Professional Documents

Culture Documents

Risk Assessment KURA WEST XING

Risk Assessment KURA WEST XING

Uploaded by

Mamuka ShaorshadzeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment KURA WEST XING

Risk Assessment KURA WEST XING

Uploaded by

Mamuka ShaorshadzeCopyright:

Available Formats

Appendix A:

Risk Assessment

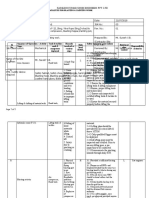

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 1 of 53

AGT Pipeline Project

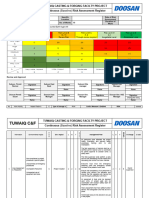

Spie Petrofac Risk Assessment/Mitigation Register

Document Title: Risk Assessment Date: 05.08.2004

Document Type: Risk Assessment Kura West River Crossing

Document Owner: Action Owner: Activity:

J.C. Meyer / T. Harris JV Construction Manager (J. Vizcaino) Kura West River Crossing Construction

Actions Register #

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

1. IDENTIFIED HAZARD H Normal working hours should be respected and excessive L Construction Manager Pipeline H&S H&S

EXCEEDING WORKING overtime avoided (over an hour); Site Superintendent Department Manage

HOURS- EXPOSURE TO During extreme weather conditions working schedule shall be r

ADVERSE WEATHER advised by Project Site Management;

CONDITIONS (FOG, SNOW,

An adequate enclosed heated shelter will be provided at the

COLD WEATHER, etc.)

work location for drying the clothes. This will also serve as a

Daylight working hours: from lunch break / rest break area;

07.00 hrs until 19.00hrs.

This shall be kept in good sanitary condition at all times;

Breaks: Lunch Break from 1200

hrs until 1300 hrs. Rest Break Adequate supply of drinking water;

from 10.00 hrs until 10.15 hrs and When working after daylight, generator and sufficient light poles

from 15.30 hrs until 15.45 hrs. shall be install to provide light to the working area and site office

Note: Working hours may change yard;

depending on site conditions, Lightning will also be provided to the travel area on the ROW,

daylight hours and construction for the workers returning to the parking area;

schedule. Contractor shall obtain Signage will be posted in English & Georgian.

COMPANY approval prior to

changing the working hours.

ASSOCIATED RISKS

Employee’s exertion and

likelihood of

incidents/accidents

occurring.

Night time work in adverse

weather conditions, cold,

etc.

2. IDENTIFIED HAZARDS M Wearing of PPE - H/V jackets, safety hats, safety boots, and L Site Supervisor Pipeline H&S H&S

FAILING TO WEAR safety glasses - is a mandatory requirement on site. Department Safety

APPROPRIATE PERSONNEL Labourers shall also wear gloves; Officers

PROTECTION EQUIPMENT Extra protection will be worn if specific hazards are identified

ASSOCIATED RISKS and if required by weather conditions;

Personnel injuries; Life rings will be provided along the open trench;

Crushing of personnel; Plant operators will have life jackets in the cabins; life jackets

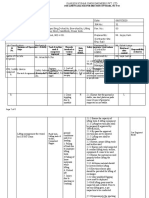

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 2 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

Personnel being hit by will be allocated to each person working near the trench;

machinery; Life saving equipment (throw lines, life rings, retrieval poles,

Getting trapped in the pinch boat with the trained operators, life jackets where applicable and

points; hypothermic kits, emergency numbers, etc. shall be available

Falling into the trench of before the work commences.

water;

Drowning.

3. IDENTIFIED HAZARD M Mobile Phones and Radios will be provided for: L Site Superintendent Pipeline H&S H&S

ABSENCE OF COMMUNICATION 1) Site Supervisors Department Manage

r

ASSOCIATED RISKS: 2) Medical Staff

Escalating factor in case of 3) Safety officers

incidents/accidents 4) Drivers

5) Traffic control

All of the above will have an emergency phone list.

Use of mobile phones while driving is forbidden.

Each driver shall have a copy of the Emergency response Plan in

his vehicle.

4. IDENTIFIED HAZARD: H Medical Provider “Medi Club” will provide: L Construction Manager Pipeline H&S H&S

ABSENCE OF MEDICAL/FIRST 1) One Paramedic; Site Superintendent Department Manage

AID COVERAGE r

2) One fully equipped Ambulance for emergency with the

fully dedicated driver. Trauma and crash extraction will

have to be available/on call within 30 minutes;

ASSOCIATED RISKS:

3) Camps, Clinic in the camp;

Escalating factor in case of

incidents/accidents; Due to the fact that the local hospitals cannot provide an

acceptable level of emergency health care, serious cases will

Hypothermia from cold and be conveyed to the Medi Club Clinic in Tbilisi, while less

from water exposure. serious cases will be treated at the Akhaltsikhe Camp

MediClub Clinic;

One First Aider and One Advanced First Aider will be part of

each working crew;

A First aid kit suitable for trauma response with burn blankets

shall be made available at site or readily available by

Ambulance;

Wool blankets and hypothermia kit will also be provided;

Life saving equipment (throw lines, life rings, retrieval poles,

boat with the trained operators, life jackets where applicable

and hypothermic kits, emergency numbers, etc. shall be

available before the work commences;

Doctor numbers along with emergency numbers will be posted

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 3 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

on site.

5. M The workforce will conform to the approved Project Emergency L Construction Manager Pipeline H&S Safety

IDENTIFIED HAZARD: Response Plan; Department officer

ABSENCE OF CONTINGENCY Site Superintendent

PLAN IN CASE OF Site will be equipped with hand held warning horns; life jackets

EMEGERGENCY (e.g. Fire) will be equipped with whistles;

In case of fire or any other emergency, employees shall cease

work immediately and assemble at designated Emergency

ASSOCIATED RISKS: Assembly Point;

Escalating factor in case of All vehicles/equipment shall carry an Emergency Response

emergency Plan in the glove box;

Approved Fire Extinguishers will be available for all classes of

fire relative to the work being undertaken;

All drivers/operators shall be trained in basic fire fighting and

with the handling of fire extinguishers.

6. H Before commencing their daily driving duty, drivers will be M Journey Managers Pipeline H&S H&S

IDENTIFIED HAZARD: advised of any hazards or potential hazards that are on their Department Manage

POOR WEATHER CONDITIONS route; r

(FOG, INCLIMENT WEATHER,

All vehicles will be equipped with fire extinguishers, first aid

BAD ROAD SURFACE, ETC.)

kits, including burn blankets and warning triangles;

ASSOSIATED RISKS: If conditions require, they will use their emergency

flashers/hazard warning lights;

CONTRACTOR will be

transporting personnel daily Drivers daily checklist and trip log will be completed by the

between the ROW and living drivers;

facilities (the Alhaltsike camp Toolbox talks will be held on regular basis;

and camp David) – risk of Driver and passenger will wear seat belts at all times;

vehicle accident related

Travel will be mainly in daylight hours. Any night driving will be

trauma (Effected range from

approved by COMPANY;

minor to lethal);

List of authorised vehicles and drivers will be available in

Travel through busy

CONTRACTOR H&S Department for checking;

villages/Vehicle and

pedestrian interface – risk of Night time driving is authorised until 10.00 PM. All drivers must

incidents involving third party; sign in and out when leaving the working area for any reason;

Night driving – risk of incident. All drivers will undergo winter driving training. Night drivers will

also undergo night driving training;

Poor vision, or poor surface

condition risk of plant Snow chains will be used if necessary;

incidents; All drivers will be trained in BP “Road to Better Driving”;

Personnel injuries / fatality; All vehicles will be equipped with black boxes and Project

Property Damage; speed limits will be adhered to;

Environmental Dipped headlights are mandatory when driving;

Pollution/spills. Random alcohol and drugs tests will be performed for all

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 4 of 53

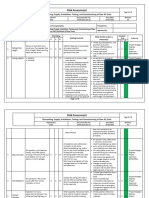

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

drivers and plant operators;

Crews will leave work site earlier if weather deteriorates to the

extent that work can not proceed safely;

Construction superintendent will perform toolbox talks with the

working crew prior to work commencing, about potential

hazards.

7. L Site Supervisor Pipeline H&S H&S

IDENTIFIED HAZARD: All equipment will be third party tested prior to work start; Department Manage

PROPER OPERATING L

The equipment operator shall be certified; r

CONDITION OF VEHICLES AND

EQUIPMENT Equipment operators shall perform daily documented

equipment inspections;

Equipment found with any defects shall be withdrawn from

ASSOSIATED RISKS: service until it has been repaired;

Personnel injuries and fatality;

A dedicated mechanic will be assigned for Kura activities;

Slips, Trips, and Falls;

Before work activity commences, the crews will be given

Personnel being hit by Toolbox Talks on the hazards and potential hazards of working

machinery; over or near water.

Getting trapped in the pinch Foreman will inspect work area before work activity

points; commences. Check for any unknown hazards. Ensure that only

Overhead hazards. authorised personnel to be in the vicinity of the river crossing

work area.

Flagmen will be employed to control the movement of

machinery.

Goal posts will be installed near the overhead cables.

The hydraulics to be locked out and booms cylinders blocked.

8. H Ensure that a visit by the “Public Awareness Team” has been M Site Supervisor Pipeline H&S Safety

IDENTIFIED HAZARD: carried prior to work commencing; Department officer

INADEQUATE INSPECTION OF

THE WORK AREA BEFORE A proper survey will be done to identify hazards that could be

COMMENCEMENT OF THE present in the working area such as overhead power/telephone

WORK lines and crumbling zones;

Ensure that these Hazards have been mitigated;

ASSOCIATED RISKS: Ensure that goal posts with bunting and proper signs have been

Personal Injury or Fatality; installed for the safe movement of the vehicles and equipment

Property Damage; underneath them;

Community related

problems;

Drowning;

Fire. Ensure that life jacket, life saver and life line are properly placed

and always available in close proximity of temporary bridge and

water filled trench;

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 5 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

Ensure that the crewmembers are fully aware of the contents of

the Risk assessment and it is explained during a kick off

meeting;

Ensure that the boat is inspected daily, fully operational at all

times, fuelled and ready to launch.

9. IDENTIFIED HAZARD H Induction training and daily Toolbox talks by Construction M Site Supervisor Pipeline H&S H&S

STRINGING CONCRETE supervisor and Site Safety Representative; Department

COATED PIPES. Manage

Ensure that all the River Crossing crews know and understand

the JSA, their daily work activity, and informed of the hazards r

The line pipe for both the BTC &

SCP has already been concreted and potential risks encountered working over and near water;

coated and transported to site. In Ensure that there is sufficient clearance for the tail swing of the

the temporary lay down area. side boom from other equipment;

Pipe will be relocated from Use only qualified and tested operators;

temporary lay down to the final lay

down/launch pad area called: Use 3 point contact when accessing and exiting machines;

”PLATFORM”. Banksmen and labourers will remain in a safe distance from

operating equipment and will only approach after making eye

ASSOCIATED RISKS contact with the operator;

Equipments accident related

Banksmen will accompany all equipment in a crowded area

trauma (effects range from

where employees are mobile, including site office area, when

minor lethal);

nearing the pipe work, tie-ins and equipment repair area.

Struck by and crush injuries

during stringing pipe;

Tipping hazard;

Equipment and pedestrian

interface.

10. IDENTIFIED HAZARD: H Most appropriate lifting appliance (Side booms, etc.) and lifting L Site superintendent Pipeline H&S Safety

PIPE LIFTING BY SIDE BOOMS equipment (slings, belts, hooks, shackles etc.) shall be Department

AND TRANSPORTATION FROM Site Supervisor officer

employed for the operation;

TEMPORARY LAY DOWN TO

Lifting appliances and lifting equipment shall be certified and

FINAL LAY DOWN/LAUNCH

SWL clearly indicated on the lifting equipment;

Only trained, certified and competent personnel shall be used

for lifting and rigging operations and operating the lifting

equipment;

ASSOCIATED RISKS: Lifting appliance and lifting equipment have to be inspected by

Personal Injury or Fatality; competent person on a daily basis;

Property Damage;

Prior to lifting & rigging operation, a thorough survey of the

Slipping of brakes due to

working place shall be carried out and all obstacles and hazards

moister and ice;

shall be clearly identified (safe distance shall be kept from

Tipping / rollover, crushing,

overhead power lines or any other hazardous utility);

rolling of pipe; collapse of

skids; If the site is crowded, or third party intrusion is possible, load

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 6 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

swing area shall be barricading;

Operator to ensure that the pipe is slung correctly;

Banksmen shall accompany each piece of equipment;

Ground conditions shall be evaluated by competent person to

ensure that safe lift can be performed;

Charge’s weight shall be determined prior to starting any lifting

operation;

If weight of the charge exceeds 20t or 50% of lifting appliance’s

lifting capacity, than a lifting plan shall be established by

competent person;

Slinging method shall be established and carried out by

competent personnel;

Convenient communication system shall be established

between lifting appliance’s operator and flagmen;

Operator to kept eye contact with the banksmen always;

Ensure that stable ground and level travel area are in place to

prevent tipping and rollover;

All operators shall ensure that the brakes on the sideboom are

dry before starting work;

Sling rods or reach rods will be used when necessary to prevent

personnel going between or under the pipe to place slings or

belts when the pipe is placed close together.

11. IDENTIFIED HAZARD: H Daily Toolbox talks by Construction supervisor and Safety Site M Site Supervisor Pipeline H&S H&S

WELDING UP PIPE STRINGS Representative. Department Manage

All workers wear the appropriate PPE for their work activity. r

Line will be prefabricated into Welders shall wear appropriate PPE and wear full face visor.

strings of five pipes and then will Welder’s helpers will wear safety goggles and fullface visor

be placed on the BTC roller for when using grinders or brushes;

welding, NDT and coating. Only trained and approved persons shall use power grinders

fitted with guards;

Ensure that the work area is clear of tripping hazards;

ASSOCIATED RISKS: Use a Striker to ignite gas;

Hand and finger injuries, Ignite Acetylene first, and then turn on the Oxygen;

Pinch points; Ensure that flash back arrestors are fitted in the gas supply

Foot injuries; hoses;

Falling into the ditch,

Burns, Area will be cleared of all inflammable material before starting

Flying objects, i.e. piece of any welding or cutting operations and shields put in place to

wire and metal, stop the passing workers being affected by arc flash;

Scrapes radiation; All gas cylinders will be stored up right and chained in purpose

Burns Arc eye; built bottle racks with protective cylinder caps in place;

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 7 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

Tight work area and All cylinder gauges shall be in undamaged condition;

electrocution;

Oxygen and fuel gas will be separated in different racks;

Slips, trips, falls, struck by,

caught between, crushing; Metal worker to wear appropriate PPE;

Working with electrical in wet Ensure that pipe is properly skidded up and chocked;

areas and adverse weather. Ensure that an approved and fully charged fire extinguisher shall

be made available at all times during welding operations;

Proper grounding will take place.

12. IDENTIFIED HAZARD H Before the work activity of the river crossing commences, all the L Site Manager Pipeline H&S H&S

crew members involved in the construction will attend on the site Department Manage

WORK IN THE RIVER BED H&S manager

safety meeting were they will be made aware of the contents of r

the Method Statement and Risk Assessment, the hazards and

ASSOCIATED RISKS: potential hazards of working on the river crossing operation

Movement of equipment; crossing the main pipeline ROW;

Condensed work area;

Method Statement and Risk Assessment to be at work location

Drowning;

always;

Struck by;

Night work; A JSA will be discussed and the workers will be made aware of

Exposure to harsh the hazards and potential hazards of their work activity;

environment including the Appropriate PPE will be worn by all workers, including life

waterways. jackets, when necessary;

Site will be provided with heated rooms, washrooms and

lightning in accordance with the Method statement.

13. IDENTIFIED HAZARD: H Daily Toolbox talks by Construction supervisor and Site Safety L Site Supervisor Pipeline H&S H&S

CONSTRUCTING ACCESS Representative; Department Manage

RAMP AND INSTALLING FORD r

All personnel to wear appropriate PPE for the task being carried

CROSSING FOR VEHICLE AND

out;

EQUIPMENT CROSSING

Ensure that only qualified and very well experienced operators

ASSOCIATED RISKS: are operating the equipment;

Ensure that audible reversing alarms are working on the

Slips Trips, and Falls construction vehicles/equipment;

Trapping Exposure Ensure that the work area is clear of unauthorised personnel

Crushing and the local population;

Noise

Ensure that Banksmen/flagmen are in eye contact with the

Moving construction

operators at all times;

equipment.

Dust and Airborne particles Ensure that Buoyancy lines are rigged across the river both

Eye exposure, falls from upstream and downstream;

different levels All the personnel on or in close proximity to water shall wear a

Drowning, High Visibility approved personal flotation device. They will be

Falling of equipment trained in the proper use and care of the flotation equipment;

A rescue boat positioned downstream shall be on location

during working hours in case employees fall in and are swept

away. Boat operator will be trained and experienced;

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 8 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

There will be two persons trained to operate the boat. Two

persons will be in the boat (one for operation, one for rescue);

A pole substantial enough to support the weight of a person

shall be available to rescue employees;

Life rings will be placed along the bank of the excavation on

both sides and when necessary they will be placed in close

proximity of the activities taken place;

Ensure that a suitable fire extinguisher is in the work place and

suitable first aid kits available;

First Aid Kit suitable for trauma response with burn blankets

shall be made available at site.

Proper lightning will be in place, in accordance with the Method

Statement.

14. IDENTIFIED HAZARD: Daily Toolbox talks by Construction supervisor and Site Safety

DIVERSION DAM Representative to ensure that all the River Crossing crew know

INSTALLATION, H M Site Supervisor Pipeline H&S H&S

and understand the JSA, Method Statement, Risk Assessment,

AND OPEN CUT EXCAVATION Department Manage

their daily work activity, and be informed of the hazards and

(TRENCH) BY EXCAVATOR. r

potential risks encountered working over or near water process;

Adhere to environmental requirements;

ASSOCIATED RISKS:

Drowning, Falling, and Induction training for all employees;

Struck by; Ensure that all underground services are identified and

Trapping exposure, mitigation measures are taken to minimize the hazard working in

Crushing exposure; close proximity to underground services.

Confined space; If any underground service is identified, ensure that warning

Noise; signs are erected close to highlighting the hazard;

Moving construction

Excavator operator to maintain smooth tail movement and watch

equipment;

for tail swing on the rotating backhoe;

Dust and Airborne particles;

Eye exposure; The tail swing radius area shall be barricaded off;

Falls from different levels; Only certified and competent operators to operate excavators;

Overhead and underground All equipment will be certified;

services.

Only competent person supervises the excavation activity and is

available at all time during working hours;

Permit will be required when entering the trench;

Banksmen/labourers will remain at a safe distance from

operating equipment and will only approach after making eye

contact with the operator;

Ensure that the work area is clear from unauthorised personnel;

Special care must be taken while surveyors are measuring the

depth of the ditch;

All personnel on or in close proximity to water shall wear a High

Visibility life jacket. They will be trained in the proper use and

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 9 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

care of the flotation equipment;

All site personnel will wear appropriate PPE.

15.

IDENTIFIED HAZARD: PLATFORM PREPARATION

LAUNCH PLATFORM H

PREPARATION AND Daily Toolbox talks by Construction supervisor and Site Safety

INSTALLING PIPE ROLLERS Representative to ensure that all crew members know and

understand the JSA, Method Statement, Risk Assessment, their

ASSOCIATED RISKS: daily work activity, and be informed of the hazards and potential

Drowning, risks encountered working over or near water process;

Falling, and Struck by;

Night shift workers are not allowed to work in close proximity to

Trapping

water, where there s a hazard of drowning;

exposure, Crushing exposure;

Noise; Only certified and competent operators will operate equipments.

Moving Only competent person supervises the earth work activity and is

construction equipment; available at all time during working hours;

Pinch points; Ensure that Banksmen are in eye contact with the operators at

Drowning; all times and able to give signals to the excavator operator;

Dust and

Banksmen/labourers will remain at a safe distance from

Airborne particles;

operating equipment and will only approach after making eye

Eye exposure;

contact with the operator;

Electrocution.

All grounding practices must be in pace including RCD’s –

residual current device, GFCI’s – ground fault circuit

interrupters.

PIPE ROLLER INSTALATION

When platform and roller foundations are ready, lifting and

placing Pipe Roller will be done by Side Boom. See Item No 12.

GENERAL

Ensure that competent person supervises the excavation activity

and is available at all time during working hours;

Ensure that the work area is clear of unauthorised personnel;

All personnel on or in close proximity to water shall wear a High

Visibility life jacket. They will be trained in the proper use and

care of the flotation equipment;

Wear appropriate PPE;

All equipment must be certified;

All operators must be certified.

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 10 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

16. Ensure that all the River Crossing crew know and understand

IDENTIFIED HAZARD: the JSA, Method Statement, Risk Assessment, their daily work

H M Site Supervisor Pipeline H&S H&S

activity, and be informed of the hazards and potential risks

INSTALLING WELDED Department Manage

encountered working over or near water process;

FABRICATION IN EXCAVATED r

Ensure that the river crossing foreman only or his designated

TRENCH IN THE RIVER KURA

deputy give authorised signals to the side boom/excavator

operators;

After welding, NDT, FJC and

coating, 3x 5 pipes strings will be Pipes strings will be pushed to the trench and supported on the

pushed to the trench and water by flotation devices;

supported on the water by In case of any puncture due to accident or vandalism, spare

flotation devices. flotation device must be provided on site;

Warning signs will be installed near the water where potential

hazard of drowning is present;

ASSOCIATED RISKS:

Devices as personal floatation vests, life rings or buoys attached

Struck by moving equipment.

to life line must be placed at or near areas where bodies of

Falls on uneven ground.

water present a reasonable potential hazard of drowning;

Pinch points.

Crushing injuries. Signal horn “type air horn” must be situated at well-defined

Ground failure locations for use in the event of an emergency;

Drowning For rescue boat (with petrol engine), operated by an

experienced operator, is provided and kept ready for immediate

use when employees are working on or near equipment in

vicinity of bodies of water. There will be two persons in the boat

– one to operate and one for rescue;

Adequate life lines available as per regulations;

Ensure that Banks men are in eye contact with the operators at

all times and able to give signals to the excavator operator;

Banksmen/labourers will remain at a safe distance from

operating equipment and will only approach after making eye

contact with the operator;

All personnel will wear appropriate PPE;

No unauthorised personnel in the hazard area;

3x 5 pipes strings will be pushed by Side Booms to the trench

and supported by flotation devices as per Item No 12;

Pipelines will be lowered by the removal of successive flotation

Devices;

Removal operation of all flotation will be done by Competent

and Certified Diver;

Diver shall wear appropriate diving PPE and must be trained in

the proper use and care of his equipment;

All personnel on or in close proximity to water shall wear a High

Visibility life jacket.

Workers will be trained in the proper use and care of the

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 11 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

flotation equipment.

17. IDENTIFIED HAZARD: M Ensure that all machines are removed from the river and parked L Site Supervisor Pipeline H&S H&S

REMOVING EQUIPMENT FROM up safety and night security in place; Department Manage

FABRICATION WHEN IT IS IN r

A proper method Statement will be followed for removal of

PLACE

equipment.

ASSOCIATED RISKS:

Slips, Trips, and Falls

Hand and Finger exposure

18. IDENTIFIED HAZARD: H All drivers/operators to ensure that engine is switched off, L Site Supervisor Pipeline H&S Safety

UNSAFE REFUELING OF brakes applied when refuelling takes place; Department officer

EQUIPMENT / VEHICLES

Mobile phones are not to be used in the vicinity of refuelling;

All equipment must be bonded / grounded during refuelling

operations;

Fuel truck drivers to be trained in spill prevention and

containment;

Spill clean up kit and drip tray to be carried in fuel truck;

ASSOSIATED RISKS:

Appropriate fire fighting equipment to be carried on refuelling

trucks;

Environmental Pollution/Oil

Spill All refuelling must be performed at least 50M away from

Fire; watercourse;

Eye injuries. No smoking during refuelling operations;

Proper Sign “STAY AWAY REFUELLING!”, “NO SMOKING”,

“NO USE OF MOBILE PHONES” to be placed when re-fuelling

machinery.

19. IDENTIFIED HAZARD: M Dedicated security personnel will be assigned to the KURA L Site Superintendent Pipeline Security

UNAUTHORISED VISITORS TO River Site in accordance with the approved security procedure Security

(Kura River Crossing SECURITY PROCEDURE – BTC00 Manage

THE WORK PLACE – Department

SECURITY COVERAGE -B010-SE-PRO-00001); r

Pipeline Safety

Security personnel will be equipped with radios and/or mobile Department

phones, in accordance with the approved security procedure.

ASSOCIATED RISKS: Safety

Barbed wire fence will be installed at each side of the AGT FCI-

Non-project related Manage

ROW to prevent livestock and members of public entering the

personnel and children r

construction site;

entering site – Risks of

Access to work place is unauthorised for non-project related

accident involving the third

personnel;

party;

To prevent public entering the construction area, security guards

Cattle entering site – risk will be deployed at strategic points. They will also perform

of falling into the trench; scheduled walking rounds along the fencing perimeter and the

Wild animals or stray yard. (Guards will not enter the hazard zone created by open

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 12 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

dogs entering site – risk of trench;

bites. Security will keep a regular check of the fence. Daily inspection

Risk Security of of the fence will be documented;

personnel whilst working. All work has to stop if non-project related personnel are present

in the working area;

Risk of Fraud, pilfering,

vandalism and theft. Visitors must undergo a complete Spie Capag - Petrofac Visitors

Safety Induction, which should be documented and available for

Mugging, burglary, armed inspection. Any visitors must be accompanied by a member of

robbery, carjacking, smuggling the Spie - Petrofac / Subcontractor workforce;

and kidnapping.

All visitors must sign in/out on the visitors log sheet;

Site block off and

Visitors must wear appropriate PPE at all times on site.

occupation.

20. IDENTIFIED HAZARD: M This Risk Assessment is a “living document”. As such, if or when L Site Supervisor Pipeline H&S H&S

NEW OR UNFORESEEN new or unforeseen hazards or missing mitigation steps arise, they Department Manage

HAZARDS OR MISSING shall be added to this Risk Assessment by specific directions given r

MITIGATION STEPS by the SPJV H&S Department, Supervisor and SPJV Site

Management, taking into account the project safety documents and

in consultation with Company HS advisor.

If any potentially hazardous activity, i.e. ROW clearing, Excavating,

Winching / Pulling, securing of pipe, etc. has to suffer any

significant change to the approved Method Statement, the site

supervisor will suspend activity and inform the spread boss and

senior safety advisor.

The work shall not commence unless the risks of revised work are

assessed, new hazards identified, and associated risk mitigated.

Change will be documented by revised risk assessment and an

updated method Statement.

21. CLOSE OF WORK ACTIVITY H Leave the work area clean and tidy. L Crew Supervisor Pipeline H&S H&S

All Waste shall be placed in drums and bins, which shall be Department Manage

emptied regularly. r

22. IDENTIFIED HAZARD: M Installation Works scheduled to ensure the main eastern L Construction Manager Construction Project

FLASH FLOOD OF THE RIVER channel is closed for the minimum time period; Site Superintendent Manager Manage

DURING INSTALLATION r

Dams to be designed and installed to cope with a rise in the

WORKS

water levels based on historical data;

Western Channel to be dredged to cope with a rise in the

ASSOCIATED RISKS: water levels based on historical data;

Breaching of Dams All works in the river beds to be complete by the end of

Possible Loss or Damage to February 2005;

Pipe String

Close monitoring of the weather forecast and river

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 13 of 53

Supervisor

Post

Pre Responsible Action(s) Checke

# Risk Description Actions Mitigatio

Mitigation For Implementing Verified By d By

n

Action(s)

conditions upstream of crossing during the installation period;

Contingency Plan in place to lower the pipe string to the

bottom of the trench should a flash flood occur;

Excess pumping capacity available to cope with sudden

rise in water levels;

Contingency Plan to open Eastern Channel dam early (as

soon as pipe(s) laid) though a narrower river bed to ease water

flow in the Western Channel;

23. IDENTIFIED HAZARD: M Close monitoring of progress against detailed programme L Construction Manager Project Project

DELAY IN PROGRESS OF THE of works to identify any slippage before becoming critical; Manager Director

WORKS

Possibility to mobilise additional resources from the Spread

1 works to supplement resources;

ASSOCIATED RISKS:

Failure to complete the Contingency plan to only partially complete the SCP

crossing in accordance with crossing (positive bank to island) and then complete BTC as

the schedule priority with SCP completed late summer 2005;

Failure to compete the BTC

Pipeline by 31 March 2004

Increased risk of flood as water

levels rise in Spring

24. IDENTIFIED HAZARD: L Construction team experienced with installation of river L Construction Manager Project Project

LOSS OR TOTAL DAMAGE TO crossings; Manager Director

PIPE STRINGS

Installation Works scheduled to ensure the main eastern

channel is closed for the minimum time period;

ASSOCIATED RISKS:

Failure to compete the BTC All works in the river beds to be complete by the end of

Pipeline by 31 March 2004 February 2005;

Close monitoring of the weather forecast and river

conditions upstream of crossing during the installation period;

Contingency Plan in place to lower the pipe string to the

bottom of the trench should a flash flood occur;

Contingency Plan to open Eastern Channel dam early (as soon

as pipe(s) laid) though a narrower river bed to ease water flow in

the Western Channel;

Electronic File Reference: BTC004-B210-CM-PRO-00096-A06 Page 14 of 53

You might also like

- Risk Assessment Template For Fit-OutDocument5 pagesRisk Assessment Template For Fit-OutJedz Gumapas79% (14)

- Generic Heavy Equipment Operator SOPDocument3 pagesGeneric Heavy Equipment Operator SOPImran KhanNo ratings yet

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (2)

- Risk Assessment For External Façade & Canopies CleaningDocument6 pagesRisk Assessment For External Façade & Canopies Cleaningjulius0% (1)

- Health Safety and Environmental Management Plan - C01Document43 pagesHealth Safety and Environmental Management Plan - C01Mamuka ShaorshadzeNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Nma100776 O&m-Section 1 PDFDocument23 pagesNma100776 O&m-Section 1 PDFMichael CaoNo ratings yet

- Excavation Adjacent To Underground Assets Swms 10285-8Document13 pagesExcavation Adjacent To Underground Assets Swms 10285-8JamesNo ratings yet

- SOP Filling Plant SectionDocument21 pagesSOP Filling Plant SectionBesan LaduNo ratings yet

- Osha StandardsDocument18 pagesOsha Standardsmojback100% (3)

- Cyanide Management For Gold Mining PDFDocument164 pagesCyanide Management For Gold Mining PDFNataniel Linares100% (1)

- Manual Excavation For Identified Depth and Elevation of Existing PipelineDocument15 pagesManual Excavation For Identified Depth and Elevation of Existing PipelineshahbazchafekarNo ratings yet

- Risk Assessment (STL-STR)Document15 pagesRisk Assessment (STL-STR)Abdullah Twfeeq100% (1)

- Risk Assessment - Tree-Disposal And-RemovalDocument4 pagesRisk Assessment - Tree-Disposal And-RemovalQAISAR ABBASNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument30 pagesJSA For Scaffolding Erection Dismantling and Modification Workkmohamedkeita906No ratings yet

- RA Sand BlastingDocument2 pagesRA Sand BlastingAbdus Samad100% (1)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- JSA Excavation For Lighting Pole FoundationDocument18 pagesJSA Excavation For Lighting Pole FoundationMohammad Al Masa'deh100% (1)

- HKGGA - ELS & Pile Cap RADocument12 pagesHKGGA - ELS & Pile Cap RAymkawai224No ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument20 pagesJSA For Scaffolding Erection Dismantling and Modification Workbagas prakoso100% (1)

- JSA For Hydro Jetting, Removal and Cleaning of SludgeDocument18 pagesJSA For Hydro Jetting, Removal and Cleaning of Sludgesk sajidNo ratings yet

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- TRA-BRS-030 Rev 00 SHIFTING LIFTING AND LOAD OUT TO PERMANENT JETTYDocument21 pagesTRA-BRS-030 Rev 00 SHIFTING LIFTING AND LOAD OUT TO PERMANENT JETTYFariz Fatahillah AlbugisiNo ratings yet

- TRA For ScaffoldingDocument3 pagesTRA For Scaffoldingaparna_losariNo ratings yet

- Dewatering Risk Assessment (0075) - Rev-02Document16 pagesDewatering Risk Assessment (0075) - Rev-02Muhammad OsamaNo ratings yet

- BAWTP1A Project: (Sign Name & Position (Sign Name & PositionDocument6 pagesBAWTP1A Project: (Sign Name & Position (Sign Name & PositionazerNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- JSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling ActivityDocument20 pagesJSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling Activitywhtez0neNo ratings yet

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- Demobilization Risk Assessment and Method StatementDocument25 pagesDemobilization Risk Assessment and Method StatementVishu KumarNo ratings yet

- JSA For Erection and Repair Work of TanksDocument19 pagesJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- TRA of Cladding Using LadderDocument2 pagesTRA of Cladding Using LadderAsh SoliNo ratings yet

- RA for Lifting & Installation of Ladder and PlatformDocument2 pagesRA for Lifting & Installation of Ladder and Platformferoz khanNo ratings yet

- JSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling ActivityDocument12 pagesJSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling Activitybagas prakoso100% (1)

- JSA Format Erection of Exchanger 903-E-04Document6 pagesJSA Format Erection of Exchanger 903-E-04sakthi venkatNo ratings yet

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- Risk Assessment For Installation & Testing of HDPE PipesDocument9 pagesRisk Assessment For Installation & Testing of HDPE PipesLawrence adeleke OmisakinNo ratings yet

- RA Sandblasting and Painting of SheetsSpoolsDocument3 pagesRA Sandblasting and Painting of SheetsSpoolshashibpervez.shvenergybdNo ratings yet

- RA0019 General Lifting Operation v1Document6 pagesRA0019 General Lifting Operation v1dsadasNo ratings yet

- Risk Assesment ScotDocument18 pagesRisk Assesment ScotSujith KunjumonNo ratings yet

- Risk Assessment For Installation of A New AC UnitDocument9 pagesRisk Assessment For Installation of A New AC Unitservice.amepNo ratings yet

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- Task Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBDocument2 pagesTask Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBmyo lwinNo ratings yet

- Cooling Tower BiomateDocument8 pagesCooling Tower BiomateJavid AaqibNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- 29 Housekeeping and CleaningDocument3 pages29 Housekeeping and CleaningMohammed Ali QaziNo ratings yet

- RA 18 (Well Bore Using Excavator Mounted Earth Auger Drill) 2Document8 pagesRA 18 (Well Bore Using Excavator Mounted Earth Auger Drill) 2abdulthahseen007No ratings yet

- L2 Risk Assessment Leakage HVAC Ducting Rectification - PlanDocument5 pagesL2 Risk Assessment Leakage HVAC Ducting Rectification - PlanHaris Risdiana100% (2)

- Deep Excavation Risk AssessmentDocument12 pagesDeep Excavation Risk Assessmentdonfrancis639No ratings yet

- 028 - JSA - Hydrotesting - 27-02-2012Document7 pages028 - JSA - Hydrotesting - 27-02-2012sathishkumarNo ratings yet

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- SO MELVIN SOR May 10 - 23, 2024Document8 pagesSO MELVIN SOR May 10 - 23, 2024melvinlago29No ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- JHA ISO Container Lifting Point MPI InspectionDocument7 pagesJHA ISO Container Lifting Point MPI InspectionMohamedNo ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- Project: K028-Fayyhealth-Polyclinic Risk Assessment For Slab Coring WorkDocument5 pagesProject: K028-Fayyhealth-Polyclinic Risk Assessment For Slab Coring Workadeniyi abiolaNo ratings yet

- JSA ELETRICAL MaintenanceDocument17 pagesJSA ELETRICAL MaintenanceWeru MorrisNo ratings yet

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 pagesNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor60% (5)

- JSA 06 (Rebar Assembly Work)Document8 pagesJSA 06 (Rebar Assembly Work)abdulthahseen007100% (1)

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- BAWTP1A Project: (Sign Name & Position (Sign Name & PositionDocument8 pagesBAWTP1A Project: (Sign Name & Position (Sign Name & PositionAsad PrinceNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Obie86 Bahhier100% (1)

- Tra 002Document6 pagesTra 002Bilal0% (1)

- AKH - HS - COVID-19 - PCR Testing Report - 011Document3 pagesAKH - HS - COVID-19 - PCR Testing Report - 011Mamuka ShaorshadzeNo ratings yet

- AKH - HS - COVID-19 - PCR Testing Report - 007Document3 pagesAKH - HS - COVID-19 - PCR Testing Report - 007Mamuka ShaorshadzeNo ratings yet

- AKH - HS - COVID-19 - PCR Testing Report - 011Document3 pagesAKH - HS - COVID-19 - PCR Testing Report - 011Mamuka ShaorshadzeNo ratings yet

- AKH - HS - COVID-19 - PCR Testing Report - 007Document3 pagesAKH - HS - COVID-19 - PCR Testing Report - 007Mamuka ShaorshadzeNo ratings yet

- AKH - HS - COVID-19 - PCR Testing Report - 009Document3 pagesAKH - HS - COVID-19 - PCR Testing Report - 009Mamuka ShaorshadzeNo ratings yet

- COVID-19 Employee Readiness and Responsiveness PlanDocument11 pagesCOVID-19 Employee Readiness and Responsiveness PlanMamuka ShaorshadzeNo ratings yet

- Construction Sites Injury ConditionsDocument11 pagesConstruction Sites Injury ConditionsMamuka ShaorshadzeNo ratings yet

- PIPERONALDocument5 pagesPIPERONALasesoresmtc05No ratings yet

- MSMEUnitsforCovid-19-MSME-DI, KolkataDocument33 pagesMSMEUnitsforCovid-19-MSME-DI, KolkataUday kumarNo ratings yet

- 3a2494en LDocument78 pages3a2494en LRăzvan GarbeaNo ratings yet

- MSDS-002 Sureflow 100Document45 pagesMSDS-002 Sureflow 100joker batmanNo ratings yet

- Safety ManualDocument331 pagesSafety ManualTim ChongNo ratings yet

- Ti O2Document4 pagesTi O2Muhamad Fahmi Dermawan EndonesyNo ratings yet

- ETT2010 Certification Elements DescriptionsDocument13 pagesETT2010 Certification Elements DescriptionsPhillip BlackNo ratings yet

- CV For HSE DepartmentDocument4 pagesCV For HSE Departmentshahnawaz ahmedNo ratings yet

- COMPREHENSIVE - CONSTRUCTION SAFETY and HEALTH PROGRAMDocument15 pagesCOMPREHENSIVE - CONSTRUCTION SAFETY and HEALTH PROGRAMcoc cdoNo ratings yet

- BaOH2 PDFDocument5 pagesBaOH2 PDFGhana Cintai DiaNo ratings yet

- MSDS of Ordinary Portland CementDocument6 pagesMSDS of Ordinary Portland CementAchmad Wahid HasyimNo ratings yet

- Service Manual en - WindDocument392 pagesService Manual en - Windsanele100% (1)

- IceBreakerRange ManualDocument96 pagesIceBreakerRange ManualJaelani Painting n Powder Coating WagnerNo ratings yet

- Event Reporting and Investigation: at The Completion of This Module, You Will Be Able ToDocument20 pagesEvent Reporting and Investigation: at The Completion of This Module, You Will Be Able ToLiza Nashielly GrandeNo ratings yet

- Report 14 16june2022akgDocument24 pagesReport 14 16june2022akgMithilesh KumarNo ratings yet

- Materials Safety Data Sheet RENCO Annatto Food Colour (Hazardous)Document3 pagesMaterials Safety Data Sheet RENCO Annatto Food Colour (Hazardous)Abdullah KamelNo ratings yet

- The Practices and Challenges of Occupational Safety and Health in Meta Abo Brewery Sc. CoDocument83 pagesThe Practices and Challenges of Occupational Safety and Health in Meta Abo Brewery Sc. CoTewfic SeidNo ratings yet

- Progress Help Waste Pickers ProposalDocument9 pagesProgress Help Waste Pickers ProposalFika JeNo ratings yet

- Nalcolyte 8100 Coagulant: MSDS NumberDocument3 pagesNalcolyte 8100 Coagulant: MSDS NumberEko Setyo BudiNo ratings yet

- Santisimo Rosario National High Schoo2Document47 pagesSantisimo Rosario National High Schoo2Kissarah B. VillanuevaNo ratings yet

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- 35V Prussian Blue .75ozDocument8 pages35V Prussian Blue .75ozEscobar ValderramaNo ratings yet

- MSRA Door ReplacementDocument3 pagesMSRA Door ReplacementBala KrishnanNo ratings yet