Professional Documents

Culture Documents

Data Sheet C11000

Data Sheet C11000

Uploaded by

TAEWARAT RAKRUANG0 ratings0% found this document useful (0 votes)

12 views2 pagesData Sheet C11000

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentData Sheet C11000

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

12 views2 pagesData Sheet C11000

Data Sheet C11000

Uploaded by

TAEWARAT RAKRUANGData Sheet C11000

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

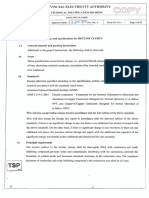

Further capitalizing on its casting extrusion and manufacturing expertise,

A

CI100

Electrolytic Tc

Data Sheet

‘Our Company has added UNS C1000 Electro Tough

Pitch (ETP) copper to its porifoio of brass alloys and products.As with its brass rod and bar products, by controlling the process from

casting through the production of the end procuct, Mueller Brass Company's C! 1000 ETP Copper is fabricated and certified to comply

with ASTM Standards and customer requirements

cu 99994000)

Jeusbars Switch Gears Sb Terminal, Conducts, Magnet Wee, Sranded Conductor Wire, let

o: oan | cs ermal Sviches Raco Parts Contacte Welding Ftures Grou Strap Commas

» vecure [Bovwapouts Fishing Rooling Gutters Balang Fronts Sign Frames

Ca eek iar sonen Counter Tope

[Astorotire [caskets Rasators

Bulers Hardware

ea Fons, us Rivet Nall Catr Pines Soldorng CopperTila Nos & Ba

nde

ex: Exchangers Pans Vs Road Bed Expansion Pes Rotating Sands Ketion

Icnenney Cap Screens, Cobre Call Presnre Vessels Anode, Crem Process

Esuipmen Pipe Weleing Des Backap Weng Snes Pring Rolls stn Racks Hooks

Because ofits inherent characteristics and mechanical properties, Cl 1000 ETP Copper can be readily fabricated via a variety of different

‘methods including: bending, soldering, criling and formed to ft numerous cesign applications as required by the customer

ASTHE-187-1

i

z

t

i

aalalal lalalslalalé

Bongrton nx

diameter of tloese

“Tense Strength (i)

(oan

@

50

€

30

Rod

Upt6 0375" Re

50375" 6 [000 Fe

© 1000" w 2.000" re

32.000" 10 20007 ne

(ea)

5

2

=

2

@

2

1s

1s

33007 5

Br

Up te O75 he

Up t0 #000"

Thane

Wet

Profiles Tube/Pine

Al ies

ALLOY ~

Cc! 1000 -

Data Sheet

N

Metting Point (Liquidus) wart roa" ¢

[Melting Point (Solidus) Dee Teese

[Density OSD bin a GE Bl griend aI

[Specitic Gravity 2) 25

[Electrical Resistivity x) TO ons ani BEF TH mizokm an

[Electrical Conductivity fal SERA BEEF ‘BT MegaSiemensvem @20°C

[Thermal Conductivity DESEO RAE or ee BLL Win Kale

[Coefficient of Thermal Expansion | 94 10per iP -2121) 169106 per"E QO" - 100°C)

[Coefficient of Thermal Expansion | 4-1 par (6-390) 169-106 per "© Qo 200°C)

[Coefficient of Thermal Expansion | 910 par 6572") 169106 par"© QU" 300°C)

[Specific Heat Capacity D092 Bulb Oe WAS jig KN

[Modulus of Elasticity in Tension 70K 117000 MPa

[Modulus of Rigidity 400 Ey

Cone with

feesbity ord venieaton

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm A123-17Document9 pagesAstm A123-17TAEWARAT RAKRUANG0% (1)

- แบบเลขที่ SB1 -015 - 22013 คอนสายแบบเหล็ก 1000120001 เหล็กคอนสาย 100x50x3.2mm, ยาว 4,200mm.Document1 pageแบบเลขที่ SB1 -015 - 22013 คอนสายแบบเหล็ก 1000120001 เหล็กคอนสาย 100x50x3.2mm, ยาว 4,200mm.TAEWARAT RAKRUANGNo ratings yet

- Provincial Electricity AuthorityDocument19 pagesProvincial Electricity AuthorityTAEWARAT RAKRUANGNo ratings yet

- IEC 61284 :1997-09 Overhead Lines - Requirements And Tests For Fittings มี Licensee PEA ห้ามเผยแพร่Document1 pageIEC 61284 :1997-09 Overhead Lines - Requirements And Tests For Fittings มี Licensee PEA ห้ามเผยแพร่TAEWARAT RAKRUANGNo ratings yet

- TIS 64-2517 ตัวนำไฟฟ้าทองแดงรีดแข็งสำหรับสายส่งกำลังเหนือดินDocument17 pagesTIS 64-2517 ตัวนำไฟฟ้าทองแดงรีดแข็งสำหรับสายส่งกำลังเหนือดินTAEWARAT RAKRUANGNo ratings yet

- ANSI C29.9-1983 (R2002) Wet-Process Porcelain Insulators - Apparatus, Post TypeDocument15 pagesANSI C29.9-1983 (R2002) Wet-Process Porcelain Insulators - Apparatus, Post TypeTAEWARAT RAKRUANGNo ratings yet

- Thickness GaugeDocument1 pageThickness GaugeTAEWARAT RAKRUANGNo ratings yet

- Itokin2000 Index PHP 2022 06 29 17 - 37 - 06Document7 pagesItokin2000 Index PHP 2022 06 29 17 - 37 - 06TAEWARAT RAKRUANGNo ratings yet

- NZI 2016 A5 Full Range CatalogueDocument108 pagesNZI 2016 A5 Full Range CatalogueTAEWARAT RAKRUANGNo ratings yet

- EH - Force Gauge - 2015Document1 pageEH - Force Gauge - 2015TAEWARAT RAKRUANGNo ratings yet

- Clamp For Line Post InsulatorDocument4 pagesClamp For Line Post InsulatorTAEWARAT RAKRUANGNo ratings yet

- NGK - IEC Catalog 014 PolymerDocument30 pagesNGK - IEC Catalog 014 PolymerTAEWARAT RAKRUANGNo ratings yet

- Safety Data Sheet: Penetrox A-13 Oxide Inhibiting Compound Product NameDocument8 pagesSafety Data Sheet: Penetrox A-13 Oxide Inhibiting Compound Product NameTAEWARAT RAKRUANGNo ratings yet

- Kumwell Grounding and Lightning Protection-12Document1 pageKumwell Grounding and Lightning Protection-12TAEWARAT RAKRUANGNo ratings yet

- ASTM D 4325-13 Standard Test Methods For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesDocument7 pagesASTM D 4325-13 Standard Test Methods For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesTAEWARAT RAKRUANGNo ratings yet

- Astm D 4388 - 02Document3 pagesAstm D 4388 - 02TAEWARAT RAKRUANGNo ratings yet

- ASTM D 4388-13 Standard Specification For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesDocument3 pagesASTM D 4388-13 Standard Specification For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesTAEWARAT RAKRUANGNo ratings yet

- AL Terminal Lug SD..073935-01Document24 pagesAL Terminal Lug SD..073935-01TAEWARAT RAKRUANGNo ratings yet

- IEC 61643-11 Page 51-52 PDFDocument2 pagesIEC 61643-11 Page 51-52 PDFTAEWARAT RAKRUANG100% (1)

- ASTM B 211-95 - Aluminum PDFDocument10 pagesASTM B 211-95 - Aluminum PDFTAEWARAT RAKRUANGNo ratings yet