Professional Documents

Culture Documents

Splices, Development & Standard Hooks For Concrete Masonry Based On The 2009 & 2012 Ibc

Splices, Development & Standard Hooks For Concrete Masonry Based On The 2009 & 2012 Ibc

Uploaded by

Thilan SenarathneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Splices, Development & Standard Hooks For Concrete Masonry Based On The 2009 & 2012 Ibc

Splices, Development & Standard Hooks For Concrete Masonry Based On The 2009 & 2012 Ibc

Uploaded by

Thilan SenarathneCopyright:

Available Formats

An information series from the national authority on concrete masonry technology

SPLICES, DEVELOPMENT & STANDARD

HOOKS FOR CONCRETE MASONRY

BASED ON THE 2009 & 2012 IBC TEK 12-6A

Reinforcement & Connectors (2013)

INTRODUCTION SPLICES AND DEVELOPMENT LENGTH

Building codes include requirements for minimum rein- Minimum development lengths are necessary to adequately

forcement development lengths and splice lengths, as well as transfer stresses between reinforcement and the grout or mor-

requirements for standard hooks, to ensure the adequate transfer tar in which it is embedded. Splicing of reinforcement serves

of stresses between the reinforcement and the masonry. This a similar purpose: to adequately transfer stresses from one

TEK presents these requirements, based on the provisions of reinforcing bar to another.

both the 2012 and 2009 editions of the International Build- Reinforcement can be developed by embedment length,

ing Code (IBC) (refs. 1, 2). Masonry design in these codes is hook, or mechanical anchoring device. The development of

primarily based on Building Code Requirements for Masonry the reinforcing bars relies on mechanical interlock of the bar

Structures (MSJC) (refs. 3, 4). Differences between the MSJC deformations, hook, and/or anchor along with sufficient ma-

and IBC are noted in the text when they occur. sonry cover to prevent splitting of the masonry. Reinforcing

There are two main differences between the 2008 and 2011 bars may be spliced by lapping the reinforcement, by proprietary

editions of the MSJC that impact reinforcement development mechanical splices or by welding.

and splice lengths in the corresponding 2009 and 2012 editions The required length of lap or development is determined

of the IBC: according to the design procedure used (allowable stress design

1. under 2011 MSJC allowable stress design, the allowable or strength design). In addition, these detailing requirements

tensile stress, Fs, of Grade 60 steel was increased from have been frequently revised in recent years. As a result, the

24,000 psi (166 MPa) to 32,000 psi (221 MPa), and minimum lap and development lengths can vary considerably

2. the 2011 MSJC includes new lap splice length provisions from one code to the next as well as from one design method

for when confinement reinforcement is used at lap splices. to another.

TEK 12-4D (ref. 5) includes basic material requirements, The following sections present the requirements for both

corrosion protection and placement tolerances for reinforcement the 2009 IBC and 2012 IBC for both allowable stress and

used in concrete masonry construction. In addition, prestressing strength design.

steel is discussed in Post-Tensioned Concrete Masonry Wall

Construction, TEK 3-14 (ref. 6). 2009 IBC SPLICE & DEVELOPMENT

TEK 12-6, Splices, Development and Standard Hooks for REQUIREMENTS

Concrete Masonry (ref. 7), covers these requirements based

2009 IBC Allowable Stress Design

on the 2003 and 2006 editions of the IBC.

Development Length & Lap Splicing

While the 2008 MSJC includes an equation to determine

development and lap splice lengths, the 2009 IBC modifies

Related TEK: Keywords: allowable stress design, building codes, confinement rein-

3-14, 12-4D, 12-6 forcement, development, embedment, joint reinforcement, reinforcing bars,

reinforcing steel, splices, standard hooks, strength design, working stress

NCMA TEK 12-6A 1

the MSJC lap splice length. In accordance with the 2009 IBC, Alternatives to Lap Splicing

the minimum required lap length for spliced reinforcing bars Reinforcing bars can also be spliced by welding, mechanical

is determined using Equation 1 (see Table 1). splicing and in some cases end-bearing splicing. Reinforcing

ld = 0.002db fs (SI: ld = 0.29db fs), (Eqn. 1) bars larger than No. 9 (M#29) are required to be spliced using

but not less than 12 in. (305 mm) or 40db, whichever mechanical connectors.

is greater Welded splices require the bars to be butted or shortly

Further, in regions of flexure where the design tensile lapped and welded to develop in tension at least 125% of the

stresses in the reinforcement, fs, exceed 80% of the allowable specified yield strength of the bar. All welding is required to

steel tensile stress, Fs, the IBC requires that the required length conform to AWS D1.4 (ref. 8), and steel for welded splices

of lap determined by Equation 1 must be increased by 50%. must conform to ASTM A706 (ref. 9). In practice, however,

Alternatively, equivalent means of stress transfer to accomplish welding tends to be an expensive splicing option.

the same 50% increase is permitted. Where epoxy coated bars Mechanical splicing of reinforcement typically employs

are used, lap length is also required to be increased by 50% proprietary couplers specifically designed for this application.

but does not apply to the 12 in. (305 mm) minimum. Mechanical splices are required to have the bars connected to

Development length requirements for allowable stress develop in tension or compression, as required, at least 125%

design are determined in accordance with Equation 3 except of the specified yield strength of the bar.

that there is no maximum length limit of 72db. Reinforcing bars can also be spliced using end-bearing

When noncontact lap splices are used, the bars must be splices, but only in members containing closed ties, closed

spaced no farther apart than one-fifth the required length of stirrups or spirals for bars subject to compression only. End-

lap nor more than 8 in. (203 mm). bearing splices rely on the transmission of compressive stress

When using the allowable stress design method, develop- by bearing of square-cut ends held in concentric contact by a

ment of wires in tension is determined using Equation 2 (see suitable device. The bar ends are required to terminate in flat

Table 2). The development length of epoxy-coated wires is surfaces within 11/2 degrees of a right angle to the axis of the

increased 50% above the value determined using Equation 2 bars and be fitted within 3 degrees of full bearing after assembly.

but does not apply to the 6 in. (152 mm) minimum.

ld = 0.0015db fs (SI: ld = 0.22db fs), (Eqn. 2) 2009 IBC Strength Design

but not less than 6 in. (152 mm)

Development Length & Lap Splice Length

For development and lap splice length requirements, the

2009 IBC references the 2008 MSJC (see Equation 3 and Table

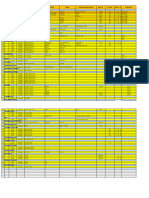

Table 1—2009 IBC Allowable Stress Design 3), but adds a maximum length limit of 72db.

Lap Splice Lengths (ref. 2) 0.13db 2 f yγ 1.5db 2 f yγ

Minimum lap splice length , in.

C =ld = SI: ld

K f 'm K f 'm , (Eqn. 3)

(mm), based on:

Bar size Allowable Stress Design A but not less than 12 in. (305 mm) and not more than

fs < 80%Fs fs = Fs 72db

No. 3 (M #10) 15 (381) 27 (686) where K = the least of the masonry cover, 5db and

No. 4 (M#13) 20 (508) 36 (914) the clear spacing between adjacent reinforcement, in.

No. 5 (M#16) 25 (635) 45 (1,143)

No. 6 (M#19) 30 (762) 54 (1,372) Table 2—2009 & 2012 IBC Allowable Stress

Design Development Lengths for Wire (refs. 1, 2)A

No. 7 (M#22) 35 (889) 63 (1,600)

No. 8 (M#25) 40 (1,016) 72 (1,829) Minimum development

length, in. (mm):

No. 9 (M#29)B 46 (1,168) 82 (2,083) Wire size

A

See Equation 1. Lap splice length not less than 12 W1.1 (11 gage, MW 7) 6 (152)

in. (305 mm) nor 40db. Minimum lap lengths may be W1.7 (9 gage, MW 11) 7 (178)

smaller in cases where fs < 0.8Fs. W2.1 (8 gage, MW 13) 8 (203)

B

Bars larger than No. 9 (M#29) are required to be

spliced by mechanical connectors. W2.8 (3/16 in., MW 17) 9 (229)

C

Lap splice lengths are to be increased by 50% when W4.9 (1/4 in., MW 32) 12 (305)

epoxy coated reinforcement is used.

D

Bar size not to exceed 1/8 nominal wall thickness nor

A

See Equation 2. fs = 30,000 psi (207 MPa). Lap

more than 1/4 the least dimension of the cell, course splice length not less than 6 in. (152 mm). Increase

or collar joint in which it is placed. development lengths by 50% when epoxy coated

wire is used, but this increase does not apply to the

6 in. (152 mm) minimum..

2 NCMA TEK 12-6A

(mm) (note that under the 2011 MSJC/2012 IBC the or special reinforced walls nor in special moment frames of

5db criteria is changed to 9db) masonry.

For Equation 3, the reinforcement size factor, γ, is taken

equal to 1.0 for No. 3 through No. 5 (M#10–M#16) reinforc- 2012 IBC SPLICE & DEVELOPMENT

ing bars; 1.3 for No. 6 and No. 7 (M#19, M#22) bars; and REQUIREMENTS

1.5 for No. 8 and No. 9 (M#25, M#29) bars. When epoxy

coated bars are used, the development length determined

Regarding development and splice lengths, two significant

by Equation 3 is required to be increased by 50%.

Bars spliced by noncontact lap splices must be spaced no changes were incorporated into the 2011 MSJC, which are

farther apart than one-fifth the required length of lap and no included by reference in the 2012 IBC:

more than 8 in. (203 mm). 1. in the 2011 MSJC, the allowable tensile stress, Fs, of Grade

60 steel when using allowable stress design was increased

Alternatives to Lap Splicing from 24,000 psi (166 MPa) to 32,000 psi (221 MPa), and

Mechanical splices are required to have the bars connected 2. the 2011 MSJC includes new provisions for confinement

to develop at least 125% of the specified yield strength of the reinforcement, for both allowable stress and strength design

bar in tension or compression, as required.

methods.

The IBC further stipulates that mechanical splices be

classified as Type 1 or 2 according to Section 21.2.6.1 of ACI

318, Building Code Requirements for Structural Concrete 2012 IBC Allowable Stress Design

and Commentary (ref. 10). Type 1 splices may not be used

within the plastic hinge zone nor within a beam-column joint Equation 1 is still applicable for use in the 2012 IBC but

of intermediate or special reinforced masonry shear walls or with the increase in Fs the splice lengths of fully stressed bars

special moment frames. Type 2 are permitted at any location. will increase by 33%. Significant reductions of splice lengths

A Type 2 splice is defined as a full mechanical splice that in low stress areas are achieved, however. The minimums of

develops in tension or compression, as required, at least 1.25fy

12 in. (305 mm) or 40db whichever is greater still apply as

of the bar. This requirement is intended to avoid a splice failure

well.

when the reinforcement is subjected to expected stress levels

in yielding regions. Type 1 splices are not required to satisfy The 2012 IBC allows the MSJC development length

the more stringent requirements for Type 2 splices, and so their equation (Equation 3) to be used as an alternate to the IBC

use is limited as noted above. equation (Equation 1). When using Equation 3 under the

Welded splices must have the bars butted and welded to 2012 IBC, however, the value of K is defined as the least

develop at least 125% of the bar's specified yield strength in of the masonry cover, 9db (vs. 5db in the 2009 IBC) and the

tension or compression, as required. Welded splices must use clear spacing between adjacent reinforcement.

ASTM A706 (ref. 9) steel reinforcement. Welded splices are Tabulated values are presented in Tables 4a through 4d.

not permitted to be used in plastic hinge zones of intermediate

Note, however, that there is no maximum length limit of 72db

Table 3—2009 IBC Strength Design Lap Splice Lengths (ref. 2)A

Minimum lap splice length, in. (mm), based on:

Bar in center of: K=

Bar size

6-in. CMU 8-in. CMU 10-in. CMU 12-in. CMU 11/2 in. (38 mm) 2 in. (51 mm)

No. 3 (M #10) 16 (406) 16 (406) 16 (406) 16 (406) 19 (483) 15 (381)

No. 4 (M#13) 21 (533) 21 (533) 21 (533) 21 (533) 34 (864) 26 (660)

No. 5 (M#16) 32 (813)D 26 (660) 26 (660) 26 (660) 45 (1,143) 40 (1,016)

No. 6 (M#19) 54 (1,372)D 43 (1,092) 40 (1.016) 40 (1,016) 54 (1,372) 54 (1,372)

No. 7 (M#22) NPB 60 (1,524) 46 (1,164) 46 (1,164) 63 (1,600) 63 (1,600)

No. 8 (M#25) NPB 72 (1,829) 71 (1,803) 61 (1,549) 72 (1,829) 72 (1,829)

No. 9 (M#29)C NPB NPB 82 (2,083) 74 (1,880) 82 (2,083) 82 (2,083)

A

See Equation 3. Based on fy = 60,000 psi (414 MPa) for Grade 60 steel and f'm = 1,500 psi (10.3 MPa).

B

Bar is too large for this wall; db exceeds 1/4 of the least clear dimension of the cell to be grouted, 1/8 of the nominal unit

thickness, or 4% of the cell area to be grouted. Dimensions are based on specified minimum dimensions for a two-core,

square core unit and take into account a cell taper of 1/4 in. (6.4 mm) and mortar protrusions not exceeding 1/2 in. (13 mm).

C

Strength design provisions do not permit the use of reinforcing bars larger than No. 9 (M#29).

D

Permitted only if all mortar fins are removed from the cell to be grouted. Not permitted if all mortar fins are not removed.

NCMA TEK 12-6A 3

for allowable stress design. nation of hooks and development length. These requirements

Tables 4a and 4b present minimum lap splice lengths for apply to both the 2009 and 2012 IBC, for both allowable stress

reinforcement placed in the center of the wall, for f'm= 1,500 and strength design. Table 5 lists minimum dimensions and

and 2,000 psi (10.3 and 13.7 MPa), respectively. equivalent embedment lengths for standard hooks of various

Tables 4c and 4d present minimum lap splice lengths for sizes. A combination of hook and development length must be

used when the equivalent embedment length of the hook, le, is

reinforcement offset in the wall, for f'm= 1,500 and 2,000 psi

less than the required minimum development length, ld. In this

(10.3 and 13.7 MPa), respectively.

case, development length equal to (ld - le) must be provided

Other requirements for lap, mechanical, welded and end-

in addition to the hook. This additional development length is

bearing splices are identical to those under the 2009 IBC, with measured from the start of the hook (point of tangency with

the exception of the new provisions for confinement reinforce- the main portion of the bar).

ment, presented below.

JOINT REINFORCEMENT SPLICES

2012 IBC Strength Design

Requirements for development length as well as lap, me- Joint reinforcement must have a minimum splice length of

chanical and welded splices are identical to those for allowable 6 in. (152 mm) to transfer shrinkage stresses. Slippage of the

stress design, and are presented in Tables 4a through 4d. deformed side wires is resisted by surface bond as well as by

mechanical anchorage of the embedded portions of the cross

2012 IBC Lap Splices With Confinement wires.

Reinforcement

The 2012 IBC, by reference to the 2011 MSJC, includes

new lap splice criteria where confinement reinforcement is

placed. The criteria are the same for both allowable stress

design and strength design. Grouted cells

The confinement reinforcement criteria allow a reduced

lap splice length when reinforcement is provided transverse

to lapped bars. Research has found that the transverse, or 8 in. (203 mm)

confinement, reinforcement increases the lap performance max. (typ.)

significantly, as long as there is at least one No. 3 (M#10) or

larger transverse bar placed within the last 8 in. (203 mm)

of each end of the lap (see Figure 1). Because of this effect, t (typ.)

calculated lap splice lengths are permitted to be reduced by a

confinement factor, ξ, determined using Equation 4:

ξ = 1 - 2.3Asc (SI: ξ = 1 - 11.59Asc ) (Eqn. 4)

db2.5 db2.5

22 in.

Footer

where: (559 mm)

2.3Asc clear

≤ 1, and

db2.5

19 in.

Asc < 0.35 in.2 (226 mm2) and (482.6 mm)

db is the bar diameter of the vertical reinforcement t

The reduced lap splice length is not permitted to be less

than 36db. The clear space between the transverse bars and the If continuous horizontal reinforcement is not

lapped bars may not exceed 1.5 in. (38 mm), and the transverse otherwise provided within the end 8 in. (203 mm) of

If continuous horizontal reinforcement is not otherwise

bars must be fully developed in grouted masonry at the point each end of the splice, confined requirements may be

provided within the end 8 in. (203 mm) of each end of the

satisfied by providing hooked reinforcement as detailed

where they cross the lapped reinforcement (see Figure 1). splice, confinement requirements may be satisfied by pro-

here. See Table 3 for lt minimum length requirements.

These provisions are included in Tables 4a through 4d. viding hooked reinforcement as detailed here. See Tables

Hook extensions are permitted to overlap.

4a through 4d for lt minimum length requirements. Hook

STANDARD HOOKS extensions are permitted to overlap.

Figure 2 illustrates the requirements for standard hooks, Figure 1—Confinement Reinforcement

when reinforcing bars are anchored by hooks or by a combi- at Lap Splice

4 NCMA TEK 12-6A

Table 4a—2012 IBC Lap Splice Lengths, f’m = 1,500 psi (10.3 MPa),

Reinforcement in Center of Wall (ref. 1)A

Minimum lap splice length, in. (mm), for:

6-in. CMU 8-in. CMU 10-in. CMU 12-in. CMU

Longitudinal

Unconfined Con- Unconfined Confined Unconfined Confined Uncon- Confined

bar size

fined fined

No. 3 (M #10) 12 (305)B — 12 (305)B — 12 (305)B — 12 (305)B —

No. 4 (M#13) 20 (508) — 15 (381) — 12 (305) B

— 12 (305)B —

No. 5 (M#16) 32 (813) F, 6

— 23 (584) — 18 (457) — 15 (381) —

No. 6 (M#19) 54 (1,372) D, F, 7

29 (737) 1

43 (1.092) 7

27 (686) 2

34 (864) 27 (686) 3

28 (711) —

No. 7 (M#22) NP C

— 60 (1,524) 8

32 (813) 2

46 (1,164) 8

32 (813) 3

38 (965) 32 (813)3

No. 8 (M#25) NPC — 72 (1,829)D, 9 50 (1,270)2 71 (1,803)9 36 (914)3 57 (1,448)9 36 (914)3

No. 9 (M#29)E NPC — NPC — 82 (2,083)D, 10 41 (1,041)3 74 (1,880)10 48 (1,219)3

Footnotes common to Tables 4a through 4d:

A

See Equation 3. Based on fy = 60,000 psi (414 MPa) for Grade 60 steel. Applies to both allowable stress design and

strength design.

B

12 in. (305 mm) minimum governs.

C

Bar is too large for this wall; db exceeds 1/4 of the least clear dimension of the cell to be grouted, 1/8 of the nominal unit

thickness, or 4% of the cell area to be grouted. Dimensions are based on specified minimum dimensions for a two-core,

square core unit and take into account a cell taper of 1/4 in. (6.4 mm) and mortar protrusions not exceeding 1/2 in. (13

mm).

D

Maximum splice length of 72db governs.

E

Allowable stress design requires bars larger than No. 9 (M#29) to be spliced by mechanical connectors. Strength design

provisions do not permit the use of reinforcing bars larger than No. 9 (M#29).

F

Permitted only if all mortar fins are removed from the cell to be grouted. Not permitted if all mortar fins are not re-

moved.

4

Per 2012 IBC and 2011 MSJC, splice length may be reduced to amount shown if confinement reinforcement is provided

within the last 8 in. (203 mm) of each end of the longitudinal bar lap. Confinement reinforcement may be provided by

continuous horizontal reinforcement of the size indicated or greater. Alternatively, a hooked bar with min. lt indicated

in footnote and extending into adjacent cells as shown in Figure 1 may be used.

For Allowable Stress Design, reduce to the length indicated below when limiting to fs < 80% Fs (25,600 psi, 177 MPa):

5

26 in. (660 mm)

6

32 in. (813 mm)

7

39 in. (991 mm)

8

45 in. (1,143 mm)

9

52 in. (1,321 mm)

10

58 in. (1,473 mm)

Footnotes unique to Table 4a:

1

No. 3 (M#10) confinement bar with lt = 6 in. (152 mm) min., see Figure 1.

2

No. 4 (M#13) confinement bar with lt = 13 in. (330 mm) min., see Figure 1.

3

No. 4 (M#13) confinement bar with lt = 9 in. (229 mm) min., see Figure 1.

NCMA TEK 12-6A 5

Table 4b—2012 IBC Lap Splice Lengths, f’m = 2,000 psi (13.7 MPa),

Reinforcement in Center of Wall (ref. 1)A

Minimum lap splice length, in. (mm), for:

6-in. CMU 8-in. CMU 10-in. CMU 12-in. CMU

Longitudinal

Unconfined Con- Unconfined Confined Unconfined Confined Uncon- Confined

bar size

fined fined

No. 3 (M #10) 12 (305)B — 12 (305)B — 12 (305)B — 12 (305)B —

No. 4 (M#13) 17 (432) — 13 (330) — 12 (305)B — 12 (305)B —

No. 5 (M#16) 27 (686) F

— 20 (508) — 15 (381) — 13 (330) —

No. 6 (M#19) 53 (1,346)D, F, 7

29 (737) 1

37 (940) 7

27 (686) 2

29 (737) 27 (686)3 24 (610) —

No. 7 (M#22) NP C

— 52 (1,321) 8

32 (813) 2

40 (1,016)8 32 (813)3 33 (838) 32 (813)3

No. 8 (M#25) NP C

— 72 (1,829)D, 9

50 (1,270) 2

61 (1,549)9 36 (914)3 50 (1,270) 9

36 (914)3

No. 9 (M#29)E NPC — NPC — 73 (1,854)D, 10 41 (1,041)3 64 (1,626)10 48 (1,219)3

Footnotes unique to Table 4b (for footnotes common to Tables 4a through 4d, see Table 4a):

1

No. 3 (M#10) confinement bar with lt = 6 in. (152 mm) min., see Figure 1.

2

No. 4 (M#13) confinement bar with lt = 11 in. (279 mm) min., see Figure 1.

3

No. 4 (M#13) confinement bar with lt = 8 in. (203 mm) min., see Figure 1.

Table 4c—2012 IBC Lap Splice Lengths, f’m = 1,500 psi (10.3

MPa), Reinforcement Off-Center (ref. 1)A

Footnotes unique to Table 4c (for foot-

Minimum lap splice length, in. (mm), based on off-

notes common to Tables 4a through 4d,

center reinforcement with masonry cover of:

see Table 4a):

Longitudinal 11/2-in. (38 mm) 2 in. (51 mm) 1

No. 4 (M#13) confinement bar with lt =

bar size

Unconfined Confined 4

Unconfined Confined4 18 in. (457 mm) min., see Figure 1.

No. 3 (M #10) 19 (483) — 15 (381) —

2

No. 5 (M#16) confinement bar with lt =

28 in. (711 mm) min., see Figure 1.

No. 4 (M#13) 34 (864) 5

— 26 (660) 5

— 3

No. 4 (M#13) confinement bar with lt =

No. 5 (M#16) 45 (1,143) D, 6

23 (584) 1

40 (1,016) 6

23 (584)3 14 in. (356 mm) min., see Figure 1.

No. 6 (M#19) 54 (1,372)D, 7 27 (686)1 54 (1,372)D, 7 27 (686)3

No. 7 (M#22) 63 (1,600)D, 8 48 (1,219)1 63 (1,600)D, 8 36 (914)3

No. 8 (M#25) 72 (1,829) D, 9

58 (2,057) 2

72 (1,829)D, 9

82 (2,083)3

No. 9 (M#29)E 82 (2,083)D, 10 — 82 (2,083)D, 10 —

Table 4d—2012 IBC Lap Splice Lengths, f’m = 2,000 psi (13.7

MPa), Reinforcement Off-Center (ref. 1)A

Minimum lap splice length, in. (mm), based on off- Footnotes unique to Table 4d (for foot-

center reinforcement with masonry cover of: notes common to Tables 4a through 4d,

Longitudinal see Table 4a):

11/2-in. (38 mm) 2 in. (51 mm)

bar size

1

No. 4 (M#13) confinement bar with lt =

Unconfined Confined 4

Unconfined Confined4 16 in. (406 mm) min., see Figure 1.

No. 3 (M #10) 17 (432) — 13 (330) — 2

No. 5 (M#16) confinement bar with lt =

No. 4 (M#13) 30 (762)5 — 22 (559)5 — 22 in. (559 mm) min., see Figure 1.

3

No. 4 (M#13) confinement bar with lt =

No. 5 (M#16) 45 (1,143) D, 6

23 (584) 1

34 (864) 23 (584)3

11 in. (356 mm) min., see Figure 1.

No. 6 (M#19) 54 (1,372)D, 7 27 (686)1 54 (1,372)D, 7 27 (686)3 11

No. 5 (M#16) confinement bar with lt =

No. 7 (M#22) 63 (1,600)D, 8 42 (1,067)1 63 (1,600)D, 8 32 (813)3 18 in. (457 mm) min., see Figure 1.

No. 8 (M#25) 72 (1,829) D, 9

50 (1,270) 2

72 (1,829)D, 9

38 (965)11

No. 9 (M#29)E 82 (2,083)D, 10 — 82 (2,083)D, 10 —

6 NCMA TEK 12-6A

d e

db

Di

Standard 180° hook

At least 4d b but not less

d e

db than 2 1 2 in. (64 mm)

Di

Standard 90° hook

12db

d e

db

5d b

90° stirrup or tie 6db , but not less than

for No. 5 (M#16) bar

2 1 2 in. (64 mm)

or smaller

d e

db

5db

135° stirrup or tie

for No. 5 (M#16) bar 6db , but not less than

or smaller 2 1 2 in. (64 mm)

Figure 2—Standard Hooks

Table 5—Standard Hooks—Dimensions and Equivalent Embedment Lengths

Bar size Bar Minimum 180o hook. Stirrups & 90o hook. 12db Equivalent

diameter, inside 4db tiesC, 6db extension, in. embedment length,

db, in. (mm) diameter of extension, extension, (mm) le, 13db, in. (mm)

bend, Di, in. in. (mm) in. (mm)

(mm)

No. 3 (M #10) 0.375 (9.5) 2.3 (57) 2.5B (64) 2.5C (64) 4.5 (114) 4.8 (122)

No. 4 (M#13) 0.500 (13) 3.0 (76) 2.5B (64) 3.0 (76) 6.0 (152) 6.5 (165)

No. 5 (M#16) 0.625 (16) 3.8 (95) 2.5 (64) 3.8 (95) 7.5 (191) 8.1 (206)

No. 6 (M#19) 0.750 (19) 4.5 (114) 3.0 (76) NP C 9.0 (229) 9.7 (246)

No. 7 (M#22) 0.875 (22) 5.3 (133) 3.5 (89) NP C 10.5 (267) 11.3 (287)

No. 8 (M#25) 1.000 (25) 6.0 (152) 4.0 (102) NP C 12.0 (305) 13.0 (330)

No. 9 (M#29) 1.128 (29) 9.0 (229) 4.5 (115) NP C 13.5 (343) 14.6 (371)

No. 10 (M#32) 1.270 (32) 10.2 (259) 5.1 (130) NP C 15.2 (386) 16.5 (404) D

No. 11 (M#36) 1.410 (36) 11.3 (287) 5.6 (142) NP C 16.9 (429) 18.3 (449) D

A

Based on Grade 60 reinforcing bars as follows: Di must equal or exceed 6db for bar sizes No. 3 through 8 (M#10–M#25);

8db for No. 9–11 (M #29–M#36) bars. Diameters of bend may be decreased to 5db for stirrups and for Grade 40, No. 3–7

(M#10–M#22).

B

For 180o standard hooks, bar extensions may not be less than 21/2 in. (64 mm).

C

For stirrups and ties that terminate in a 90o or 135o standard hook, bar size is limited to No. 5 (M#16) and smaller, and

extensions may not be less than 21/2 in. (64 mm).

D

Not permitted when using strength design, as the maximum reinforcing bar size is No. 9 (M#29)

NCMA TEK 12-6A 7

NOTATIONS:

Asc = area of the transverse bars at each end of the lap splice, in.2 (mm2)

Di = min. inside diameter of bend for standard hooks, in. (mm)

db = nominal diameter of reinforcement, in. (mm)

K = the least of the masonry cover, 9db for the 2012 IBC (5db for the 2009 IBC) and the clear spacing between adjacent reinforce-

ment, in. (mm)

Fs = allowable tensile stress in reinforcement, psi (MPa)

f'm = specified compressive strength of masonry, psi (MPa)

fs = calculated tensile or compressive stress in steel, psi (MPa)

fy = specified yield strength of steel, psi (MPa)

ld = embedment length or lap splice length of straight reinforcement, in. (mm)

le = equivalent embedment length provided by standard hooks measured from the start of the hook (point of tangency), in. (mm)

lt = length of bar extension of hooked confinement reinforcement, in. (mm)

γ = reinforcement size factor

ξ = lap splice confinement reinforcement factor

REFERENCES

1. International Building Code 2012. International Code Council, 2012.

2. International Building Code 2009. International Code Council, 2009.

3. Building Code Requirements for Masonry Structures, TMS 402-11 /ACI 530-11/ASCE 5-11. Reported by the Masonry Standards

Joint Committee, 2011.

4. Building Code Requirements for Masonry Structures, TMS 402-08 /ACI 530-08/ASCE 5-08. Reported by the Masonry Standards

Joint Committee, 2008.

5. Steel Reinforcement for Concrete Masonry, TEK 12-4D. National Concrete Masonry Association, 2007.

6. Post-Tensioned Concrete Masonry Wall Construction, TEK 3-14. National Concrete Masonry Association, 2002.

7. TEK 12-6, Splices, Development and Standard Hooks for Concrete Masonry. National Concrete Masonry Association, 2007.

8. Structural Welding Code—Reinforcing Steel, AWS D 1.4-05. American Welding Society, 2005.

9. Standard Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement, ASTM A706/A706M-09b.

ASTM International, Inc., 2009.

10. Building Code Requirements for Structural Concrete and Commentary, ACI 318-11. American Concrete Institute, 2011.

NCMA and the companies disseminating this technical information disclaim any and all responsibility and liability for the accuracy

and the application of the information contained in this publication.

NATIONAL CONCRETE MASONRY ASSOCIATION

13750 Sunrise Valley Drive, Herndon, Virginia 20171

www.ncma.org

To order a complete TEK Manual or TEK Index, contact NCMA Publications (703) 713-1900

8 NCMA TEK 12-6A

You might also like

- GEO Updated-CheatsheetDocument3 pagesGEO Updated-CheatsheetGiovanni LinNo ratings yet

- Aashto Lap Splice 1Document66 pagesAashto Lap Splice 1hamsarajshettyNo ratings yet

- Dry Stack Manual & Reference Tek 14-22Document6 pagesDry Stack Manual & Reference Tek 14-22rickbmayNo ratings yet

- Offshore PlatformDocument292 pagesOffshore Platformgalih santoso100% (3)

- Waler Wall Connection Design TemplateDocument1 pageWaler Wall Connection Design TemplateArjun RajaNo ratings yet

- Stair Case Pressurization Calculation - Class ADocument8 pagesStair Case Pressurization Calculation - Class ALarry Bea100% (4)

- Splices, Development and STD - HooksDocument6 pagesSplices, Development and STD - Hooksjem guiNo ratings yet

- TEK 12-6 Reinforcement & Connectors (2007)Document6 pagesTEK 12-6 Reinforcement & Connectors (2007)B0B_PNo ratings yet

- Tek 12-03CDocument16 pagesTek 12-03CponjoveNo ratings yet

- Ncma Tek: Design of Concrete Masonry Noncomposite (Cavity) Walls TEK 16-4ADocument4 pagesNcma Tek: Design of Concrete Masonry Noncomposite (Cavity) Walls TEK 16-4AmurdicksNo ratings yet

- NCMA TEK 6-1B - R Values of Multi-Wythe Concrete Masonry Walls 2009Document4 pagesNCMA TEK 6-1B - R Values of Multi-Wythe Concrete Masonry Walls 2009SugarPOP666No ratings yet

- Tek 01-03C PDFDocument4 pagesTek 01-03C PDFFNo ratings yet

- Tek 14-01B PDFDocument8 pagesTek 14-01B PDFzeek77No ratings yet

- Ncma Tek: Sampling and Testing Segmental Retaining Wall Units TEK 18-10Document4 pagesNcma Tek: Sampling and Testing Segmental Retaining Wall Units TEK 18-10Jorge Luis Arevalo LopezNo ratings yet

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocument4 pagesNcma Tek: Segmental Retaining Wall Units TEK 2-4BJorge Luis Arevalo LopezNo ratings yet

- Ncma Tek: Concrete Masonry Highway Sound Barriers TEK 13-3ADocument4 pagesNcma Tek: Concrete Masonry Highway Sound Barriers TEK 13-3AalbertoxinaNo ratings yet

- Tek 10-02C1Document8 pagesTek 10-02C1albertoxinaNo ratings yet

- Ncma Tek 10-03Document4 pagesNcma Tek 10-03Jeff HedmanNo ratings yet

- Crack Control For Concrete Brick and Masonry Veneer (NCMA TEK 10-4)Document4 pagesCrack Control For Concrete Brick and Masonry Veneer (NCMA TEK 10-4)pazz0No ratings yet

- Tek 14-01BDocument8 pagesTek 14-01BkevinalmerNo ratings yet

- Tek 14-07C11 PDFDocument8 pagesTek 14-07C11 PDFsaadyamin2821No ratings yet

- Ncma Tek: Compressive Strength Testing Variables For Concrete Masonry Units TEK 18-7Document4 pagesNcma Tek: Compressive Strength Testing Variables For Concrete Masonry Units TEK 18-7williamptyNo ratings yet

- NCMA TEK 19-4A Water Penetration Resistance (2008)Document4 pagesNCMA TEK 19-4A Water Penetration Resistance (2008)B0B_PNo ratings yet

- Formula BookDocument52 pagesFormula Bookmatshona100% (2)

- Design of Concrete Masonry Walls For Blast Loading: TEK 14-21ADocument9 pagesDesign of Concrete Masonry Walls For Blast Loading: TEK 14-21Afoush bashaNo ratings yet

- Tek 17-01B PDFDocument4 pagesTek 17-01B PDFJacky LeongNo ratings yet

- Asd Tables For Reinforced Concrete Masonry Walls Based On THE 2012 IBC & 2011 MSJCDocument8 pagesAsd Tables For Reinforced Concrete Masonry Walls Based On THE 2012 IBC & 2011 MSJCJason PowellNo ratings yet

- Tek 18-01B5 PDFDocument8 pagesTek 18-01B5 PDFMohamed HNo ratings yet

- Masonry Control Joints (TEK - 10-02B) PDFDocument4 pagesMasonry Control Joints (TEK - 10-02B) PDFCesar RjszvlNo ratings yet

- Tek 14-03a PDFDocument4 pagesTek 14-03a PDFdaveshitNo ratings yet

- TEK - 01-01E ASTM Specifications For Concrete Masonry Units (7-2007)Document4 pagesTEK - 01-01E ASTM Specifications For Concrete Masonry Units (7-2007)Ryan KuntzNo ratings yet

- Emperical Design of Concrete MasonryDocument8 pagesEmperical Design of Concrete MasonryKmrnKhnNo ratings yet

- Tek 09-01aDocument4 pagesTek 09-01aJerry LeeNo ratings yet

- Tek 16-04aDocument4 pagesTek 16-04akip2001No ratings yet

- Typical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BDocument4 pagesTypical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BfostbarrNo ratings yet

- Segmental Retaining Wall Design TEKDocument8 pagesSegmental Retaining Wall Design TEKlcruz117No ratings yet

- Rebars Splicing Handbook - Dayton SuperiorDocument76 pagesRebars Splicing Handbook - Dayton SuperiorJimmy090% (1)

- Tek 17-04B PDFDocument4 pagesTek 17-04B PDFGérard PIERRE LOUISNo ratings yet

- Dev and Lap Splice Lengths - ETN-D-1-15 PDFDocument9 pagesDev and Lap Splice Lengths - ETN-D-1-15 PDFsathiyaprasathNo ratings yet

- Joints in RC StructuresDocument10 pagesJoints in RC StructuresMahmood MuftiNo ratings yet

- Design of Glass Structures PDFDocument126 pagesDesign of Glass Structures PDFricosanojuanNo ratings yet

- Ncma Tek: Loadbearing Concrete Masonry Wall Design TEK 14-5ADocument6 pagesNcma Tek: Loadbearing Concrete Masonry Wall Design TEK 14-5AfostbarrNo ratings yet

- IGU Quality Standard Reference DocumentDocument33 pagesIGU Quality Standard Reference DocumentBrian MabenNo ratings yet

- SSB03 ActionsDocument64 pagesSSB03 Actionsanil97232No ratings yet

- Rebars Arrangement For Concrete ReinforcementsDocument5 pagesRebars Arrangement For Concrete ReinforcementsAntónio Fontes100% (1)

- Stone Cladding Fixation 1Document3 pagesStone Cladding Fixation 1wadyspring100% (2)

- Tek 14-01aDocument6 pagesTek 14-01aJoe IlaganNo ratings yet

- Manual ViewerDocument4 pagesManual ViewerLeonardo CruzNo ratings yet

- Hybrid Concrete Masonry Construction DetailsDocument8 pagesHybrid Concrete Masonry Construction DetailsB0B_PNo ratings yet

- Tek 14-15BDocument6 pagesTek 14-15BalbertoxinaNo ratings yet

- Ncma Tek: Concrete Masonry Bond Patterns TEK 14-6Document4 pagesNcma Tek: Concrete Masonry Bond Patterns TEK 14-6MarioleRouxNo ratings yet

- SIFS Product Submision PDFDocument72 pagesSIFS Product Submision PDFmahmoud IbrahemNo ratings yet

- Tek 5-5B Integrating Concrete Masonry Walls With Metal Building SystemsDocument4 pagesTek 5-5B Integrating Concrete Masonry Walls With Metal Building Systemsclam2014No ratings yet

- Tek 12-03C6 PDFDocument6 pagesTek 12-03C6 PDFAlex MaxNo ratings yet

- Construction, and Maintenance of Relief Wells PDFDocument92 pagesConstruction, and Maintenance of Relief Wells PDFArif RusyanaNo ratings yet

- Types of FdnsDocument41 pagesTypes of Fdnshiwotnesh girmaNo ratings yet

- Concrete Masonry Units Specifications - : CAN3 - A165Document2 pagesConcrete Masonry Units Specifications - : CAN3 - A165naconnetNo ratings yet

- Ncma Tek: Glossary of Concrete Masonry Terms TEK 1-4Document6 pagesNcma Tek: Glossary of Concrete Masonry Terms TEK 1-4Heriberto Yau BNo ratings yet

- Ultimate Behaviour and Design of Post-TensionedDocument8 pagesUltimate Behaviour and Design of Post-TensionedManuel RochaNo ratings yet

- Reinforcement CouplersDocument24 pagesReinforcement Couplersvishalgore100% (2)

- C I 3304 Detailing CornerDocument5 pagesC I 3304 Detailing CornerNono_geotecNo ratings yet

- Limit States in RCCDocument15 pagesLimit States in RCCprashmceNo ratings yet

- Limit State of Serviceability in RCCDocument19 pagesLimit State of Serviceability in RCCprashmceNo ratings yet

- Shrinkage Compensating Admixtures by Sunanda CoatingsDocument2 pagesShrinkage Compensating Admixtures by Sunanda Coatingss.skumar10% (1)

- For Viewing Platform and Sea Wall Bait Al BarakahDocument1 pageFor Viewing Platform and Sea Wall Bait Al Barakahs.skumar1No ratings yet

- Bored Pile Record SheetDocument1 pageBored Pile Record Sheets.skumar1100% (1)

- Inspection Testing Plan (Itp)Document2 pagesInspection Testing Plan (Itp)s.skumar1No ratings yet

- Risk Assessment For Piling Rig: Hazard Identified Severity Likelihood Risk RatingDocument12 pagesRisk Assessment For Piling Rig: Hazard Identified Severity Likelihood Risk Ratings.skumar1No ratings yet

- Impac Pier Method Statement 1Document8 pagesImpac Pier Method Statement 1s.skumar1No ratings yet

- Health, Safety & Environmental Plan ForDocument1 pageHealth, Safety & Environmental Plan Fors.skumar1No ratings yet

- Method Statement For CFA Piling Works For Viewing Platform and Sea Wall Bait Al BarakahDocument1 pageMethod Statement For CFA Piling Works For Viewing Platform and Sea Wall Bait Al Barakahs.skumar1No ratings yet

- Aggregate Test ReportsDocument15 pagesAggregate Test Reportss.skumar1No ratings yet

- Strengthening of Slab at First Floor LevelDocument1 pageStrengthening of Slab at First Floor Levels.skumar1No ratings yet

- MS - Thoroseal FX100Document2 pagesMS - Thoroseal FX100s.skumar1No ratings yet

- Section Details of Tower Crane Foundation: SCALE:1:50Document1 pageSection Details of Tower Crane Foundation: SCALE:1:50s.skumar1No ratings yet

- New Carpentry Workshop DesignDocument1 pageNew Carpentry Workshop Designs.skumar1No ratings yet

- 05 - TDS - Thoroseal FX100Document4 pages05 - TDS - Thoroseal FX100s.skumar1No ratings yet

- Traffic LawDocument149 pagesTraffic LawalidoonNo ratings yet

- Section Details of Tower Crane Foundation: SCALE:1:50Document1 pageSection Details of Tower Crane Foundation: SCALE:1:50s.skumar1No ratings yet

- Car Park FinishDocument6 pagesCar Park Finishs.skumar1No ratings yet

- Product Information For "Acer Aspire 5740-333G32Mn": GeneralDocument9 pagesProduct Information For "Acer Aspire 5740-333G32Mn": Generals.skumar1No ratings yet

- Catalouge For Lenton CouplersDocument18 pagesCatalouge For Lenton Couplerss.skumar1No ratings yet

- DomeDocument8 pagesDomes.skumar1No ratings yet

- Car Park FinishDocument6 pagesCar Park Finishs.skumar1No ratings yet

- 4 Vertical Soil Support Wall ConstructionDocument49 pages4 Vertical Soil Support Wall ConstructionHammad Salahuddin100% (1)

- SPW C0706-C1806 DXH8 (Series 6 Eco I 2 Pipe VRF) Om & Service-1-60Document60 pagesSPW C0706-C1806 DXH8 (Series 6 Eco I 2 Pipe VRF) Om & Service-1-60Jacek NawrotNo ratings yet

- Chapter 1: Introduction: 1.1 Practical Column Base Details in Steel StructuresDocument135 pagesChapter 1: Introduction: 1.1 Practical Column Base Details in Steel Structuressom_bs79100% (1)

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Document14 pagesDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoNo ratings yet

- 1 Dimensions of Tank Proper:: Design of 50 KL OhsrDocument30 pages1 Dimensions of Tank Proper:: Design of 50 KL OhsrMegatech Engineering ConsultantsNo ratings yet

- Performance Based Design by Ashraf H.Document86 pagesPerformance Based Design by Ashraf H.korosh75100% (2)

- MCT SEM 4 Engineer WoodDocument16 pagesMCT SEM 4 Engineer WoodKhushi ChauhanNo ratings yet

- Schedule & Bar Chart For RFCLDocument14 pagesSchedule & Bar Chart For RFCLSalmon SaliNo ratings yet

- Building Structures Assignment 1Document2 pagesBuilding Structures Assignment 1alfredobarraganNo ratings yet

- Block 15 Gairsain - ResourceRate - LabourDocument2 pagesBlock 15 Gairsain - ResourceRate - LabourManojNo ratings yet

- Doosan AnnualReport EnglishDocument68 pagesDoosan AnnualReport Englishkelvinc2560% (1)

- DownHole Tubular PDFDocument14 pagesDownHole Tubular PDFMHazmiMNasirNo ratings yet

- Self-Healing Concrete - ReportDocument15 pagesSelf-Healing Concrete - ReportRekan DahoNo ratings yet

- SBV07N03 061307Document8 pagesSBV07N03 061307Jaime MurilloNo ratings yet

- Data List Mesin MHB Rev.01Document4 pagesData List Mesin MHB Rev.01jimivritNo ratings yet

- Harnessing Indegineouse Building Materials For Sustainable DevelopmentDocument14 pagesHarnessing Indegineouse Building Materials For Sustainable DevelopmentNtaji PatrickNo ratings yet

- Method Statement For Earth WorksDocument26 pagesMethod Statement For Earth WorksReynaldo PruelNo ratings yet

- Aquaforce 30XA080-500 Air Cooled ChillersDocument56 pagesAquaforce 30XA080-500 Air Cooled Chillerssriomprakash100% (1)

- Pipeline Anchor Force CalculationDocument1 pagePipeline Anchor Force Calculationmassive85No ratings yet

- Extensometro Strain Gauge P 66.81 Dehnungsaufnehmer Stahl DSC enDocument1 pageExtensometro Strain Gauge P 66.81 Dehnungsaufnehmer Stahl DSC enFreddy Sanchez LuckNo ratings yet

- Tubo 5128343Document4 pagesTubo 5128343VladimirCarrilloNo ratings yet

- Sample RRLDocument2 pagesSample RRLSo JuNo ratings yet

- ENDS 3271 Architecture Design Project - Course Outline - EUI 2023Document8 pagesENDS 3271 Architecture Design Project - Course Outline - EUI 2023Eunice KhainzaNo ratings yet

- Gypsum Board Part III PDFDocument77 pagesGypsum Board Part III PDFimran100% (1)

- Rammed Aggregate Pier Construction and Quality Control Procedures For The Impact SystemDocument39 pagesRammed Aggregate Pier Construction and Quality Control Procedures For The Impact SystemvillarpolancoNo ratings yet

- Lightweight ConcreteDocument2 pagesLightweight ConcreteAnish PandeyNo ratings yet

- Wood Sliding Folding SystemDocument3 pagesWood Sliding Folding SystemHimanshi guptaNo ratings yet