Professional Documents

Culture Documents

Assignment 2

Assignment 2

Uploaded by

Arjun AgarwalCopyright:

Available Formats

You might also like

- ConductionDocument159 pagesConductionNugi100% (1)

- HW 04Document2 pagesHW 04Icy45No ratings yet

- Fins SolutionsDocument5 pagesFins Solutionsdab111No ratings yet

- Homework#2Document1 pageHomework#2Chemical EngineeringNo ratings yet

- Heat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D EDocument4 pagesHeat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D ERotten AppleNo ratings yet

- Holman 1Document4 pagesHolman 1Kumar SamyanaikNo ratings yet

- Heat Trandfer Mid-Term (Chapter1 4)Document3 pagesHeat Trandfer Mid-Term (Chapter1 4)ipns109010010No ratings yet

- HT Notes For ESEDocument25 pagesHT Notes For ESEM BhurleNo ratings yet

- Sheet Three ConductionDocument3 pagesSheet Three ConductionMichael EmadNo ratings yet

- Question BankDocument5 pagesQuestion BankkshitijsdiwakarNo ratings yet

- Tutorial 2Document3 pagesTutorial 2Yik Vui KongNo ratings yet

- Heat and Mass Transfer Practice Questions 1Document2 pagesHeat and Mass Transfer Practice Questions 1Lucky 230503No ratings yet

- HT Important Questions For End ExamDocument10 pagesHT Important Questions For End ExamSandeepKattaNo ratings yet

- HMT16 MarksDocument12 pagesHMT16 MarkstagoreboopathyNo ratings yet

- HT QuestionsDocument3 pagesHT QuestionsSanthoshirathnam GunjaNo ratings yet

- HT QuestionsDocument3 pagesHT QuestionsSanthoshirathnam GunjaNo ratings yet

- 4th Sem.-ME 1251-HMTDocument18 pages4th Sem.-ME 1251-HMTPon ShanmugakumarNo ratings yet

- (An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaDocument2 pages(An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaMohammed Maaz100% (1)

- 8S 2105 Mepc22 1Document2 pages8S 2105 Mepc22 1Challa YachendraNo ratings yet

- Ejercicios Transferencia de CalorDocument15 pagesEjercicios Transferencia de CalorWilliam Hernan HenaoNo ratings yet

- Practice Set 19 (Fins)Document2 pagesPractice Set 19 (Fins)Nibir SahaNo ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2bhaskar5377No ratings yet

- ConductionDocument4 pagesConductionjaibalayyaNo ratings yet

- Home Assignment - 2Document6 pagesHome Assignment - 2Rounak MajumdarNo ratings yet

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyNo ratings yet

- Special Question BankDocument8 pagesSpecial Question BankAKHIL HARINo ratings yet

- Home Assignment - 2Document6 pagesHome Assignment - 2Akash FuryNo ratings yet

- HEAT TRANSFER 2011 JNTUH Question PaperDocument8 pagesHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousNo ratings yet

- Heat Transfer - R2015 - 23-10-2018Document2 pagesHeat Transfer - R2015 - 23-10-2018G.Chaitanya KiranNo ratings yet

- HMT Unit 1Document9 pagesHMT Unit 1rp0212No ratings yet

- HW#02 2018SDocument2 pagesHW#02 2018SAshley Delano100% (1)

- Me52102 - HMT Sheet - I Conduction Jul-Dec'23Document3 pagesMe52102 - HMT Sheet - I Conduction Jul-Dec'23HarshNo ratings yet

- Heat and Mass Transfer: "Solved Problems"Document16 pagesHeat and Mass Transfer: "Solved Problems"qiritical99No ratings yet

- TutorialDocument3 pagesTutorialPaartiban PaneerselvamNo ratings yet

- Work Sheet 1 2022Document6 pagesWork Sheet 1 2022Fikadu GonfaNo ratings yet

- HMT University QuestionsDocument12 pagesHMT University QuestionsDharshan KofiNo ratings yet

- Sheet 2Document4 pagesSheet 2Yasmin RedaNo ratings yet

- HT ProblemsDocument2 pagesHT ProblemsNipun SharmaNo ratings yet

- Unit IIIDocument8 pagesUnit IIIPrashant NandanNo ratings yet

- Tutorial 2-1Document4 pagesTutorial 2-1chandan rajNo ratings yet

- Heat Transfer - 012110043920 - 1Document8 pagesHeat Transfer - 012110043920 - 1shweta_770587No ratings yet

- 4.tutorial HMTDocument5 pages4.tutorial HMTdearsaswatNo ratings yet

- DR - Safaa Hameed Faisal Heat Transfer HW NO-6Document1 pageDR - Safaa Hameed Faisal Heat Transfer HW NO-6Safaa Hameed Al NaseryNo ratings yet

- Heattransfer1 HW1 PDFDocument2 pagesHeattransfer1 HW1 PDFharrysalmonNo ratings yet

- 1492Document15 pages1492_Anggyaa_No ratings yet

- Heat Transfer AssignmentDocument2 pagesHeat Transfer Assignmentdodo123dodo0% (1)

- Tutorial 7Document2 pagesTutorial 7Fardeen RazifNo ratings yet

- Worksheet 1 HMTDocument5 pagesWorksheet 1 HMTmubarekjemal3279No ratings yet

- Department of Mechanical Engineering Question Bank Subject Name: HEAT & MASS TRANSFER Year/Sem: III / V Unit - I Conduction Part - ADocument20 pagesDepartment of Mechanical Engineering Question Bank Subject Name: HEAT & MASS TRANSFER Year/Sem: III / V Unit - I Conduction Part - AjoeannieNo ratings yet

- HMT5Document9 pagesHMT5SriniNo ratings yet

- Met302 Heat and Mass Transfer: DATE OF SUBMISSION: 31-3-2023 Submission Type: OfflineDocument2 pagesMet302 Heat and Mass Transfer: DATE OF SUBMISSION: 31-3-2023 Submission Type: OfflineVISHNU JNo ratings yet

- To UploadDocument2 pagesTo Uploadsmg26thmayNo ratings yet

- Tutorial SheetsDocument5 pagesTutorial SheetsDhiraj DhimanNo ratings yet

- Updated ProblemsDocument3 pagesUpdated Problemsmahmoud koriemNo ratings yet

- Heat Transfer April2003 NR 320305Document8 pagesHeat Transfer April2003 NR 320305Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Format For Declaration by InternsDocument4 pagesFormat For Declaration by InternsNavya IshaNo ratings yet

- Encoder Leinelinde ADS Upgrade Unit Flyer enDocument2 pagesEncoder Leinelinde ADS Upgrade Unit Flyer enWilliamcreisNo ratings yet

- The Contractor' S H&S Plan-ToolsDocument16 pagesThe Contractor' S H&S Plan-ToolsnervozaurNo ratings yet

- 5KE Series - Supressor DiodesDocument4 pages5KE Series - Supressor DiodesMarcelo VilachanNo ratings yet

- IoT ProtocolsDocument10 pagesIoT ProtocolsMushfiq ShahedNo ratings yet

- NSK Tools CatalogDocument20 pagesNSK Tools CatalogRobert OrtegaNo ratings yet

- Stat&probab Q3 Week 1 DLLDocument13 pagesStat&probab Q3 Week 1 DLLKILVEN MASIONNo ratings yet

- Siemens Sipart DR19 ControllersDocument18 pagesSiemens Sipart DR19 Controllersdaniel builesNo ratings yet

- ANKO Candy Floss Maker NoticeDocument8 pagesANKO Candy Floss Maker NoticeSYLVIENo ratings yet

- SamplingDocument24 pagesSamplingLyn MargaretteNo ratings yet

- KWU Electro Hydraulic Governing Final1Document41 pagesKWU Electro Hydraulic Governing Final1Rahul Dev Goswami100% (3)

- Quality Risk Management Ich Q9Document57 pagesQuality Risk Management Ich Q9prakash deshmukhNo ratings yet

- Affiniti 70 Compatibility MatrixDocument36 pagesAffiniti 70 Compatibility MatrixgimenNo ratings yet

- Math Minute 6 Pages 1 - 50 - Flip PDF Download - FlipHTML5Document112 pagesMath Minute 6 Pages 1 - 50 - Flip PDF Download - FlipHTML5saraNo ratings yet

- E Waste Management in BangladeshDocument1 pageE Waste Management in BangladeshKazi Sajharul Islam 1410028630No ratings yet

- Swire Helifuel Tanks US Spec SheetDocument2 pagesSwire Helifuel Tanks US Spec SheetBruno Moreira SilvaNo ratings yet

- Southernization QsDocument2 pagesSouthernization Qsapi-552667678No ratings yet

- A Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsDocument6 pagesA Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsfareesaNo ratings yet

- Simulation Based Performance Analysis of Heat Exchangers: A ReviewDocument7 pagesSimulation Based Performance Analysis of Heat Exchangers: A Reviewانجینئر بلاول شمیرNo ratings yet

- Computers and Automation (1968)Document22 pagesComputers and Automation (1968)Edgardo CánepaNo ratings yet

- 2 Combination StrategyDocument4 pages2 Combination Strategyxomavi8122No ratings yet

- Pre-Int Unit1 Follow-upEmailDocument3 pagesPre-Int Unit1 Follow-upEmailJennifer Leal PavaNo ratings yet

- CH 02Document54 pagesCH 02Chris SerranoNo ratings yet

- Pneumatic Conveying - GJ74, HauckDocument6 pagesPneumatic Conveying - GJ74, Hauckjfejfe100% (1)

- Global Animation TheoryDocument282 pagesGlobal Animation TheoryEdgaras GerasimovičiusNo ratings yet

- ZTT Fittings 21-XJ03014 7.31Document26 pagesZTT Fittings 21-XJ03014 7.31jaiver28No ratings yet

- Contactless Attendance Marking System With Thermal Screening Using ArduinoDocument4 pagesContactless Attendance Marking System With Thermal Screening Using Arduinorm6501769No ratings yet

- 40.00 EnForcer HF Full Line Brochure Page by page-LowResDocument6 pages40.00 EnForcer HF Full Line Brochure Page by page-LowResLuis Alberto Rivas GarciaNo ratings yet

- Acmm 56-11-24 Rev 5 - Jan 19Document16 pagesAcmm 56-11-24 Rev 5 - Jan 19rüşdi işlerNo ratings yet

- Fire Alarm Control Panel: Product Includes A 5 Year WarrantyDocument3 pagesFire Alarm Control Panel: Product Includes A 5 Year WarrantyEolo RojasNo ratings yet

- PT Antesena Geosurvey Indonesia: "Your Partner in Managing Subsurface Risk"Document26 pagesPT Antesena Geosurvey Indonesia: "Your Partner in Managing Subsurface Risk"Fauzia RizkyNo ratings yet

Assignment 2

Assignment 2

Uploaded by

Arjun AgarwalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 2

Assignment 2

Uploaded by

Arjun AgarwalCopyright:

Available Formats

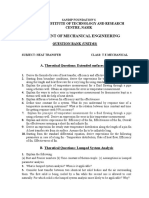

Assignment#2

ME 346 (S1)

Heat Transfer Date: 31/08/2021

Marks: 100

Instructions:

1. Due date for submission: 05/09/2021 (before 21:00 hrs).

2. Only pdf files are to be submitted and the files are to be named as “RollNo.pdf”.

3. You can take necessary but feasible assumptions whenever required.

4. Copying solutions from others will attract penalty of marks.

5. Each question carries 10 marks.

1. A shaft of radius Rs rotates inside a sleeve of inner radius Rs and outer radius Ro.

Frictional heat is generated at the interface providing flux of q". The outside surface of

the sleeve is cooled by convection with an ambient fluid at T∞. The associated heat

transfer coefficient is h. Considering one-dimensional steady state conduction in the

radial direction, determine the temperature distribution in the shaft and sleeve.

2. Steam in a heating system flows through tubes whose outer diameter is 5 cm and whose

walls are maintained at a temperature of 180°C. Circular aluminium alloy 2024-T6 fins

(k =186 W/m°C) of outer diameter 6 cm and constant thickness 1 mm are attached to

the tube. The space between the fins is 3 mm, and thus there are 250 fins per meter

length of the tube. Efficiency of the individual fin is determined to be 97%. Heat is

transferred to the surrounding air at T=25°C, with a heat transfer coefficient of 40

W/m2°C. Determine the increase in heat transfer from the tube per meter of its length

as a result of adding fins.

3. A copper sheet of thickness 2L = 2 mm has an initial temperature of Ti = 118 ᵒC. It is

suddenly quenched in liquid water, resulting in boiling at its two surfaces. For boiling,

Newton’s law of cooling is expressed as 𝑞 " = ℎ(𝑇𝑠 − 𝑇𝑠𝑎𝑡 ), where 𝑇𝑠 is the solid surface

temperature and 𝑇𝑠𝑎𝑡 is the saturation temperature of the fluid (in this case 𝑇𝑠𝑎𝑡 = 100

ᵒC). The convection heat transfer coefficient may be expressed as h = 1010 (T - 𝑇𝑠𝑎𝑡 )2.

Determine the time needed for the sheet to reach a temperature of Tin = 102 ᵒC. (ρcopper

= 8960 kg/m3, Cp=377 J/kg ᵒC)

4. A 5 cm diameter steel pipe is covered with a 1 cm layer of insulating material having

thermal conductivity of 0.22 W/m-K followed by another insulation of thickness 3 cm

with a material having thermal conductivity of 0.06W/mK. The entire assembly is

exposed to an environment at 15°C providing convective heat transfer coefficient 60

W/m2K. The outside surface temperature of the steel pipe is 400°C. Calculate the heat

loss by the pipe insulation assembly for a pipe length of 20 m.

5. Obtain a relation for the fin efficiency for a fin of constant cross-sectional area Ac,

perimeter p, length L, and thermal conductivity k exposed to convection to a medium

at T∞ with a heat transfer coefficient h. Assume the fins are sufficiently long so that the

temperature of the fin at the tip is nearly T∞. Take the temperature of the fin at the base

to be Tb and neglect heat transfer from the fin tips. Simplify the relation for

(a) a circular fin of diameter D.

(b) a rectangular fin of thickness t and width w.

6. Radioactive wastes are packed in a thin walled spherical container and generate thermal

energy uniformly according to the relation 𝑞̇ = 𝑞̇𝑜 [1 − (𝑟/𝑟𝑜)2], where 𝑞̇ is the local rate

of energy generation per unit volume, 𝑞̇𝑜 is a constant, 𝑟𝑜 is the radius of the container.

Steady state conditions are maintained by submerging the container in a liquid which

is at 𝑇∞ and providing a heat transfer coefficient, h. Obtain an expression for the total

rate at which thermal energy is generated in the container. Use the result to obtain an

expression for the temperature, 𝑇𝑠 of the container wall.

7. A long cylindrical rod of radius 10 cm consists of a nuclear reacting material of thermal

conductivity 0.5 W/mK generating 24000 W/m3 uniformly throughout the volume. This

rod is encapsulated inside another cylinder having outer radius 20 cm and thermal

conductivity 4 W/mK. The outer surface is surrounded by a fluid at 100°C providing a

convective heat transfer coefficient of ℎ = 20 W/m2K. Find the temperature at the

interface between the two cylinders and at the outer surface.

8. A copper sphere (k = 386 W/mK) having a diameter of 5 cm is exposed to a convection

environment at 25°C and h = 15 W/m2K. Heat is generated uniformly at the rate of 1

MW/m3. Evaluate the steady state temperature at the centre of the sphere.

9. A constant rate of energy per unit volume qg in the form of heat is uniformly generated

in a long solid cylinder. The temperature at the outer surface of the cylinder (𝑟 = 𝑎) is

maintained at 𝑇𝑎 . Calculate the temperature profile and the heat flux at the outer wall

under steady-state conditions.

10. A very long rod 5 mm in diameter has one end maintained at 100°C. The surface of the

rod is exposed to ambient air at 25°C with a convection heat transfer coefficient of

100 𝑊/𝑚2 𝐾. (a) Determine the temperature distributions along rods constructed from

pure copper, 2024 aluminium alloy, and type AISI 316 stainless steel. What are the

corresponding heat losses from the rods?

(b) Estimate how long the rods must be for the assumption of infinite length to yield an

accurate estimate of the heat loss.

𝑇𝑏 + 𝑇∞

Properties: copper [𝑇 = =

2

62.5°𝐶 = 335 𝐾]: 𝑘 = 398 𝑊/

𝑚𝐾.

2024 aluminium (335 𝐾): 𝑘 =

180 𝑊/𝑚𝐾. stainless steel, AISI

316 (335 𝐾): 𝑘 = 14 𝑊/𝑚𝐾.

You might also like

- ConductionDocument159 pagesConductionNugi100% (1)

- HW 04Document2 pagesHW 04Icy45No ratings yet

- Fins SolutionsDocument5 pagesFins Solutionsdab111No ratings yet

- Homework#2Document1 pageHomework#2Chemical EngineeringNo ratings yet

- Heat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D EDocument4 pagesHeat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D ERotten AppleNo ratings yet

- Holman 1Document4 pagesHolman 1Kumar SamyanaikNo ratings yet

- Heat Trandfer Mid-Term (Chapter1 4)Document3 pagesHeat Trandfer Mid-Term (Chapter1 4)ipns109010010No ratings yet

- HT Notes For ESEDocument25 pagesHT Notes For ESEM BhurleNo ratings yet

- Sheet Three ConductionDocument3 pagesSheet Three ConductionMichael EmadNo ratings yet

- Question BankDocument5 pagesQuestion BankkshitijsdiwakarNo ratings yet

- Tutorial 2Document3 pagesTutorial 2Yik Vui KongNo ratings yet

- Heat and Mass Transfer Practice Questions 1Document2 pagesHeat and Mass Transfer Practice Questions 1Lucky 230503No ratings yet

- HT Important Questions For End ExamDocument10 pagesHT Important Questions For End ExamSandeepKattaNo ratings yet

- HMT16 MarksDocument12 pagesHMT16 MarkstagoreboopathyNo ratings yet

- HT QuestionsDocument3 pagesHT QuestionsSanthoshirathnam GunjaNo ratings yet

- HT QuestionsDocument3 pagesHT QuestionsSanthoshirathnam GunjaNo ratings yet

- 4th Sem.-ME 1251-HMTDocument18 pages4th Sem.-ME 1251-HMTPon ShanmugakumarNo ratings yet

- (An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaDocument2 pages(An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaMohammed Maaz100% (1)

- 8S 2105 Mepc22 1Document2 pages8S 2105 Mepc22 1Challa YachendraNo ratings yet

- Ejercicios Transferencia de CalorDocument15 pagesEjercicios Transferencia de CalorWilliam Hernan HenaoNo ratings yet

- Practice Set 19 (Fins)Document2 pagesPractice Set 19 (Fins)Nibir SahaNo ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2bhaskar5377No ratings yet

- ConductionDocument4 pagesConductionjaibalayyaNo ratings yet

- Home Assignment - 2Document6 pagesHome Assignment - 2Rounak MajumdarNo ratings yet

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyNo ratings yet

- Special Question BankDocument8 pagesSpecial Question BankAKHIL HARINo ratings yet

- Home Assignment - 2Document6 pagesHome Assignment - 2Akash FuryNo ratings yet

- HEAT TRANSFER 2011 JNTUH Question PaperDocument8 pagesHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousNo ratings yet

- Heat Transfer - R2015 - 23-10-2018Document2 pagesHeat Transfer - R2015 - 23-10-2018G.Chaitanya KiranNo ratings yet

- HMT Unit 1Document9 pagesHMT Unit 1rp0212No ratings yet

- HW#02 2018SDocument2 pagesHW#02 2018SAshley Delano100% (1)

- Me52102 - HMT Sheet - I Conduction Jul-Dec'23Document3 pagesMe52102 - HMT Sheet - I Conduction Jul-Dec'23HarshNo ratings yet

- Heat and Mass Transfer: "Solved Problems"Document16 pagesHeat and Mass Transfer: "Solved Problems"qiritical99No ratings yet

- TutorialDocument3 pagesTutorialPaartiban PaneerselvamNo ratings yet

- Work Sheet 1 2022Document6 pagesWork Sheet 1 2022Fikadu GonfaNo ratings yet

- HMT University QuestionsDocument12 pagesHMT University QuestionsDharshan KofiNo ratings yet

- Sheet 2Document4 pagesSheet 2Yasmin RedaNo ratings yet

- HT ProblemsDocument2 pagesHT ProblemsNipun SharmaNo ratings yet

- Unit IIIDocument8 pagesUnit IIIPrashant NandanNo ratings yet

- Tutorial 2-1Document4 pagesTutorial 2-1chandan rajNo ratings yet

- Heat Transfer - 012110043920 - 1Document8 pagesHeat Transfer - 012110043920 - 1shweta_770587No ratings yet

- 4.tutorial HMTDocument5 pages4.tutorial HMTdearsaswatNo ratings yet

- DR - Safaa Hameed Faisal Heat Transfer HW NO-6Document1 pageDR - Safaa Hameed Faisal Heat Transfer HW NO-6Safaa Hameed Al NaseryNo ratings yet

- Heattransfer1 HW1 PDFDocument2 pagesHeattransfer1 HW1 PDFharrysalmonNo ratings yet

- 1492Document15 pages1492_Anggyaa_No ratings yet

- Heat Transfer AssignmentDocument2 pagesHeat Transfer Assignmentdodo123dodo0% (1)

- Tutorial 7Document2 pagesTutorial 7Fardeen RazifNo ratings yet

- Worksheet 1 HMTDocument5 pagesWorksheet 1 HMTmubarekjemal3279No ratings yet

- Department of Mechanical Engineering Question Bank Subject Name: HEAT & MASS TRANSFER Year/Sem: III / V Unit - I Conduction Part - ADocument20 pagesDepartment of Mechanical Engineering Question Bank Subject Name: HEAT & MASS TRANSFER Year/Sem: III / V Unit - I Conduction Part - AjoeannieNo ratings yet

- HMT5Document9 pagesHMT5SriniNo ratings yet

- Met302 Heat and Mass Transfer: DATE OF SUBMISSION: 31-3-2023 Submission Type: OfflineDocument2 pagesMet302 Heat and Mass Transfer: DATE OF SUBMISSION: 31-3-2023 Submission Type: OfflineVISHNU JNo ratings yet

- To UploadDocument2 pagesTo Uploadsmg26thmayNo ratings yet

- Tutorial SheetsDocument5 pagesTutorial SheetsDhiraj DhimanNo ratings yet

- Updated ProblemsDocument3 pagesUpdated Problemsmahmoud koriemNo ratings yet

- Heat Transfer April2003 NR 320305Document8 pagesHeat Transfer April2003 NR 320305Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Format For Declaration by InternsDocument4 pagesFormat For Declaration by InternsNavya IshaNo ratings yet

- Encoder Leinelinde ADS Upgrade Unit Flyer enDocument2 pagesEncoder Leinelinde ADS Upgrade Unit Flyer enWilliamcreisNo ratings yet

- The Contractor' S H&S Plan-ToolsDocument16 pagesThe Contractor' S H&S Plan-ToolsnervozaurNo ratings yet

- 5KE Series - Supressor DiodesDocument4 pages5KE Series - Supressor DiodesMarcelo VilachanNo ratings yet

- IoT ProtocolsDocument10 pagesIoT ProtocolsMushfiq ShahedNo ratings yet

- NSK Tools CatalogDocument20 pagesNSK Tools CatalogRobert OrtegaNo ratings yet

- Stat&probab Q3 Week 1 DLLDocument13 pagesStat&probab Q3 Week 1 DLLKILVEN MASIONNo ratings yet

- Siemens Sipart DR19 ControllersDocument18 pagesSiemens Sipart DR19 Controllersdaniel builesNo ratings yet

- ANKO Candy Floss Maker NoticeDocument8 pagesANKO Candy Floss Maker NoticeSYLVIENo ratings yet

- SamplingDocument24 pagesSamplingLyn MargaretteNo ratings yet

- KWU Electro Hydraulic Governing Final1Document41 pagesKWU Electro Hydraulic Governing Final1Rahul Dev Goswami100% (3)

- Quality Risk Management Ich Q9Document57 pagesQuality Risk Management Ich Q9prakash deshmukhNo ratings yet

- Affiniti 70 Compatibility MatrixDocument36 pagesAffiniti 70 Compatibility MatrixgimenNo ratings yet

- Math Minute 6 Pages 1 - 50 - Flip PDF Download - FlipHTML5Document112 pagesMath Minute 6 Pages 1 - 50 - Flip PDF Download - FlipHTML5saraNo ratings yet

- E Waste Management in BangladeshDocument1 pageE Waste Management in BangladeshKazi Sajharul Islam 1410028630No ratings yet

- Swire Helifuel Tanks US Spec SheetDocument2 pagesSwire Helifuel Tanks US Spec SheetBruno Moreira SilvaNo ratings yet

- Southernization QsDocument2 pagesSouthernization Qsapi-552667678No ratings yet

- A Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsDocument6 pagesA Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsfareesaNo ratings yet

- Simulation Based Performance Analysis of Heat Exchangers: A ReviewDocument7 pagesSimulation Based Performance Analysis of Heat Exchangers: A Reviewانجینئر بلاول شمیرNo ratings yet

- Computers and Automation (1968)Document22 pagesComputers and Automation (1968)Edgardo CánepaNo ratings yet

- 2 Combination StrategyDocument4 pages2 Combination Strategyxomavi8122No ratings yet

- Pre-Int Unit1 Follow-upEmailDocument3 pagesPre-Int Unit1 Follow-upEmailJennifer Leal PavaNo ratings yet

- CH 02Document54 pagesCH 02Chris SerranoNo ratings yet

- Pneumatic Conveying - GJ74, HauckDocument6 pagesPneumatic Conveying - GJ74, Hauckjfejfe100% (1)

- Global Animation TheoryDocument282 pagesGlobal Animation TheoryEdgaras GerasimovičiusNo ratings yet

- ZTT Fittings 21-XJ03014 7.31Document26 pagesZTT Fittings 21-XJ03014 7.31jaiver28No ratings yet

- Contactless Attendance Marking System With Thermal Screening Using ArduinoDocument4 pagesContactless Attendance Marking System With Thermal Screening Using Arduinorm6501769No ratings yet

- 40.00 EnForcer HF Full Line Brochure Page by page-LowResDocument6 pages40.00 EnForcer HF Full Line Brochure Page by page-LowResLuis Alberto Rivas GarciaNo ratings yet

- Acmm 56-11-24 Rev 5 - Jan 19Document16 pagesAcmm 56-11-24 Rev 5 - Jan 19rüşdi işlerNo ratings yet

- Fire Alarm Control Panel: Product Includes A 5 Year WarrantyDocument3 pagesFire Alarm Control Panel: Product Includes A 5 Year WarrantyEolo RojasNo ratings yet

- PT Antesena Geosurvey Indonesia: "Your Partner in Managing Subsurface Risk"Document26 pagesPT Antesena Geosurvey Indonesia: "Your Partner in Managing Subsurface Risk"Fauzia RizkyNo ratings yet