Professional Documents

Culture Documents

FD 36628 Gonfreville 2009 Ang

FD 36628 Gonfreville 2009 Ang

Uploaded by

A N MadhavanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FD 36628 Gonfreville 2009 Ang

FD 36628 Gonfreville 2009 Ang

Uploaded by

A N MadhavanCopyright:

Available Formats

IMPEL - Ministry of Sustainable Development - DGPR / SRT / BARPI-DREAL Upper Normandy No.

36628

Explosion of a sulphuric acid tank Chemistry

Sulphuric acid

4 August 2009 Hydrogen

Gonfreville-l'Orcher Explosion

Tank

(Seine-Maritime) Maintenance

France Equipment defect

Organisation / controls

THE FACILITIES INVOLVED

The site :

This plant, rated upper-tier SEVESO, was using naphtha and butane as inputs to produce the most widespread

intermediate chemical compounds in the petrochemical industry (i.e. ethylene, propylene, butadiene and benzene), for

subsequent input into plastics manufacturing processes.

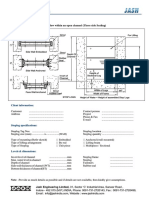

The unit involved :

The accident occurred on a 100-m3 capacity tank (built in 1974) containing sulphuric acid concentrated to 96%. Installed

outdoors on piles above a retention basin lined with epoxy resin and part of the unit for treating sodium-bearing water,

this tank was used to supply :

• the neutralisation reactor for sodium water stemming from the absorption of hydrogen sulphide on the vapour

cracking unit ;

• demineralisation chains of water for boilers and cooling towers with sulphuric acid when the dedicated tank

was undergoing maintenance.

Location after

the accident

Initial location

Neutralisation

drum for

Retention

sodium-

bearing water basin

Diagram of the accident scene

File last updated: May 2011 1

IMPEL - Ministry of Sustainable Development - DGPR / SRT / BARPI-DREAL Upper Normandy No. 36628

This tank had already been repaired in 1989 following an incident that caused its delamination, yet without breaking any

fastenings, due to a release of carbonic gas during the sulphuric acid neutralisation step (ARIA 23705). A support

bracket had been added in response to this initial accident, and the cleaning procedure was also revised.

THE ACCIDENT, ITS CHRONOLOGY, EFFECTS AND CONSEQUENCES

The accident :

On 17 July 2009, a leak was detected on the F2 tank containing 70 m³ of concentrated sulphuric acid (caused by a 1-

mm hole). This leak was plugged on 18 July using a temporary sealant system following approvals delivered by the

onsite inspection department.

On Friday 31 July, the tank was emptied to a point of inducing pump cavitation. The remaining product was drained into

the retention basin and the tank was rinsed with water over the weekend. A scaffolding was set up to accomplish the rest

of the works programme.

On Monday 3 August, the rinsing water collected in the retention basin was conveyed to the water treatment plant.

On Tuesday 4 August, the task of chemical consignment (platinum plating) of the inventory was undertaken in order to

isolate the storage capacity. A member of the plant staff, accompanied by 2 subcontractor employees, climbed onto the

tank to open the manhole. An explosion occurred around 9:15 am when the plant technician used a grinder to shear the

seized bolts.

The F2 tank, empty at the time of the accident, was suddenly lifted 2 or 3 m high and then fell back to the ground on top

of a nearby drum. As it was falling, the tank brought down the scaffolding that had been installed for upcoming

maintenance.

The Internal Emergency Plan was activated. The site operator notified the local Prefecture, town halls and the general

public.

Consequences of this accident :

Three individuals were hurt, with two of the injuries serious.

Two subcontracted employees and a site technician were on the scaffolding at the top of the tank at the time of the

explosion. One subcontractor was ejected towards a neighbouring structure 5 metres aboveground when the tank

suddenly thrust upward. He landed back on the ground away from the scaffolding. The other subcontractor was pinned

in the scaffolding. The third victim (plant technician) took a hard fall and was found on the ground unconscious. Ten

other people were seen by the psychological response team at a treatment office opened onsite.

No environmental impact was reported and no hazardous substances released.

The damages were limited to destruction of the tank and all connecting piping; the unit was shut down. The tank was

torn apart over half the shell/bottom junction circumference. Its anchorages were also ripped out.

Photos courtesy of DREAL: Damaged tank

Concrete base where the tank was positioned

File last updated: May 2011 2

IMPEL - Ministry of Sustainable Development - DGPR / SRT / BARPI-DREAL Upper Normandy No. 36628

The European scale of industrial accidents

By applying the rating rules applicable to the 18 parameters of the scale officially adopted in February 1994 by the

Member States' Competent Authority Committee for implementing the ‘SEVESO’ directive on handling hazardous

substances, and in light of information available, this accident can be characterised by the four following indices:

As the accident unfolded, an explosion occurred that revealed the presence of a Seveso-listed substance, namely

hydrogen. Since the quantity was estimated at 200 g, the index relative to hazardous substances released was set equal

to 1 (see parameter Q1). Three injuries were reported, two of them serious, assigning the index relative to human and

social consequences a "2" score (parameter H4). No environmental consequence was identified, resulting in a "0" rating

for the environmental consequences index. Lastly, the cost due to property damage and operating losses was estimated

at €6 M, yielding a score of "3" for the index relative to economic consequences (parameters €15 and €16).

The parameters composing these indices and their corresponding rating protocol are available from the following

Website: http://www.aria.developpement-durable.gouv.fr.

THE ORIGIN, CAUSES AND CIRCUMSTANCES SURROUNDING THIS ACCIDENT

Insufficient rinsing of the tank (just a single rinsing

cycle was performed) combined with the presence

of a low concentration of sulphuric acid caused an

acid attack of the metal, leading to the formation

and accumulation of hydrogen at the top of the tank

(dome-shaped tank roof). The explosion occurred

by means of igniting the flammable mix created with

air at the time of splitting the corroded bolts on the

dome manhole with a grinder.

The metallurgical assessment performed on this

tank indicated the presence of extensive internal

corrosion over the lower part of the structure. This

observation confirmed the sudden onset of

corrosion at the tank sidewall due to diluted acid,

thus generating a source of hydrogen production.

Photo courtesy of DREAL: The damaged tank

File last updated: May 2011 3

IMPEL - Ministry of Sustainable Development - DGPR / SRT / BARPI-DREAL Upper Normandy No. 36628

ACTIONS TAKEN

A lawsuit was filed against the site operator; a safety perimeter was set up around the installation on the day of the

accident.

On the day following the accident, an extraordinary session of the Committee for Hygiene, Safety and Working

Conditions (CHSCT) launched an investigation commission that held its first meeting on 13 August. An executive

summary of the accident analysis, accompanied by a set of guidelines (see below under "Lessons learnt"), was

presented at a second meeting of the full CHSCT body. This report stated the findings of a 200-g release of hydrogen

and the formation of a 4 to 6-m³ flammable gas cloud, in accordance with simulations run in-house when reproducing the

effects observed due to the presence of sulphuric acid at low concentrations inside the tank after failing to bleed the

tank.

The sodium water treatment facility remained idle for several weeks. Following its temporary storage (which entailed a

temporary authorisation, with renewal) within a bulk chemicals warehouse immediately adjacent to the site, the sodium

water was conveyed as waste to authorised treatment centres.

A temporary sulphuric acid storage unit was set up to allow restarting the sodium water treatment unit.

LESSONS LEARNT

Regarding risk identification and evaluation

Iron, like the primary common metals (zinc, aluminium), is attacked by diluted acids with hydrogen release, according to

the following reaction:

+ 2+

Fe + 2H ↔ Fe + H2

Hydrogen is a highly flammable gas (4%-75% in air) at very low levels of ignition energy (0.02 mJ, vs. 0.29 mJ for

methane). The risk of a hydrogen explosion is present whenever an acid corrosion of metal has extended to a point of

being observable. In certain cases, the flow of fluid against a wall (through friction) or a shock can be of sufficient

magnitude to ignite.

A locally high hydrogen concentration (above 4% in air), e.g. in a dead air pocket or at the upper level of an enclosed

capacity, can engender an explosion risk when undertaking works on a tank. Such an event occurred in Saint Fons (69),

on 9 August, 1989 (ARIA 169), where preliminary flammability measurements conducted prior to the works phase had

not enabled detecting the presence of hydrogen at the top of the tank.

The feedback available included reports of several H2 explosions following an attack of diluted acid on steel tanks in a

number of facilities: ARIA 169, 22278, 31082 (detailed accident report).

Regarding feedback management, organisation and controls

A series of recommendations were issued before placing the installation back into operation:

− Design : The new tank would be fitted with a bleed valve that was both accessible and manoeuvrable.

− Tank availability (through steps of drainage and rinsing) was improved. The completed drainage step,

facilitated by tank design, was to be visually inspected by opening a manhole at a high point. This improved

accessibility will serve to minimise the quantity of residual acid to just drippings at the tank bottom and on its

sidewalls, in addition to enhancing not only acid neutralisation to return to a neutral pH but also tank rinsing.

Moreover, this operation avoids producing diluted acid and attacking the tank.

− The method for awarding hot-work permits was improved. Feedback mainly focused on building awareness

among onsite personnel of both the risks incurred and the atmospheric measurement methods to be

implemented (as regards positioning of the explosimeter probe).

− The tank was to be rebuilt using carbon steel; this solution was preferred over a composite so as to streamline

inspections.

− During the normal operations phase, a very minor hydrogen release into the tank remains a possibility.

Measures were taken to minimise hydrogen production and prevent its accumulation by means of :

• a vent positioned at a high point, with no internal tank structure causing evacuation of the hydrogen

eventually produced during operations and preparation;

• continuous flushing with dry air to allow hydrogen to evacuate and the tank to breathe; this feature serves

to prevent moist air from entering the tank (one possible cause of corrosion).

− The classified facilities inspectorate requested that the tank be made breakable at the shell-roof junction, so

that in case of an incident, the tank would remain in place and its contents not ejected.

File last updated: May 2011 4

IMPEL - Ministry of Sustainable Development - DGPR / SRT / BARPI-DREAL Upper Normandy No. 36628

Following this accident and several others during the same period within the chemical and petroleum industries as well

as in the transport of hazardous substances via pipeline, a meeting was organised in September 2009 between the

Secretary of State for Ecology and leading figures in these sectors to review the key challenges inherent in industrial

safety and environmental protection. Industry leaders forwarded a series of proposals intended to improve the safety of

their installations, with emphasis on strengthening controls dedicated to facility ageing and maintenance, while agreeing

to pay special attention to ecologically-sensitive zones with the aim of enhancing species protection or protecting

designated habitat. As part of the action plan intended to limit the risks tied to equipment ageing, launched on 13

January 2010, this resulted in the issuance of two administrative orders on 4-5 October 2010 relative to structural ageing

and technological risk, making it possible to incorporate ageing concerns into the site's safety management system

(SMS).

File last updated: May 2011 5

You might also like

- Particulate Preview Wrap-Up: Avogadro Constant MoleDocument24 pagesParticulate Preview Wrap-Up: Avogadro Constant MoleBunny Smith100% (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Case Study - Brent SparDocument3 pagesCase Study - Brent SparKunal Mandpe100% (1)

- PETRONAS Floating Liquefied Natural GasDocument9 pagesPETRONAS Floating Liquefied Natural GasDaniel Ismail100% (2)

- Final Presentation - BP Oil SpillDocument27 pagesFinal Presentation - BP Oil SpillLekh Raj100% (1)

- Technical Handbook EN 2019-07 E2029 Web No PDFDocument96 pagesTechnical Handbook EN 2019-07 E2029 Web No PDFFelipe SantosNo ratings yet

- Butadiene Leakage in A Petrochemical UnitDocument4 pagesButadiene Leakage in A Petrochemical UnitPhạm Nhật MinhNo ratings yet

- CEP Magazine 2023 1691466815Document6 pagesCEP Magazine 2023 1691466815SameerNo ratings yet

- Watergel (Slurry) ExplosivesDocument9 pagesWatergel (Slurry) ExplosivesmoolmanspitcontrolNo ratings yet

- Analysis of Tianjin Port Explosion - Swiss Re - Leading Global ReinsurerDocument8 pagesAnalysis of Tianjin Port Explosion - Swiss Re - Leading Global ReinsurerKhaing Myint MyatNo ratings yet

- Case Study - Butadiene IncidentDocument4 pagesCase Study - Butadiene IncidentHimat KhimaniNo ratings yet

- Rupture of Crude Oil TankDocument12 pagesRupture of Crude Oil TankdndudcNo ratings yet

- Explosion and Fire at A Paint Manufacturing PlantDocument3 pagesExplosion and Fire at A Paint Manufacturing PlantGeorgiana BălaşNo ratings yet

- Wheal Jane Mine Water Active Treatment Plant - Design, Construction and OperationDocument8 pagesWheal Jane Mine Water Active Treatment Plant - Design, Construction and OperationGeoffrey NyamagodoNo ratings yet

- Rupture and Ignition of A Gas Pipeline in Ghislenghien, BelgiumDocument6 pagesRupture and Ignition of A Gas Pipeline in Ghislenghien, BelgiumRahulNo ratings yet

- Chapter 1Document8 pagesChapter 1LINA AK BALUNNo ratings yet

- Tiwai Point Aluminium SmelterDocument5 pagesTiwai Point Aluminium SmelterStuff NewsroomNo ratings yet

- BuncefieldDocument2 pagesBuncefieldnyaraiziyeraNo ratings yet

- September 21, 2001: Explosion in The AZF Fertilizer PlantDocument13 pagesSeptember 21, 2001: Explosion in The AZF Fertilizer PlantTalal MehfoozNo ratings yet

- Descargas Electricas 2Document13 pagesDescargas Electricas 2Gustavo AgudeloNo ratings yet

- Investigation Reportsuncor Altares PDFDocument12 pagesInvestigation Reportsuncor Altares PDFR GunalanNo ratings yet

- Guadalajara 1992 AngDocument4 pagesGuadalajara 1992 AngIgor BogoyavlenskiyNo ratings yet

- ST Auban Eb AngDocument3 pagesST Auban Eb AngCostas AggelidisNo ratings yet

- Weather Forecasting.02Document8 pagesWeather Forecasting.02Muhammad ZeeshanNo ratings yet

- The Azf Factory ExplosionDocument29 pagesThe Azf Factory ExplosionHitakshi AroraNo ratings yet

- Ethanol Tank FireDocument20 pagesEthanol Tank FireAhmedAmer1No ratings yet

- Materials Express: Single Step Preparation of Nano Size Gamma Alumina Exhibiting Enhanced Uoride AdsorptionDocument7 pagesMaterials Express: Single Step Preparation of Nano Size Gamma Alumina Exhibiting Enhanced Uoride Adsorptionavinash.grey.bizNo ratings yet

- Piper Alpha Background & ShortcomingsDocument4 pagesPiper Alpha Background & Shortcomingsfashwin0% (1)

- Flammable Hazards in Sewerage SystemsDocument81 pagesFlammable Hazards in Sewerage SystemsKarel OstenNo ratings yet

- Behaviour of Cement-Treated MSWI Bottom AshDocument5 pagesBehaviour of Cement-Treated MSWI Bottom AshCosmin Cristian FlorianNo ratings yet

- Tecnologia de Tratamiento de Efluentes de Minas de UranioDocument20 pagesTecnologia de Tratamiento de Efluentes de Minas de Uranioignacio.toriggiaNo ratings yet

- Acoustic Emission Testing (AT) For The Detection of Corrosion Attack On Ships (Oil Tankers)Document8 pagesAcoustic Emission Testing (AT) For The Detection of Corrosion Attack On Ships (Oil Tankers)Maria Cristina DijmarescuNo ratings yet

- Ammonium NitrateDocument23 pagesAmmonium NitratejennyNo ratings yet

- Research Article: Novel Photocatalytic Reactor Development For Removal of Hydrocarbons From WaterDocument8 pagesResearch Article: Novel Photocatalytic Reactor Development For Removal of Hydrocarbons From WaterhusseinhshNo ratings yet

- Piper AlphaDocument23 pagesPiper AlphahazimraadNo ratings yet

- Radio PW PaperDocument13 pagesRadio PW PaperWameath Sh. Abdul MajeedNo ratings yet

- Explosion in A Nitrogenous Fertiliser Plant 21 September 1921Document5 pagesExplosion in A Nitrogenous Fertiliser Plant 21 September 1921hazopmanNo ratings yet

- Case Study - Fire Incident On MV of SPMDocument4 pagesCase Study - Fire Incident On MV of SPMHedi Ben MohamedNo ratings yet

- CCC 8-INF.10 - Summary of Comments Provided To The Correspondence Group (Safety Information For The Use Of... (Japan)Document121 pagesCCC 8-INF.10 - Summary of Comments Provided To The Correspondence Group (Safety Information For The Use Of... (Japan)siddharth18No ratings yet

- Conocophillips Response To The Saturate Gas Plant Fire and Explosion IncidentDocument9 pagesConocophillips Response To The Saturate Gas Plant Fire and Explosion IncidentvengielNo ratings yet

- Comah and The Environment Lessons Learned From Major Accidents 1999-2000Document7 pagesComah and The Environment Lessons Learned From Major Accidents 1999-2000Idehen KelvinNo ratings yet

- Causes of Failures in Bulk StorageDocument7 pagesCauses of Failures in Bulk StorageDilip JaviyaNo ratings yet

- Consequence Modelling of The Hydrocarbon Fire at Longford, Australia, 25 September 1998Document15 pagesConsequence Modelling of The Hydrocarbon Fire at Longford, Australia, 25 September 1998disconnecting nowNo ratings yet

- Practical Methods To Control Explosives Losses and Reduce Ammonia and Nitrate Levels 1n M1ne WaterDocument4 pagesPractical Methods To Control Explosives Losses and Reduce Ammonia and Nitrate Levels 1n M1ne WaterCARLOS OSIEL SEBASTIÁN VALDÉSNo ratings yet

- Spe 0413 0012 OgfDocument6 pagesSpe 0413 0012 OgfZenga Harsya PrakarsaNo ratings yet

- Effect of Organic Chloride Contamination of Crude Oil On Refinery Corrosion - OnePetroDocument2 pagesEffect of Organic Chloride Contamination of Crude Oil On Refinery Corrosion - OnePetroIrene CarrilloNo ratings yet

- CN-CP MW Site JasperDocument14 pagesCN-CP MW Site Jasperapi-449168853No ratings yet

- Dinamicas: Study Case 1 (13.1)Document10 pagesDinamicas: Study Case 1 (13.1)Mentor2- Mto OrienteNo ratings yet

- The Fires and Explosion at BP Oil Grangemouth Refinery LTD PDFDocument48 pagesThe Fires and Explosion at BP Oil Grangemouth Refinery LTD PDFBurgosg ValeryNo ratings yet

- Violent Self-Polymerization ReactionsDocument7 pagesViolent Self-Polymerization ReactionsericdiffNo ratings yet

- Offshore Project LastDocument23 pagesOffshore Project LastchigooNo ratings yet

- JFPearsonHzChemConf Rev0Document15 pagesJFPearsonHzChemConf Rev0abdel manaf ZAKARINo ratings yet

- No. 124 Movements of Tankers and Liquids Atthe Wrong Time or Intothe Wrong PlaceDocument8 pagesNo. 124 Movements of Tankers and Liquids Atthe Wrong Time or Intothe Wrong PlaceLisa FosterNo ratings yet

- Epcsm Term PaperDocument13 pagesEpcsm Term PaperFake accNo ratings yet

- EIA PreparationDocument7 pagesEIA Preparationsaudwala1No ratings yet

- Norm PaperDocument11 pagesNorm PaperelizabethchemestryNo ratings yet

- The Amoco Cadiz Oil Spill Cleanup Operations - An Overview of The Organization Control and Evaluation of The Cleanup Techniques EmployedDocument8 pagesThe Amoco Cadiz Oil Spill Cleanup Operations - An Overview of The Organization Control and Evaluation of The Cleanup Techniques EmployedmidanxiousNo ratings yet

- Imperial Oil Company, Inc./ Champion Chemicals New Jersey: Epa Region 2Document4 pagesImperial Oil Company, Inc./ Champion Chemicals New Jersey: Epa Region 2devitulasiNo ratings yet

- MJV Safety Culture (NL) - Safety Culture and AccidentsDocument8 pagesMJV Safety Culture (NL) - Safety Culture and AccidentsHesham HamyNo ratings yet

- Application Data Sheet: Product: StoplogsDocument4 pagesApplication Data Sheet: Product: StoplogsA N MadhavanNo ratings yet

- 876 - Section V CompiledDocument4,176 pages876 - Section V CompiledA N MadhavanNo ratings yet

- Hydraulic Structures Design ManualDocument171 pagesHydraulic Structures Design ManualA N Madhavan100% (1)

- Lecture On TWS, TR&CS, SLG - 04.09.2019Document93 pagesLecture On TWS, TR&CS, SLG - 04.09.2019A N MadhavanNo ratings yet

- MSDSDocument6 pagesMSDSMari Sherlin Salisi-ChuaNo ratings yet

- Using Cathodic Protection To Control Corrosion in Marine EnvironmentsDocument12 pagesUsing Cathodic Protection To Control Corrosion in Marine EnvironmentsMark ByramNo ratings yet

- Daman Utgst Final (2594) PDFDocument38 pagesDaman Utgst Final (2594) PDFHarpreet SinghNo ratings yet

- Invert Sugar From Cationinc SystemDocument5 pagesInvert Sugar From Cationinc SystemOsmar AlmeidaNo ratings yet

- Heavy Fuel OilsDocument114 pagesHeavy Fuel Oilsrenatomico2No ratings yet

- The Bitumen Industry - A Global Perspective - March 2011 EditionDocument43 pagesThe Bitumen Industry - A Global Perspective - March 2011 EditionRaluca Dobre100% (1)

- Brewing Water Chemistry Calculator - Brewer's FriendDocument4 pagesBrewing Water Chemistry Calculator - Brewer's FriendCurro Espadafor Fernandez AmigoNo ratings yet

- Excipientes ModificadosDocument19 pagesExcipientes ModificadosArnaldo Arnedo MayoralNo ratings yet

- Verbena Price ListDocument1 pageVerbena Price Listkhan gulNo ratings yet

- CoatedDocument3 pagesCoatedmatteo2009No ratings yet

- Opasan OtpadDocument74 pagesOpasan OtpadEllyONo ratings yet

- PrefaceDocument228 pagesPrefaceClarissa DiasNo ratings yet

- PAN (Peroksi Asetil Nitrat)Document2 pagesPAN (Peroksi Asetil Nitrat)Nuril JadidahNo ratings yet

- Advanced Welding Technology SyllabusDocument1 pageAdvanced Welding Technology Syllabusfaiz ahmadNo ratings yet

- SASO 1431 (GS 1355) SorbitolDocument5 pagesSASO 1431 (GS 1355) SorbitolakNo ratings yet

- Basics of Reverse Osmosis PDFDocument14 pagesBasics of Reverse Osmosis PDFVinod KumarNo ratings yet

- Bio 150 Exp 3Document5 pagesBio 150 Exp 3nureen fasiha67% (6)

- Bonus Infused OilsDocument4 pagesBonus Infused OilsSubash DNo ratings yet

- Aqua RegiaDocument6 pagesAqua RegiaGanesh DixitNo ratings yet

- Mineral ResourcesDocument7 pagesMineral ResourcesTudor PipirigNo ratings yet

- DMEDocument7 pagesDMEc_vivi92No ratings yet

- Pysical Organic Chapter OneDocument34 pagesPysical Organic Chapter OneTeferaNo ratings yet

- 33 Strong Vs Weak Acids-SDocument5 pages33 Strong Vs Weak Acids-SRando AyNo ratings yet

- Dipentaerythritol MSDSDocument5 pagesDipentaerythritol MSDSJaymit PatelNo ratings yet

- Full Text 01Document51 pagesFull Text 01Ahsan KhanNo ratings yet

- Drawing Resonance Structures - Organic ChemistryDocument13 pagesDrawing Resonance Structures - Organic ChemistryParas Thakur100% (6)

- Mass SpectrometryDocument40 pagesMass SpectrometryvitrekNo ratings yet

- B1 StoichiometryDocument123 pagesB1 StoichiometryWhite MochiNo ratings yet

- Synolac 6883: Product Application DetailsDocument2 pagesSynolac 6883: Product Application DetailsmonrmNo ratings yet