Professional Documents

Culture Documents

Te Mech Sand Which 23 June2014

Te Mech Sand Which 23 June2014

Uploaded by

Safety DeptOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Te Mech Sand Which 23 June2014

Te Mech Sand Which 23 June2014

Uploaded by

Safety DeptCopyright:

Available Formats

University of Pune

UNIVERSITY OF PUNE

Structure and Syllabus

FOR

T.E. Mechanical (Sandwich)Engineering

2012 Course

UNDER FACULTY OF ENGINEERING

EFFECTIVE from July 2014

TE Mechanical (Sandwich) 2012 course

Page 1

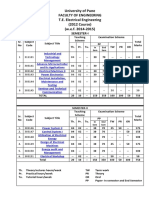

University of Pune

T. E. Mechanical (Sandwich) Semester – I

(w.e.f. Academic year 2014-15)

Code Subject Teaching Scheme

(Weekly Load in Examination Scheme (Marks)

hrs)

Lect. Tut Pract. Theory TW PR OR Total

In

End Sem.

Sem.

Numerical

Methods &

302061 3 -- 2 30 70 25 -- -- 125

Computational

Techniques

302042 Heat Transfer* 4 -- 2 30 70 -- 50# -- 150

*

302050 Mechatronics 3 -- 2 30 70 25 -- -- 125

Theory of

302043 4 -- 2 30 70 -- -- 50 150

Machines II* $

** @

302062 Machine Design 4 -- 2 30 70 25 -- 50 175

302063 Machine Shop -- -- 2 -- -- 25 -- -- 25

Total of Semester – I 18 -- 12 150 350 100 50 100 750

* Subjects common with Mechanical Engineering (refer T.E Mechanical Engineering 2012 course

syllabus for the same)

$ Common Oral will be based on both TOM-I and TOM-II term work at end of first Semester of

T.E. Mechanical Sandwich.

# Evaluation should be on performance in practical examination and oral based on Term Work

by Internal Examiner and one External Examiner

Important Notes

1. In-Sem Theory examination will be conducted, approximately one and half month after the

commencement of each semester

2. In-Sem Theory examination will be based on first three units from Syllabus and will be conducted

by the University of Pune

3. Total time allotted for In-Sem Theory examination will be 1 hr.

4. (** ) Total time allotted for In-Sem Theory examination (Machine Design) will be 1 hr 30 mins.

5. Total time allotted for End-Sem Theory examination will be 2 hrs 30 min.

6. ( @ ) Total time allotted for End-Sem Theory examination (Machine Design) will be 3 hrs.

TE Mechanical (Sandwich) 2012 course

Page 2

University of Pune

T. E. Mechanical (Sandwich) Semester – II

(w.e.f. Academic year 2014-15)

Code Subject Teaching Scheme

Examination Scheme (Marks)

(Weekly Load in hrs)

Lect. Tut Pract. Theory TW PR OR Total

In

End Sem.

Sem.

Industrial In- One contact hour per

302064 - - 150 - 100* 250

plant Training student per week@

302065 Seminar - - - - - - - 50# 50

Materials and

Manufacturing

302066 - - - - 100+ 25 - - 125

Engineering

(Self Study-I)

Industrial

Engineering and

302067 Production - - - - 100+ 25 - - 125

Management

(Self Study –II)

Total of Semester – II 60 Hrs/ for 60 -

200 200 - 150 550

students

+ Only End-Sem Theory examination will be conducted and there will not be In-Sem examination

for self study subjects - I & II

@ Contact hour is provided for supervision of student under training.

* Oral based on TW by one Internal Examiner and one External Examiner from Industry

# Presentation in front of one Internal Examiner & one External Examiner.

TE Mechanical (Sandwich) 2012 course

Page 3

University of Pune

T.E. Mechanical (Sandwich) - 2012 Course

Numerical Methods & Computational Techniques [302061]

Code Subject Teaching Scheme Examination Scheme (Marks)

(Weekly Load in hrs)

Lect. Tut Pract. Theory TW PR OR Total

In End

Sem. Sem.

Numerical 3 --- 2 30 70 25 --- --- 125

Methods & (1Hr.) (2 Hr.

302061

Computational 30

Techniques Min.)

COURSE OBJECTIVES

1. The student shall understand Concept of Numerical Methods and its engineering

applications.

2. Student shall learn various techniques to solve mathematical problem in different ways.

3. The student shall able to undergo the programming skills to solve mathematical problems.

4. To prepare the students for their higher education.

COURSE OUTCOMES

1. The student will understand Concept of Numerical Methods and its role in solving engineering

mathematical problems.

2. The student will be good at programming skills.

3. The student will be able to carry out proper selection of the method for solving the mathematical

problems.

Unit – I (08 hrs)

Roots of Equations and Numerical Integration

Newton Raphson method, Modified Newton Raphson method, and Successive approximation method.

Trapezoidal rule, Simpson's Rules (1/3rd , 3/8th ), Gauss Quadrature Method- 2 point,

Double integration - Trapezoidal rule, Simpson's 1/3th rule.

Unit – II (08 hrs)

Interpolation

Lagrange's Interpolation, Newton's interpolation - Forward, Backward, Hermit Interpolation, Spline

Interpolation- cubic, inverse interpolation, extrapolation.

Unit – III (08 hrs)

Linear Simultaneous Equations

Gauss Elimination Method, partial pivoting, Thomas algorithm for tridiagonal matrix, Gauss-seidal method.

Unit – IV (08 hrs)

Curve Fitting and errors

Least square technique- straight line, quadratic equation, power equation, exponential equation.

Errors and approximations

TE Mechanical (Sandwich) 2012 course

Page 4

University of Pune

Unit – V (08 hrs)

Numerical Solutions of ODE

Taylor series method, Euler Method, Modified Euler Method, Runge Kutta Methods- second order and

fourth order, Predictor-corrector method.

Unit – VI (08 hrs)

Finite difference methods

Introduction to finite difference method, PDEs- Parabolic - explicit, Crank Nicholson method, Hyperbolic

equations , and Elliptic equations.

Term-Work

Term work shall consist of following assignment:

1 Program on Roots of Equations

2 Program on Numerical Integration

3 Program on Interpolation

4 Program on Simultaneous Equations

5 Program on Curve Fitting

6 Program on ODE

7 Program on Finite difference methods

8 One assignment on all above topics using any suitable Solver

Practical Exams.

1. One program on Unit No 1.

2. Any one program from unit 2 to 6 option within unit

Text Books

1. Steven C. Chapra, Raymond P. Canale, Numerical Methods for Engineers, 4/e, Tata McGraw Hill

Editions, 2002, ISBN 0-07-047437-0Dr. B. S. Garewal, Numerical Methods in Engineering and

Science, 7/e, Khanna Publishers, ISBN 81-74009-205-6

2. M. K. Jain, S R K Iyengar, R K Jain, Numerical Methods for Scientific and Engineering

Computations, 5/e New Age International Publishers ISBN 13 978-81¬224-2001-2008

3. Gerold/ Wheatley, Applied Numerical Analysis, 6/e, Pearson Education Asia, 2002 ISBN 81-7808-

567-4

Reference Books

1. B. V. Ramana, Higher Engineering Mathematics, Tata McGraw Hill Publishing Company Ltd, New

Delhi, ISBN 10: 0-07-0643419-X

2. Steven C. Chapra, Applied Numerical Methods with MATLAB for Engineers and Scientist, 2/e,

Tata Mc-GrawHill Publishing Co-Ltd, 2008, ISBN 0-07-064853-0,

TE Mechanical (Sandwich) 2012 course

Page 5

University of Pune

T.E. Mechanical (Sandwich) - 2012 Course

Machine Design [302062]

Code Subject Teaching Scheme

Examination Scheme (Marks)

(Weekly Load in hrs)

Lect. Tut Pract. Theory TW PR OR Total

End

In Sem.

Sem.

Machine 30

70

302062 Design 4 -- 2 25 -- 50 175

(90

(3 Hrs.)

Min.)

COURSE OBJECTIVES

1. The student shall gain appreciation and understanding of the design function in Mechanical Engineering,

the steps involved in designing and the relation of design activity with manufacturing activity.

2. Shall be able to choose proper materials for different machine elements depending on their physical and

mechanical properties. Thus he shall be able to apply the knowledge of material science in real life usage.

3. Student shall gain a thorough understanding of the different types of failure modes and failure criteria. He

will be conversant with various failure theories and be able to judge which criterion is to be applied in

which situation.

4. Student shall be able to design different machine elements e.g. shafts, couplings, springs, gears etc. by

applying basic design process.

COURSE OUTCOMES

1. Ability to analyze the stress and strain of mechanical components and understand, identify and

quantify failure modes for Machine components.

2. Ability to select standard machine components from Manufacturer’s catalogue.

3. Enhancement in proficiency of CAD software for designing Mechanical systems and to generate

production drawing

Unit – I (08 hrs)

Design Process and design of Simple Machine elements:

Machine Design, Design Process, Design considerations, Standards and codes, Use of preferred series,

Factor of safety, Service factor.

Design of Cotter joint, Knuckle joint.

Design of Shafts, Keys and Couplings:

Shaft design on the basis of strength, torsional rigidity and lateral rigidity, A.S.M.E. code for shaft design,

Design of parallel keys and splines, Design of Flange Coupling.

TE Mechanical (Sandwich) 2012 course

Page 6

University of Pune

Unit – II (08 hrs)

Design for Fluctuating Loads:

Stress concentration-causes & remedies, fluctuating stresses, fatigue failures, S-N curve, endurance limit,

notch sensitivity, endurance strength modifying factors, design for finite and infinite life, cumulative damage

in fatigue failure, Soderberg, Gerber, Goodman, Modified Goodman diagrams.

Power Screws:

Forms of threads, multiple start screws, Torque analysis and Design of power screws with square and

trapezoidal threads, Self locking screw, Collar friction torque, Stresses in power screws, design of a C-

Clamp, design of screw jack.

Unit – III (08 hrs)

Mechanical Springs:

Types, applications and materials for springs, Design of helical compression and helical tension springs,

Style of ends, Springs in series and parallel, Concentric helical springs.

Welded Joints:

Welding symbols, Stresses in butt and fillet welds, Strength of butt, parallel and transverse fillet welds,

Axially loaded unsymmetrical welded joints, Eccentric load in plane of welds, Welded joints subjected to

bending and torsional moments.

Unit – IV (08 hrs)

Gear Drives: Classification of gears, Selection of types of gears, Selection of materials for gears, Standard

gear tooth systems, Basic modes of gear tooth failures, Gear Lubrication Methods.

Spur Gears: Number of teeth and face width, Constructional details of gear wheel, Force analysis, Beam

strength (Lewis) equation, Velocity factor, Service factor, Load concentration factor, Effective load on gear,

Wear strength (Buckingham’s) equation, Estimation of module based on beam and wear strength, Estimation

of dynamic tooth load by velocity factor and Buckingham’s equation, Design of spur gears.

Helical Gears: Transverse and normal module, Virtual no of teeth, Force analysis, Beam and wear strengths,

Effective load on gear tooth, Estimation of dynamic load by velocity factor and Buckingham’s equation,

Design of helical gears.

Unit – V (08 hrs)

Rolling Contact Bearings:

Types of rolling contact Bearings, Static and dynamic load carrying capacities, Stribeck’s Equation,

Equivalent bearing load, Load-life relationship, Selection of bearing life, Selection of rolling contact

bearings from manufacturer’s catalogue, Design for cyclic loads, bearing with probability of survival other

than 90%

Lubrication and mounting of bearings, Preloading of rolling contact bearings, Types of failure in rolling

contact bearings – causes and remedies.

Selection of Taper roller bearings.

Unit – VI (08 hrs)

Belts, Rope and Chain Drives:

Belt drive:

Materials and construction of flat and V belts, geometric relationships for length of belt, power rating of

TE Mechanical (Sandwich) 2012 course

Page 7

University of Pune

belts, concept of slip & creep, initial tension, effect of centrifugal force, maximum power condition,

selection of flat and V belts from manufacturer’s catalogue, belt tensioning methods, relative advantages

and limitations of flat and V belts, construction and applications of timing belts.

Wire Ropes

Construction of wire ropes, lay of wire ropes, stresses in wire rope, selection of wire ropes.

Chain Drives

Types of power transmission chains, Geometry of Chain, Polygon effect of chain, Modes of failure for

chains, Lubrication of chains, Selection of roller chain from manufacturers catalogue.

Term-Work

Term work shall consist of:

1. One design project based on Design of a Two Stage Gear Box

2. The design project shall consist of two full imperial (A1) size sheets involving assembly

drawing with a part list and overall dimensions and drawings of individual components.

Manufacturing tolerances, surface finish symbols and geometric tolerances should be specified

wherever required. A design report giving all necessary calculations of the design of components

and assembly should be submitted in a separate file. Design data book shall be used wherever

necessary to achieve selection of standard components. Drawing Sheets should be plotted using any

CAD software.

2. Three assignments should be based on following topics:

i) Design of Flexible bush pin coupling

ii) Design of screw jack.

iii) Selection of Belt / Chain / Rope drive from manufacturer’s catalogue.

Text Books

1) Shigley J.E. and Mischke C.R., Mechanical Engineering Design, McGraw Hill Publication Co. Ltd.

2) Spotts M.F. and Shoup T.E., Design of Machine Elements, Prentice Hall International.

3) Bhandari V.B., Design of Machine Elements, Tata McGraw Hill Publication Co. Ltd.

4) Juvinal R.C., Fundamentals of Machine Components Design, John Wiley and Sons

Reference Books

1) Black P.H. and O. Eugene Adams, Machine Design, McGraw Hill Book Co. Inc.

2) Willium C. Orthwein, Machine Components Design, West Publishing Co. and Jaico Publications House.

3) Hall A.S., Holowenko A.R. and Laughlin H.G, Theory and Problems of Machine Design, Schaum‟s

Outline Series.

4) C.S.Sharma and Kamlesh Purohit, Design of Machine Elements, PHI Learing Pvt. Ltd.

5) D.K.Aggarwal & P.C.Sharma, Machine Design, S.K Kataria and Sons

6) P. C. Gope, Machine Design: Fundamentals and Applications, PHI Learing Pvt. Ltd.

7) Design Data - P.S.G. College of Technology, Coimbatore.

8) Bhandari, V. B. Machine Design data book, Tata McGraw Hill Publication Co. Ltd.

9) K. Mahadevan, K. Balveera Reddy, Design Data Handbook for Mechanical Engineers, CBS Publishers.

TE Mechanical (Sandwich) 2012 course

Page 8

University of Pune

T.E. Mechanical (Sandwich) - 2012 Course

MACHINE SHOP [302063]

Code Subject Teaching Scheme

(Weekly Load in Examination Scheme (Marks)

hrs)

Lect. Tut Pract. Theory TW PR OR Total

In End

Sem. Sem.

MACHINE

302063 SHOP -- -- 02 -- -- 25 -- -- 25

COURSE OBJECTIVES

1. To prepare the appropriate manufactory setup.

2. To select appropriate process parameters for machining component.

3. To understand the operational problems and suggest remedial solution for adopted manufacturing process.

COURSE OUTCOMES

Student will be able to design the process for manufacturing job as per need.

COURSE CONTENT

Each candidate is required to complete and submit the following

A) Jobs

1) Any one marketable assembly consisting of at least three components involving use of lathe, drilling,

milling, grinding and any additional machine tool or processes as per requirement .

2) Development and execution of one milling job on CNC machine.

B) Journal

a. Design and drawing of one jig / fixture for a component. (manual drafting)

b. Process planning sheets for job 1 and Part program details for job 2.

Note :-

Term work assessment will be based on job completed and journal write-ups.

Text Books:

1. S. K Hajra Choudhury , Elements of workshop technology – Vol. II,, Media Promoters And

Publishers, Mumbai

2. P. C. Sharma, Production Engineering, S. Chand Publication.

Reference Books

o P. N. Rao, CAD/CAM Principles and Applications, McGraw Hill Education, Third Edition.

TE Mechanical (Sandwich) 2012 course

Page 9

University of Pune

TE-Mechanical (Sandwich) Engineering 2012 Course

Industrial In-plant Training [302064]

Code Subject Teaching Scheme

(Weekly Load in Examination Scheme (Marks)

hrs)

Lect. Tut Pract. Theory TW PR OR Total

In End

Sem. Sem.

Industrial In-

302064 - - 150 - 100 250

plant Training -

Notes:-

1. Teaching load - One contact hour per student per week.

2. Duration of Industrial In-plant training: 6 months.

COURSE OBJECTIVES

1. Student will get the exposure to the industry.

2. Understand day to day working of the industry.

3. To understand design, manufacturing processes, quality control and testing of products.

4. Student will undertake small assignments.

5. To interact with various departments of industry during work.

COURSE OUTCOMES

1. Student will understand industrial environment and practices.

2. Work on a specific project and complete it in given stipulated time period.

3. Able to understand the importance of quality of product and human safety.

4. Able to relate theory and practical for while dealing with industrial problem.

Students are expected to learn followings during their Industrial In-Plant Training. He or She shall be given

training in Large or Medium size manufacturing unit in various departments.

1. Orientation: Types of Industry, Industrial Environment, Industrial Psychology, Industrial

Management, Industrial Relations, Government Policies, Associated organizations and their role.

Company profile, Organizational structure of the company, Organizational behavior, Scale and type

of production, Types of products.

2. Departments in Manufacturing Industries: R & D (research and development), quality control,

shipping, distribution, production, purchasing, recruiting or human resources, operations, finance,

accounting, accounts payable, accounts receivable, billing, sales, marketing, advertising,

maintenance, etc., There could be additional departments within other departments depending on the

size and type of business.

3. Industrial Design and Drawing Practice: Design and Drawing Standards, Study of mechanical

components and component design such as gears, gear boxes, chain and belt drives, couplings, shaft,

keys, bearings, brackets, bolted and welded connections. Sub-assembly and assembly drawings.

Simple assignments based on the above items.

TE Mechanical (Sandwich) 2012 course

Page 10

University of Pune

4. Manufacturing processes:

To understand manufacturing concepts applied in industry. Study of material requirements, material

standards. Heat treatments applied to products.

5. Machine Tools:

Machine tool classifications, types of machines tool, special machine tools, machine tool design,

CNC controls, Programming languages and codes, Machine tool maintenance.

6. Manufacturing Automation:

Automation level, types of automation, application of hydraulics and pneumatics, mechatronics

control, use of sensors and feedback in control, robotic control over the process.

7. Material Handling:

Unit load concept, types of material handling equipments, selection of Material handling equipment,

design requirement of material handling system.

8. Measurement and Quality Control:

Precision measurement, Control chart, Statistical process control, Process capability.

9. Processes and Operation Planning:

Production planning and control, Order preparation, Material planning, Process planning, Route

sheets, documents in process planning, production control- dispatching, follow-up.

10. Machines, Personal and Plant safety.

Safety rules in organization, posters exhibits and publicity, fire prevention and protection, Health

and sanitation, Protective wearing apparel, Safety signs, Industrial safety standards.

Operational Guidelines:

Institute and Industry will prepare detail training program at the beginning of the training, covering

as much as possible from above mentioned topics.

It is expected that students get exposure to all departments in industry.

The student shall be asked to do simple assignments in various departments where he or she is

undergoing training.

Institute will assign a supervisor faculty to each student.

Supervisor will guide and monitor student’s training by visiting the industry once a month.

Student will maintain logbook during the training.

Term Work:

Term Work shall consist of a comprehensive report based on his or her observations, training received and

assignments (at least three) completed during six months of training. The report shall also include drawings,

figures, process sheets, machine and product specifications and any other relevant details. The report should

include a certificate of successful completion of training and attendance from concerned industry.

Examination:

Oral will be based on Term Work completed during training.

Oral Examination shall be conducted by appointing one Internal Examiner and one External Examiner from

industry.

TE Mechanical (Sandwich) 2012 course

Page 11

University of Pune

T.E. Mechanical (sandwich) - 2012 Course

Seminar [302065]

Teaching Scheme

Examination Scheme (Marks)

(Weekly Load in hrs)

Code Subject Lect. Tut Pract. Theory TW PR OR Total

In End

Sem. Sem.

302065 Seminar - - - - - 50 50

The Seminar topic must be related to one of the following

1. Mechanical Engineering

2. Interdisciplinary subjects

3. Recent trends in Engineering

INSTRUCTIONS FOR SEMINAR REPORT WRITING

It is important that the procedures listed below be carefully followed by all the students.

Prepare 3 COPIES of your Seminar report.

1. Limit your seminar report to preferably 20 – 25 pages

2. Header For e.g. University of Pune

3. The footer For e.g. Mechanical Engineering

Institute Name, Mechanical Engineering Times New Roman 10 pt. and centrally aligned.

4. Page number as second line of footer, Times New Roman 10 Pt, centrally aligned

5. Print the report using

a) Letter quality computer printing.

b) The main part of report should be Times New Roman 12 pt. and justified.

c) Use 1.5 line spacing.

d) Entire report shall be one chapter. No chapters for Seminar report.

6. Use the paper size 8.5’’ × 11’’ or A4 (210 × 197 mm). Please follow the margins given below.

Margin Location Paper 8.5”× 11” Paper A4 (210 × 197 mm)

Top 1” 25.4 mm

Left 1.5” 37 mm

Bottom 1.25” 32 mm

Right 1” 25.4 mm

7. All paragraphs will be 1.5 line spaced with a one blank line between each paragraph. Each

paragraph will begin with without any indentation.

8. Section titles should be bold with 14 pt typed in all capital letters and should be left aligned.

9. Sub-Section headings should be aligning at the left with 12 pt, bold and Title Case (the first letter

of each word is to be capitalized).

10. Illustrations (charts, drawings, photographs, figures) are to be in the text. Use only illustrations

really pertinent to the text. Illustrations must be sharp, clear, black and white. Illustrations

downloaded from internet are not acceptable.

a) Illustrations should not be more than two per page. One could be ideal

b) Figure No. and Title at bottom with 12 pt

c) Legends below the title in 10 pt

d) Leave proper margin in all sides

TE Mechanical (Sandwich) 2012 course

Page 12

University of Pune

e) Illustrations as far as possible should not be in xerox form.

University of Pune

11. Photographs if any should of glossy prints

12. Equations if any, should be typed in text (it should not be copied as image)

13. Please use SI system of units. If students would like to add the equivalent in inch-pound (British)

units, they must be stated in parenthesis after the SI units. In case the final result comes out in any

other units (say due to empirical formula etc.) covert the unit to SI unit.

14. Please number the pages on the front side, centrally below the footer

15. References should be either in order as they appear in the report or in alphabetical order by last

name of first author

16. Symbols and notations if any should be included in nomenclature section only

17. Following will be the order of report

i) Cover page and Front page as per specimen on separate sheet

ii) Certificate from Institute as per specimen on separate sheet

iii) Acknowledgement

iv) List of Figures

v) List of Tables

vi) Nomenclature

vii) Contents

18. All section headings and subheadings should be numbered. For sections use numbers 1, 2, 3, ….

and for subheadings 1.1, 1.2, …. etc and section subheadings 2.1.1, 2.1.2, …. etc.

19. References should be given in the body of the text and well spread. No verbatim copy or

excessive text from only one or two references. If figures and tables are taken from any reference

then indicate source of it. Please follow the following procedure for references

Reference Books

Collier, G. J. and Thome, J. R., “Convective boiling and condensation”, 3rd ed., Oxford University

Press, UK, 1996, pp. 110 – 112.

Papers from Journal or Transactions

Jung, D. S. and Radermacher, R., “Transport properties and surface tension of pure and mixed

refrigerants”, ASHRAE Trans, 1991, 97 (1), pp. 90 – 98.

Bansal, P. K., Rupasinghe, A. S. and Jain, A. S., “An empirical correction for sizing capillary

tubes”, Int. Journal of Refrigeration, 1996, 19 (8), pp.497 – 505.

Papers from Conference Proceedings

Colbourne, D. and Ritter, T. J., “Quantitative assessment of flammable refrigerants in room air

conditioners”, Proc. of the Sixteenth International Compressor Engineering Conference and Ninth

International Refrigeration and Air Conditioning Conference, Purdue University, West Lafayette,

Indiana, USA, 2002, pp. 34 – 40.

Reports, Handbooks etc.

United Nations Environmental Programme, Report of the Refrigeration, Air Conditioning and

Heat Pumps, Technical Option Committee, 2002, Assessment - 2002.

ASHRAE Handbook: Refrigeration, 1994 (Chapter 44)

Patent

Patent no, Country (in parenthesis), date of application, title, year.

Internet

www.(Site) [Give full length URL]

TE Mechanical (Sandwich) 2012 course

Page 13

University of Pune

A Seminar on (TNR, 16pt, centrally aligned)

Title (TNR, 27pt, Bold, Centrally Aligned,Title Case)

By (TNR, 16pt, Centrally Aligned)

Mr. Student’s Name (TNR, 16pt, Centrally Aligned)

Guided by (TNR, 16pt, Centrally Aligned)

Guide’s Name (TNR, 16pt, Centrally Aligned)

Institute

Logo

Department of Mechanical Engineering

Name of the Institute

[2011-12](TNR, 22pt, Title Case Centrally Aligned)

TE Mechanical (Sandwich) 2012 course

Page 14

University of Pune

Name of the Institute

Institute

Logo

CERTIFICATE

This is to certify that Mr/Miss. ............, has successfully completed the Seminar

work entitled “Performance analysis of……..” under my supervision, in the partial

fulfillment of Bachelor of Engineering - Mechanical Engineering, by University of

Pune.

Date :

Place :

__________________ __________________

Guide Head Department

Name: Name:

__________________

Seal Principal,

Name

TE Mechanical (Sandwich) 2012 course

Page 15

University of Pune

T.E. Mechanical (Sandwich) - 2012 Course

Materials and Manufacturing Engineering [302066]

Code Subject Teaching Scheme

(Weekly Load in hrs) Examination Scheme (Marks)

Lect. Tut Pract. Theory TW PR OR Total

In Sem. End Sem.

Materials and

Self 100

302066 Manufacturing -- --- --- 25 -- --- 125

Study (3 Hrs.)

Engineering

COURSE OBJECTIVES

1. The student shall understand different materials and their properties.

2. Student shall learn various advanced materials used in actual industrial practice.

3. The student shall able to undergo with various powder metallurgy processes.

4. The student will be able to carry out proper selection of Material in actual practice.

5. The student will be able to learn CNC machines.

6. Student shall be able to understand advanced manufacturing processes-Broaching, Gear & Thread

Manufacturing.

COURSE OUTCOMES

1. The student will understand advanced materials and manufacturing processes and its use in

industry.

2. The student will display professional skills in selecting proper materials at work.

3. The student will develop a good product by using proper manufacturing process.

Unit – I (08 hrs)

Study of Non-Metallic Materials:

Introduction & Classification of Materials, Definition, Classification & characteristics of polymers, Types of

polymerization, Polymer processing, Elastomers, properties and applications of engineering polymers.

Properties, processing and applications of ceramic materials (WC, TIC, Al2O3), cermets. Composite

materials, Classification & Types of composite, Properties & applications, Metal matrix composite, Ceramic

matrix composite, Fiber Reinforced plastic , Numerical based on composite (isostress & isostrain

conditions).

Unit – II (08 hrs)

Introduction to Advanced Materials:

Classification of biomaterials - Comparison & properties of some common biomaterials, Metallic, Ceramic

and Polymeric implant materials, Introduction to bio sensors. Basic concepts of Nano science and

technology, Properties and technological advantages of Nano materials, Carbon Nanotubes and applications.

Magnetic materials: Soft & Hard Ferrites, Dielectric materials: Piezo electric and ferro electric materials and

their applications, superconductors. Modern Materials for high, low temperatures and Cryogenic

applications Smart materials, Shape memory alloys.

TE Mechanical (Sandwich) 2012 course

Page 16

University of Pune

Unit – III (08 hrs)

Corrosion and Its Prevention:

Mechanism of corrosion, Classification of corrosion: General, Pitting, Crevice, Intergranular, Stress

corrosion & cracking. Velocity related corrosion: Erosion, Impingement, and Cavitations corrosion.

Corrosion fatigue, Hydrogen Blistering. High temperature corrosion. Corrosion prevention methods:

Inhibitors, Internal & External coating, Cathodic & Anodic protection, Use of special alloys, Control over

temperature & velocity, Dehydration, Improvement in design/ changes in design to prevent or control

corrosion

Unit – IV (08 hrs)

Powder Metallurgy Processes:

Basic steps of powder metallurgy process, powder manufacturing, characteristics of metal powders,

Conditioning of metal powders (Screening, Blending & mixing, annealing), Compacting (cold compaction,

hot compaction, Isostatic compaction & powder rolling) Pre-sintering & sintering secondary operations

Advantages, limitations and applications of powder metallurgy. Production of typical P/M components (with

flow charts), self lubricated bearing, cemented carbides, cermets, refractory metals, electrical contact

materials, friction materials, and diamond impregnated tools.

Unit – V (08 hrs)

CNC machines:

Introduction and working of NC, CNC, DNC machines. CNC axis and drives, Introduction to Automatic

Tool Changer and Automatic pallet changer. Principles and block diagram of Machining centers, advantages

and applications. CNC programming for simple parts on Lathe and Drilling machines. Introduction to FMS.

Unit – VI (08 hrs)

Broaching, Gear & Thread Manufacturing:

Broaching: Introduction to broaching, broach tool geometry, Types of broaching machines and operations.

Numerical on broach design

Gear Manufacturing: Different Gear manufacturing Methods: Gear hobbing, Gear shaping, Gear shaving.

Gearfinishing processes: Gear grinding and lapping.

Thread Manufacturing: Thread cutting, chasing and dies, milling, rolling, Thread finishing processes:

grinding and lapping.

Term-Work

Term work shall consist of following assignment.(Any six)

1. Study of different non-metallic materials used in industrial applications.

2. Selection of non-metallic materials for different applications.

3. A report on nano materials and their applications in mechanical engineering.

4. Study of advanced materials and their application in manufacturing industry.

5. Assignment on corrosion and its prevention.

6. Assignment on conditioning of metal powders.

7. Report of production of powder metallurgy components.

8. Case study report on working of CNC machines.

9. Assignment on CNC programming.

10. Assignment on study of gear manufacturing methods.

Text Books

1. V.D. Kodgire and S.V. Kodgire, Material Science and Metallurgy for Engineers, EverestPublishing

House, Pune, 24th edition, 2008.

2. P. C. Sharma, Production Engineering, Khanna Publishers.

TE Mechanical (Sandwich) 2012 course

Page 17

University of Pune

Reference Books

1. W.D. Callister, Jr., Materials Science and Engineering: An Introduction, John Wiley and Sons,

5thedition, 2001

2. Mechanical Metallurgy, Dieter, G.E., McGraw-Hill, 1988.

3. P. N. Rao, Manufacturing Technology Vol I & II Tata McGraw Hill Publishers

TE Mechanical (Sandwich) 2012 course

Page 18

University of Pune

T.E. Mechanical (Sandwich) - 2012 Course

Industrial Engineering and Production Management [302067]

Code Subject Teaching Scheme

Examination Scheme (Marks)

(Weekly Load in hrs)

Lect. Tut Pract. Theory TW PR OR Total

In Sem. End Sem.

Industrial

Engineering and Self 100

302067 -- --- --- 25 -- --- 125

Production Study (3 Hrs.)

Management

COURSE OBJECTIVES

1. The student shall understand Concept of Industrial Engineering and its role in production

management.

2. Student shall learn various Industrial Engineering techniques implemented in relation to production

management in actual industrial practice.

3. The student shall able to undergo with various world class techniques in practice.

4. The student will be able to carry out proper selection of process for production in actual practice in

industry

5. To develop overall personality by exposing them to soft skills and professional ethics programs

6. Student shall be able to understand industrial psychology.

COURSE OUTCOMES

1. The student will understand Concept of Industrial engineering and its role in production management.

2. The student will be good team member and project leaders to carry out projects in companies.

3. The student will display professional ethics while dealing with their colleagues at work.

4. The student will develop good inter personnel skills to deal with their superiors, peers as well as juniors.

Unit – I (8 hrs)

Industrial Engineering: History, development, definition, functions and applications of Industrial

Engineering, contribution of F.W Taylor, Gilberth, Gantt and Maynard to industrial engineering, motivation

and control, Maslow’s hierarchy of needs,

Management concept: Basic concepts and functions of management, Evolution of management thoughts,

various approaches to the management

Unit – II (8 hrs)

Method Study: Introduction, steps, tools and techniques used in method study, Recording of facts, Process

chart, symbols, flow diagrams, Two hand chart, Multiple activity chart,5W&1H , use of motion pictures and

analysis ,critical examination, selection of job, maintenance of proposed method, SIMO charts, importance

of ergonomics in industry.

TE Mechanical (Sandwich) 2012 course

Page 19

University of Pune

Work Measurement : Time Study: Aim and objectives, use of work measurement data, techniques of

work measurement, Time study procedures, Time study forms, Performance rating, allowances and types,

calculation of standard time. Work Sampling ,Procedure.

Unit – III (8 hrs)

The Production Function: Concept of production, Productivity, total productivity, organization of

production, responsibilities of production manager, qualities of production manager, organization structure

of engineering company.

Plant layout and Material handling: Location- importance and factor affecting location, single and muti

facility location problems, Layout-Need ,importance, objectives and principles of good plant lay out, types

of layouts and applications, Material Handling- Objectives ,functions, principles of material handling, types

of material handling equipment and selection.

Unit – IV (8 hrs)

Production planning and control: Functions of PPC, work order preparation material planning, Bill of

materials, Material requirement planning (MRP), Moving average method, Exponential smoothing, capacity

planning

Inventory control- objectives, basic EOQ, Safety stock inventory control systems, Numerical treatment),

Cost associated with inventory, selective control of inventory ABC,FMS,VED.

Unit – V (8 hrs)

Process Planning

Introduction- Production Engineering, Role of Product Engineering department, Phases of process planning,

process planning principles and process sheet design, factors affecting process design, general

considerations in selecting machining methods, planning the sequence of machining operations.

Project Scheduling with CPM and PERT- Objectives, Basic concepts in network, Programme evaluation

and review Techniques,Time cost trade off( crashing), Comparison between CPM and PERT

Unit – VI (8 hrs)

Loading & Scheduling

Concept of loading & scheduling, master production schedule, basic sequencing and scheduling techniques,

dispatching rules, expediting and evaluating the production plans, design of production planning & control

system for Intermittent & continuous production

Supply chain management- Managing supply chain cycle inventory. Uncertainty in the supply chain –

Analyzing impact of supply chain redesign on the Pricing and Revenue Management. Computerized

production management system, just in time and Lean manufacturing, Agile & reconfigurable

manufacturing, green production, energy conservation & energy audit.

World class techniques

5’S, TPM, SMED, Muda (Waste) elimination, Kaizen, Concurrent Engineering, JIT, Kanban, Poka Yoke.

TE Mechanical (Sandwich) 2012 course

Page 20

University of Pune

Term-Work

Term work shall consist of following assignment. (Any six)

1. Preparation of organization structure of a company indicating hierarchy of operation.

2. A report on plant location indicating economic survey of the site selection.

3. Detail schematic layout of plant indicating all facilities.

4. Assignment on unit load concept of material handling and criteria for selection of material handling

equipment.

5. Case study on maintenance schedule of plant.

6. Report of Method study using charting techniques

7. Assignment on study of Statistical Process control - control charts

8. Case study report using world class technique.

Text Books

1. Prof L C Jhamb, ”Production(Operations) Management, Everest Publishing house

2. Mukherjee & Kachwala, “Operations Management & Productivity Tech”, Prentice

Hall of India

3. M. Mahajan, “Industrial Engineering & Production Management”, Dhanpat Rai and

Company

4. P. Rama Murthy, “Production & Operation Management”, New Age Internation (P) Ltd.

5. Banga ans Sharma,”Industrial Organisation and Engineering Economics”,Khanna Publishers.

6. Adam EE & RJ Ebert, “Production and operation management:, Prentice Hall

7. Riggs. J. L., “Production system, planning, analysis and control”, John Weily and sons

8. James Dilworth, “Production and operation management”, McGraw Hill Book Company, New

York.

9. Martand Telsang, “Industrial Engineering and Production Management”, S Chand & Co, New Delhi

10. Janat Shah, Supply Chain Management – Text and Cases, Pearson Education, 5th edition, 2012.

11. Sunil Chopra and Peter Meindl, Supply Chain Management-Strategy Planning and

Operation,PHI Learning / Pearson Education, 5th edition, 201

Reference Books

1 Buffa. E.S., “Modern production and Operation Management”, Willey, New

Delhi.ISBN9971511630

2 Barry Shore, “Operation Management”, McGraw Hill Book Company, New York.

3. Samuel Elion, “Production planning and control”.ISBN8185027099.

4. Joseph Monks, “Operation Management Theory and Problems”, McGraw Hill Book

Company, New York.ISBN007100579X.

5. Koontz & Weihrich, “Essentials of Management by”, TMH. ISBN007062030X.

6. F. L. Francis, J. A. White, L. F. McGinnis, “Facilities Layout and Location”, Prentice

Hall of India Pvt. Ltd., ISBN 81-203-1460-3. 8120314603.

7. Richard Muther, “Systematic Layout Planning

8. Paneerselvam R., “Production and Operations Management”, Prentice Hall India 2005.

TE Mechanical (Sandwich) 2012 course

Page 21

You might also like

- Lookingbill and Marks Principles of DermatologyDocument5 pagesLookingbill and Marks Principles of DermatologybillyNo ratings yet

- C12 Engine: Electrical Circuit DiagramDocument8 pagesC12 Engine: Electrical Circuit DiagramPhil B.100% (1)

- Maintenance Process (Breakdown, Preventive Maintenance)Document3 pagesMaintenance Process (Breakdown, Preventive Maintenance)Safety Dept100% (1)

- Checklist For Full Body Safety HarnessDocument1 pageChecklist For Full Body Safety HarnessSafety DeptNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Oxy-Fuel Gas WeldingDocument2 pages(Your Business Name Here) - Safe Work Procedure Oxy-Fuel Gas WeldingSafety DeptNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Metal LatheDocument1 page(Your Business Name Here) - Safe Work Procedure Metal LatheSafety DeptNo ratings yet

- Pedestal Grinder: DO NOT Use This Machine Unless A Teacher Has Instructed You in Its SafeDocument1 pagePedestal Grinder: DO NOT Use This Machine Unless A Teacher Has Instructed You in Its SafeSafety DeptNo ratings yet

- FE Syllabus KJSCE 2014 15 Feb 16 (1) 11032016Document54 pagesFE Syllabus KJSCE 2014 15 Feb 16 (1) 11032016Shivangi ThakkerNo ratings yet

- TE - Mechanical Engineering (2019 Course)Document59 pagesTE - Mechanical Engineering (2019 Course)Ganesh DhumalNo ratings yet

- TE - Mechanical Engineering (Sandwich) (2019 Course) - 03122021-1Document47 pagesTE - Mechanical Engineering (Sandwich) (2019 Course) - 03122021-1DarrkeaageNo ratings yet

- University of Pune: T.E. Automobile Engineering 2012 CourseDocument28 pagesUniversity of Pune: T.E. Automobile Engineering 2012 Courselimboo timbooNo ratings yet

- SE-Mechanical SW (Sandwich) (2019 Course) - 27.012021Document39 pagesSE-Mechanical SW (Sandwich) (2019 Course) - 27.012021Gopal LoharNo ratings yet

- New Structure For TE and BE - 29!3!2014 - SE - TEDocument2 pagesNew Structure For TE and BE - 29!3!2014 - SE - TEvitthalmech8687No ratings yet

- TE MECH. Syllabus 2015 Course-3!4!17 PDFDocument64 pagesTE MECH. Syllabus 2015 Course-3!4!17 PDFSudhanshu TiwariNo ratings yet

- SE To BE Mechanical Engineering CBCGS 2016Document184 pagesSE To BE Mechanical Engineering CBCGS 2016Naresh Gurajarapu ChinnaNo ratings yet

- Mechanical Engineering SyllabusDocument171 pagesMechanical Engineering SyllabusMesprit BgmiNo ratings yet

- SE-Mechanical CBCGS SyllabusDocument40 pagesSE-Mechanical CBCGS SyllabusmopoNo ratings yet

- Vdocuments - MX - Curriculum of Civil EngineeringDocument171 pagesVdocuments - MX - Curriculum of Civil EngineeringandersonvallejosfloresNo ratings yet

- SE CIVIL SYLLABUS - 2019 Course FinalDocument46 pagesSE CIVIL SYLLABUS - 2019 Course Finalvijay9481No ratings yet

- First-Year-Engineering Mumbai PDFDocument39 pagesFirst-Year-Engineering Mumbai PDFsiddharathNo ratings yet

- All - Semesters - Modules - Computer Engineering DJ SanghviDocument246 pagesAll - Semesters - Modules - Computer Engineering DJ SanghviDivyam ShethNo ratings yet

- First Yr MS - I-Scheme DraftDocument98 pagesFirst Yr MS - I-Scheme DraftSamir GedamNo ratings yet

- Final SPPU - Mech - Structure - 29.03.2016Document6 pagesFinal SPPU - Mech - Structure - 29.03.2016vitthalmech8687No ratings yet

- Savitribai Phule Pune University: Teaching SchemeDocument4 pagesSavitribai Phule Pune University: Teaching Schemesandeshs4No ratings yet

- SE To BE Production Engineering CBCGS 2016Document152 pagesSE To BE Production Engineering CBCGS 2016trupti rokadeNo ratings yet

- Savitribai Phule Pune University: S.E. Mechanical and Automobile Engineering 2015 CourseDocument958 pagesSavitribai Phule Pune University: S.E. Mechanical and Automobile Engineering 2015 CourseSurya RNo ratings yet

- SE Mech (2015 Course) - 25-7-16Document55 pagesSE Mech (2015 Course) - 25-7-16Ashish KambleNo ratings yet

- TE Mechanical Engineering (2019 Course) 27 - Savitribai Phule Pune University Faculty of Science - Studocu PDFDocument1 pageTE Mechanical Engineering (2019 Course) 27 - Savitribai Phule Pune University Faculty of Science - Studocu PDFSarthak Joshi100% (1)

- SAES D.Voc (Production Technology)Document6 pagesSAES D.Voc (Production Technology)Abhishek GhoshNo ratings yet

- Second Year Mechanical Engineering Course: Scheme of Instruction and Examination Revised Course 2019-2020Document6 pagesSecond Year Mechanical Engineering Course: Scheme of Instruction and Examination Revised Course 2019-2020Abi DemNo ratings yet

- Syllabus S.E-Printing 2019-Course 20-05-2020 FinalDocument47 pagesSyllabus S.E-Printing 2019-Course 20-05-2020 Finalmani.kanchana8882No ratings yet

- Mech PDFDocument78 pagesMech PDFmanyapandeyNo ratings yet

- B.E Printing - 2019 Pattern - SyllabusDocument64 pagesB.E Printing - 2019 Pattern - SyllabusRohit KumarNo ratings yet

- University of MumbaiDocument20 pagesUniversity of MumbaitrimohitNo ratings yet

- S Y B Tech Production Engg. SyllabusDocument30 pagesS Y B Tech Production Engg. SyllabusAmeya BandekarNo ratings yet

- BE (Mech Engg) 2nd Year Syllabus 2018-19-1 PDFDocument46 pagesBE (Mech Engg) 2nd Year Syllabus 2018-19-1 PDFPrahlad M PaiNo ratings yet

- 15 P 19 Curriculum CO Semester IDocument34 pages15 P 19 Curriculum CO Semester Ivayobo1203No ratings yet

- SE Civil Engg. 2019 Patt - 30.062020Document44 pagesSE Civil Engg. 2019 Patt - 30.062020Kalyani ingoleNo ratings yet

- 20180521162959-b e Mechanical3rdto8th2017-18 PDFDocument223 pages20180521162959-b e Mechanical3rdto8th2017-18 PDFMukul SenNo ratings yet

- Syllabus of B.E. (Electronics and Computer)Document46 pagesSyllabus of B.E. (Electronics and Computer)4th2001No ratings yet

- Wa0006Document65 pagesWa0006Anonymous pgBcXLNo ratings yet

- SE Electrical Engg. 2019 PattDocument47 pagesSE Electrical Engg. 2019 PattPrathameshNo ratings yet

- T.E (E&TC) - 2019 Course - 09.07.2021Document95 pagesT.E (E&TC) - 2019 Course - 09.07.2021ind.sudhirNo ratings yet

- Me-Ug-Scheme 3-8 PDFDocument7 pagesMe-Ug-Scheme 3-8 PDFManish Kumar SinghNo ratings yet

- T.E. Electrical EngineeringDocument26 pagesT.E. Electrical EngineeringRam DinNo ratings yet

- Fe 2014 Syllabus Mumbai UniversityDocument54 pagesFe 2014 Syllabus Mumbai UniversityAtul DwivediNo ratings yet

- Electronics Sem III IV C Scheme Syllabus 13062020Document76 pagesElectronics Sem III IV C Scheme Syllabus 13062020Keiran LeeNo ratings yet

- Honors - 3D - Printing - 2019 Course - 01122021Document10 pagesHonors - 3D - Printing - 2019 Course - 01122021omkar7No ratings yet

- 1 2 Sem 2017 18Document36 pages1 2 Sem 2017 18NishchalNo ratings yet

- Syllabusbtechcivil1213 PDFDocument100 pagesSyllabusbtechcivil1213 PDFneeraj dasNo ratings yet

- S-17 ME SyllabusDocument178 pagesS-17 ME SyllabusSuhail KhanNo ratings yet

- BE Syllabus of Mumbai Uni1Document8 pagesBE Syllabus of Mumbai Uni1Rajendra B PawarNo ratings yet

- Be Civil CBCGS 2019 Syllabus (Mumbai University)Document69 pagesBe Civil CBCGS 2019 Syllabus (Mumbai University)Atiq SayedNo ratings yet

- 16 P 19 Curriculum CO Semester IIDocument36 pages16 P 19 Curriculum CO Semester IIvayobo1203No ratings yet

- TE CivilDocument81 pagesTE Civilvijay9481100% (1)

- 012-T.Y B-Tech-Electrical-2016-17-ACAD PDFDocument51 pages012-T.Y B-Tech-Electrical-2016-17-ACAD PDFakshay khairnarNo ratings yet

- 4.25 ME Computer EnggDocument95 pages4.25 ME Computer Enggall2enjoyNo ratings yet

- SE SyllabusDocument76 pagesSE SyllabusRohan TiwariNo ratings yet

- B.E Mechanical Engg.Document110 pagesB.E Mechanical Engg.rNo ratings yet

- Sy Btech Cbcs 2019-20 SyllabusDocument52 pagesSy Btech Cbcs 2019-20 SyllabusSachin BoleNo ratings yet

- Annexure - A1 (Mechenical Engg - )Document7 pagesAnnexure - A1 (Mechenical Engg - )Anonymous CXaZaM4No ratings yet

- BTech Mechanical Engg StructureDocument12 pagesBTech Mechanical Engg StructureSachin BoleNo ratings yet

- First Year Curriculum Wef 2017-2018Document28 pagesFirst Year Curriculum Wef 2017-2018Yogesh ChaudhariNo ratings yet

- Honors - Systems Engineering - 2019 Course - 01122021Document9 pagesHonors - Systems Engineering - 2019 Course - 01122021omkar7No ratings yet

- SE E - TC Syllabus 2019 Pattern - RemovedDocument37 pagesSE E - TC Syllabus 2019 Pattern - Removedlaxmimane245No ratings yet

- ME I Scheme 1st SEMDocument125 pagesME I Scheme 1st SEMShivNo ratings yet

- Master List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoDocument6 pagesMaster List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoSafety DeptNo ratings yet

- 8.3.3.3 - Master List of Special CharacteristicsDocument2 pages8.3.3.3 - Master List of Special CharacteristicsSafety DeptNo ratings yet

- Employee List For LOTO ProcedureDocument7 pagesEmployee List For LOTO ProcedureSafety DeptNo ratings yet

- 8.3.3.2 - Process Design Input & Verification SheetDocument3 pages8.3.3.2 - Process Design Input & Verification SheetSafety DeptNo ratings yet

- List of Internal Auditors & Competency - Qms Auditor: For - QMS Audit (ISO 9001:2015)Document1 pageList of Internal Auditors & Competency - Qms Auditor: For - QMS Audit (ISO 9001:2015)Safety DeptNo ratings yet

- 7.4 - Communication MatrixDocument1 page7.4 - Communication MatrixSafety Dept100% (2)

- Ehs Monthwise Theme PlanDocument6 pagesEhs Monthwise Theme PlanSafety DeptNo ratings yet

- DASH BOARD For PendingsDocument3 pagesDASH BOARD For PendingsSafety DeptNo ratings yet

- 6.1 Risk - Opportunity AnalysisDocument4 pages6.1 Risk - Opportunity AnalysisSafety DeptNo ratings yet

- Crane Mounted On Truck Inspection Report MH 12 FC8311Document12 pagesCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNo ratings yet

- 4.2 - Needs and Expectation With Risk AnalysisDocument3 pages4.2 - Needs and Expectation With Risk AnalysisSafety Dept50% (2)

- POSHS Metal Industries PVT - LTDDocument12 pagesPOSHS Metal Industries PVT - LTDSafety DeptNo ratings yet

- Vendor Details Plant Details External Audit Details: Vendor /factory Reg NoDocument18 pagesVendor Details Plant Details External Audit Details: Vendor /factory Reg NoSafety DeptNo ratings yet

- Checklist of Gas Cutting SetDocument3 pagesChecklist of Gas Cutting SetSafety DeptNo ratings yet

- POSHS Metal Industries PVT - LTD: Checklist of Gas Cutting SetDocument1 pagePOSHS Metal Industries PVT - LTD: Checklist of Gas Cutting SetSafety DeptNo ratings yet

- List of Barricades:: Sr. No. Section Line No DescriptionDocument4 pagesList of Barricades:: Sr. No. Section Line No DescriptionSafety DeptNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Manual Metal Arc WelderDocument1 page(Your Business Name Here) - Safe Work Procedure Manual Metal Arc WelderSafety DeptNo ratings yet

- MetallatheprocedureDocument1 pageMetallatheprocedureSafety DeptNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Bench GrinderDocument2 pages(Your Business Name Here) - Safe Work Procedure Bench GrinderSafety DeptNo ratings yet

- Oxy - Fuel Gas Welding: Safe Use and Operation and Has Given PermissionDocument2 pagesOxy - Fuel Gas Welding: Safe Use and Operation and Has Given PermissionSafety DeptNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Drill PressDocument2 pages(Your Business Name Here) - Safe Work Procedure Drill PressSafety DeptNo ratings yet

- Safe Operating Procedures 15 Oxy Acetylene Sets Cutting and WeldingDocument2 pagesSafe Operating Procedures 15 Oxy Acetylene Sets Cutting and WeldingSafety Dept100% (1)

- Cortal V Inaki A Larrazabal EnterprisesDocument11 pagesCortal V Inaki A Larrazabal Enterprisesmarie janNo ratings yet

- South Sudan Early Recovery and Humanitarian Project (Sserhp)Document57 pagesSouth Sudan Early Recovery and Humanitarian Project (Sserhp)kashiNo ratings yet

- Nicole LabayneDocument3 pagesNicole LabaynePatrick GoNo ratings yet

- Surveying For Highways: Eng. Suneth Thushara Highwy Design Division RDADocument31 pagesSurveying For Highways: Eng. Suneth Thushara Highwy Design Division RDAzeshan habibNo ratings yet

- TM 5-277 Fixed Steel Panel Bridge Bailey TypeDocument121 pagesTM 5-277 Fixed Steel Panel Bridge Bailey TypeAdvocate100% (2)

- Encyclopedia of Chinese PantheonDocument200 pagesEncyclopedia of Chinese PantheonKula100% (14)

- Formal, Informal LettersDocument2 pagesFormal, Informal LettersRodica StoianNo ratings yet

- FRB13089887411Document4 pagesFRB13089887411MAHA KAALNo ratings yet

- Colour Magazine - London 1Document103 pagesColour Magazine - London 1iccang arsenal100% (1)

- Karlan Microeconomics 2ce - Ch. 13Document24 pagesKarlan Microeconomics 2ce - Ch. 13Gurnoor KaurNo ratings yet

- Vijaya Bank ChanchalDocument2 pagesVijaya Bank ChanchalShubham sharmaNo ratings yet

- Sibulo Vs Toledo MupasDocument5 pagesSibulo Vs Toledo Mupas1222No ratings yet

- Verbal Communic-WPS OfficeDocument4 pagesVerbal Communic-WPS Officechandy RendajeNo ratings yet

- Accy 211 - Week 8 Tut HWDocument2 pagesAccy 211 - Week 8 Tut HWIsaac ElhageNo ratings yet

- List of Things in The Kitchen Vocabulary PDFDocument1 pageList of Things in The Kitchen Vocabulary PDFStefan JosephNo ratings yet

- TENSE CHART (Present Simple Vs Present Continuous)Document1 pageTENSE CHART (Present Simple Vs Present Continuous)Fmga GaNo ratings yet

- Vocabulary & Grammar Test Unit 6 Test ADocument4 pagesVocabulary & Grammar Test Unit 6 Test AStjepan RasicNo ratings yet

- Dip One GoroDocument8 pagesDip One GoroanakayamNo ratings yet

- Global AI Governance InitiativeDocument6 pagesGlobal AI Governance InitiativerebvNo ratings yet

- Business Law ModuleDocument177 pagesBusiness Law ModulePatricia Jiti100% (1)

- Unit - V: PowerDocument32 pagesUnit - V: PowerVaira PerumalNo ratings yet

- Case Presentation HydrocephalusDocument48 pagesCase Presentation HydrocephalusSu Osman50% (2)

- Digital Literacy in The 21st CenturyDocument27 pagesDigital Literacy in The 21st CenturyMary Ann Dela CruzNo ratings yet

- 2022-2 Spindle MultiphyicsDocument81 pages2022-2 Spindle Multiphyics潘季宏No ratings yet

- What Is Chlorinated Polyvinyl Chloride (CPVC) - CorzanDocument8 pagesWhat Is Chlorinated Polyvinyl Chloride (CPVC) - CorzanmrpalmistNo ratings yet

- Cancer Latest NewsDocument10 pagesCancer Latest NewsREFINERY ENGINEERINGNo ratings yet

- Multilocularis) - The Oncosphere Develops Into A Multi-ChamberedDocument2 pagesMultilocularis) - The Oncosphere Develops Into A Multi-Chamberedzoology qauNo ratings yet

- Asbasjsm College of Pharmacy BelaDocument23 pagesAsbasjsm College of Pharmacy Belaimrujlaskar111No ratings yet