Professional Documents

Culture Documents

Navrotsky Vladimir

Navrotsky Vladimir

Uploaded by

Salim BenlahceneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Navrotsky Vladimir

Navrotsky Vladimir

Uploaded by

Salim BenlahceneCopyright:

Available Formats

Siemens’ Medium Size Gas

Turbine Continued Product and

Operation Improvement Program

Olov Andersson

Dr. Vladimir Navrotsky

Scott Santamaria

Siemens Industrial

Turbomachinery AB

PowerGen Europe

June 08-10, 2010

Copyright © Siemens AG 2010. All rights reserved. 1

Content

Summary .................................................................................................................................... 3

Nomenclature ............................................................................................................................. 3

Introduction ................................................................................................................................ 4

Medium-sized gas turbines, operating experience ..................................................................... 5

SGT-500 ................................................................................................................................. 5

SGT-600 ................................................................................................................................. 6

SGT-700 ................................................................................................................................. 6

SGT-800 ................................................................................................................................. 6

Continued MGT performance and operation improvements ..................................................... 6

MGT Performance improvement ............................................................................................... 7

Repair and refurbishment solutions............................................................................................ 8

SGT-800 ................................................................................................................................... 11

SGT-600 ................................................................................................................................... 12

Life extension program ............................................................................................................ 13

Life-cycle extension ............................................................................................................. 13

Extension of the maintenance intervals................................................................................ 15

SGT-800 ........................................................................................................................... 15

SGT-600 ........................................................................................................................... 18

Maintainability improvement program .................................................................................... 19

Remote monitoring and condition monitoring systems (RMS/CMS).................................. 20

Maintenance tool development to improve maintainability................................................. 21

Dummy compressor casing .................................................................................................. 22

Conclusion................................................................................................................................ 23

Acknowledgment ..................................................................................................................... 23

References ................................................................................................................................ 23

Copyright © Siemens AG 2010. All rights reserved. 2

Summary

Gas turbine life cycle cost is one of the most important parameters for power plant owners, as

it has significant influence on power plant profitability. The importance of power plant

profitability is increasing, especially when bearing in mind dynamic market changes or

unstable economic environments. This is why continued reduction of gas turbine life cycle

cost should be considered as an essential contribution of the Original Equipment

Manufacturer (OEM) to improvements in customer power-plant profitability and

competitiveness.

There are several ways in which the OEM can reduce the life-cycle cost of a gas turbine. Two

areas with great impact are product performance enhancement and maintenance cost

reduction.

Gas turbine performance enhancement includes gas turbine efficiency improvement, power

output increase and lifetime extension via installation of modified components or systems.

Maintenance cost reduction is primarily achieved via repair and refurbishment of expensive

gas turbine components and via reduction of maintenance scope or staff, and finally a

reduction of the number of periodic overhauls included in the maintenance program.

This article describes Siemens’ strategy for development programs and solutions in the area of

life-cycle cost reduction for medium-sized gas turbines. The development programs within

Siemens are strongly supported by significant service-related R&D investments and include

upgrade solutions, repair solutions, life extension programs, new inspection technology and

tools, as well as remote monitoring and diagnostics.

Nomenclature

OEM - Original Equipment Manufacture(r),

R&D - Research and Development,

MGT - Medium-sized Gas Turbine,

SGT - Siemens Gas Turbine (SGT-500, SGT-600; …),

ISO - International Standards,

EOH - Equivalent Operating Hours,

TBC - Thermal Barrier Coating,

DLE - Dry Low Emission,

Copyright © Siemens AG 2010. All rights reserved. 3

LTA - Life Time Assessment,

LTE - Life Time Extension,

MP - Maintenance Plan,

PTP - Long Term Program,

RMS - Remote Monitoring System,

CMS - Condition Monitoring System,

cRSP - Common Remote Service Platform,

KPI - Key Performance Indicators.

Introduction

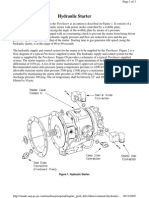

Siemens manufactures, on a global basis, several gas turbines ranging from 5-375 MW, see

Figure 1. The Medium-sized Gas Turbines (MGT) referred to in this paper and as seen in the

chart below encompass the four gas turbines manufactured in Finspong, Sweden.

SGT5-8000H 375

SGT5-4000F 292

SGT6-5000F 208

SGT6-4000F 187

SGT5-2000E 168

SGT6-2000E 113

SGT-800 47

SGT-700 31

Industrial Turbines

Siemens range of

SGT-600 25 Medium Gas Turbines

SGT-500 17

SGT-400 13

SGT-300 8

SGT-200 7

SGT-100 5

Figure 1: Siemens Utility and Industrial gas turbines.

Siemens medium-sized gas turbines: SGT-500, -600, -700, -800.

These four medium-sized gas turbines have a long history dating back to the 1940s. The SGT-

500 is the oldest industrial gas turbine currently under production at the facilities in Sweden,

in commercial operation since 1955. The turbine started with 9MW of power output and

throughout the years has been upgraded in several phases. The unit has just recently been

upgraded and now achieves a power output of 18.5MW.

Copyright © Siemens AG 2010. All rights reserved. 4

The other gas turbines being produced at the aforementioned facilities have also been

upgraded several times, the most recently being the SGT-800 from 45 to 47MW in 2007 and

the SGT-700 from 29 to 31.2MW in 2008. Continued product upgrades and the further

developments of the gas turbines have played an integral part in improving the performance,

reliability and availability of the gas turbines. Future developments and upgrades of gas

turbines have not only been focused on improving the performance of the gas turbine’s core

engine, but also on reducing maintenance costs for power plant owners. Together,

performance and maintenance-related developments have played an important role in

reducing the life-cycle costs of gas turbines.

Medium-sized gas turbines, operating experience

The world-renowned Siemens products are associated with the very high levels of quality.

Siemens Industrial Turbomachinery is absolutely committed to sustaining and enhancing its

products. Siemens’ vision is to be the most responsive source of solutions to improve the

customer’s operating-plant competitiveness and profitability. Product enhancement programs

can be considered successful only if developed improvements can be demonstrated and

sustained. Monitoring of gas turbine operating statistics, especially before and after improved

solutions implementation, can show whether the developed improvements are successful and

sustained. This is why Siemens has a solid process and tools to follow up and analyse gas

turbine operating experience and statistics. The operating experience and operating statistics

(defined in accordance with ISO 3977-9 [1]) presented below represents the current status of

the MGT fleet at the end of December 2009.

SGT-500

The current SGT-500 fleet accounts for more than 170 units, more than 70% of them in

commercial operation. The total accumulated operating experience is more then 8.7 million

Equivalent Operating Hours and >200 000 starts. The fleet leader has accumulated more than

180 000 EOH.

The operating statistics: - Reliability Factor 98.4%; -Availability Factor 95.9%.

The data from the operating statistics are based on the input from 15% of the SGT-500 fleet in

commercial operation and include all types of applications and designs.

Copyright © Siemens AG 2010. All rights reserved. 5

SGT-600

The current SGT-600 fleet accounts for more than 260 units, more than 60% of them in

commercial operation. The total accumulated operating experience is more then 5.5 million

Equivalent Operating Hours and >71 000 starts. The fleet leader has accumulated more than

145 000 EOH.

The operating statistic: -Reliability Factor 98.9%; -Availability Factor 95.9%.

The data from the operating statistics are based on the input from 40% of the SGT-600 fleet in

commercial operation and include all types of applications and designs.

SGT-700

The current SGT-700 fleet accounts for 34 units, 50% of them in commercial operation. The

total accumulated operating experience is more than 200 000 Equivalent Operating Hours and

>2 000 starts. The fleet leader has accumulated more than 40 000 EOH.

The operating statistics: -Reliability Factor 99.6%; -Availability Factor 96.4%.

The data from the operating statistics are based on the input from 75% of the SGT-700 fleet in

commercial operation and include all types of applications and designs.

SGT-800

The current fleet accounts for more than 100 units, more than 40% of them in commercial

operation. The total accumulated operating experience is more than 1,000,000 Equivalent

Operating Hours and >12 000 starts. The fleet leader has accumulated more than 67 000

EOH.

The operating statistics show good and mature records: -Reliability Factor 99.6%; -

Availability Factor 97.8%.

The data from the operating statistics are based on the input from 32% of the SGT-800 fleet in

commercial operation and include all types of applications and designs.

Continued MGT performance and operation improvements

Continued enhancement of existing OEM products and services is an important part of the

OEM’s development efforts. In order to offer, to both future and existing users, gas turbines

with high grading for efficiency, reliability, availability and maintainability at low life-cycle

cost, Siemens Energy invests significantly and with continuity in the development of its

products and services.

Copyright © Siemens AG 2010. All rights reserved. 6

MGT Performance improvement

The industrial gas turbine market is highly competitive. In order to maintain competitiveness,

gas turbine manufacturers continually develop new as well as present fleet of gas turbines.

Performance enhancements have been amongst the key areas of development for Siemens

MGT turbines as they tend to reduce further the life cycle costs of gas turbines. Some

examples of gas turbine performance enhancements that influence life cycle costs are power

output uprates, efficiency improvements, increased fuel flexibility and lifetime extension.

As part of the long-term development program for Siemens MGTs, power uprates are

achieved with design changes aimed at reducing the overall $/kW, lowering the turbine’s

overall life-cycle costs. In nearly all cases, power uprates are accompanied by efficiency

increases. Increased efficiency not only lowers fuel costs, but also results in the reduction of

CO2 emissions. In addition, power uprates are often accompanied by increased mass flow and

exhaust temperature, which increases the total cogeneration and combined-cycle efficiency of

the gas turbine (reducing CO2 emissions even further). Moreover, power upgrades can also be

accompanied by the extension of the time between maintenance overhauls, which not only

increases turbine availability, but also decreases service costs - Both contributing to decrease

life-cycle costs. Examples of two such recent MGT power uprates follow here.

Enhanced and validated in 2007, the SGT-800 is one of the latest gas turbines receiving

product enhancements. Prior to the upgrade, the SGT-800 was rated at 45MW power and 37%

electrical efficiency. Underlying the enhancement is a well-established operating record since

commercial introduction and a detailed mapping of the hot section of the turbine. Over 1900

thermo-crystals were attached to the hot gas path components, and in addition, thermal paint

and thermocouples and pressure taps were used to verify the temperature and pressure

distribution in the turbine area [2]. The results showed that the amount of the cooling air

required for blades and vanes could be redistributed and even saved. These savings, combined

with an increase in compressor airflow of 1.5%, has been the basis for a power output

increase to 47MW and an efficiency increase to 37.5% [3]. Together, the increase in mass

flow, combined with an increase in exhaust heat temperature, has increased combined cycle

efficiency from 53% to over 54%.

Another recent enhancement to the SGT-800 is a modification of the DLE combustion

system. Successful testing has shown the introduction of a passive damping of pulsations not

Copyright © Siemens AG 2010. All rights reserved. 7

only increases emission tuning potential, but also increases the reliability and life of the

combustor. The combustor modification, combined with the reduction of thermal stress in key

components (blades & vanes) has led to further increase in reliability and intervals between

maintenance, which in turn lowers the life-cycle cost of the gas turbine.

Following the upgrade of the SGT-800, the SGT-700 was upgraded and validated in 2008.

The SGT-700 was originally released at 29MW of power output and 36% electrical

efficiency. An extensive program encompassing analysis of fleet data, maintenance activities

and component improvements has led to an increase in power to 31.2MW and efficiency to

36.4%. In addition, both the mass flow and exhaust heat temperature have been increased,

leading to an overall increase in combined-cycle efficiency from 51.5% to 52.3% [4].

As part of the upgrade validation, a comprehensive crystal test was also performed for the

SGT-700. Over 700 measuring points on turbine blading showed that secondary air could be

redistributed, allowing for optimal temperatures in the turbine section [4]. Other changes were

also implemented during the power enhancement, such as compressor-turbine design changes

and the introduction of TBC-coating at the vanes. All in all, the enhancements have once

again allowed for an extension of the time between maintenance, lowering the overall life-

cycle costs of the engine.

These are just a few examples of Siemens long-term product enhancement program

addressing gas turbine performance improvement, helping to lower the overall life-cycle gas

turbine costs. As mentioned earlier, Siemens is, in addition, in the process of further

upgrading its SGT-500 and SGT-600. Also, other areas in which Siemens has been carrying

out extensive testing with positive results are the increased fuel flexibility of the DLE

combustion systems and cyclic-based maintenance programs.

Repair and refurbishment solutions

Maintenance-cost reduction is primarily achieved via repair and refurbishment of expensive

gas-turbine components. Replacement of the components is one of the dominating costs for

maintenance of a gas-turbine-based power plant. It is concentrated around the hot gas path of

the gas turbine, where the components normally require replacement on a regular basis

according to a maintenance plan, but occasionally also other areas will be subject to repair,

depending on operating conditions and environment.

Copyright © Siemens AG 2010. All rights reserved. 8

The continuous development towards higher efficiency and thus higher firing temperatures

has resulted in higher thermal loads on the hot gas path components. In parallel to continuous

progress in materials and cooling technology, increased efforts have been made for the

maintenance of these components to ensure their proper function, reliability and reasonable

cost over the whole lifetime of the engine. Especially the requirements to keep

environmentally friendly low-emission combustion with machines operating at lean fuel air

mixture, set demands for keeping structural integrity and tight tolerances during the whole

operational life.

As a Siemens’ response to that, the development of reconditioning methods for super-alloyed

materials and thermal barrier coatings has been accelerated. The main driver of these

developments is maintenance-cost reduction, i.e. extension of hot gas path component lifetime

without sacrificing the original mechanical and aerodynamic properties.

In some cases, in addition to maintenance cost reduction, the repairs give the opportunity to

shorten the delivery time of strategic components.

In order to make the reconditioning procedure efficient, Siemens have established

reconditioning processes for a number of hot gas path components for MGTs. This enables a

consistent assessment of the components going for repair and the possibility to ensure a high

quality-control level on the repaired components. It also enables process changes as a

response to findings and field experience gained from further operation.

The picture below (Figure: 2) shows the maintenance plan and components replacement

schedule for the SGT-800 medium-size gas turbine. This maintenance plan and component

replacement schedule is typical for all MGTs. In order to keep the downtime for service as

short as possible, new parts are fitted at first time of replacement, and the components coming

out from the engine are taken for repair. At the next overhaul, the repaired parts will be

installed in the engine and the replaced components will be sent for repair.

Copyright © Siemens AG 2010. All rights reserved. 9

Figure 2: SGT-800 Maintenance plan and component replacement schedule

The maintenance of the hot gas path components is predicted to be performed within specific

intervals, depending on operating hours, cycles, environment, etc. At Siemens this is the basis

for components replaced according to plan.

To respond to the needs for different repair scope due to the gas turbines’ different operating

profiles and conditions, the repair scope of hot gas path components can be broken down to

different levels and activities (scope).

As an example, in Figure 3 below the number of different inspection areas are shown for an

annular combustor. The inspection areas shown in the figure are defined, based on all

previous operating experience. Depending on the findings, the scope of repair for each

combustor could be different and not all areas that are shown in the figure will be subjected to

repair or replacement (cost reduction opportunities).

Figure 3: Inspection of annular combustor to identify repair scope

Copyright © Siemens AG 2010. All rights reserved. 10

Apart from the hot gas path components there are also a number of other components and

areas like abradable seals, honeycombs, compressor parts, etc., that will show very different

wear depending on operating conditions. The decision regarding the replacement of these

components will be done during the overhaul of the unit and the components are then repaired

on condition.

These repairs are not included in the planned activity because it is difficult to predict and

forecast them. As they normally are discovered during an overhaul, a repair will require a

short turn around time. In response to this, Siemens have increased their efforts in

regionalization. To find, qualify and approve different repair shops globally has become an

important and continuing activity at Siemens.

In order to restore gas turbine performance, to reduce the maintenance cost and to extend the

lifetime of compressor components, the reconditioning and repair processes are under

continuous development. Siemens consider the development of repair technologies and

processes as strategically important and invest significant R&D funds and efforts in this area.

As an example of currently available repair capabilities for MGTs, the repair scope of SGT-

800 and SGT-600 gas turbine components are presented below.

SGT-800

Compressor components:

• compressor casing and stator rings – recoating of abradable coating to restore the

compressor performance (restoration of radial clearance),

• repair of the rotor seals and stator Honeycombs.

Compressor components are repaired on condition (when it is necessary).

Combustor:

• local weld repair,

• exchange of outer and inner liners and front panel,

• TBC recoating,

• repairs of the burners.

Developed reconditioning and repair processes of the combustion chamber are included into

the standard maintenance plan.

Turbine components:

Copyright © Siemens AG 2010. All rights reserved. 11

Currently the following cost-reducing repair capabilities are included in the standard

maintenance plan:

• weld repair and recoating of blade 1. The latest repair solution is based on laser welding

(laser cladding) technology,

• weld repair of vanes 1 and 2,

• recoating of vanes 1 and 2,

Repair of heat shields above blades 1, 2 and 3 are currently under development.

SGT-600

Compressor components:

• blades and vanes - recoating,

• stator rings above blades – recoating with abradable coating to restore the compressor

performance,

• repair of the rotor seals,

• repair of the compressor rotors, including exchange of the compressor disks.

Compressor components are repaired on components’ condition and are not included in the

standard Maintenance Plan.

Combustor:

• local weld repair,

• exchange of outer and inner liners,

• weld repairs of the burners,

• TBC recoating.

Developed reconditioning and repair processes of the combustion chamber are included in the

standard maintenance plan. At present the further developments of the SGT-600 combustor

repair are concentrated on repair-cost reduction with the target to reduce the current repair

cost by 30%.

Turbine components:

• weld repair of blade 1 (latest solution is based on laser welding technology),

• recoating of blade 1,

• weld repair of vane 1 & 2 (latest solution),

• recoating of vane 1 & 2 (new environmentally friendly recoating technology is in use),

• repair of heat shields above blade 1 & 2 (brazing of new honeycomb).

Copyright © Siemens AG 2010. All rights reserved. 12

Reconditioning and repair processes for the compressor-turbine components are included in

the standard maintenance plan.

Life extension program

As was mentioned above, continuous improvement of the MGT fleet performance and

reliability has been provided by significant R&D investments. During the last few years the

MGT R&D portfolio has been extended by a number of additional projects dedicated to

maintainability improvement, downtime reduction and life-cycle extension.

The extension of the life-cycle of mature MGT fleet has been driven by operator demands and

an aging of the fleet. A significant number of the engines in the SGT-500 and SGT-600 fleet

are approaching their design life of 120,000 EOH.

The latest design modifications of MGT fleets and positive operating experience give

Siemens the opportunity to consider the extension of the life cycle of the engine beyond

120,000 EOH (up to 180,000 EOH, dependent on the previous operation profile and history)

and to extend the maintenance intervals.

Life-cycle extension

The scope of the life-cycle extension is strongly dependent on the engine component

condition at 120,000 EOH. The engine component’s condition is determined by the engine

operation profile, operation history and performed maintenance. In order to keep the life-cycle

extension predictable, controllable and profitable it is necessary to know the engine history

and its components’ condition before reaching the 120,000 EOH, especially for the

components that have a long lead time. Therefore, it is recommended to have two major

activities within the life-cycle extension process:

• a major inspection that determines the general state of the engine - Lifetime Assessment

(LTA) and

• actual Lifetime Extension (LTE) event.

These two activities should be carried out separately in time. In order to minimize the

downtime, the LTA should be combined with one of the standard inspections. The most

suitable standard inspection for the MGT is the C-level inspection at 80,000 EOH.

As an example of life-cycle extension the SGT-600 fleet-extension program is presented

below [5].

Copyright © Siemens AG 2010. All rights reserved. 13

The following boundary conditions were set up for SGT-600 life cycle extension:

• utilization of the standard SGT-600 Maintenance Plan (MP) with some extensions for

LTA & LTE,

• utilization of the standard replacement intervals for hot gas path components (blades,

vanes & combustor),

• LTE of the whole installation by means of extension of the lifetime of the most

expensive engine parts - rotors and casings.

The developed SGT-600 life-cycle extension program is applicable for the gas turbines that

are running in base load operation mode. In this operation mode the dominant damage

mechanism for rotors and stators is the creep. The latest tests and investigations show that the

lifetime of the compressor and turbine rotors and casings can be extended beyond 120,000

EOH. The level of lifetime extension for each individual installation depends on the previous

operation profile and history of this installation. The extension of the life cycle of SGT-600

from 120,000 to 180,000 EOH enables the operator to reduce the life-cycle cost by

approximately 10 % (extra cost for LTA<E is included in the total life- cycle cost).

The standard SGT-600 Maintenance schedule with added LTA & LTE milestones is

presented in Figure 4.

SGT-600/GT10 Maintenance Schedule with LTA and LTE

LTE

Level “E

+ LTA”

Level “D”

Level “C”

Level “B”

Level “A”

Operation

Maintenance

EOH x 1000

10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 110’ 120’ 130’ 140’ 150’ 160’

Figure 4: SGT-600 Maintenance schedule with LTA & LTE

The scope of inspections and activities at the LTA are as follows:

• inspections according to Level-E (compressor blades and vanes, turbine blades and

vanes, fuel rods, couplings and gears, auxiliary systems),

• inspections to determine status of major components include non-destructive and

destructive tests:

Copyright © Siemens AG 2010. All rights reserved. 14

o non-destructive (compressor rotor, flange/bolt connections, casing positions,

roundness measurements and exhaust parts),

o destructive (power turbine vanes 3 and 4, power turbine blade 4).

The outcome of the LTA is a tailored scope of reconditioning/ replacement during the LTE.

The scope of inspections and activities at the LTE are as follows:

• the Level-C activities performed with some add-ons,

• replacements based upon LTA and Level-C inspection.

The purpose of the LTE is that the gas turbine shall be fit for another 40,000+ EOH, with a

potential for further life extensions in the future.

The first SGT-600 life-cycle extension was done in autumn 2007, since then 10+ life cycle

extensions have been done in the SGT-600 fleet.

Extension of the maintenance intervals

A Maintenance Plan (MP) with minimized downtime is strongly requested by all users and in

particular by the oil & gas industry for both mechanical drive and power generation

applications for on- and offshore installations. Currently the Maintenance intervals are

extended for SGT-600 and SGT-800; SGT-500 and SGT-700 maintenance interval extension

development is ongoing.

As an example of maintenance-intervals extension program, the SGT-800 [5] and SGT-600

[6] extension programs are presented below.

SGT-800

The latest Siemens’ modifications of SGT-800 engine and its hot gas path components enable

not only the enhancement of power output and efficiency, but also the extension of

components’ life and, as a result, extension of the time between overhauls.

The extension of the maintenance intervals from 20,000 to 30,000 EOH enables the operator

to save two level B/C overhauls by performing three overhauls instead of five (see Figure 5

and 6). For the whole life cycle, the planned outage hours were reduced by more than 30%.

This modification increases the availability of the SGT-800 by about 1%.

Comparison of overall maintenance duration and corresponding availabilities for MP with

maintenance intervals 20,000 EOH and 30,000 EOH is presented in Table 1.

Copyright © Siemens AG 2010. All rights reserved. 15

Table 1: Maintenance duration and corresponding availabilities

Overhaul intervals 20 000 EOH 30 000 EOH

POH maintenance/PH*100

(POH - Planned Outage Hours; PH - Planned Hours)

1-shift: 3.0 % 2.0 %

2-shift: 2.3 % 1.6 %

2-shift (with exchange turbine module and stator 1): 2.0 % 1.4 %

Extension of the maintenance intervals and reduction of the number of major inspections

(level B/C overhauls) requires more information about the engine and its components’

condition to mitigate the risk associated with extended maintenance interval. This is why MP

with extended maintenance intervals will be offered to the customers only in conjunction with

a Long Term Program (LTP) and installation of an RMS/CMS system (see below). Also,

additional technical and operational requirements apply to the SGT-800 with extended

maintenance intervals:

• base-load operation profile,

• latest component designs and features corresponding to 47 MW rating (standard in

SGT-800 47 MW version),

• natural gas fuel operation – no H2S in fuel,

• static filters (standard in SGT-800 47 MW version),

• air dust trap after compressor (standard in SGT-800 47 MW version),

• drier in exhaust (standard in SGT-800 47 MW version).

The Maintenance Plan with extended intervals will initially be implemented on the 47MW

SGT-800 installations, with a base-load operation profile. The development of the extension

programs for other operation profiles is planned as a next step.

Current MP and MP with extended maintenance intervals are shown in Figures 5 and 6.

Copyright © Siemens AG 2010. All rights reserved. 16

SGT-800 basic Maintenance Plan SGT-800 Extended Intervals Maintenance Plan

Level D

Level C

Level C

Level B

Level B

Level A

Level A

Operation

Maintenance Operation

Maintenance

10 20 30 40 50 60 70 80 90 100 110 120

10 20 30 40 50 60 70 80 90 100 110 120

Eqivalent Operating Hrs x 1000

Equivalent Operating Hours x 1000

Figure 5: SGT-800 Maintenance Plan Figure 6: SGT-800 Maintenance Plan

(Maintenance interval - 20 000 EOH) (Maintenance interval - 30 000 EOH)

The scope and duration of the different inspection levels for Maintenance Plan with extended

maintenance intervals are presented in Table 2. The extended-intervals Maintenance Plan

component-replacement schedule is presented in Figure 7.

Table 2: The scope and duration of the different inspection levels

Extended Intervals Maintenance Plan Activities

Equivalent Operating

10 20 30 40 50 60 70 80 90 100 110 120

Hours x1000 Hours

Level schedule A A B A A C A A B A A -

Level Level Level

A B C

Expected down 1-shift 3 days * 26 days** 31 days**

time incl. 2-shift N/A 20 days*** 22 days***

cooling down

2-shift, turbine tbd 16 days**** 19 days****

module and

turbine stator 1

Scope of inspection Boroscope insp. of: NDT of: NDT of:

- Compressor blading & - Turbine discs & rings - Compressor blading &

stator stator

- Combustion chamber Boroscope insp. of: - Turbine discs & rings

- Burners - Compressor blading &

- Turbine blading stator

Inspection of: Inspection of: Inspection of:

- Auxiliary systems - Turbine guide vanes - Turbine guide vanes

- Electric generator and blades and blades

- Burners - Burners

- Auxiliary systems - Couplings and gears

- Couplings and gears - Auxiliary systems

- Electric generator (L4 - Electric generator (L3)

at 90’ EOH rotor

extraction)

Replacement or Recondition as See replacement See replacement See replacement

required schedule (Figure 11) schedule(Figure 11) schedule(Figure 11)

Verification Control system and Control system and Control system and

instruments instruments instruments

•12 h/d **10 h/d, 6 d/w ***10h/shift, 6 d/w ****10 h/shift, 6 d/w, exchange of turbine module and turbine stator 1

Copyright © Siemens AG 2010. All rights reserved. 17

Extended Intervals Replacement Schedule

Equivalent Operating

10 20 30 40 50 60 70 80 90 100 110 120

Hours x1000 Hours

Level schedule A A B A A C A A B A A -

set #1 Original Recon. Recon

Burners

set #2 New Recon. Recon.

set #1 Original

Combustion set #2 New

chamber set #3 New

set #4 New

set #1 Original

set #2 New

1st Vane

set #3 New

set #4 New

set #1 Original

set #2 New

1st Blade

set #3 New

set #4 New

set #1 Original

set #2 New

2nd Vane,

set #3 New

set #4 New

set #1 Original

set #2 New

2nd Blade

set #3 New

set #4 New

set #1 Original

3rd Vane

set #2 New

set #1 Original

3rd Blade

set #2 New

Figure 7: SGT-800 extended-intervals component-replacement schedule

SGT-600

The target for SGT-600 downtime reduction was the establishment of a new MP with

increased availability via planned outage hour reduction:

• extension of the maintenance intervals from 20,000 EOH to 30,000 EOH,

• reduction of the current inspections and site activities downtime:

– extension of shift work,

– reduction of the Level-A inspection from 3 days to 1 day,

– improvement of the maintenance processes and tools.

The developed MP with maintenance intervals of 30,000 EOH will initially be implemented

on the SGT-600 installations with base- load operation profile and with latest component

design and features:

• DLE combustors (for both liquid and gas fuel) and

• latest component design:

– compressor guide vane 2,

– combustor design and combustor governing system,

– compressor turbine blade 1 & 2,

– compressor turbine guide vane 1 & 2,

Copyright © Siemens AG 2010. All rights reserved. 18

– power turbine blade 3,

– diffuser.

The extension of the maintenance intervals from 20,000 to 30,000 EOH enables the operator

to save two overhauls, performing three overhauls instead of five. Furthermore, the duration

of the remaining inspections has been reduced. In total, for the whole life cycle, the planned

outage hours were reduced by about 50%. This modification increases the availability of the

SGT-600 by about 1%.

The current MP and the MP with extended maintenance intervals are presented in Figures 8

and 9.

SGT-600 Maintenance Plan SGT-600 Maintenance Plan

Extended Intervals Base load operation Base load operation TBO 20’ EOH

SGT-600 basic maintenance plan SGT-600 basic maintenance plan

Level “E”

Level “D” Level “D”

Level “C” Level “C”

Level “B” Level “B”

Level “A24h” Level “A”

Operation Operation

Maintenance Maintenance

Eq. Op. Hrs x 1000 Eq. Op. Hrs x 1000

10 20 30 40 50 60 70 80 90 100 110 120 10 20 30 40 50 60 70 80 90 100 110 120

Sid 8 Sid 7

Figure 8 : SGT-600 Maintenance Plan Figure 9 : SGT-600 Maintenance Plan

(Maintenance interval of 20,000 EOH) (Maintenance interval of 30,000 EOH)

Maintainability improvement program

Continued improvement of the MGT performance and reliability has been supported by

significant R&D investments. To meet the challenges of the market and to improve our

customers’ operating-plant competitiveness and to ensure their mutual profitability, new and

innovative maintenance concepts and appropriate technologies and tools have to be developed

and employed. Thus, during the last three years, the MGT R&D portfolio has been extended

by a number of additional projects dedicated to serviceability and maintainability

improvement.

These R&D programs include the development of maintenance tools, advanced repair, non-

destructive inspection technology, remote monitoring, condition monitoring, diagnostics and

new maintenance concepts including maintenance with extended intervals, cycle-based

maintenance and finally condition-based maintenance [7].

Copyright © Siemens AG 2010. All rights reserved. 19

Some of the results of the developments that support MGT maintainability improvement are

briefly presented below.

Remote monitoring and condition monitoring systems (RMS/CMS)

To get more individual information about operation of each gas turbine and by doing this to

be better prepared for coming maintenance, a continued monitoring of the gas turbine is very

important. Continued monitoring of gas turbine operation and condition of its components

enables the operator to reduce the downtime, to support flexible plant operation, to minimize

the risk of plant malfunction or breakdown and, finally, to reduce the plant/gas turbine life

cycle cost.

STA-RMS – Siemens Remote Monitoring System is a common remote and condition-

monitoring system that has been developed for all Siemens Industrial Turbomachinery

rotating equipment (gas turbines, steam turbines and compressors) and provides a wide range

of functionalities:

• monitoring, trending and analysis of main engine parameters (e.g. speed rotation,

pressures, temperatures),

• performance monitoring and analysis,

• vibration monitoring and analysis,

• emission monitoring and analysis (for gas turbine),

• automatic report generation.

Siemens believes that operators will have many benefits from this system as it shares

accumulated OEM knowledge and experience with the operator. The most recent

development of the Siemens’ STA-RMS (see Figure 1) provides a powerful tool for the

operator to follow up his rotating equipment, predict its future maintenance and provide a way

for optimization of the rotating equipment and the plant operation.

The STA-RMS concept includes the following levels:

• Level 1 - data collection on site. Data collectors have been designed for the various

types of rotating equipment for industrial applications within Siemens Energy

• Level 2 - data transfer and remote access. A common Siemens cRSP solution (common

Remote Service platform) has been developed and implemented.

• Level 3 - data storage in a common Siemens Energy Industrial Applications database,

RMS database.

Copyright © Siemens AG 2010. All rights reserved. 20

• Level 4 - data presentation in the form of graphs, KPIs (statistics), trends, automatic

reports, automatic diagnostics, common Siemens Energy Industrial Applications RMS

web interface.

• Level 5 - different plug-ins or customer support services: help desk, evaluated reporting,

remote services, advanced diagnostics (under development), risk assessment, decision

support, condition-based maintenance (currently under development).

Customer –

purchased data

PGI Units at customer site Data Transmission Common Central Data Evaluation/

Database Processing

Common Top +

GT ST

Siemens Solution

(Remote Services) AI

ST Data CP

AI

Collection

on site

AI

CP GT

Data Filter/ AI

Compression Secure -Raw Data

Other for Transmission -Std. interfaces Other

Transmission -Internet -Std. protocols

-Modem Automatic

-Phone Line Diagnostic PG I1-6 24/7

Algorithm Expert

Centres

Level 1 Level 2 Level 3 Level 4 Level 5

Figure 10: Remote Monitoring System concept and structure

Maintenance tool development to improve maintainability

Accumulated experience and analysis of performed inspections, maintenance and overhauls of

the current MGT fleets showed that maintainability and maintenance down-time could be

further improved by developing new maintenance tools and/or modernizing the existing tools.

In Figure 8 a few examples of the maintenance tools developed for SGT-800 are presented:

• universal table for work with SGT-800 stators,

• universal lifting tool (weight 13 kg) applicable for all turbine disks replaces two

existing tools weighing 50 kg each,

• universal location pin applicable for all possible conjugations of parts. Replaces existing

two sets (each consisting of 6 pins),

• dummy compressor casing.

Copyright © Siemens AG 2010. All rights reserved. 21

a b c

Figure 11: SGT-800 Maintenance tools: a -universal table for works with stators; b- universal

lifting tool for all turbine disks; c-universal location pin

Dummy compressor casing

To provide good access to compressor components during inspection and maintenance, the

compressor casing has been designed with a vertically split plane. Since the compressor

casing is a part of the supporting structure, one of the two vertical halves of the compressor

casing always has to be assembled during compressor maintenance. As a result, the

attachment of the rear inner stator requires the compressor casing to be disassembled and

assembled repeatedly during the maintenance and repair of the compressor. To avoid this, a

dummy compressor casing has been designed (see Figure 12). During maintenance this

replaces one of the halves of the compressor casing and enables work with the rear inner

stator. This allows for a reduction of down-time during level C/D inspection by approx. 1 day.

Moreover, the compressor casing dummy reduces the risk of damage to blade and guide

vanes.

Figure 12: SGT-800 Compressor Maintenance tool - dummy compressor casing

Copyright © Siemens AG 2010. All rights reserved. 22

Conclusion

Siemens has been working hard with continued enhancement of MGT fleets and lowering

their overall life-cycle costs. All these enhancement programs are part of Siemens’ long-term

product development strategy and resulted in:

• High reliability and availability of the MGT gas turbine thanks to continued

improvements and enhancement of the gas turbines and their component designs. The

operating statistics show good and mature records.

• The positive operation experience and the results of the latest development and

extended R&D programs have made it possible to develop the extension of maintenance

intervals from 20,000 to 30,000 EOH for SGT-600 & SGT-800; SGT-700 is currently

under development.

• Several performance enhancement and maintenance-related programs that have been

invested in are developed with the sole purpose of reducing life-cycle costs for power-

plant producers.

Acknowledgment

The authors of this paper would like to thank the following people for their assistance or

material reference: Mats Björkman, Mats Blomstedt, Anders Hellberg, Georg Nordén, Lena

Strömberg, Pontus Slottner, Patrik Helgesson, Christian Troger and Mikael Rosén.

References

[1] ISO 3977-9 INTERNATIONAL STANDARD, ‘Gas turbine, Procurement, Part 9: Reliability,

availability, maintainability and safety’, First edition 1999-12-15.

[2] Mats Annerfeldt, Sergey Shukin, Mats Björkman, Agne Karlsson, Anders Jönsson, Elena

Svistounova, ‘GTX100 Turbine section measurement using a temperature sensitive crystal

technique. A comparison with 3D thermal and aerodynamic analysis’, PowerGen Europe,

Barcelona, 2004.

[3] Sergey Shukin, Mats Annerfeldt, Mats Björkman, ‘Siemens SGT-800 Industrial gas turbine

enhanced to 47MW. Design modification and operation experience’, ASME, GT2008-50087.

[4] Anders Hellberg, Georg Norden ’Siemens Industrial Gas Turbines, SGT-700 31MWe’,

Power-Gen Europe, Cologne, 2009.

Copyright © Siemens AG 2010. All rights reserved. 23

[5] Vladimir Navrotsky, Lena Strömberg, Claes Uebel, ‘SGT-800 Gas Turbine – Availability –

focused design and maintainability improvements’, Power-Gen Europe, Cologne, 2009..

[6] Vladimir Navrotsky, Mats Blomstedt, Niklas Lundin, Claes Uebel, ‘Continied Enhancement

of SGT-600 Gas Turbine and Maintenance’ 17th Conference of the Electric Power Supply

Industry, Macau, October 2008.

[7] Vladimir Navrotsky, Per Johansson, Bengt Svensson, ‘Development of the platform for

Condition Based Maintenance’, Power-Gen Asia, Singapore, 2005.

Copyright © Siemens AG 2010. All rights reserved. 24

Permission for use

The content of this paper is copyrighted by Siemens and is licensed to PennWell for

publication and distribution only. Any inquiries regarding permission to use the content of

this paper, in whole or in part, for any purpose must be addressed to Siemens directly.

Disclaimer

These documents contain forward-looking statements and information – that is, statements

related to future, not past, events. These statements may be identified either orally or in

writing by words as “expects”, “anticipates”, “intends”, “plans”, “believes”, “seeks”,

“estimates”, “will” or words of similar meaning. Such statements are based on our current

expectations and certain assumptions, and are, therefore, subject to certain risks and

uncertainties. A variety of factors, many of which are beyond Siemens’ control, affect its

operations, performance, business strategy and results and could cause the actual results,

performance or achievements of Siemens worldwide to be materially different from any

future results, performance or achievements that may be expressed or implied by such

forward-looking statements. For us, particular uncertainties arise, among others, from changes

in general economic and business conditions, changes in currency exchange rates and interest

rates, introduction of competing products or technologies by other companies, lack of

acceptance of new products or services by customers targeted by Siemens worldwide, changes

in business strategy and various other factors. More detailed information about certain of

these factors is contained in Siemens’ filings with the SEC, which are available on the

Siemens website, www.siemens.com and on the SEC’s website, www.sec.gov. Should one or

more of these risks or uncertainties materialize, or should underlying assumptions prove

incorrect, actual results may vary materially from those described in the relevant forward-

looking statement as anticipated, believed, estimated, expected, intended, planned or

projected. Siemens does not intend or assume any obligation to update or revise these

forward-looking statements in light of developments which differ from those anticipated.

Trademarks mentioned in these documents are the property of Siemens AG, its affiliates or

their respective owners.

Copyright © Siemens AG 2010. All rights reserved. 25

You might also like

- Frame 7EA 2021Document30 pagesFrame 7EA 2021Ender Galvis75% (4)

- SGT-800 Gas Turbine EN PDFDocument12 pagesSGT-800 Gas Turbine EN PDFThanapaet Rittirut100% (1)

- 05 GT13E2+Rotor+Information HandoutsDocument21 pages05 GT13E2+Rotor+Information HandoutsShangker Kanesh100% (4)

- Dry Low Nox 2.0+ System Operation: Ge Power SystemsDocument10 pagesDry Low Nox 2.0+ System Operation: Ge Power SystemsFernando Piaggio100% (2)

- LM 2500Document12 pagesLM 2500pramodtryNo ratings yet

- Thermal Tests of The 45MW SGT-800 Gas Turbine EquipmentDocument7 pagesThermal Tests of The 45MW SGT-800 Gas Turbine Equipmentbagusu_6No ratings yet

- SCOPE-1 SECTION-2 CommssinoingDocument109 pagesSCOPE-1 SECTION-2 Commssinoingahmed100% (1)

- Overview of SCF6 ExchangeDocument2 pagesOverview of SCF6 Exchangechdi100% (1)

- SGT 750Document24 pagesSGT 750andmar2011No ratings yet

- 02 Ms5001 DescriptionDocument58 pages02 Ms5001 DescriptionHafiz Usman Mahmood100% (6)

- Siemens SGT-600 Gas Turbine EOHDocument14 pagesSiemens SGT-600 Gas Turbine EOHifegwu100% (1)

- SGT-800 Maintainability ImprovementsDocument13 pagesSGT-800 Maintainability Improvementsalexandr_popov_2No ratings yet

- Service Experiences With The World Record Gas Turbine SGT-8000HDocument16 pagesService Experiences With The World Record Gas Turbine SGT-8000HabelsgNo ratings yet

- Alstom Gas-Turbines-Technical-Performance PDFDocument2 pagesAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyNo ratings yet

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet Rittirut100% (1)

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- Siemens Technical Paper Fuel Flexibility SGT 400Document11 pagesSiemens Technical Paper Fuel Flexibility SGT 400Hicham BenkhalifaNo ratings yet

- Siemens SGT-300 MD. Brian M Igoe Product Manager SGT-300. Trevor Mapleston Project Manager SGT-300Document36 pagesSiemens SGT-300 MD. Brian M Igoe Product Manager SGT-300. Trevor Mapleston Project Manager SGT-300benlahcene100% (1)

- Proven Upgrade SGT5-4000FDocument9 pagesProven Upgrade SGT5-4000FThanapaet Rittirut100% (2)

- SGT 600Document47 pagesSGT 600Nagam Abhishek100% (3)

- GEA31503e PGP Product E-Catalog 2015 R10Document47 pagesGEA31503e PGP Product E-Catalog 2015 R10juagamsar100% (1)

- 01 Tab01 130916060639 Phpapp02 PDFDocument36 pages01 Tab01 130916060639 Phpapp02 PDFajo zinzoNo ratings yet

- SGT-600 GT PowerGen ENDocument4 pagesSGT-600 GT PowerGen ENBehnamayoubzadehNo ratings yet

- GTs World Comparison Picture - 1-130 MW - 2015 01 PDFDocument2 pagesGTs World Comparison Picture - 1-130 MW - 2015 01 PDFdvcher78100% (2)

- Ansaldo Energia AE94.2 Upgrading ProjectDocument20 pagesAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

- GT Gas Fuel and Air FlowDocument38 pagesGT Gas Fuel and Air Flowhina100% (1)

- Siemens GTDocument8 pagesSiemens GThbalu007No ratings yet

- Sgt-600 GT Mechdrive enDocument4 pagesSgt-600 GT Mechdrive enRoozbeh PNo ratings yet

- HRSG Design Tutorial - Heat BalanceDocument3 pagesHRSG Design Tutorial - Heat BalanceRavi Kasaudhan100% (1)

- Proven Solutions GE-EvuletDocument48 pagesProven Solutions GE-EvuletmohamedhasNo ratings yet

- CPM - Ap - Lm6000-Ind-024 (1) 2009Document64 pagesCPM - Ap - Lm6000-Ind-024 (1) 2009Victor Nahun ReyesNo ratings yet

- SAC and DLE PDFDocument29 pagesSAC and DLE PDFMehulkumar PatelNo ratings yet

- Formas Instalacion Turbina 6000Document27 pagesFormas Instalacion Turbina 6000ferrerick100% (1)

- 3rd Party PSM Ansaldo - Energia PDFDocument30 pages3rd Party PSM Ansaldo - Energia PDFkp pk100% (1)

- 9e Turbine Gea16035b 9e GT HRDocument1 page9e Turbine Gea16035b 9e GT HRFedor Bancoff.100% (1)

- المواد المرمزة والمطلوبة ترميزها بملف واحدDocument247 pagesالمواد المرمزة والمطلوبة ترميزها بملف واحدMahdi HassanNo ratings yet

- Gt13e2 Gas Turbine 2012 UpgradeDocument2 pagesGt13e2 Gas Turbine 2012 UpgradeJJ100% (1)

- PDFDocument124 pagesPDFEmanuel Conde100% (1)

- 01 Intro&Theory GTDocument74 pages01 Intro&Theory GTHafiz Usman Mahmood100% (1)

- Gas Turbines Technical PerformanceDocument2 pagesGas Turbines Technical PerformanceLTE002100% (1)

- GT Mtc. PracticesDocument59 pagesGT Mtc. PracticesAbhishek Prakash Srivastava100% (1)

- MS5002EDocument8 pagesMS5002Eamir8100100% (1)

- 3 - Gas Turbine Overview 8.09Document25 pages3 - Gas Turbine Overview 8.09Sujeet Kumar100% (4)

- Pivot Arm Turning GearDocument24 pagesPivot Arm Turning Gearoom_tgw100% (1)

- SGT 800 Factsheet 2017Document2 pagesSGT 800 Factsheet 2017pradeepnair1710% (1)

- DLN IntructionDocument20 pagesDLN IntructionThanapaet Rittirut100% (2)

- Ansaldo Thomassen - CMU (2014)Document4 pagesAnsaldo Thomassen - CMU (2014)guerrezNo ratings yet

- Siemens Gas Turbine SGT 500 Crude OilDocument10 pagesSiemens Gas Turbine SGT 500 Crude Oilgeverett2765No ratings yet

- GTDocument33 pagesGTowais_36100% (5)

- Sobreprecio 18MM: TM2500 de EPS A DerwickDocument33 pagesSobreprecio 18MM: TM2500 de EPS A DerwickTomás LanderNo ratings yet

- MS6001FADocument14 pagesMS6001FAsureshkumar908No ratings yet

- Slides HDGT O&M ENDocument495 pagesSlides HDGT O&M ENOmarAnabi100% (4)

- SGT-700 Industrial Gas TurbineDocument4 pagesSGT-700 Industrial Gas TurbineDavichín Morató FernandezNo ratings yet

- GearboxDocument16 pagesGearboxMehul zare100% (1)

- Gas TurbineDocument31 pagesGas TurbineŞansal Dikmener100% (1)

- 2014 Pge 8000h For European Power MarketDocument18 pages2014 Pge 8000h For European Power MarketHenrique YoshidaNo ratings yet

- Advanced Sgt6-5000F Development: 09-IAGT-202Document18 pagesAdvanced Sgt6-5000F Development: 09-IAGT-202Ronald ChavezNo ratings yet

- Evoluzione Della SiemensDocument10 pagesEvoluzione Della SiemensFederico PinnaNo ratings yet

- Siemens - SGT6-5000F (W501F) Engine Enhancements To Improve OpDocument14 pagesSiemens - SGT6-5000F (W501F) Engine Enhancements To Improve OpparatonerqNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Wire Rope SlingsDocument27 pagesWire Rope Slingsnasirfahim100% (1)

- Midalloy ER70S-2Document1 pageMidalloy ER70S-2nasirfahimNo ratings yet

- Gas Tungsten Arc WeldingDocument1 pageGas Tungsten Arc WeldingnasirfahimNo ratings yet

- 17 GPM Lube Oil From Turbine Available. CT at 3RPM Turning Speed 3. Torque Converter Guide Vanes Set To MaxDocument3 pages17 GPM Lube Oil From Turbine Available. CT at 3RPM Turning Speed 3. Torque Converter Guide Vanes Set To MaxnasirfahimNo ratings yet

- Benefits From OkraDocument1 pageBenefits From OkranasirfahimNo ratings yet

- Maximizing Your P&LDocument2 pagesMaximizing Your P&LnasirfahimNo ratings yet

- Leadership: AdversityDocument4 pagesLeadership: AdversitynasirfahimNo ratings yet

- Mark VI ControlDocument27 pagesMark VI ControlnasirfahimNo ratings yet

- Heat StressDocument22 pagesHeat StressnasirfahimNo ratings yet

- Seat BeltsDocument6 pagesSeat BeltsnasirfahimNo ratings yet

- Gear Pump Design SheetDocument3 pagesGear Pump Design Sheetdeion29No ratings yet

- Internal Combustion Engines:: I.C and E.C EnginesDocument4 pagesInternal Combustion Engines:: I.C and E.C EnginesTariq AslamNo ratings yet

- H25-H15 CatalogueDocument12 pagesH25-H15 CatalogueTong Chaipanyakul100% (1)

- SUB: 18ME25 Elements of Mech Engg Faculty: Balachandra Bingi Module 1 &2 No. MarksDocument3 pagesSUB: 18ME25 Elements of Mech Engg Faculty: Balachandra Bingi Module 1 &2 No. Markshimanshu malikNo ratings yet

- 2001 ME Thesis PapersDocument53 pages2001 ME Thesis Papersazd1973No ratings yet

- Application of Digital Twin TechnologyDocument41 pagesApplication of Digital Twin TechnologyHemn Rafiq TofiqNo ratings yet

- Ansaldo EnergyDocument46 pagesAnsaldo Energysertackcdg100% (2)

- MTU 16V4000G63 Diesel Generating Sets Technical DataDocument6 pagesMTU 16V4000G63 Diesel Generating Sets Technical DataMahnooshNo ratings yet

- PDB Annual Training Program - 10-07-15 PDFDocument160 pagesPDB Annual Training Program - 10-07-15 PDFMohammed AsibNo ratings yet

- NGC Industrial Gearboxes - 20190523 - DPDocument14 pagesNGC Industrial Gearboxes - 20190523 - DPhenrymejiamNo ratings yet

- Finite ElementDocument5 pagesFinite Elementbasu2489No ratings yet

- SP 4aprobDocument1 pageSP 4aprobJexcel Hyacinth CañizaresNo ratings yet

- Syllabus CurriculumDocument27 pagesSyllabus CurriculumChitraSKNo ratings yet

- GE 7ha-Fact-Sheet-Oct15 PDFDocument2 pagesGE 7ha-Fact-Sheet-Oct15 PDFTan Nguyen HuuNo ratings yet

- C4 Specific PDFDocument44 pagesC4 Specific PDFNadim JilaniNo ratings yet

- QP PVL 2006Document45 pagesQP PVL 2006sudhakarmnNo ratings yet

- Accepted Manuscript Not Copyedited: A Review of Grooved Dynamic Gas BearingsDocument38 pagesAccepted Manuscript Not Copyedited: A Review of Grooved Dynamic Gas BearingswataruNo ratings yet

- Gt24 and Gt26 Gas TurbinesGBDocument24 pagesGt24 and Gt26 Gas TurbinesGBwangchao821100% (2)

- Combined Heat and Power (CHP) Level 1 Feasibility Analysis: Company BDocument28 pagesCombined Heat and Power (CHP) Level 1 Feasibility Analysis: Company BsebascianNo ratings yet

- De-Coupled Solid Oxide Fuel Cell Gas Turbine Hybrid (DFC-GT)Document9 pagesDe-Coupled Solid Oxide Fuel Cell Gas Turbine Hybrid (DFC-GT)Morgen GumpNo ratings yet

- RAM StudyDocument12 pagesRAM StudyputelNo ratings yet

- Thermolib GettingStartedDocument35 pagesThermolib GettingStartedArjuna SarumpaetNo ratings yet

- GE Model DesignationDocument6 pagesGE Model DesignationJerry IrawanNo ratings yet

- LNG - Innovation in The LNG Industry - Shell's ApproachDocument12 pagesLNG - Innovation in The LNG Industry - Shell's ApproachNikesh PanchalNo ratings yet

- CPPDocument19 pagesCPPKuldeepsingh ChandelNo ratings yet

- Punjab Technical University: Section - A Is CompulsoryDocument1 pagePunjab Technical University: Section - A Is CompulsoryPardeep bains100% (1)

- Turbo 4Document13 pagesTurbo 4Abdalmalek shamsanNo ratings yet

- MTU Navy Brochure 1 14Document29 pagesMTU Navy Brochure 1 14m_najmanNo ratings yet

- ME925 Fundamentals of Gas Turbine EnginesDocument54 pagesME925 Fundamentals of Gas Turbine EnginesSHESHNARAYAN SHRIVAS100% (1)

- KietlinskiDocument20 pagesKietlinskisenthil031277No ratings yet

- Sealing Compounds From Project Sales CorpDocument34 pagesSealing Compounds From Project Sales CorpProject Sales CorpNo ratings yet