Professional Documents

Culture Documents

ECOS 160 - 250 - 315 Manual Ang

ECOS 160 - 250 - 315 Manual Ang

Uploaded by

Thouraya HbsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ECOS 160 - 250 - 315 Manual Ang

ECOS 160 - 250 - 315 Manual Ang

Uploaded by

Thouraya HbsCopyright:

Available Formats

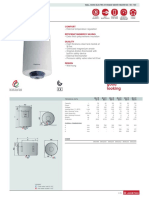

Data sheet

valid from: 11/10/20

TM 160 - 250 - 315 ECO Machine complete

Butt Fusion machine to joint PE, PP, PB pipes and fittings for pressure piping systems on building

sites and in trenches.

Hydraulically operated with manual control unit.

Temperature controller integrated in the heating element handle.

Including transport packaging (carton pallet); reduction clamping inserts and other accessories to

be ordered separately.

• BASE MACHINE

• High precision design, distortion-free and sturdy machine frame

• Good accessibility thanks to 35° inclination

• The movable (sliding) 3rd clamp allows easy and time-saving fixation of bends or tees without

need of additional tools

• Clamps are hinged on the top side and tilting. Whenever necessary, the four clamps can be

quickly removed

• Double-sided heating element pull-off mechanism to optimise the change-over phase

• Weight: Type 160 = 22 kg, Type 250 = 47 kg, Type 315 = 53 kg

• HYDRAULIC UNIT

• Compact construction with protection frame

• Precise pressure setting and fine adjusting

• Joystick operation of machine carriage

• Clearly visible, vibration-free pressure gauge with precision scaling

• Accumulator for pressure equalization during the cooling phase

• Integrated interface for welding recorder

• Max operating pressure: Type 160 = 100 bar, Type 250 - 315 = 160 bar

• Weight: 22 kg

• PLANER

• Powerful parallel planer for single or double-sided facing of pipe ends

• Ergonomic, weight-balanced handling

• Self-locking mechanism in working position

• Safety microswitch to prevent undesired start-up

• Weight: Type 160 = 7 kg, Type 250 = 14 kg, Type 315 = 17 kg

• Heating element

• High performance, electronically controlled heating element

• High-quality, non-stick PTFE-coating with long service life

• Temperature indicator integrated into the handle

• Weight: Type 160 = 5.5 kg, Type 250 = 8 kg, Type 315 = 10 kg

• Input power: Type 160 = 1200 W, Type 250 = 2000 W, Type 315 = 2500 W

• CASE

• For safe storage of planer and heating element

• Weight: Type 160 = 4.8 kg, Type 250 = 8 kg, Type 315 = 9 kg

Type d-d Performance Description Code Weight

(mm) (kg)

ECOS 160 40 ‐ 160 230 V/1900 W Without crate (carton pallet only) 790 150 009 78.000

ECOS 250 75 ‐ 250 230 V/3270 W Without crate (carton pallet only) 790 151 013 116.000

ECOS 315 90 ‐ 315 230 V/3870 W Without crate (carton pallet only) 790 152 028 129.000

ECOS 160 40 ‐ 160 230 V/1900 W With wooden transport crate 790 150 073 108.000

ECOS 250 75 ‐ 250 230 V/3270 W With wooden transport crate 790 151 073 166.000

ECOS 315 90 ‐ 315 230 V/3870 W With wooden transport crate 790 152 073 179.000

The technical data are not binding. They neither constitute expressly warranted characteristics nor guaranteed properties nor a guar-

anteed durability. They are subject to modification. Our General Terms of Sale apply.

Georg Fischer Piping Systems Ltd, Postfach, CH-8201 Schaffhausen/Switzerland

Phone +41 -(0)52-631 1111

e-mail: info.ps@georgfischer.com

Internet: http://www.gfps.com

Page 1 of 1

You might also like

- Konecranes - Hoists, Cranes & WinchesDocument16 pagesKonecranes - Hoists, Cranes & WinchesGogyNo ratings yet

- Temperature and Heat: Dr. Anis Nazihah Binti Mat DaudDocument21 pagesTemperature and Heat: Dr. Anis Nazihah Binti Mat DaudNik Ashraf100% (1)

- Manual de Control Universal ArtticoDocument139 pagesManual de Control Universal ArtticoJohn VicentNo ratings yet

- Product CatalogueDocument44 pagesProduct CatalogueMohammed k75% (4)

- File 2 10Document8 pagesFile 2 10camelod555No ratings yet

- BLU R - ChinaDocument1 pageBLU R - ChinaShishan AhmadNo ratings yet

- HammetDocument12 pagesHammetchemvimal4673No ratings yet

- DatasheetDocument2 pagesDatasheetJefatura de Planta Invemet PeruNo ratings yet

- Machine À Souder Bout À Bout IM 315 Pour Les Applications Industrielles AngDocument1 pageMachine À Souder Bout À Bout IM 315 Pour Les Applications Industrielles AngThouraya HbsNo ratings yet

- Hix HTM (Heat Transfer Machine) BookletDocument8 pagesHix HTM (Heat Transfer Machine) BookletHIX CorporationNo ratings yet

- BFPS Catalogue 2011 - MachineryDocument8 pagesBFPS Catalogue 2011 - MachineryAliArababadiNo ratings yet

- En PS-50-65 200 260 330TP2Document4 pagesEn PS-50-65 200 260 330TP2blueee archiveNo ratings yet

- Electrolux Thawing CabinetDocument4 pagesElectrolux Thawing Cabinetjeevanandraju90No ratings yet

- Esab Origo Mig 510Document2 pagesEsab Origo Mig 510Khaled MekhamerNo ratings yet

- Electrolux rbf1016 Manual de UsuarioDocument3 pagesElectrolux rbf1016 Manual de UsuarioMichell Jaimes RodriguezNo ratings yet

- Kito Product CatalogueDocument40 pagesKito Product CatalogueKito Canada100% (1)

- Брошюра на Rational CombiMaster Plus XS 6-2 - 3Document3 pagesБрошюра на Rational CombiMaster Plus XS 6-2 - 3fenixfenixxx09No ratings yet

- 11-IM-240ANE-HC Specification SheetDocument2 pages11-IM-240ANE-HC Specification SheetGibron MakhdoomiNo ratings yet

- TWE 10 - 15 - 18 ENG EU WebsiteDocument2 pagesTWE 10 - 15 - 18 ENG EU Websitemurtada gubaNo ratings yet

- Induct 0 CarlDocument13 pagesInduct 0 CarlInduct CraneNo ratings yet

- 30370v1 Optima Product RangeDocument3 pages30370v1 Optima Product Rangefichme2No ratings yet

- Pitco FryersDocument4 pagesPitco FryersniyeshNo ratings yet

- Delta Dragon 250 BDocument2 pagesDelta Dragon 250 BAnonymous YqiomOTXNo ratings yet

- Thymol Autoclave India: CatalogueDocument13 pagesThymol Autoclave India: CatalogueRamakanta Padhan Hindu100% (1)

- HDBB010Document4 pagesHDBB010zaxkleaveNo ratings yet

- Overnight Thaw Technical Datasheet: S1Ot-Ss Overnight Thaw S2Ot-Ss Overnight ThawDocument2 pagesOvernight Thaw Technical Datasheet: S1Ot-Ss Overnight Thaw S2Ot-Ss Overnight ThawKuljinder VirdiNo ratings yet

- Cas FW500Document2 pagesCas FW500Manuel AguilarNo ratings yet

- DONGFENG 220-460 kVA: Technical SpecificationsDocument2 pagesDONGFENG 220-460 kVA: Technical SpecificationsHector Sepulveda OrellanaNo ratings yet

- Caddy Tig 2200i AC/DC: For The Craftsmen and A Wide Range of Repair and Maintenance ApplicationsDocument2 pagesCaddy Tig 2200i AC/DC: For The Craftsmen and A Wide Range of Repair and Maintenance ApplicationsZoric92No ratings yet

- May Nen IntermechDocument2 pagesMay Nen IntermechUchiha SaitamaNo ratings yet

- CBH-400 SpecsDocument2 pagesCBH-400 SpecsLevi WranglerNo ratings yet

- Technical Data Sheet - Logiclave™ LAB: DesignDocument8 pagesTechnical Data Sheet - Logiclave™ LAB: DesignharishupretiNo ratings yet

- Biometra ThermoShaker BrochureDocument2 pagesBiometra ThermoShaker BrochureDean RwankoteNo ratings yet

- Leaflet Eair Fixedspeed EN USDocument4 pagesLeaflet Eair Fixedspeed EN USTrung Trinh BaoNo ratings yet

- Product Details of Total Station Survey Instrument Topcon GTS-239Document3 pagesProduct Details of Total Station Survey Instrument Topcon GTS-239Kevin Suerte CanillaNo ratings yet

- 3022 B4ce78acDocument12 pages3022 B4ce78acmmkattaNo ratings yet

- 01 STB-S19-00 - Datenblatt Nettowaage EN v03Document2 pages01 STB-S19-00 - Datenblatt Nettowaage EN v03Widhi RamadhanNo ratings yet

- Ducted Split R410Document44 pagesDucted Split R410Mohamed AmrNo ratings yet

- MovinCool Spot Cooling CatalogueDocument16 pagesMovinCool Spot Cooling CatalogueKhizerNo ratings yet

- Tetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsDocument2 pagesTetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsThinura SamarawickramaNo ratings yet

- FWSSDocument2 pagesFWSSShwan SoraniNo ratings yet

- Karcher HD Mid Class Cage Web-AmcsngDocument4 pagesKarcher HD Mid Class Cage Web-Amcsng王小冬No ratings yet

- TP22 0400Document27 pagesTP22 0400KagetenkeNo ratings yet

- ABC 140-240 Solidbatch: Asphalt-Mixing Plant ClassicDocument2 pagesABC 140-240 Solidbatch: Asphalt-Mixing Plant ClassicMuhamet KurtiNo ratings yet

- Carlstahl Craftsman PresentationDocument19 pagesCarlstahl Craftsman PresentationInduct CraneNo ratings yet

- Kito Electric Hoist CatalogueDocument36 pagesKito Electric Hoist CatalogueADITYA_PATHAKNo ratings yet

- Double Mustang Double Racer Double Horse Double StallionDocument1 pageDouble Mustang Double Racer Double Horse Double StallionabhisurajNo ratings yet

- VRF ToshibaDocument2 pagesVRF ToshibaClima ShopNo ratings yet

- PurifyDocument2 pagesPurifySamo AbdalaNo ratings yet

- One Wave Soldering Machine-Interbras PDFDocument4 pagesOne Wave Soldering Machine-Interbras PDFUserSMTNo ratings yet

- Aquarama Catalogo Stargate s4 en CompressedDocument2 pagesAquarama Catalogo Stargate s4 en CompressedmusabNo ratings yet

- GEA Ariete Homogenizer 5315: Homogenizer & High Pressure Pump Technical DatasheetDocument2 pagesGEA Ariete Homogenizer 5315: Homogenizer & High Pressure Pump Technical DatasheetJorge A. TorresNo ratings yet

- Technical Guide: DescriptionDocument40 pagesTechnical Guide: DescriptionMaqbool MNo ratings yet

- Advance Construction: Presentation On Construction ToolsDocument29 pagesAdvance Construction: Presentation On Construction ToolsANIMESH AGGARWALNo ratings yet

- Caddy Mig C200i: Portable MIG/MAG Welding Unit With Built-In Wire Feeder For Ø200 MM SpoolsDocument2 pagesCaddy Mig C200i: Portable MIG/MAG Welding Unit With Built-In Wire Feeder For Ø200 MM SpoolsDjordjeNo ratings yet

- SC-DUO-6P-7P_Brochure-ETJPUBDocument4 pagesSC-DUO-6P-7P_Brochure-ETJPUBЮрий КихтенкоNo ratings yet

- 28M Platform - UDocument3 pages28M Platform - USantosh SridharNo ratings yet

- Pc850-8e0 Cen00384-03 201506Document16 pagesPc850-8e0 Cen00384-03 201506Augusto OliveiraNo ratings yet

- Product Catalogue EylaDocument21 pagesProduct Catalogue Eylazan_anwarNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Machine À Souder Bout À Bout IM 315 Pour Les Applications Industrielles AngDocument1 pageMachine À Souder Bout À Bout IM 315 Pour Les Applications Industrielles AngThouraya HbsNo ratings yet

- Appendix A Numerical Solution To Heat EquationDocument3 pagesAppendix A Numerical Solution To Heat EquationThouraya HbsNo ratings yet

- Modeling of Thermal Contacts With Heat Generation: Application To Electrothermal ProblemsDocument20 pagesModeling of Thermal Contacts With Heat Generation: Application To Electrothermal ProblemsThouraya HbsNo ratings yet

- Article AdvanticaDocument6 pagesArticle AdvanticaThouraya HbsNo ratings yet

- Impact of Single and Dual Pressure Butt-Welding Procedures On The Reliability of PE 100 Pipe WeldsDocument7 pagesImpact of Single and Dual Pressure Butt-Welding Procedures On The Reliability of PE 100 Pipe WeldsThouraya HbsNo ratings yet

- Proceedings of The 2017 IEEE 7thDocument8 pagesProceedings of The 2017 IEEE 7thThouraya HbsNo ratings yet

- Journal Digest 2016-60-65Document6 pagesJournal Digest 2016-60-65Thouraya HbsNo ratings yet

- Possible Questions For The Final Exam - CEE 3500 - Fall 2005 Part 2 - Fluid Dynamics, Similitude, Pipe FlowDocument5 pagesPossible Questions For The Final Exam - CEE 3500 - Fall 2005 Part 2 - Fluid Dynamics, Similitude, Pipe FlowJervie OliverosNo ratings yet

- Examine2D VerificationDocument13 pagesExamine2D VerificationmarckAntony12No ratings yet

- Biology 3096 - Quiz 1 Question Pool Fall 2010Document3 pagesBiology 3096 - Quiz 1 Question Pool Fall 2010vinh360No ratings yet

- Chapter 11 - SI - Final SolutionsDocument16 pagesChapter 11 - SI - Final SolutionsDouglas FernandesNo ratings yet

- Short Notes For Soil MechanicsDocument26 pagesShort Notes For Soil MechanicsColdWinterKid50% (2)

- University of Michigan AFM WorkshopDocument2 pagesUniversity of Michigan AFM WorkshopIISER MOHALINo ratings yet

- Review 3Document18 pagesReview 3Aswin MuraleedharanNo ratings yet

- Gitter Skal ManualDocument72 pagesGitter Skal ManualCosmin TibyNo ratings yet

- NDT Films Guide-201510 For RTDocument1 pageNDT Films Guide-201510 For RTArbiMuratajNo ratings yet

- Composite Overhead ConductorsDocument21 pagesComposite Overhead ConductorsEnrique Garcia100% (1)

- ccl0 Nuclear Materials Facilities Equipment MiscellaneousDocument23 pagesccl0 Nuclear Materials Facilities Equipment MiscellaneousManual SourceNo ratings yet

- Fluid Phase Equilibria: Andr Es F. Martínez, Cesar A. Sanchez, Alvaro Orjuela, Gerardo RodríguezDocument9 pagesFluid Phase Equilibria: Andr Es F. Martínez, Cesar A. Sanchez, Alvaro Orjuela, Gerardo RodríguezJuan Camilo Rodriguez SandovalNo ratings yet

- Electrocatalyst - WikipediaDocument71 pagesElectrocatalyst - Wikipediasterling goinNo ratings yet

- File Tinh Nhiet 15.10.19 PDFDocument61 pagesFile Tinh Nhiet 15.10.19 PDFLê Hồng SơnNo ratings yet

- Structural Analysis II Syllabus 20101 2Document17 pagesStructural Analysis II Syllabus 20101 2Christian Nicolaus MbiseNo ratings yet

- Periodic Test Third Grading ScienceDocument4 pagesPeriodic Test Third Grading ScienceJaylordPalattaoNo ratings yet

- Finnie WearDocument2 pagesFinnie WearmiguelNo ratings yet

- Lecture2 PDFDocument18 pagesLecture2 PDFYavuz KaplanNo ratings yet

- Astm A320mDocument4 pagesAstm A320mSHYAM SINGHNo ratings yet

- Autofena 3D: Assessment of Static Strength and Fatigue Life According To Fkm-Guideline Within HyperworksDocument25 pagesAutofena 3D: Assessment of Static Strength and Fatigue Life According To Fkm-Guideline Within Hyperworksdeepali0305No ratings yet

- Afif Prasetya Nugraha Putra - 21050111140123 - Daftar PustakaDocument2 pagesAfif Prasetya Nugraha Putra - 21050111140123 - Daftar PustakaAfif Prasetya Nugraha PutraNo ratings yet

- Low Cycle Fatigue in AnsysDocument20 pagesLow Cycle Fatigue in AnsysSuvarnaNo ratings yet

- Vacuum-Jacketed Piping in Liquid Oxygen Service: AIGA 106/19Document24 pagesVacuum-Jacketed Piping in Liquid Oxygen Service: AIGA 106/19najiruddinshaikNo ratings yet

- Circular MotionDocument18 pagesCircular MotionPankaj MishraNo ratings yet

- Samson SizingDocument1 pageSamson Sizingเต่า วีไอNo ratings yet

- Failure Mechanisms in Toughened Epoxy Resins A Review: Amar C. GargDocument45 pagesFailure Mechanisms in Toughened Epoxy Resins A Review: Amar C. GargVansala GanesanNo ratings yet

- WPS A36 For PipesDocument3 pagesWPS A36 For PipesJuan AvellaNo ratings yet