Professional Documents

Culture Documents

Halliburton Pre-Spud Checklist

Halliburton Pre-Spud Checklist

Uploaded by

Lijo JohnCopyright:

Available Formats

You might also like

- Ms 761 1982 Code of Practice For The Storage and Handling of Flammable and Combustible Liquids Ics 75.080-709618Document94 pagesMs 761 1982 Code of Practice For The Storage and Handling of Flammable and Combustible Liquids Ics 75.080-709618cloobpsp82% (11)

- Completion FluildDocument154 pagesCompletion FluildCHUKWUEMEKE OSONDUNo ratings yet

- I Read ..... I Learn: Discover 125 ST Training Notes International BusinessDocument49 pagesI Read ..... I Learn: Discover 125 ST Training Notes International BusinessPato ErazoNo ratings yet

- 3-Waves of RoboticsDocument2 pages3-Waves of RoboticsEbrahim Abd El HadyNo ratings yet

- Idc 37 Rig Move PlanDocument15 pagesIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- 10 - WBM Products and Systems-BMS-C-2012Document105 pages10 - WBM Products and Systems-BMS-C-2012Slim.B100% (3)

- Drilling MatrixDocument3 pagesDrilling Matrixjonny727100% (1)

- Wellhead Operations & Maintenance Course SummaryDocument65 pagesWellhead Operations & Maintenance Course SummaryMustafa NaithelNo ratings yet

- Wellsite Leader Checklist Rig # 41Document3 pagesWellsite Leader Checklist Rig # 41IgorCencičNo ratings yet

- Well Service IWCF Test and AnswersDocument33 pagesWell Service IWCF Test and Answersseyyid ali lylNo ratings yet

- CH3 Workover FluidsDocument65 pagesCH3 Workover FluidsWael abo adelNo ratings yet

- Drilling Hazard Management - Part 3Document4 pagesDrilling Hazard Management - Part 3Yamamoto_KZ100% (1)

- Chapter 10-FDocument12 pagesChapter 10-FMahrouz MadoNo ratings yet

- Drilling and Well ConstructionDocument36 pagesDrilling and Well ConstructionMarcio Nascimento BezerraNo ratings yet

- 2017-18 Drilling ProgrammeDocument32 pages2017-18 Drilling ProgrammesmashfacemcgeeNo ratings yet

- How To Read A Daily Mud ReportDocument13 pagesHow To Read A Daily Mud ReportAhmet Can Zorbilmez100% (1)

- Basic Course of Drilling ProcedureDocument4 pagesBasic Course of Drilling ProcedureAli Samani100% (2)

- IADC Vol-2 07 Rotating and Pipe Handling EquipmentDocument28 pagesIADC Vol-2 07 Rotating and Pipe Handling Equipmentvvzcmq8k75No ratings yet

- 01 MOC For Mud Change For 17.5inch Hole Rev 1Document4 pages01 MOC For Mud Change For 17.5inch Hole Rev 1Anonymous U5t9NYzhLWNo ratings yet

- Chapter 2-JDocument14 pagesChapter 2-JMahrouz MadoNo ratings yet

- Rig Evaluation MiSWACO New-LogoDay 2Document72 pagesRig Evaluation MiSWACO New-LogoDay 2Cerón Niño SantiagoNo ratings yet

- Brochure - Rig Equipment Inspection Virtual TrainingDocument5 pagesBrochure - Rig Equipment Inspection Virtual TrainingSyed IrtazaNo ratings yet

- Well Control Incident Response Plan: N A Le RTDocument76 pagesWell Control Incident Response Plan: N A Le RTChristian Olascoaga MoriNo ratings yet

- API RP 19G13 - Section 5.6 - Very Deep Gas-Lift - Version 2011-04-03Document51 pagesAPI RP 19G13 - Section 5.6 - Very Deep Gas-Lift - Version 2011-04-03Sufian R EllabbadNo ratings yet

- Manual Coiled Tubing p1Document500 pagesManual Coiled Tubing p1Luis Fernando Grajales MorenoNo ratings yet

- Well InterventionDocument83 pagesWell InterventionJosue FishNo ratings yet

- Saudi Aramco: Installation of Telecommunication Equipment On High Structures, Including Radio TowersDocument5 pagesSaudi Aramco: Installation of Telecommunication Equipment On High Structures, Including Radio TowersaymenmoatazNo ratings yet

- A ULTRADRIL Engineering Guidelines DJ!!!Document15 pagesA ULTRADRIL Engineering Guidelines DJ!!!kbrinaldi100% (1)

- Rig Acceptance Check ListDocument2 pagesRig Acceptance Check ListAhmedNo ratings yet

- Wild Well FluidsDocument26 pagesWild Well FluidsAndrés LópezNo ratings yet

- Drilling Fluids: Islamic Azad University Science and Research Branch Drilling DepartmentDocument26 pagesDrilling Fluids: Islamic Azad University Science and Research Branch Drilling Departmentali nahiNo ratings yet

- Hydraulic Fracturing Report 4.18.11Document32 pagesHydraulic Fracturing Report 4.18.11Aayush BhatnagarNo ratings yet

- FORMATEMANUAL A5 Crystallization TemperatureDocument20 pagesFORMATEMANUAL A5 Crystallization TemperaturejcNo ratings yet

- Workover Manual IndexDocument4 pagesWorkover Manual IndexMahrouz MadoNo ratings yet

- Rig Move Brochure: Parker Drilling CompanyDocument39 pagesRig Move Brochure: Parker Drilling CompanyJonathan CustodioNo ratings yet

- 24 - HTHP WellsDocument25 pages24 - HTHP WellsSlim.BNo ratings yet

- Pre-Spud InspectionDocument6 pagesPre-Spud InspectionHany100% (2)

- 0068 - POOH Dual String Completion TubingDocument3 pages0068 - POOH Dual String Completion TubingDrillerNo ratings yet

- Optimum ST PlugsDocument49 pagesOptimum ST PlugsDanish KhanNo ratings yet

- Well PalnningDocument30 pagesWell PalnningPankaj Singh ChauhanNo ratings yet

- Fishing & StucksDocument51 pagesFishing & Stucksمحمد العراقيNo ratings yet

- IADC DDR Codes 2 13 2019Document4 pagesIADC DDR Codes 2 13 2019txcrudeNo ratings yet

- UH Final Presentation 1 - Sept 9, 2013 - PrintingDocument68 pagesUH Final Presentation 1 - Sept 9, 2013 - PrintingTauqeer IqbalNo ratings yet

- 10 - Drilling Fluids Design and Selection - HandoutDocument18 pages10 - Drilling Fluids Design and Selection - HandoutFauzan Rahman HaqNo ratings yet

- PetroSkills - Surface Production OperationsDocument2 pagesPetroSkills - Surface Production OperationsMausam GauravNo ratings yet

- Drilling SupervisorDocument2 pagesDrilling Supervisoreng7mohamed7hashimNo ratings yet

- A Cost-Effective Rig MoveDocument4 pagesA Cost-Effective Rig MoveNA NANo ratings yet

- WELL: HH 83/1D: WIND SPEED at 6:00 AM 44-46 KNTS. (N-NW)Document5 pagesWELL: HH 83/1D: WIND SPEED at 6:00 AM 44-46 KNTS. (N-NW)anon_975742003No ratings yet

- Assistant Slickline Operator 001Document3 pagesAssistant Slickline Operator 001Muhammad shehryar KhanNo ratings yet

- Cementing Program For The 13 38 Inch CasingDocument40 pagesCementing Program For The 13 38 Inch CasingMarvin OmañaNo ratings yet

- Saudi Aramco: Kill and Livening Procedures For WorkoversDocument6 pagesSaudi Aramco: Kill and Livening Procedures For WorkoversMahrouz MadoNo ratings yet

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- 7B - HydraulicsDocument33 pages7B - Hydraulicsagus alexandri100% (1)

- Mud Program RequirementDocument3 pagesMud Program RequirementMahrouz MadoNo ratings yet

- Mud Mixing and StorageDocument3 pagesMud Mixing and Storagecaca666No ratings yet

- How To Ensure H2S Safety On Offshore Rigs - Drilling ContractorDocument10 pagesHow To Ensure H2S Safety On Offshore Rigs - Drilling ContractorTg TarroNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Format Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Document11 pagesFormat Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Lijo JohnNo ratings yet

- Method StatementDocument16 pagesMethod StatementMark FashNo ratings yet

- VIL HSW: Working at Height: Vodafone Idea LTDDocument5 pagesVIL HSW: Working at Height: Vodafone Idea LTDMuthiah ManiNo ratings yet

- VIL HSW: Working at Height: Vodafone Idea LTDDocument4 pagesVIL HSW: Working at Height: Vodafone Idea LTDMuthiah ManiNo ratings yet

- Final Inspection Report With Codes ExampleDocument23 pagesFinal Inspection Report With Codes Exampleeraswasta100% (1)

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 pagesVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNo ratings yet

- Fall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Document2 pagesFall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Lijo JohnNo ratings yet

- Gas Detection System (GDS)Document2 pagesGas Detection System (GDS)Lijo JohnNo ratings yet

- Gas Testing FormDocument1 pageGas Testing FormLijo John100% (1)

- 019 Smoke Detector ChecklistDocument1 page019 Smoke Detector ChecklistLijo JohnNo ratings yet

- 003 Vehicle Pre-Use ChecklistDocument1 page003 Vehicle Pre-Use ChecklistLijo JohnNo ratings yet

- 002 EAD ChecklistDocument1 page002 EAD ChecklistLijo JohnNo ratings yet

- 001 Emergency Shower and Eye Wash ChecklistDocument1 page001 Emergency Shower and Eye Wash ChecklistLijo JohnNo ratings yet

- Format Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Document11 pagesFormat Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Lijo JohnNo ratings yet

- Your Boarding PassDocument1 pageYour Boarding PassLijo JohnNo ratings yet

- Lijo John Kennedy - F - 21012021213850Document1 pageLijo John Kennedy - F - 21012021213850Lijo John100% (1)

- Design of CouplingDocument75 pagesDesign of CouplingVatsal BhalaniNo ratings yet

- Kohler CH26 Service ManualDocument218 pagesKohler CH26 Service Manualjaken202100% (2)

- EDC 17 For H-Series BSIII and BSIV Engines-PassDocument82 pagesEDC 17 For H-Series BSIII and BSIV Engines-PassAsadullah H A0% (1)

- 4/3, 4/2 and 3/2 Directional Valve With Fluidic Actuation: RE 22282/03.07 Replaces: 06.05Document12 pages4/3, 4/2 and 3/2 Directional Valve With Fluidic Actuation: RE 22282/03.07 Replaces: 06.05Phạm Xuân ChínhNo ratings yet

- 2016 Kawasaki kx250f 52453Document203 pages2016 Kawasaki kx250f 52453Alexander alfaro gomezNo ratings yet

- Silnik MechanikaDocument167 pagesSilnik MechanikamorusNo ratings yet

- Aggiornamento OHW 22.2.4 en-GBDocument9 pagesAggiornamento OHW 22.2.4 en-GBmojbarNo ratings yet

- HSDE - Requirements of C.C-1Document39 pagesHSDE - Requirements of C.C-1Fa CaNo ratings yet

- Brake+system New ModelDocument30 pagesBrake+system New ModelTimkenNo ratings yet

- Caterpillar Diesel Engine GeneratorsDocument7 pagesCaterpillar Diesel Engine GeneratorsalfonsoNo ratings yet

- Seminor PPT FinalDocument17 pagesSeminor PPT FinalMukesh SamNo ratings yet

- M Series: Round Line, Non-Repairable Cylinder LineDocument62 pagesM Series: Round Line, Non-Repairable Cylinder LineJezie ReyesNo ratings yet

- MP20 Measuring Head: Dimensions & WeightsDocument1 pageMP20 Measuring Head: Dimensions & WeightsJose Sostenes100% (1)

- Autometer Pro Control 2650-238XDocument4 pagesAutometer Pro Control 2650-238XPat POUPNo ratings yet

- Activity 1.1.2 Simple Machines Practice: ProcedureDocument7 pagesActivity 1.1.2 Simple Machines Practice: ProcedureYonjou-Divine VictorinNo ratings yet

- Rear Drive AxleDocument28 pagesRear Drive Axlemebarki aberraoufNo ratings yet

- Cobra Electronics 8185 Instruction Manual 221137Document6 pagesCobra Electronics 8185 Instruction Manual 221137anthonyNo ratings yet

- Design and Development of Segway Human Transporter: Manish S. Lade Shubhank C. Jaunjal V. D. DhopteDocument3 pagesDesign and Development of Segway Human Transporter: Manish S. Lade Shubhank C. Jaunjal V. D. DhopteSaransh JainNo ratings yet

- Unknown 6Document380 pagesUnknown 6Tina TinaNo ratings yet

- S3 30 - TDSDocument2 pagesS3 30 - TDSMiguel ArizaNo ratings yet

- Hydraulic Presses: Dies and Straighteners For Presses F39Document1 pageHydraulic Presses: Dies and Straighteners For Presses F39Luthfi AnandhikaNo ratings yet

- Quick User GuideDocument43 pagesQuick User GuideEink SimNo ratings yet

- ch420 Winch Parts ManualDocument8 pagesch420 Winch Parts ManualAlok Mishra100% (1)

- Service Manual: ForewordDocument906 pagesService Manual: ForewordredNo ratings yet

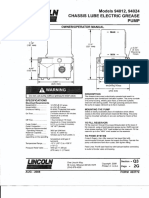

- Lincoln Lube Model 94012Document6 pagesLincoln Lube Model 94012luisNo ratings yet

- Dataset 1Document52 pagesDataset 1elvishernandezNo ratings yet

- RUNNER: Nissan Case Study: Final Analysis Page - 1Document31 pagesRUNNER: Nissan Case Study: Final Analysis Page - 1AliceJohnNo ratings yet

Halliburton Pre-Spud Checklist

Halliburton Pre-Spud Checklist

Uploaded by

Lijo JohnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Halliburton Pre-Spud Checklist

Halliburton Pre-Spud Checklist

Uploaded by

Lijo JohnCopyright:

Available Formats

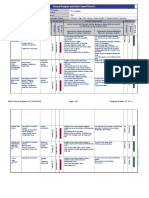

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 1 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Contractor / Rig #: ____SINO 45 Location / Well #: _UTMN 654

Assessor / Company: ___________________ HES_______ Date: ____4th July, 2016

Answer Yes or No to each question. Provide short comments, as needed, in boxes next to the assessed item.

Provide long comments in Table 15 at the end of the form.

Yes

1.0 - General Rig Site / No

Comments / Actions

1. Access to location (office side), main road & direction signs. Yes

2. Entrance barrier in use, warning and safety signs displayed, visitors Yes

directed to DSV & TP Offices.

3. Parking area marked, cars parked in reverse position. No Particular item in -progress

4. Different areas well segregated, Tubular storage, cementing unit, Yes

engines, workshops, chemicals, accommodations etc.

5. Safety perimeter around the well head with warning signs. Yes

6. Two Muster Points (opposite positions). Wind socks visible & in Yes

good condition.

7. Emergency alarm (two action point), can be heard at all Rig Site Yes

locations. Hand bill/ Portable siren if power breakdown.

8. Notice Board available, essential HSE info. Posted / updated. Yes Available but not clear. Replacement

recommended

9. Different Emergency alarms code posted & known. Yes

10. Lighting adequate around the rig site. Yes

11. At least four First Aid Attendants at the site Yes

12. Rig Manager – certificate in First Aid. Yes

13. Adherence to no smoking policy. Adequate signs posted. Yes

14. General housekeeping and hygiene at the rig site. Yes Generally good but must be monitored

15. Burn pit well cited, clear of internal/ external combustibles. Yes

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 2 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

2.0 – General HS&E Issues / No

Comments / Action

1. Adequate stocks of hard hats, safety glasses, gloves & Yes

hearing/respiratory protection available & in good condition.

2. Adequate supplies of wet weather gear held at the site Yes

3. Fire Protection:

4. Adequate fire extinguishers available, strategically located around

the site (Plan), checked & logged monthly? Yes

5. Fire-pump available, adequate flow/ accessories, working. Yes

6. Fire Emergency Response Team designated & trained

Yes

7. Medical First Aid:

8. Ambulance available with stretcher & first aid kit & trauma pack. Yes

Crew trained First Aid, Medic on site.

9. Fall Protection

10. Five full body harnesses in good condition at the site? Yes

11. Adequate stocks of karabiners, lanyards, slings at the site? Yes

12. Man Riding basket adequate & certified. Yes

13. H2S & hydrocarbon detection system in place & tested. Yes

14. Portable gas detector (multi-gas) available and in test. Yes

15. Date when due for re-test for calibrating. 3/Aug/ 16 Yes

16. Explosion proof torches for the key personnel (DSV, TP , etc.) Yes

17. Four SCBAs sets available at the site, spare bottles available. Yes

18. Dates when due for re-test. Last H2S Drill. 20/June/16

19. First aid Kits (3), clean and adequately stocked. One in DSV/TP Yes

offices, one in the dog house and one at camp.

20. Emergency eyewash stations, sufficient (hoppers, dog house, Yes

workshops) and correctly maintained.

21. Emergency shower installed and operating – Mud mixing area. Yes

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 3 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

3.0 - Environmental Issues / No

Comments / Action

1. No evidence of any off-track driving or short cutting. No

2. No additional area or vegetation has been cleared away. No

3. Camp away from natural watercourses, surface water, etc. Yes

4. Dry rubbish pit is covered. NA

5. All waste contained in bins or appropriate receptacles. Yes

6. Sewage pit is adequate, no excessive odour. Yes

7. No evidence of HC spills or contamination of water/ground. No

8. Fuel hoses, nozzles tanks etc serviceable & in good condition. Yes

9. Adequate servicing & no excessive exhaust from generators Yes

10. Fuel & chemicals stored within contained area – drip trays. Yes

11. Adequate spill control equipment located at the site Yes

12. Earth drains are clear and allow for adequate filtration NA

13. Vehicle refueling & maintenance is confined to the fuel area Yes

14. Controls in place for issues identified in the Environmental Risk Yes

Assessment

Yes

4.0 – Accumulator, BOP, Choke Manifold & Flare / No

Comments / Action

1. General housekeeping in & around well control equipment area Yes

2. Accumulator fluid levels & Operating pressures as required Yes

3. Auto start of pumps as required, Blind/Shear ram safety cover. Yes

4. Adequate lighting (Exproof), lighting guarded. Backup lights Yes

5. BOP manual closing device, operational, checked No

6. Guy lines installed (with turn buckles), Kill/choke lines secured & Yes

Hydraulic hoses in good condition.

7. BOP Work platform & safety line for working at height Yes

8. Cellar covered with a grating Yes

9. Rig Floor Koomey Remote Panel pressures gauges working & same Yes

on main Koomey Unit, Blind/Shear ram safety cover.

10. All the lights on the Rig Floor remote panel working Yes

11. Safety & Gray valves on rig floor. Kelly cocks inspected. Yes

12. BOP Choke Panel DP & annulus pressure gauges working, Pump Yes

stroke counters in good condition & controls labeled.

13. BOP tools available and in good condition Yes

14. Choke manifold valves & pressure gauges in good condition Yes

15. Flare bleed-off lines laid and staked (anchored). Yes

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 4 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

5.0 – Substructure, Cellar & Pipe Racks / No

Comments / Action

1. Area clean & drainage system clear of obstructions.

2. Assembly pins in place and secured with keepers.

3. BOP lifting device available, in good condition, correct SWL Yes

4. Dead line anchor, sensator gap, wire clamp

5. Adequate lighting (Exproof), lighting guarded. Backup lights Yes

6. Cellar protected with a grating cover & accessed with ladder Yes

7. “V” Door Ramp and stairs in good condition. Yes

8. Catwalk in good condition, end stop fitted Yes

9. Pipe rack level with stop pins in place. Pins in good condition. Yes

10. Pipe bins for tubular storage (lifting ears, bins not overloaded).

Yes

6.0 – Rig Floor / No

Comments / Action

1. Rig Floor Handrails and toe boards complete, Steps secure & “V” Yes

door guarded.

2. Rotary floor and racking area correctly maintained Yes

3. Working area around rotary table has suitable non-slip surface. Yes

4. Driller’s console protected with cage(posts) & Shaded Yes

5. Floor free from grease, tripping hazards and open holes. Housekeeping required and when

completed monitored.

6. Moving machinery guards in place. (cathead) Yes

7. Lighting adequate, guarded, explosion proof, backup lights Yes

8. BOP choke panel controls labeled. Yes

9. Doghouse tidy, hand tools, subs/bits, well stored. Housekeeping required.

10. Emergency procedures, Bulletin, safety signs, notices, BOP Yes

procedures posted at doghouse.

11. Two means of egress from doghouse and rig floor. Yes

12. Rig tong backup lines adequate (5/8 “ min.) & posts condition. Yes

13. Dies condition & pins in place. Tong parts NDT inspected. Yes

14. Counter balance condition (grease, cable condition, fittings) Yes

15. Slips condition (dies, retainers, handles, hinges) and bushings. Yes

16. Air Winch condition, SWL adequate & displayed. Yes

17. Air winch cable spooler & drum guard installed. Yes

18. Condition of the air hose (leak, noise, etc.) Yes

19. Air winch cable condition, fitted with swivel, hook condition. Yes

20. Cable way free from obstruction on derrick. Yes

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 5 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

7.1 – Mast – General / No

Comments / Action

1. General condition of mast, no visible cracks, no corrosion no missing Yes

bolts. All structural beams straight.

2. Manufacturer ID Plate, Derrick Characteristics (Mnf Yr, Pwr) Yes

3. Mast ladder in safe condition, adequate attachment to derrick, Yes

crinoline & climbing assist device installed, adjusted and used.

4. Masthead light (aircraft warning light) installed & operative. Yes

5. Lighting adequate, secured with safety chain & Exproof type. Yes

6. Dead line stabilizer in place and effective. Yes

7. Fast line anchor well secured. Correct type of shackles. Yes

8. No loose items or tools in the mast and adequate safety chains used Yes

on all equipment suspended above the floor.

9. Safety lines on all mast pulleys, shackles safety type with pins. Yes

10. Chinstrap used with hard hat worn by mast worker. Yes

11. Wrist straps, tool belts used for tools when working at heights No Only slings to secure specific tools/ some

wrist straps

12. Life lines along the beams for attaching Harnesses lanyards. Yes

13. Raising lines, sockets, pulleys, “A” frame roller, equalizer yoke Yes

condition, last inspected.

Yes

7.2 – Mast – Monkey Board / Stabbing Board / No

Comments / Action

1. Monkey board condition, attachment to mast, handrails fitted. Yes

2. Full body safety harness, horizontal lanyards, inertia reel. Yes

3. Escape line set, secured to the mast (not to handrails), tested, brakes, Yes

access, anchor on ground, cable length & condition.

4. Condition of racks & safety chains, pulling rope, etc. Yes

5. Racking Kelly air winch fitted, cable condition, no leaks. NA

6. No non used tools left on monkey board, pulleys, shackles secured Yes

and pins in place. Water bottles well secured.

7. Monkey board weather / wind protection available. Yes

8. Stabbing board condition, attachment (pins complete/ secure). NA

9. Stabbing board inspected & operative. Adequate access. NA

10. Stabbing board operating winch & cable, brake working. NA

11. Fall arrestor & horizontal rope condition. Safety chain. Yes

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 6 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

7.3 – Mast – Hoisting Equipment / No

Comments / Action

1. Crown block condition. Inspected / Certified. Yes

2. Bloc line jump bar fitted. Handrails & toe boards on Platform. Yes

3. Crown dumper beam fitted and secured. Yes

4. Swivel condition, threads inspected/ certified. Yes

5. Kelly spinner, attachment, operating hoses condition, etc. NA

6. Condition of rotary hose. Yes

7. Block & Hook condition, inspected / certified. Yes

8. Travelling bloc guards securely bolted Yes

9. Hook & lock in good condition Yes

10. Elevators inspected (inspection type) & certified Yes

11. Elevator latches and hinge pins condition Yes

Yes

8.0 – Draw Works / No

Comments / Action

1. Moving parts guarded. Yes

2. Crown-O-Matic adjusted, properly fixed. Twin-stop adjusted. Yes

3. Condition of catheads (drum, cable and chain). Yes

4. Drilling line kickback rollers, condition. Attachment. Yes

5. Drill line Slipping & cutting program. Yes

6. Main brake condition & adjustment. Yes

7. Auxiliary brake condition Yes

8. Drillers panel instrument working. Gauges visible & labelled. Yes

9. Emergency Stop clearly marked & tested (date last test).

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 7 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

9.0 – HP System, Shakers & Mud Tanks / No

Comments / Action

1. Stand pipe pressure rating, flanged / integrated. (Not screwed).

2. Safety chains at swivel & gooseneck ends, attached to mast.

3. All 2” hammer union lines are Fig. 1502.

4. Pump drives guarded. Yes

5. All pressure (shock) hoses have effective safety chains. Yes

6. Pumps & tanks area well lighted. Lights secure & exproof. Yes

7. Steps and walkways clear and guard rails in place. Yes

8. Access stairs away from HP manifold / lines. Yes

9. Free access to shakers, gratings, handrails stairs condition. Yes

10. Mixing hopper clean and at convenient height.

11. Mixing pump drives guarded

12. Eye wash station & emergency shower at mixing area. Accessible, Yes

kept clean & fresh water.

13. Fire extinguishers available & adequate. Date last inspection. Yes

14. Chemicals accessible and packages in good condition. Yes

15. Chemical warning signs & MSDS positioned & legible Yes

16. PPE, gloves, apron, goggles, masks available and used. Yes

10.0 – Generators, SCR Room, Motors, Drives & Yes

Comments / Action

Compressors / No

1. Generators area Clean & no oil spills, combustibles removed. Yes

2. SCR Room clean, dry and cool. Yes

3. Lockout / Tagout procedures in place and used. Yes

4. All guards, inspection plates, covers in place. Yes

5. All moving machinery properly guarded. Yes

6. Generator earthed and shacks earth bonded. Yes

7. Resistance of rig electrical grounding measured & recorded. Yes Current record to be presented prior to

spudding

8. High voltage signs positioned as appropriate. Yes

9. Hearing protection available and used, signs visible. Yes

10. Eletcric chock Emergency Kit available Yes

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 8 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

11.0 – Electric, Mechanic & Welding Workshops / No

Comments / Action

1. Clean and no oil spills, combustibles removed. Yes

2. Welding equipment serviceable and correctly stored. Yes

3. Hearing protection available and used, signs visible. Yes

4. Friction lighters used – no matches or gas lighters. Yes

5. Compressed gas cylinders properly stored, capped. Yes

6. Gas welding hoses, gauges, regulators in good condition. Yes

7. Grinding wheels guarded & tool rests adjusted. NA

8. Eye protection used and eye wash available. Yes

9. Hand tools in good condition, electric units & extension cords have Yes

current leakage protection and tagged with date of test.

10. All oxy/acetylene welding sets fitted Flashback arrestors. Yes

11. Specific Welder PPE available and worn. Yes

Yes

12.0 – Fuel/Oil Storage & Water Supply / No

Comments / Action

1. Area clean and tidy Yes

2. Power lines buried or elevated. Yes

3. Flammable material labelled & stored in designated area Yes

4. Adequate fire extinguishers. Yes

5. Combustibles safely stored in designated area Yes

6. Rubbish bins – covered bins for oil soaked rags No Garbage skips to be covered

7. Walkways clear Yes

8. No Smoking signs and contents labelled for fuel storage areas Yes

9. Tanks vented and earthed Yes

Yes

13.0 – Crane, Forklift & Vehicles / No

Comments / Action

1. Crane hoisting/lowering load rating charts on display Yes

2. All wire rope and slings serviceable Yes

3. Rollover protection to be provided on relevant mobile plant. Yes

4. Lights, horns, brakes, reverse beeper etc, to be operative on all Yes

cranes, forklifts, vehicles and trailers.

5. Vehicles fitted with fire extinguishers Yes

6. Dedicated parking area in a safe area, reverse parking & signs Yes

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 9 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Yes

14.0 – Rig Site Accommodation / No

Comments / Action

1. Offices tidy, well ventilated Yes

2. Electrical wiring to standard. Cabins earthed/tied with rig. Yes

3. Emergency procedures posted in the Offices / Rooms. Yes

4. Offices stairs with platform, handrails, Floor not slippery, doors open Yes

outside freely, wind-check chains.

5. Rooms with smoke detectors & Fire extinguishers. Yes

6. Toilets & showers, tidy & sufficient. Yes

7. Sewage line adequate, connected to sewage pit, covered. Yes

8. Offices area well lighted. No tripping hazards. Yes

9. Emergency lights in the main offices (DSV, TP). Yes

10. Offices muster skid with adequate lifting ears. Yes

11. Wooden ladder to safe access offices roof. No Removable metal ladders exist.

12. Shelves adequate, secure not overloaded. Mean to reach. Yes

Provide additional comments, as needed. Priorities: H=high / M=medium / L=low

Ref. Priority

No.

15.0 – Comments / Actions H/ M /L

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

FORM

Title:

Halliburton Management System

RIG ACCEPTANCE FORM

Document Number:

Region: Function/PSL:

FO-GL-HAL-HPM-WC-310

Global Halliburton Project Management

Owner: Approved By: Job Revision By: Rev Date: Rev No:

Page 10 of 10

Director – HPM Global Ops D. Nicholson D. Nicholson 14.AUG.13 2

Date Rev Summary of Key Revisions By

14.AUG.13 2 Renumbered from GND-GL-HAL-HPM-3100 to FO-GL-HAL-HPM-WC-310 D. Nicholson

Added item numbers

19.JUN.09 1 Original Issue J. Nino

Printed copies of this document are UNCONTROLLED

Printed copies of this document are UNCONTROLLED

You might also like

- Ms 761 1982 Code of Practice For The Storage and Handling of Flammable and Combustible Liquids Ics 75.080-709618Document94 pagesMs 761 1982 Code of Practice For The Storage and Handling of Flammable and Combustible Liquids Ics 75.080-709618cloobpsp82% (11)

- Completion FluildDocument154 pagesCompletion FluildCHUKWUEMEKE OSONDUNo ratings yet

- I Read ..... I Learn: Discover 125 ST Training Notes International BusinessDocument49 pagesI Read ..... I Learn: Discover 125 ST Training Notes International BusinessPato ErazoNo ratings yet

- 3-Waves of RoboticsDocument2 pages3-Waves of RoboticsEbrahim Abd El HadyNo ratings yet

- Idc 37 Rig Move PlanDocument15 pagesIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- 10 - WBM Products and Systems-BMS-C-2012Document105 pages10 - WBM Products and Systems-BMS-C-2012Slim.B100% (3)

- Drilling MatrixDocument3 pagesDrilling Matrixjonny727100% (1)

- Wellhead Operations & Maintenance Course SummaryDocument65 pagesWellhead Operations & Maintenance Course SummaryMustafa NaithelNo ratings yet

- Wellsite Leader Checklist Rig # 41Document3 pagesWellsite Leader Checklist Rig # 41IgorCencičNo ratings yet

- Well Service IWCF Test and AnswersDocument33 pagesWell Service IWCF Test and Answersseyyid ali lylNo ratings yet

- CH3 Workover FluidsDocument65 pagesCH3 Workover FluidsWael abo adelNo ratings yet

- Drilling Hazard Management - Part 3Document4 pagesDrilling Hazard Management - Part 3Yamamoto_KZ100% (1)

- Chapter 10-FDocument12 pagesChapter 10-FMahrouz MadoNo ratings yet

- Drilling and Well ConstructionDocument36 pagesDrilling and Well ConstructionMarcio Nascimento BezerraNo ratings yet

- 2017-18 Drilling ProgrammeDocument32 pages2017-18 Drilling ProgrammesmashfacemcgeeNo ratings yet

- How To Read A Daily Mud ReportDocument13 pagesHow To Read A Daily Mud ReportAhmet Can Zorbilmez100% (1)

- Basic Course of Drilling ProcedureDocument4 pagesBasic Course of Drilling ProcedureAli Samani100% (2)

- IADC Vol-2 07 Rotating and Pipe Handling EquipmentDocument28 pagesIADC Vol-2 07 Rotating and Pipe Handling Equipmentvvzcmq8k75No ratings yet

- 01 MOC For Mud Change For 17.5inch Hole Rev 1Document4 pages01 MOC For Mud Change For 17.5inch Hole Rev 1Anonymous U5t9NYzhLWNo ratings yet

- Chapter 2-JDocument14 pagesChapter 2-JMahrouz MadoNo ratings yet

- Rig Evaluation MiSWACO New-LogoDay 2Document72 pagesRig Evaluation MiSWACO New-LogoDay 2Cerón Niño SantiagoNo ratings yet

- Brochure - Rig Equipment Inspection Virtual TrainingDocument5 pagesBrochure - Rig Equipment Inspection Virtual TrainingSyed IrtazaNo ratings yet

- Well Control Incident Response Plan: N A Le RTDocument76 pagesWell Control Incident Response Plan: N A Le RTChristian Olascoaga MoriNo ratings yet

- API RP 19G13 - Section 5.6 - Very Deep Gas-Lift - Version 2011-04-03Document51 pagesAPI RP 19G13 - Section 5.6 - Very Deep Gas-Lift - Version 2011-04-03Sufian R EllabbadNo ratings yet

- Manual Coiled Tubing p1Document500 pagesManual Coiled Tubing p1Luis Fernando Grajales MorenoNo ratings yet

- Well InterventionDocument83 pagesWell InterventionJosue FishNo ratings yet

- Saudi Aramco: Installation of Telecommunication Equipment On High Structures, Including Radio TowersDocument5 pagesSaudi Aramco: Installation of Telecommunication Equipment On High Structures, Including Radio TowersaymenmoatazNo ratings yet

- A ULTRADRIL Engineering Guidelines DJ!!!Document15 pagesA ULTRADRIL Engineering Guidelines DJ!!!kbrinaldi100% (1)

- Rig Acceptance Check ListDocument2 pagesRig Acceptance Check ListAhmedNo ratings yet

- Wild Well FluidsDocument26 pagesWild Well FluidsAndrés LópezNo ratings yet

- Drilling Fluids: Islamic Azad University Science and Research Branch Drilling DepartmentDocument26 pagesDrilling Fluids: Islamic Azad University Science and Research Branch Drilling Departmentali nahiNo ratings yet

- Hydraulic Fracturing Report 4.18.11Document32 pagesHydraulic Fracturing Report 4.18.11Aayush BhatnagarNo ratings yet

- FORMATEMANUAL A5 Crystallization TemperatureDocument20 pagesFORMATEMANUAL A5 Crystallization TemperaturejcNo ratings yet

- Workover Manual IndexDocument4 pagesWorkover Manual IndexMahrouz MadoNo ratings yet

- Rig Move Brochure: Parker Drilling CompanyDocument39 pagesRig Move Brochure: Parker Drilling CompanyJonathan CustodioNo ratings yet

- 24 - HTHP WellsDocument25 pages24 - HTHP WellsSlim.BNo ratings yet

- Pre-Spud InspectionDocument6 pagesPre-Spud InspectionHany100% (2)

- 0068 - POOH Dual String Completion TubingDocument3 pages0068 - POOH Dual String Completion TubingDrillerNo ratings yet

- Optimum ST PlugsDocument49 pagesOptimum ST PlugsDanish KhanNo ratings yet

- Well PalnningDocument30 pagesWell PalnningPankaj Singh ChauhanNo ratings yet

- Fishing & StucksDocument51 pagesFishing & Stucksمحمد العراقيNo ratings yet

- IADC DDR Codes 2 13 2019Document4 pagesIADC DDR Codes 2 13 2019txcrudeNo ratings yet

- UH Final Presentation 1 - Sept 9, 2013 - PrintingDocument68 pagesUH Final Presentation 1 - Sept 9, 2013 - PrintingTauqeer IqbalNo ratings yet

- 10 - Drilling Fluids Design and Selection - HandoutDocument18 pages10 - Drilling Fluids Design and Selection - HandoutFauzan Rahman HaqNo ratings yet

- PetroSkills - Surface Production OperationsDocument2 pagesPetroSkills - Surface Production OperationsMausam GauravNo ratings yet

- Drilling SupervisorDocument2 pagesDrilling Supervisoreng7mohamed7hashimNo ratings yet

- A Cost-Effective Rig MoveDocument4 pagesA Cost-Effective Rig MoveNA NANo ratings yet

- WELL: HH 83/1D: WIND SPEED at 6:00 AM 44-46 KNTS. (N-NW)Document5 pagesWELL: HH 83/1D: WIND SPEED at 6:00 AM 44-46 KNTS. (N-NW)anon_975742003No ratings yet

- Assistant Slickline Operator 001Document3 pagesAssistant Slickline Operator 001Muhammad shehryar KhanNo ratings yet

- Cementing Program For The 13 38 Inch CasingDocument40 pagesCementing Program For The 13 38 Inch CasingMarvin OmañaNo ratings yet

- Saudi Aramco: Kill and Livening Procedures For WorkoversDocument6 pagesSaudi Aramco: Kill and Livening Procedures For WorkoversMahrouz MadoNo ratings yet

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- 7B - HydraulicsDocument33 pages7B - Hydraulicsagus alexandri100% (1)

- Mud Program RequirementDocument3 pagesMud Program RequirementMahrouz MadoNo ratings yet

- Mud Mixing and StorageDocument3 pagesMud Mixing and Storagecaca666No ratings yet

- How To Ensure H2S Safety On Offshore Rigs - Drilling ContractorDocument10 pagesHow To Ensure H2S Safety On Offshore Rigs - Drilling ContractorTg TarroNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Format Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Document11 pagesFormat Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Lijo JohnNo ratings yet

- Method StatementDocument16 pagesMethod StatementMark FashNo ratings yet

- VIL HSW: Working at Height: Vodafone Idea LTDDocument5 pagesVIL HSW: Working at Height: Vodafone Idea LTDMuthiah ManiNo ratings yet

- VIL HSW: Working at Height: Vodafone Idea LTDDocument4 pagesVIL HSW: Working at Height: Vodafone Idea LTDMuthiah ManiNo ratings yet

- Final Inspection Report With Codes ExampleDocument23 pagesFinal Inspection Report With Codes Exampleeraswasta100% (1)

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 pagesVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNo ratings yet

- Fall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Document2 pagesFall Protection Equipment Inspection Checklist - GL-HAL-HSE-0604Lijo JohnNo ratings yet

- Gas Detection System (GDS)Document2 pagesGas Detection System (GDS)Lijo JohnNo ratings yet

- Gas Testing FormDocument1 pageGas Testing FormLijo John100% (1)

- 019 Smoke Detector ChecklistDocument1 page019 Smoke Detector ChecklistLijo JohnNo ratings yet

- 003 Vehicle Pre-Use ChecklistDocument1 page003 Vehicle Pre-Use ChecklistLijo JohnNo ratings yet

- 002 EAD ChecklistDocument1 page002 EAD ChecklistLijo JohnNo ratings yet

- 001 Emergency Shower and Eye Wash ChecklistDocument1 page001 Emergency Shower and Eye Wash ChecklistLijo JohnNo ratings yet

- Format Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Document11 pagesFormat Rig Acceptance Checlist (FO-GL-HAL-HPM-WC-310Lijo JohnNo ratings yet

- Your Boarding PassDocument1 pageYour Boarding PassLijo JohnNo ratings yet

- Lijo John Kennedy - F - 21012021213850Document1 pageLijo John Kennedy - F - 21012021213850Lijo John100% (1)

- Design of CouplingDocument75 pagesDesign of CouplingVatsal BhalaniNo ratings yet

- Kohler CH26 Service ManualDocument218 pagesKohler CH26 Service Manualjaken202100% (2)

- EDC 17 For H-Series BSIII and BSIV Engines-PassDocument82 pagesEDC 17 For H-Series BSIII and BSIV Engines-PassAsadullah H A0% (1)

- 4/3, 4/2 and 3/2 Directional Valve With Fluidic Actuation: RE 22282/03.07 Replaces: 06.05Document12 pages4/3, 4/2 and 3/2 Directional Valve With Fluidic Actuation: RE 22282/03.07 Replaces: 06.05Phạm Xuân ChínhNo ratings yet

- 2016 Kawasaki kx250f 52453Document203 pages2016 Kawasaki kx250f 52453Alexander alfaro gomezNo ratings yet

- Silnik MechanikaDocument167 pagesSilnik MechanikamorusNo ratings yet

- Aggiornamento OHW 22.2.4 en-GBDocument9 pagesAggiornamento OHW 22.2.4 en-GBmojbarNo ratings yet

- HSDE - Requirements of C.C-1Document39 pagesHSDE - Requirements of C.C-1Fa CaNo ratings yet

- Brake+system New ModelDocument30 pagesBrake+system New ModelTimkenNo ratings yet

- Caterpillar Diesel Engine GeneratorsDocument7 pagesCaterpillar Diesel Engine GeneratorsalfonsoNo ratings yet

- Seminor PPT FinalDocument17 pagesSeminor PPT FinalMukesh SamNo ratings yet

- M Series: Round Line, Non-Repairable Cylinder LineDocument62 pagesM Series: Round Line, Non-Repairable Cylinder LineJezie ReyesNo ratings yet

- MP20 Measuring Head: Dimensions & WeightsDocument1 pageMP20 Measuring Head: Dimensions & WeightsJose Sostenes100% (1)

- Autometer Pro Control 2650-238XDocument4 pagesAutometer Pro Control 2650-238XPat POUPNo ratings yet

- Activity 1.1.2 Simple Machines Practice: ProcedureDocument7 pagesActivity 1.1.2 Simple Machines Practice: ProcedureYonjou-Divine VictorinNo ratings yet

- Rear Drive AxleDocument28 pagesRear Drive Axlemebarki aberraoufNo ratings yet

- Cobra Electronics 8185 Instruction Manual 221137Document6 pagesCobra Electronics 8185 Instruction Manual 221137anthonyNo ratings yet

- Design and Development of Segway Human Transporter: Manish S. Lade Shubhank C. Jaunjal V. D. DhopteDocument3 pagesDesign and Development of Segway Human Transporter: Manish S. Lade Shubhank C. Jaunjal V. D. DhopteSaransh JainNo ratings yet

- Unknown 6Document380 pagesUnknown 6Tina TinaNo ratings yet

- S3 30 - TDSDocument2 pagesS3 30 - TDSMiguel ArizaNo ratings yet

- Hydraulic Presses: Dies and Straighteners For Presses F39Document1 pageHydraulic Presses: Dies and Straighteners For Presses F39Luthfi AnandhikaNo ratings yet

- Quick User GuideDocument43 pagesQuick User GuideEink SimNo ratings yet

- ch420 Winch Parts ManualDocument8 pagesch420 Winch Parts ManualAlok Mishra100% (1)

- Service Manual: ForewordDocument906 pagesService Manual: ForewordredNo ratings yet

- Lincoln Lube Model 94012Document6 pagesLincoln Lube Model 94012luisNo ratings yet

- Dataset 1Document52 pagesDataset 1elvishernandezNo ratings yet

- RUNNER: Nissan Case Study: Final Analysis Page - 1Document31 pagesRUNNER: Nissan Case Study: Final Analysis Page - 1AliceJohnNo ratings yet