increase in total soluble

0.5% of xanthan gum at 30 days of storage).

sugars produced during hydrolysis of polysaccharides like

starch, cellulose and pectin substances into simpler substances. Viscosity of the guava squash increased as concentration of

Maximum increase in TSS (from 40 to 42.91o Brix) was noticed xanthan gum increased. Maximum viscosity was observed in

in treatment G1 (25% of pulp, 40o Brix, 1% acidity, 0% of xanthan the treatment G6 (25% of pulp, 40o Brix, 1% acidity, 0.5% of

gum). Minimum increase in TSS was observed in the treatment xanthan gum) i.e. from 0.137 to 2.037 pa-sec. (Table 2). There

G6 (25% of pulp, 400 Brix, 1% acidity, 0.5% of xanthan gum) i.e., was significant decrease in viscosity as temperature increased at

from 40 to 40.09o Brix. Xanthan gum level and storage days (0, different levels of xanthan gum (Table 3). The reason is that the

30, 60, 90, 120, 150 & 180) interaction resulted in a significant viscosity of liquids is due to intermolecular cohesion and this

(P=0.05) increase in total soluble solids throughout storage period. cohesion decreases with increases in temperature. Aroma and

Maximum increase in TSS was noticed in the treatment G1D6 flavour were significantly influenced by xanthan gum levels in all

(25% of pulp, 40o Brix, 1% acidity, 0% of xanthan gum) i.e., from treatments. Overall acceptability of guava squash was significantly

40 to 45.370 Brix. There was no change in TSS in the treatment higher at 0.1% of xanthan gum followed by 0.2% in terms of aroma

G6D6 (25% of pulp, 40o Brix, 1% acidity, 0.5% of xanthan gum). flavour acceptance (Table 3). Guava squash prepared with different

Guava squash showed an increase in pH during storage. Maximum treatment combinations was found completely free from spoilage

increase in pH was noticed in treatment G1 (25% of pulp, 40o Brix, due to higher total soluble solids (40°Brix) and effective processing

1% acidity, 0% of xanthan gum) i.e., from pH 2.74 to 3.49. The of the product. Settlement of pulp particles at the bottom of bottles

smallest change in pH was observed in treatment G6 (25% of pulp, was noticed in the treatments G1 (25% of pulp, 40o Brix, 1%

40o Brix, 1% acidity, 0.5% of xanthan gum) i.e., from pH 2.74 to acidity, 0% of xanthan gum level) and G2 (25% of pulp, 40o Brix,

2.95. Xanthan gum level and storage time interaction significantly 1% acidity, 0.1% of xanthan gum). On reducing the percentage of

(P=0.05) affected the pH. Maximum increase in pH was observed xanthan gum from 0.5% (G6) in the preliminary treatments to 0.1%

in the treatment G4D6 (25% of pulp, 400 Brix, 1% acidity, 0.3% (G2) resulted in the separation of pulp particles and suspended at

of xanthan gum at 180 days of storage period) i.e., from pH 2.74 the bottom within 24 days of bottling. The addition of 0.2, 0.3, 0.4

to 4.73. Minimum increase in pH was observed in the treatment and 0.5% of xanthan gum to guava squash treatments (G3, G4, G5

G2D1 (25% of pulp, 40o Brix, 1% acidity, 0.1% of xanthan gum at and G6) resulted in the stability of the suspension upto 180 days

experimental storage at 18-25oC. Results indicate that addition

30 days of storage period) i.e., from pH 2.74 to 2.78. The increase

of xanthan gum to bottled guava squash positively impart on the

in pH of guava squash during storage could be attributed to acid

stability and acts as emulsifier to the product and also acts as dietary

hydrolysis of polysaccharides and non-reducing sugars to hexose

fibre which is helpful from consumers’ point of view.

sugars (reducing sugars) or complexing in the presence of metal

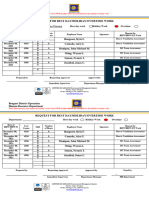

ions as reported in aonla juice (Gajanana, 2002). Xanthan gum Table 1. Recipes for guava squash

level and storage time interaction effect in changing the acidity Recipe Pulp content TSS (0Brix ) Acidity Xanthan

(%) (%) gum

were significant. Maximum reduction in acidity was noticed in

G1 25 40 1 0

the treatment G5D4 (25% of pulp, 40o Brix, 1% acidity, 0.4% of G2 25 40 1 0.1

xanthan gum at 120 days of storage period) i.e., from 1 to 0.63% G3 25 40 1 0.2

minimum reduction in acidity from intial values (1%) was noticed G4 25 40 1 0.3

in the treatment G6D3 (25% of pulp, 40o Brix, 1% acidity, 0.5% G5 25 40 1 0.4

of xanthan gum) and maximum in G6D2. A declining trend in the G6 25 40 1 0.5

Complementary Copy-Not for Sale

84 Processing and quality evaluation of guava squash

Table 2. Influence of different levels of xanthan gum, storage period and Table 3. Variation in viscosity and organoleptic characteristics with

their interaction on TSS, pH, acidity, ascorbic acid and OD (browning) varied levels of xanthan gum at 4 levels of temperature at 180 days of

in guava squash storage in guava squash

Description TSS pH Acidity Ascorbic acid OD at Xanthan gum Viscosity (pa-sec) Organoleptic scores

(0Brix) (%) (mg/100 mL) 440nm (%) Temperature (°C) Temperature (°C)

Initial value 40.00 2.74 1.00 37.18 0.00 30 40 50 25 30 40 50

Xanthan gum (%) 0.0 (G1) 0.207 0.173 0.030 1.28 1.23 1.75 1.00

0.0 (G1) 42.91 3.49 0.80 27.05 0.053 0.1 (G2) 0.700 0.600 0.417 3.50 3.58 3.16 3.37

0.1 (G2) 42.20 3.21 0.82 29.63 0.013 0.2 (G3) 1.197 0.897 0.700 3.52 3.30 2.50 3.12

0.2 (G3) 42.18 3.16 0.83 29.70 0.010

0.3 (G4) 1.740 1.330 1.027 3.56 2.81 2.22 2.42

0.3 (G4) 41.70 3.10 0.88 31.64 0.009

0.4 (G5) 40.67 3.10 0.88 34.83 0.002 0.4 (G5) 1.950 0.560 1.200 3.61 2.61 1.73 2.13

0.5 (G6) 40.09 2.95 0.91 33.85 0.001 0.5 (G6) 2.847 2.427 1.647 3.72 2.48 1.23 2.05

LSD (P=0.05) 0.08 0.03 0.03 0.84 0.002

Storage in days LSD (P=0.05) 0.031 0.23 0.32 0.23 0.30

Complementary Copy-Not for Sale

30 days (D1) 40.30 2.80 0.971 35.68 0.007

60 days (D2) 40.82 2.92 0.944 33.59 0.010 Acknowledgement

90 days (D3) 41.49 3.01 0.746 31.25 0.013

120 days (D4) 41.79 3.17 0.839 30.14 0.017 The author is thankful to Dr. P. Manivel and Dr. V. Baskaran,

150 days( D5) 42.38 3.40 0.836 28.68 0.020 DMAPR, Anand, Gujarat for suggestions in the manuscript.

180 days (D6) 42.96 3.71 0.812 27.36 0.022

LSD (P=0.05) 0.08 0.03 0.033 0.84 0.002 References

Interaction Anonymous, 2004. Economic Review (2003-2004). Government of

G 1× D 1 40.50 2.81 0.96 33.63 0.019 West Bengal, Statistical Appendix.

G1 × D2 41.44 2.88 0.94 29.30 0.030

Amerine, M.A., R.M. Pangbron and E.B. Roesler, 1965. Principles of

G1 × D3 42.46 3.00 0.92 27.60 0.047 Sensory Evaluations of Food. Academic Press, New York, 123-

G1 × D4 43.16 3.13 0.89 26.46 0.060 125.

G1 × D5 44.53 3.45 0.88 23.46 0.073

Brock, V.D., L .Ludikhuyze, C .Weemaes, L.A. Van and M. Hendrickx,

G1 × D6 45.37 3.71 0.85 21.86 0.087 1998. Kinetics for isobaric isothermal degradation of L-Ascorbic

G2 × D1 40.41 2.78 0.97 35.47 0.010 acid. J. Agric. Food Chem., 46(5): 2001-2006.

G2 × D2 40.97 2.82 0.94 33.93 0.010

Bose, T.K., S.K. Sanyal and S.K. Mitra, 2001. Fruits: Tropical and

G2 × D3 42.03 2.89 0.90 28.60 0.012

Subtropical. Naya Udyog, Calcutta, p.617-618.

G2 × D4 42.58 3.14 0.86 27.63 0.013

G2 × D5 43.13 3.32 0.84 26.74 0.015 Deka, B.C., V. Sethi and A. Saikia, 2005. Changes in mango-pineapple

G2 × D6 44.06 3.67 0.80 25.43 0.018 spiced beverage during storage. Indian J. Hort., 62(1): 71-75.

G3 × D1 40.37 2.78 0.96 35.79 0.009 Gajanana, K. 2002. Processing of Aonla (Emblica officinalis Gaertn.)

G3 × D2 41.00 2.83 0.93 33.80 0.007 fruits. Thesis submitted to UAS, GKVK, Bangalore, India.

G3 × D3 42.13 2.89 0.89 28.96 0.008 Ranganna, S. 1986. Handbook of Analysis of Fruit and Vegetable Products.

G3 × D4 42.53 3.14 0.87 27.70 0.012 Tata McGraw-Hill Publishing Company Limited, New Delhi, India.

G3 × D5 43.09 3.30 0.83 26.65 0.011 Ramanarao, P.B., S. Balakrishnan and R. Rajagopalan, 1956. Fruit and

G3 × D6 44.00 3.66 0.80 25.30 0.013 Vegetable industry in India, CFTRI, Mysore pp.272-273

G4 × D1 40.36 2.83 0.95 35.97 0.000 Sundararaj, N., S. Nagaraju, M.N.Venkataramana and M.K. Jagannath,

G4 × D2 40.86 3.02 0.89 33.38 0.007 1972. Design and Analysis of Field Experiments, UAS, Bangalore.

G4 × D3 41.50 3.12 0.85 31.78 0.011 Received: December, 2009 Revised: April, 2010 Accepted: August, 2010

G4 × D4 41.96 3.37 0.81 30.65 0.011

G4 × D5 42.40 3.86 0.76 29.71 0.012

G4 × D6 43.10 4.73 0.74 28.37 0.013

G5 × D1 40.20 2.81 0.96 36.08 0.000

G5 × D2 40.30 2.98 0.96 36.95 0.000

G5 × D3 40.56 3.17 0.81 36.15 0.000

G5 × D4 40.63 3.30 0.63 35.23 0.003

G5 × D5 41.10 3.46 0.75 33.46 0.007

G5 × D6 41.26 3.53 0.70 31.11 0.000

G6 × D1 40.00 2.81 0.99 37.17 0.000

G6 × D2 40.36 3.00 0.99 34.18 0.003

G6 × D3 40.30 3.00 0.09 34.41 0.000

G6 × D4 39.86 2.93 0.96 33.17 0.000

G6 × D5 40.03 3.00 0.94 32.08 0.000

G6 × D6 40.00 2.96 0.96 32.11 0.000

LSD (P=0.05) 0.20 0.07 0.08 2.05 0.010

Complementary Copy-Not for Sale

You might also like

- Contingency Measures and ProceduresDocument2 pagesContingency Measures and ProceduresKua Warren Muñez72% (18)

- Effect of Xanthan Gum On Storage Stability and Sensory Attributes of Guava SquashDocument5 pagesEffect of Xanthan Gum On Storage Stability and Sensory Attributes of Guava SquashharshaNo ratings yet

- Buckwheat Flour Proteins Are Safe For Coeliac Patients: Hurdle Technology Preserve Fruit ChunksDocument0 pagesBuckwheat Flour Proteins Are Safe For Coeliac Patients: Hurdle Technology Preserve Fruit ChunksProf C.S.PurushothamanNo ratings yet

- Reaction Kinetics of Physico-Chemical Attributes in Coconut Inflorescence Sap During FermentationDocument9 pagesReaction Kinetics of Physico-Chemical Attributes in Coconut Inflorescence Sap During FermentationElena ContrerasNo ratings yet

- Rheological Characteristics of Arabic Gum Suspension and Plantago Seeds MucilageDocument7 pagesRheological Characteristics of Arabic Gum Suspension and Plantago Seeds MucilageTalha HabibNo ratings yet

- Food Chemistry: A B A ADocument10 pagesFood Chemistry: A B A APaul Jefferson Flores HurtadoNo ratings yet

- Influence of Chemical Preservatives and Pasteurization Temperature On Preservation of Custard Apple Pulp in Deep FreezerDocument6 pagesInfluence of Chemical Preservatives and Pasteurization Temperature On Preservation of Custard Apple Pulp in Deep FreezerTJPRC PublicationsNo ratings yet

- Soursop Efficacy Research For HealthDocument10 pagesSoursop Efficacy Research For HealthDaniel BartoloNo ratings yet

- 1 s2.0 S0960852402000755 MainDocument3 pages1 s2.0 S0960852402000755 MainVinícius BalducoNo ratings yet

- Artikel 3 EngDocument8 pagesArtikel 3 EngAndri PratamaNo ratings yet

- 4 MangopaperDocument5 pages4 MangopaperMunaza Binte ayubNo ratings yet

- Dried Fruit Study N°2Document6 pagesDried Fruit Study N°2minbinlosamoNo ratings yet

- Ijfftv 2 N 2 LDocument5 pagesIjfftv 2 N 2 LHabib BekhchiNo ratings yet

- Studies On The Storage Behaviour of Amla Jam: Esearch AperDocument5 pagesStudies On The Storage Behaviour of Amla Jam: Esearch AperharshaNo ratings yet

- 7 PBDocument7 pages7 PBat6315763No ratings yet

- Physicochemical Analysis of Jam Preparations From Watermelon WasteDocument4 pagesPhysicochemical Analysis of Jam Preparations From Watermelon WasteHamada AhmedNo ratings yet

- Comparative Study of Fruit Bioactivity of SpondiasDocument4 pagesComparative Study of Fruit Bioactivity of SpondiasIJAERS JOURNALNo ratings yet

- Jurnal TIN Fitry Filianty 2010 PDFDocument8 pagesJurnal TIN Fitry Filianty 2010 PDFFitry FiliantyNo ratings yet

- Basundi : Patel and Upadhyay (2003) ConcludedDocument7 pagesBasundi : Patel and Upadhyay (2003) ConcludedAshutosh MasihNo ratings yet

- Media Pertumbuhan MikrobaDocument9 pagesMedia Pertumbuhan MikrobaUmmu AthiyyahNo ratings yet

- SapotamarmaladeDocument9 pagesSapotamarmaladeBob FloresNo ratings yet

- 21501-Texto Del Artículo-70381-2-10-20200204Document7 pages21501-Texto Del Artículo-70381-2-10-20200204Nórida Pájaro GómezNo ratings yet

- Effect of Edible Gum Coating Glycerin and Calcium Lactate Application On The Post Harvest Quality of Guava FruitDocument5 pagesEffect of Edible Gum Coating Glycerin and Calcium Lactate Application On The Post Harvest Quality of Guava FruitIJARP PublicationsNo ratings yet

- Utilization of Fruit WasteDocument11 pagesUtilization of Fruit WasteherondaleNo ratings yet

- 6757-Article Text-21884-1-10-20220412Document9 pages6757-Article Text-21884-1-10-20220412Gabrielle Ann SalazarNo ratings yet

- Preparation of Fruits Candy From Jackfruit and Mango Using A Mechanical DryerDocument11 pagesPreparation of Fruits Candy From Jackfruit and Mango Using A Mechanical DryerKrishna DangiNo ratings yet

- Postharvest Biology and TechnologyDocument6 pagesPostharvest Biology and Technologywell -turnNo ratings yet

- Microbial Diversity and Proximate Composition of Tapai, A Sabah's Fermented BeverageDocument6 pagesMicrobial Diversity and Proximate Composition of Tapai, A Sabah's Fermented BeverageNURUL SHAEERA BINTI SULAIMAN -No ratings yet

- Ginat and Alghamdi, 2013Document5 pagesGinat and Alghamdi, 2013Vy NguyenNo ratings yet

- International Journal of Biological MacromoleculesDocument9 pagesInternational Journal of Biological Macromoleculesfawole olaniyiNo ratings yet

- Antidesma Bunius: Physicochemical Properties of Bignay ( (L.) Spreng.) Wine at Different Stages of ProcessingDocument8 pagesAntidesma Bunius: Physicochemical Properties of Bignay ( (L.) Spreng.) Wine at Different Stages of ProcessingSendo SegundoNo ratings yet

- Dioscorea Hispida DennstDocument7 pagesDioscorea Hispida DennstCicy IrnaNo ratings yet

- L A B TRC Khu MauDocument9 pagesL A B TRC Khu MauHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Rehydration Kinetics and Soluble Solids Lixiviation of Candied Mango Fruit As Affected by Sucrose ConcentrationDocument10 pagesRehydration Kinetics and Soluble Solids Lixiviation of Candied Mango Fruit As Affected by Sucrose ConcentrationMiguel Angel Ramos RuizNo ratings yet

- Pão Clean Label Com Suco de Limão e EnzimasDocument10 pagesPão Clean Label Com Suco de Limão e EnzimasLennon BarrosNo ratings yet

- 2019, Hennessey-Ramos Et Al., Evaluation of A Colorant and Oil Extracted From Avocado Waste As Functional ComponentsDocument8 pages2019, Hennessey-Ramos Et Al., Evaluation of A Colorant and Oil Extracted From Avocado Waste As Functional ComponentsNaitOner 99No ratings yet

- H NG XiêmDocument7 pagesH NG XiêmPham Binh AnNo ratings yet

- Effect of Storage Temperature On Physicochemical and Sensory Evaluation of Kinnow Mandarin Juice Blends 2157 7110.1000361Document4 pagesEffect of Storage Temperature On Physicochemical and Sensory Evaluation of Kinnow Mandarin Juice Blends 2157 7110.1000361Asif MerajNo ratings yet

- Process Standardization, Characterization and Storage Study of A Sweet Potato (Ipomoea Batatas L.) WineDocument8 pagesProcess Standardization, Characterization and Storage Study of A Sweet Potato (Ipomoea Batatas L.) WinePrasanna KumarNo ratings yet

- Akpa 1Document7 pagesAkpa 1Whirl BambiNo ratings yet

- JamunDocument9 pagesJamunSajiv3No ratings yet

- JFBT - Volume 08 - Issue 1 - Pages 35-46Document12 pagesJFBT - Volume 08 - Issue 1 - Pages 35-46Boban ThomasNo ratings yet

- Effects of Sodium Benzoate On Storage Stability of Previously Improved Beverage From Tamarind (Tamarindus Indica L.)Document12 pagesEffects of Sodium Benzoate On Storage Stability of Previously Improved Beverage From Tamarind (Tamarindus Indica L.)Sitar JoshiNo ratings yet

- Food Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen DewettinckDocument8 pagesFood Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen Dewettincklaycang malangNo ratings yet

- Shelf Life Enhancement of Fresh Pears Using Tulsi (Ocimum Sanctum) Herbal Edible CoatingsDocument8 pagesShelf Life Enhancement of Fresh Pears Using Tulsi (Ocimum Sanctum) Herbal Edible CoatingsShailendra RajanNo ratings yet

- Development and Shelf Life Assessment of ADocument8 pagesDevelopment and Shelf Life Assessment of AMarian BelmisNo ratings yet

- Development of A Fruit Bar Using Zapodilla 2015Document7 pagesDevelopment of A Fruit Bar Using Zapodilla 2015subdireccion licenciaturaNo ratings yet

- 1 53696 1 10 20170125Document10 pages1 53696 1 10 20170125iwanNo ratings yet

- Studies On Preparation of Custard Apple VinegarDocument6 pagesStudies On Preparation of Custard Apple VinegarIJAERS JOURNALNo ratings yet

- Effect of Treatments CMC and Storage ConDocument4 pagesEffect of Treatments CMC and Storage Conshreyaspatil954No ratings yet

- Evaluation and Preparation of Guava Jam Stored at Ambient TemperatureDocument10 pagesEvaluation and Preparation of Guava Jam Stored at Ambient Temperatureiftikhar AhmedNo ratings yet

- Recipe Pickled FishDocument5 pagesRecipe Pickled FishRohit MarcNo ratings yet

- Kualitas Asam Cuka Kelapa (Cocos Nucifera L.) Dengan Metode Lambat (Slow Methods)Document13 pagesKualitas Asam Cuka Kelapa (Cocos Nucifera L.) Dengan Metode Lambat (Slow Methods)Anonymous WHaqMRqQNo ratings yet

- Production of Star Fruit Alcoholic Fermented BeverageDocument6 pagesProduction of Star Fruit Alcoholic Fermented Beveragejungkook jeonNo ratings yet

- Utilization of Black Rice (Oryza Sativa L. Indica) Extract in Making Sarabba As Functional DrinkDocument8 pagesUtilization of Black Rice (Oryza Sativa L. Indica) Extract in Making Sarabba As Functional DrinkAr Rahman ArifNo ratings yet

- Cultivo de PitayaDocument7 pagesCultivo de PitayaNando FranklinNo ratings yet

- Amla Candy ResearchDocument3 pagesAmla Candy ResearchYasin AnsariNo ratings yet

- Fermented Guava by L PlantarumDocument3 pagesFermented Guava by L PlantarumUjang KarnaNo ratings yet

- 19 IFRJ 20 (02) 2013 WanDocument6 pages19 IFRJ 20 (02) 2013 WanNguyễn Thành VinhNo ratings yet

- March 2015 1427458365 82Document5 pagesMarch 2015 1427458365 82Kiều ChâuNo ratings yet

- Aquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaFrom EverandAquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaNo ratings yet

- Anti-Stress Effects of Melatonin Pre-Treatment On GerminationDocument6 pagesAnti-Stress Effects of Melatonin Pre-Treatment On GerminationShailendra RajanNo ratings yet

- Effect of Phytosanitary Radiation Treatments On Storage QualityDocument7 pagesEffect of Phytosanitary Radiation Treatments On Storage QualityShailendra RajanNo ratings yet

- A Study On Nutrient Optimization For Enhanced Geranium Oil YieldDocument5 pagesA Study On Nutrient Optimization For Enhanced Geranium Oil YieldShailendra RajanNo ratings yet

- Recent Patents On Intelligent Automated Fruit Harvesting Robots For Sweet Pepper and AppleDocument4 pagesRecent Patents On Intelligent Automated Fruit Harvesting Robots For Sweet Pepper and AppleShailendra RajanNo ratings yet

- The Addition of Glucose in Holding Solution Enhances Vase Life and Inflorescence Quality of Cut Hydrangea Flower Over The Application of Sucrose or MannitolDocument7 pagesThe Addition of Glucose in Holding Solution Enhances Vase Life and Inflorescence Quality of Cut Hydrangea Flower Over The Application of Sucrose or MannitolShailendra RajanNo ratings yet

- Design of Dry Coconut Dehusking and Deshelling Machine Components Using Solidworks SimulationDocument6 pagesDesign of Dry Coconut Dehusking and Deshelling Machine Components Using Solidworks SimulationShailendra RajanNo ratings yet

- Journal of Applied Horticulture 183Document80 pagesJournal of Applied Horticulture 183Shailendra RajanNo ratings yet

- Lactic Acid Production by Immobilized Rhizopus SP IIUM GÛ5 in Air Pulsed ALR Using Agriculture Waste SubstratesDocument6 pagesLactic Acid Production by Immobilized Rhizopus SP IIUM GÛ5 in Air Pulsed ALR Using Agriculture Waste SubstratesShailendra RajanNo ratings yet

- A Comparison of Cabbage Crop Growth Parameters and Harvest Maturity Indices Under Different Planting Methods, With An Emphasis On Mechanical HarvestingDocument5 pagesA Comparison of Cabbage Crop Growth Parameters and Harvest Maturity Indices Under Different Planting Methods, With An Emphasis On Mechanical HarvestingShailendra RajanNo ratings yet

- The Economic and Technical Analysis of Peach GrowingDocument5 pagesThe Economic and Technical Analysis of Peach GrowingShailendra RajanNo ratings yet

- Genetical Studies in Mango (Mangifera Indica L.)Document2 pagesGenetical Studies in Mango (Mangifera Indica L.)Shailendra RajanNo ratings yet

- BSR-1 - A High Yielding, Self-Fruitful Aonla VarietyDocument2 pagesBSR-1 - A High Yielding, Self-Fruitful Aonla VarietyShailendra RajanNo ratings yet

- Relative Uptake of The Fungicide CarbendazimDocument5 pagesRelative Uptake of The Fungicide CarbendazimShailendra RajanNo ratings yet

- NBRI MarigoldDocument2 pagesNBRI MarigoldShailendra RajanNo ratings yet

- In Vitro Establishment of Tolerant Clones of Banana Against Race-1 Fusarium Oxysporum F. Sp. CubenseDocument4 pagesIn Vitro Establishment of Tolerant Clones of Banana Against Race-1 Fusarium Oxysporum F. Sp. CubenseShailendra RajanNo ratings yet

- Control Air DryerDocument23 pagesControl Air DryerGeorgiNo ratings yet

- Quant Question Practice-Test4Document8 pagesQuant Question Practice-Test4Ss AaNo ratings yet

- From Cells To Tissue To Organs To Organ Systems: LS1.A: Structure and FunctionDocument3 pagesFrom Cells To Tissue To Organs To Organ Systems: LS1.A: Structure and FunctionSaleh AlsowayanNo ratings yet

- 1SDA083658R1 t4v Ha 250 Tma 80 800 3p F F 800v AcDocument3 pages1SDA083658R1 t4v Ha 250 Tma 80 800 3p F F 800v AcJuan Esteban Benjumea BenjumeaNo ratings yet

- Pai ToolDocument2 pagesPai TooldjanetNo ratings yet

- 8MAN100072-0001 A en Technical Description Onboard DC Grid™ System Sales PDFDocument30 pages8MAN100072-0001 A en Technical Description Onboard DC Grid™ System Sales PDFStefanitaNo ratings yet

- CE306 Shallow and Deep FoundationsDocument34 pagesCE306 Shallow and Deep FoundationsMustafa LuayNo ratings yet

- S - A - Retailer's Impact Woolworth CaseDocument8 pagesS - A - Retailer's Impact Woolworth CaseKonrad GłowackiNo ratings yet

- Recreational Mathematics. A Scroll Known As The Rhind PapyrusDocument2 pagesRecreational Mathematics. A Scroll Known As The Rhind PapyrusYonas D. EbrenNo ratings yet

- Guelen, Jeanne ThereseDocument2 pagesGuelen, Jeanne ThereseJay GeeNo ratings yet

- Seven, SeeDocument39 pagesSeven, SeeShybe Elrik100% (1)

- Past Paper Compilation - EnzymesDocument36 pagesPast Paper Compilation - Enzymessaim mughalNo ratings yet

- Introduction To Photography: Study Material For StudentsDocument100 pagesIntroduction To Photography: Study Material For Studentsjoe aliaNo ratings yet

- C. v. Raman - WikipediaDocument50 pagesC. v. Raman - Wikipedianagpalhiteshi132No ratings yet

- F 28969256Document254 pagesF 28969256luke7670No ratings yet

- Iso 18254-2015 - ApeoDocument18 pagesIso 18254-2015 - ApeoDoulat RamNo ratings yet

- ISU APC Review - Recommendations ExtractDocument8 pagesISU APC Review - Recommendations ExtractAinobushoborozi AntonyNo ratings yet

- Gen 003 Mod 15Document5 pagesGen 003 Mod 15jhonrievelascoNo ratings yet

- The KybalionDocument165 pagesThe KybalionBig piggyNo ratings yet

- Calculus Based Physics 1 Midterm Quiz 1 by JezzaDocument3 pagesCalculus Based Physics 1 Midterm Quiz 1 by JezzaMichalcova Realisan Jezza100% (1)

- Research Proposal Application Form and Endorsement of Immediate SupervisorDocument2 pagesResearch Proposal Application Form and Endorsement of Immediate SupervisorRommel YabisNo ratings yet

- Class 2 - Kahneman and Tversky - Judgment Under Uncertainty, Heuristic and BiasesDocument9 pagesClass 2 - Kahneman and Tversky - Judgment Under Uncertainty, Heuristic and BiasesSamantha Nicole GuiaoNo ratings yet

- Technical Seminar Report (Word) - 1MJ18AE098Document24 pagesTechnical Seminar Report (Word) - 1MJ18AE098Prasanna Pk0% (1)

- HR Forms HDRDOT Wok RequestDocument1 pageHR Forms HDRDOT Wok RequestZico WooNo ratings yet

- 5 1 Mine Dump Truck Wheel Spindle REMANDocument2 pages5 1 Mine Dump Truck Wheel Spindle REMANSACHIDHANANDHAM ANo ratings yet

- Caffeine Is A Widely UsedDocument5 pagesCaffeine Is A Widely UsedHarry HopeNo ratings yet

- Mercurius Health ENGDocument20 pagesMercurius Health ENGKhải 3A1 Trần QuốcNo ratings yet

- Fruit Fly Lab: A. Observation IDocument3 pagesFruit Fly Lab: A. Observation IDJ ISAACSNo ratings yet

- Klein Educ 723 Final Synthesis Paper Final VersionDocument10 pagesKlein Educ 723 Final Synthesis Paper Final Versionapi-609448544No ratings yet