Professional Documents

Culture Documents

Bopp Matt Film, Both Sides Heat Sealable, Treated: Properties

Bopp Matt Film, Both Sides Heat Sealable, Treated: Properties

Uploaded by

Matteo DMCopyright:

Available Formats

You might also like

- OPTI 517 - HW1 - JillellaDocument11 pagesOPTI 517 - HW1 - JillellaPriyanka JillellaNo ratings yet

- Cooling Tower SOPDocument8 pagesCooling Tower SOPBoiler Scrubber50% (2)

- AS 5100 ExampleDocument17 pagesAS 5100 ExampleMuhammad Abdullah100% (1)

- Beer ch1Document16 pagesBeer ch1Roudy Al HaddadNo ratings yet

- LTL - MeDocument2 pagesLTL - MeQUALITY CONTROLNo ratings yet

- TDS BOPP Blanco LSG57 y 60 - EUDocument2 pagesTDS BOPP Blanco LSG57 y 60 - EUEmmanuel AlvarezNo ratings yet

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezNo ratings yet

- TDS HMTDocument1 pageTDS HMTKarthiNo ratings yet

- Lix - EuDocument2 pagesLix - EuQUALITY CONTROLNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- B-THL: Standard Transparent Heat Sealable BOPP FilmDocument2 pagesB-THL: Standard Transparent Heat Sealable BOPP FilmSayed FathyNo ratings yet

- HF515Document1 pageHF515P Singh KarkiNo ratings yet

- Datasheet Saphir Flex 2016 EN v1Document2 pagesDatasheet Saphir Flex 2016 EN v1André CardosoNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- Technical Information: Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information: Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- 3 Zxepfrwec 6 Eiofni 13 A 6 Ajjmhvomyv 9Document1 page3 Zxepfrwec 6 Eiofni 13 A 6 Ajjmhvomyv 9vikramNo ratings yet

- Laserlite Multiwall: Product Data SheetDocument2 pagesLaserlite Multiwall: Product Data SheetOmer TahaNo ratings yet

- Flexmetprotect C-CNM-M: Technical Data SheetDocument1 pageFlexmetprotect C-CNM-M: Technical Data Sheetminni choubeyNo ratings yet

- B-TVL-M: Standard Barrier Metallized BOPP FilmDocument2 pagesB-TVL-M: Standard Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- B-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmDocument2 pagesB-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmSayed FathyNo ratings yet

- Addigy FPB 2684 000000 A - en - 86299607 22256723 22681304Document4 pagesAddigy FPB 2684 000000 A - en - 86299607 22256723 22681304propornhub42No ratings yet

- EasyFil PLA - TDS - Formfutura PDFDocument1 pageEasyFil PLA - TDS - Formfutura PDFRui MatiasNo ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetSilversnape00No ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Multipurpose Boxes With LidsDocument3 pagesMultipurpose Boxes With Lidssava cristianNo ratings yet

- Datasheet Saphir HCE 2021 EN v1Document2 pagesDatasheet Saphir HCE 2021 EN v1André CardosoNo ratings yet

- Ultra-Soft Thermal Conductive PadDocument2 pagesUltra-Soft Thermal Conductive PadArunkumar PBNo ratings yet

- FLEXmount 344 Series AdhesivesDocument4 pagesFLEXmount 344 Series Adhesiveshuynh thi y viNo ratings yet

- TDS HBMDocument1 pageTDS HBMP Singh KarkiNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Properties: Test Conditions Units Properties Test Conditions Units Typical ValuesDocument1 pageProperties: Test Conditions Units Properties Test Conditions Units Typical ValueszaherNo ratings yet

- 1661ff33-51be - ZA - LF2103 Film - EN-ZADocument2 pages1661ff33-51be - ZA - LF2103 Film - EN-ZApepeNo ratings yet

- Datasheet SaphirAF 2016 EN v1Document2 pagesDatasheet SaphirAF 2016 EN v1André CardosoNo ratings yet

- 01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Document1 page01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Aswin MustaminNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- Riblene FF20Document2 pagesRiblene FF20Stefan PopaNo ratings yet

- Spec Sheet Yuhwa Polypro SB1930HDocument2 pagesSpec Sheet Yuhwa Polypro SB1930HzoxxxnNo ratings yet

- Premium PLA - TDS - FormfuturaDocument1 pagePremium PLA - TDS - FormfuturaRui MatiasNo ratings yet

- Formosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SDocument1 pageFormosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SluisalbertolvNo ratings yet

- PolyMide CoPA TDS V5.2-20240223Document7 pagesPolyMide CoPA TDS V5.2-20240223Rakan El AtracheNo ratings yet

- GM - TDS-111: Europe North America AsiaDocument3 pagesGM - TDS-111: Europe North America AsiaMarjan ArhNo ratings yet

- Ptfe - G400Document1 pagePtfe - G400Alessio Di BellaNo ratings yet

- MST 33Document2 pagesMST 33Imawan WastNo ratings yet

- Matrox TDS PDFDocument1 pageMatrox TDS PDFrajanarenderNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- H1 AftDocument4 pagesH1 Aftmp3475No ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- TDS Co-3-X 27 03 2018 (003) - 1687274055Document2 pagesTDS Co-3-X 27 03 2018 (003) - 1687274055KSXNo ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- ASTM UT404 Eng 240223Document1 pageASTM UT404 Eng 240223MERVENo ratings yet

- FEP & PFA Welding Grade Films: F E F W H SDocument2 pagesFEP & PFA Welding Grade Films: F E F W H SmansurudinNo ratings yet

- BPC - BG HD 7000fDocument1 pageBPC - BG HD 7000fSLKM Engineering & ConsultantsNo ratings yet

- T-Pet: Product Data SheetDocument1 pageT-Pet: Product Data SheetHamdy AkkadNo ratings yet

- KD2DB1301Document1 pageKD2DB1301Customer ServiceNo ratings yet

- Im-022-21 Oc 4500008668 Siemens (Col)Document1 pageIm-022-21 Oc 4500008668 Siemens (Col)Gustaavo Caarvaajal HeerreraNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Technical Characteristics 2023 ENDocument1 pageTechnical Characteristics 2023 ENmohammedsirajuddin777No ratings yet

- HT - Tribol GR 100-2PDDocument3 pagesHT - Tribol GR 100-2PDRomulo Davila GarciaNo ratings yet

- Features: Property Units Methods Typical ValuesDocument1 pageFeatures: Property Units Methods Typical ValuesJavier Martinez CañalNo ratings yet

- A Review Paper On Techniques and Design For Metamaterial AbsorberDocument5 pagesA Review Paper On Techniques and Design For Metamaterial AbsorberPratik AvhadNo ratings yet

- Special Process Presentation NewDocument23 pagesSpecial Process Presentation Newvivek nuthiNo ratings yet

- Comparative Study of AISC-360 and EC3 Strength Limit StatesDocument15 pagesComparative Study of AISC-360 and EC3 Strength Limit StatesMehmet YavuzNo ratings yet

- Vibration Measurements Enotes1Document10 pagesVibration Measurements Enotes1NAYEEMNo ratings yet

- API Piping Plan 13: REV 2.0 DefinitionDocument3 pagesAPI Piping Plan 13: REV 2.0 DefinitionvijaysatawNo ratings yet

- Noise DataDocument42 pagesNoise Dataadil aminNo ratings yet

- I V Savelyev Physics General Course Vol 3Document319 pagesI V Savelyev Physics General Course Vol 3thuongtunhienNo ratings yet

- Improvement of Crystalline Quality in Gan Films by Air-Bridged Lateral Epitaxial GrowthDocument5 pagesImprovement of Crystalline Quality in Gan Films by Air-Bridged Lateral Epitaxial GrowthshuvoNo ratings yet

- Vibration IsolationDocument8 pagesVibration Isolationofitecnicajg100% (1)

- Development of Processes For C4 Hydrocarbons SeparationDocument11 pagesDevelopment of Processes For C4 Hydrocarbons SeparationTasneem MNo ratings yet

- Optical Fiber ModesDocument45 pagesOptical Fiber Modesnavyasanuj1No ratings yet

- Chapter 1 Solid State PrinciplesDocument65 pagesChapter 1 Solid State PrinciplesPeter YekNo ratings yet

- ATD AssignmentDocument2 pagesATD AssignmentsamarthgkNo ratings yet

- Geotechnical Report & Design Summary - San Fernando, MasbateDocument17 pagesGeotechnical Report & Design Summary - San Fernando, MasbateNeil Clark EsberNo ratings yet

- Partial Pressure Equilibrium and EntropyDocument6 pagesPartial Pressure Equilibrium and EntropyJoeNo ratings yet

- How Galileo Inferred ThatDocument13 pagesHow Galileo Inferred ThatYay SandovalNo ratings yet

- Wood Plastic Composites Produced From PostconsumerDocument9 pagesWood Plastic Composites Produced From PostconsumerPedro AlbanNo ratings yet

- Matter Energy Lab ReportDocument2 pagesMatter Energy Lab ReportOhrida BallaNo ratings yet

- 1 Metallography Lab SheetDocument5 pages1 Metallography Lab SheetAlexNo ratings yet

- Aphron Invasion Control System (ICS)Document8 pagesAphron Invasion Control System (ICS)LoganBohannonNo ratings yet

- Em Lecture 2Document21 pagesEm Lecture 2upspeed5050No ratings yet

- A-Level Physics Standing WavesDocument4 pagesA-Level Physics Standing Wavesprofitmaker_2No ratings yet

- Vent Line Pressure Drop CalculationDocument4 pagesVent Line Pressure Drop CalculationRubensBoerngenNo ratings yet

- AFB - RockwoolDocument12 pagesAFB - RockwoolCristhian RangelNo ratings yet

- Is Iec 60534 2 1 1998 PDFDocument48 pagesIs Iec 60534 2 1 1998 PDFJorge DuranNo ratings yet

- Stiffening Ring Cal For Exteneral Press.Document11 pagesStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

Bopp Matt Film, Both Sides Heat Sealable, Treated: Properties

Bopp Matt Film, Both Sides Heat Sealable, Treated: Properties

Uploaded by

Matteo DMOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bopp Matt Film, Both Sides Heat Sealable, Treated: Properties

Bopp Matt Film, Both Sides Heat Sealable, Treated: Properties

Uploaded by

Matteo DMCopyright:

Available Formats

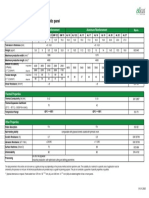

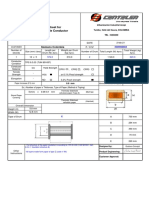

MUS

BoPP matt film, both sides heat

sealable, treated

Treated heat sealable layer

OPP core

Matt heat sealable layer (MST=120°C)

PROPERTIES

• One side matt silk appearance, other side

glossy

• Heat sealable on both sides

• Glossy side treated for printing/lamination

• Good antistatic and slip properties

TYPICAL APPLICATIONS

• Paper look lamination

• Rotogravure and flexographic reverse

printing

• HFFS and VFFS packaging

• General wrapping

ROLL SIZE AVAILABILITY*

Standard Length 4x ** 7x

Film

(m) (m) (m)

MUS 20 3,200 12,800 22,400

MUS 25 2,550 10,200 17,850

MUS 30 2,100 8,400 14,700

MUS 35 1,800 7,200 12,600

Outside diameter – core 76 mm 305 mm 588 mm

Outside diameter - core 152 mm 337 mm 605 mm 783 mm

*Regional availability of roll sizes (multiples of standard length)-please refer to the corresponding Sales Representative

**Length rolls on 152 mm cores could be produced with reduced length in Europe to maintain roll diameters below 600 mm

MUS

Properties Method Unit Ref. Typical values

Nominal thickness µm 20 25 30 35

Unit weight Internal method g/m2 18.0 22.5 27.0 31.5

Yield m2/kg 55.6 44.4 37.0 31.7

MD 150

Tensile strength N/mm2

TD 280

ASTM D882

MD 160

Elongation at break %

TD 50

Haze ASTM D1003 % 60

Gloss 12 (matt side)

Gloss (45°) ASTM D2457

Unit 55 (glossy side)

Dynamic cof ASTM D1894 NT/NT 0.25

MD 6.0

Thermal shrinkage OPMA TC4(a) %

TD 3.0

Heat seal range Internal method °C 120÷140 (both sides)

NT/NT

Internal method

Seal strength g/cm 300

130°C ;0.5 s

Treatment level ASTM D2578 mN/m 38

Water vapour ASTM F1249

g/m2/d 7.0 6.0 5.0 4.0

permeability (38°C - 90% RH)

Tolerance

≤ 1.000 kg ± 20%

Weight 1.001-10.000 kg ± 10%

> 10.000 kg ± 5%

STORAGE, HANDLING AND APPLICATION

MUS does not require special storage conditions. A storage temperature below 30°C is recommended in

order to minimise the deterioration of the film properties in general. It is advisable to turn over the inventory

according to the delivery date (first in-first out). The film should be conditioned in the operating environment

at least for 24 hours before processing. MUS is suitable for use up to 6 months from the date of production.

INDICATION OF SURFACE TREATMENT

MUS is usually supplied with treatment on the outside surface (TO).

MUS can be supplied either with treatment on the inside surface (TI) or treated on both sides (DO, DI). This

must be agreed with our sales representative before processing the order.

FOOD CONTACT

MUS complies with EU and FDA regulations. Specific documents and MSDS are available on request.

The property values represented in the table do not constitute product specifications, but represent the average or typical values.

Use of this information is limited to the specific recipient. While the information is accurate to the best of our knowledge as of the

date compiled, it is limited to the information as specified. No representation or warranty, expressed or implied, is made

regarding the information, or its completeness or fitness to a particular use. The user is solely responsible for all determinations

regarding use and we disclaim liability for any loss or damage that may occur from the use of this information. Ti does not

guarantee the typical (or other) values.

Last update: 2018/03/A Taghleef Industries • staff@ti-films.com • www.ti-films.com

You might also like

- OPTI 517 - HW1 - JillellaDocument11 pagesOPTI 517 - HW1 - JillellaPriyanka JillellaNo ratings yet

- Cooling Tower SOPDocument8 pagesCooling Tower SOPBoiler Scrubber50% (2)

- AS 5100 ExampleDocument17 pagesAS 5100 ExampleMuhammad Abdullah100% (1)

- Beer ch1Document16 pagesBeer ch1Roudy Al HaddadNo ratings yet

- LTL - MeDocument2 pagesLTL - MeQUALITY CONTROLNo ratings yet

- TDS BOPP Blanco LSG57 y 60 - EUDocument2 pagesTDS BOPP Blanco LSG57 y 60 - EUEmmanuel AlvarezNo ratings yet

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezNo ratings yet

- TDS HMTDocument1 pageTDS HMTKarthiNo ratings yet

- Lix - EuDocument2 pagesLix - EuQUALITY CONTROLNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- B-THL: Standard Transparent Heat Sealable BOPP FilmDocument2 pagesB-THL: Standard Transparent Heat Sealable BOPP FilmSayed FathyNo ratings yet

- HF515Document1 pageHF515P Singh KarkiNo ratings yet

- Datasheet Saphir Flex 2016 EN v1Document2 pagesDatasheet Saphir Flex 2016 EN v1André CardosoNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- Technical Information: Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information: Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- 3 Zxepfrwec 6 Eiofni 13 A 6 Ajjmhvomyv 9Document1 page3 Zxepfrwec 6 Eiofni 13 A 6 Ajjmhvomyv 9vikramNo ratings yet

- Laserlite Multiwall: Product Data SheetDocument2 pagesLaserlite Multiwall: Product Data SheetOmer TahaNo ratings yet

- Flexmetprotect C-CNM-M: Technical Data SheetDocument1 pageFlexmetprotect C-CNM-M: Technical Data Sheetminni choubeyNo ratings yet

- B-TVL-M: Standard Barrier Metallized BOPP FilmDocument2 pagesB-TVL-M: Standard Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- B-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmDocument2 pagesB-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmSayed FathyNo ratings yet

- Addigy FPB 2684 000000 A - en - 86299607 22256723 22681304Document4 pagesAddigy FPB 2684 000000 A - en - 86299607 22256723 22681304propornhub42No ratings yet

- EasyFil PLA - TDS - Formfutura PDFDocument1 pageEasyFil PLA - TDS - Formfutura PDFRui MatiasNo ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetSilversnape00No ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Multipurpose Boxes With LidsDocument3 pagesMultipurpose Boxes With Lidssava cristianNo ratings yet

- Datasheet Saphir HCE 2021 EN v1Document2 pagesDatasheet Saphir HCE 2021 EN v1André CardosoNo ratings yet

- Ultra-Soft Thermal Conductive PadDocument2 pagesUltra-Soft Thermal Conductive PadArunkumar PBNo ratings yet

- FLEXmount 344 Series AdhesivesDocument4 pagesFLEXmount 344 Series Adhesiveshuynh thi y viNo ratings yet

- TDS HBMDocument1 pageTDS HBMP Singh KarkiNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Properties: Test Conditions Units Properties Test Conditions Units Typical ValuesDocument1 pageProperties: Test Conditions Units Properties Test Conditions Units Typical ValueszaherNo ratings yet

- 1661ff33-51be - ZA - LF2103 Film - EN-ZADocument2 pages1661ff33-51be - ZA - LF2103 Film - EN-ZApepeNo ratings yet

- Datasheet SaphirAF 2016 EN v1Document2 pagesDatasheet SaphirAF 2016 EN v1André CardosoNo ratings yet

- 01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Document1 page01.03.02.106 Spesifikasi-SOLMAX THA HDPE 2.00mm Black Smooth - 1084285 (HDS-200LM)Aswin MustaminNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- Riblene FF20Document2 pagesRiblene FF20Stefan PopaNo ratings yet

- Spec Sheet Yuhwa Polypro SB1930HDocument2 pagesSpec Sheet Yuhwa Polypro SB1930HzoxxxnNo ratings yet

- Premium PLA - TDS - FormfuturaDocument1 pagePremium PLA - TDS - FormfuturaRui MatiasNo ratings yet

- Formosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SDocument1 pageFormosa Taisox: High Density Polyethylene (HDPE) - Fi L M GR Ade Dat A Sheet SluisalbertolvNo ratings yet

- PolyMide CoPA TDS V5.2-20240223Document7 pagesPolyMide CoPA TDS V5.2-20240223Rakan El AtracheNo ratings yet

- GM - TDS-111: Europe North America AsiaDocument3 pagesGM - TDS-111: Europe North America AsiaMarjan ArhNo ratings yet

- Ptfe - G400Document1 pagePtfe - G400Alessio Di BellaNo ratings yet

- MST 33Document2 pagesMST 33Imawan WastNo ratings yet

- Matrox TDS PDFDocument1 pageMatrox TDS PDFrajanarenderNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- H1 AftDocument4 pagesH1 Aftmp3475No ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- TDS Co-3-X 27 03 2018 (003) - 1687274055Document2 pagesTDS Co-3-X 27 03 2018 (003) - 1687274055KSXNo ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- ASTM UT404 Eng 240223Document1 pageASTM UT404 Eng 240223MERVENo ratings yet

- FEP & PFA Welding Grade Films: F E F W H SDocument2 pagesFEP & PFA Welding Grade Films: F E F W H SmansurudinNo ratings yet

- BPC - BG HD 7000fDocument1 pageBPC - BG HD 7000fSLKM Engineering & ConsultantsNo ratings yet

- T-Pet: Product Data SheetDocument1 pageT-Pet: Product Data SheetHamdy AkkadNo ratings yet

- KD2DB1301Document1 pageKD2DB1301Customer ServiceNo ratings yet

- Im-022-21 Oc 4500008668 Siemens (Col)Document1 pageIm-022-21 Oc 4500008668 Siemens (Col)Gustaavo Caarvaajal HeerreraNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Technical Characteristics 2023 ENDocument1 pageTechnical Characteristics 2023 ENmohammedsirajuddin777No ratings yet

- HT - Tribol GR 100-2PDDocument3 pagesHT - Tribol GR 100-2PDRomulo Davila GarciaNo ratings yet

- Features: Property Units Methods Typical ValuesDocument1 pageFeatures: Property Units Methods Typical ValuesJavier Martinez CañalNo ratings yet

- A Review Paper On Techniques and Design For Metamaterial AbsorberDocument5 pagesA Review Paper On Techniques and Design For Metamaterial AbsorberPratik AvhadNo ratings yet

- Special Process Presentation NewDocument23 pagesSpecial Process Presentation Newvivek nuthiNo ratings yet

- Comparative Study of AISC-360 and EC3 Strength Limit StatesDocument15 pagesComparative Study of AISC-360 and EC3 Strength Limit StatesMehmet YavuzNo ratings yet

- Vibration Measurements Enotes1Document10 pagesVibration Measurements Enotes1NAYEEMNo ratings yet

- API Piping Plan 13: REV 2.0 DefinitionDocument3 pagesAPI Piping Plan 13: REV 2.0 DefinitionvijaysatawNo ratings yet

- Noise DataDocument42 pagesNoise Dataadil aminNo ratings yet

- I V Savelyev Physics General Course Vol 3Document319 pagesI V Savelyev Physics General Course Vol 3thuongtunhienNo ratings yet

- Improvement of Crystalline Quality in Gan Films by Air-Bridged Lateral Epitaxial GrowthDocument5 pagesImprovement of Crystalline Quality in Gan Films by Air-Bridged Lateral Epitaxial GrowthshuvoNo ratings yet

- Vibration IsolationDocument8 pagesVibration Isolationofitecnicajg100% (1)

- Development of Processes For C4 Hydrocarbons SeparationDocument11 pagesDevelopment of Processes For C4 Hydrocarbons SeparationTasneem MNo ratings yet

- Optical Fiber ModesDocument45 pagesOptical Fiber Modesnavyasanuj1No ratings yet

- Chapter 1 Solid State PrinciplesDocument65 pagesChapter 1 Solid State PrinciplesPeter YekNo ratings yet

- ATD AssignmentDocument2 pagesATD AssignmentsamarthgkNo ratings yet

- Geotechnical Report & Design Summary - San Fernando, MasbateDocument17 pagesGeotechnical Report & Design Summary - San Fernando, MasbateNeil Clark EsberNo ratings yet

- Partial Pressure Equilibrium and EntropyDocument6 pagesPartial Pressure Equilibrium and EntropyJoeNo ratings yet

- How Galileo Inferred ThatDocument13 pagesHow Galileo Inferred ThatYay SandovalNo ratings yet

- Wood Plastic Composites Produced From PostconsumerDocument9 pagesWood Plastic Composites Produced From PostconsumerPedro AlbanNo ratings yet

- Matter Energy Lab ReportDocument2 pagesMatter Energy Lab ReportOhrida BallaNo ratings yet

- 1 Metallography Lab SheetDocument5 pages1 Metallography Lab SheetAlexNo ratings yet

- Aphron Invasion Control System (ICS)Document8 pagesAphron Invasion Control System (ICS)LoganBohannonNo ratings yet

- Em Lecture 2Document21 pagesEm Lecture 2upspeed5050No ratings yet

- A-Level Physics Standing WavesDocument4 pagesA-Level Physics Standing Wavesprofitmaker_2No ratings yet

- Vent Line Pressure Drop CalculationDocument4 pagesVent Line Pressure Drop CalculationRubensBoerngenNo ratings yet

- AFB - RockwoolDocument12 pagesAFB - RockwoolCristhian RangelNo ratings yet

- Is Iec 60534 2 1 1998 PDFDocument48 pagesIs Iec 60534 2 1 1998 PDFJorge DuranNo ratings yet

- Stiffening Ring Cal For Exteneral Press.Document11 pagesStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)