Professional Documents

Culture Documents

Co Gas Detector: Features

Co Gas Detector: Features

Uploaded by

Le VinhCopyright:

Available Formats

You might also like

- NCR ATM Service Aid Manual From WWWDocument67 pagesNCR ATM Service Aid Manual From WWWanon_69018194129% (7)

- Fujifilm Finepix S1000fd Service ManualDocument112 pagesFujifilm Finepix S1000fd Service ManualAstronom SuceavaNo ratings yet

- Fujifilm Finepix s8000fdDocument134 pagesFujifilm Finepix s8000fdzilikonNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- COSMO Manual I56-3747Document4 pagesCOSMO Manual I56-3747leandro FigueiredoNo ratings yet

- Operating Manual: Infrared Point Gas Detector GD10-P00Document28 pagesOperating Manual: Infrared Point Gas Detector GD10-P00bango7886No ratings yet

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDocument6 pagesLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaNo ratings yet

- SV - 03678 - en - Na 2Document16 pagesSV - 03678 - en - Na 2eduardodluffy268No ratings yet

- 9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioDocument26 pages9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioPa PlastireNo ratings yet

- Instruction Manual: Model RSP Sanitary Electronic Pressure TransmitterDocument16 pagesInstruction Manual: Model RSP Sanitary Electronic Pressure TransmitterHectorNo ratings yet

- Smoke Detector ManualDocument4 pagesSmoke Detector ManualKarthik VelNo ratings yet

- JMC Tech DMS ENDocument4 pagesJMC Tech DMS ENVaidas BartkevičiusNo ratings yet

- OXY-Gas - Manual Do UsuarioDocument25 pagesOXY-Gas - Manual Do UsuarioMagno DelmiroNo ratings yet

- Honeywell C7632a B Sensor Co2 PDFDocument4 pagesHoneywell C7632a B Sensor Co2 PDFMarcello PorrinoNo ratings yet

- KB Manual v5Document26 pagesKB Manual v5nathanaelsilva076No ratings yet

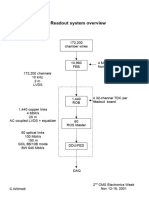

- ReadoutDocument11 pagesReadoutsamirmartil676No ratings yet

- Fujifilm Finepix s9000 s9500 SM ET 1Document147 pagesFujifilm Finepix s9000 s9500 SM ET 1newionNo ratings yet

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorDocument14 pagesBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectorluisrruiz_123No ratings yet

- MCD288 DVD Micro Theatre: /all VersionsDocument39 pagesMCD288 DVD Micro Theatre: /all VersionsLeonelHernandezNo ratings yet

- LG LCD Monitor M1917a-K, F, GZD - eDocument33 pagesLG LCD Monitor M1917a-K, F, GZD - evideosonNo ratings yet

- Detector 2151-A05-0182Document2 pagesDetector 2151-A05-0182Tiago SilvaNo ratings yet

- Ecotech Ex22dT50Document13 pagesEcotech Ex22dT50Rujisak MuangsongNo ratings yet

- I4series Datasheet CODS303Document4 pagesI4series Datasheet CODS303b.leite.domNo ratings yet

- 7.1 Method Statement For Termination & GlandingDocument24 pages7.1 Method Statement For Termination & GlandingMedrouaNo ratings yet

- SHD-260LS Combustible Toxic GasDocument25 pagesSHD-260LS Combustible Toxic Gasryan azzaamNo ratings yet

- 300 Series Photoelectric Smoke Detector SystemDocument4 pages300 Series Photoelectric Smoke Detector SystemgeoffffNo ratings yet

- E2s Atex BeaconDocument3 pagesE2s Atex BeaconControlgearNo ratings yet

- SCM-W Datasheet v41Document10 pagesSCM-W Datasheet v41nguyenam2008No ratings yet

- In Touch With The Medium: BEDIA Level - Monitoring - Probes Type PLS 10 Type PLS 30 Type PLS 40Document27 pagesIn Touch With The Medium: BEDIA Level - Monitoring - Probes Type PLS 10 Type PLS 30 Type PLS 40ALEJONo ratings yet

- Ultrasonic Level Transmitter NUS ManualDocument39 pagesUltrasonic Level Transmitter NUS ManualAli Hadi100% (1)

- Fuji Finepix s5200 s5600Document121 pagesFuji Finepix s5200 s5600zilikonNo ratings yet

- Parking Radar: Parking Aid, or As Eye S' For Robo T Projec TsDocument0 pagesParking Radar: Parking Aid, or As Eye S' For Robo T Projec TsBalvendra SinghNo ratings yet

- Bondmaster Pitch-Catch Probe Adaptor: Getting StartedDocument6 pagesBondmaster Pitch-Catch Probe Adaptor: Getting StartedSaadNo ratings yet

- Sony HCD-GNX60Document76 pagesSony HCD-GNX60kalentoneschatNo ratings yet

- Color Monitor Service ManualDocument49 pagesColor Monitor Service ManualAlexandre MagriNo ratings yet

- Oi Kcap300-En eDocument20 pagesOi Kcap300-En ejaime HernandezNo ratings yet

- ElektronikaBa dualCHDocument16 pagesElektronikaBa dualCHedroalNo ratings yet

- CO1224TDocument2 pagesCO1224TJhonny SilvaNo ratings yet

- Fiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Document16 pagesFiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Amila BalasooriyaNo ratings yet

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDocument2 pagesData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaNo ratings yet

- Acw 1709B User Manual 230818Document22 pagesAcw 1709B User Manual 230818armando.wellavNo ratings yet

- WDG-1210 現址式氧氣分析儀Document4 pagesWDG-1210 現址式氧氣分析儀SeanKuoNo ratings yet

- SP Series Magnetostrictive Probe 2016 V2.0Document16 pagesSP Series Magnetostrictive Probe 2016 V2.0Mantenimiento MineriaNo ratings yet

- Installation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92Document22 pagesInstallation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92carlos_sagitarioNo ratings yet

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorDocument15 pagesBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectoryesid rodriguezNo ratings yet

- Conventional Reflective Beam Detector: Technical SpecificationsDocument2 pagesConventional Reflective Beam Detector: Technical SpecificationsdalanruhunaNo ratings yet

- Model 872 Ultrasonic Level Transmitter Two-Wire, Loop PoweredDocument2 pagesModel 872 Ultrasonic Level Transmitter Two-Wire, Loop Poweredandres49mNo ratings yet

- Instruction Manual: Model RSP Sanitary Electronic Pressure TransmitterDocument16 pagesInstruction Manual: Model RSP Sanitary Electronic Pressure Transmittergrincheu70No ratings yet

- S 5800Document114 pagesS 5800elenoremailNo ratings yet

- Mcdonnell & Miller: WarningDocument8 pagesMcdonnell & Miller: WarningALEXANDER VARELANo ratings yet

- 3BLWKB2intden100 ABB KPM KB2 20220406 Fabricca Digital WithSpecs FinalNEWDocument2 pages3BLWKB2intden100 ABB KPM KB2 20220406 Fabricca Digital WithSpecs FinalNEWMajedur Rahman RejaNo ratings yet

- TC100N enDocument15 pagesTC100N enThanosEleftheroudisNo ratings yet

- KM260 Inst EngDocument13 pagesKM260 Inst EngFermalux FermaluxNo ratings yet

- TrackSo Datasheet Installation Guide Solar Radiation Sensor PYRA300VDocument10 pagesTrackSo Datasheet Installation Guide Solar Radiation Sensor PYRA300VGaurav DwivediNo ratings yet

- Do 5519-1Document2 pagesDo 5519-1Ethan PollNo ratings yet

- Operation ManualDocument12 pagesOperation ManualSeaze RooNo ratings yet

- C7232A, B Sensor and Controller: FeaturesDocument8 pagesC7232A, B Sensor and Controller: FeaturesNanû CbralNo ratings yet

- 400 Series Plug-In Smoke Detector: IonizationDocument4 pages400 Series Plug-In Smoke Detector: IonizationJun AntonioNo ratings yet

- DIY Geiger Counter Radiation Detector Kit Ver.2 PDFDocument16 pagesDIY Geiger Counter Radiation Detector Kit Ver.2 PDFLeonardo VelezNo ratings yet

- D116 CatalogDocument8 pagesD116 CatalogLe VinhNo ratings yet

- Hydrant Test Meter: Flowmaster 250Document2 pagesHydrant Test Meter: Flowmaster 250Le VinhNo ratings yet

- ASTM A249 Seamless Tube, ASME SA249 Welded Tube ManufacturerDocument11 pagesASTM A249 Seamless Tube, ASME SA249 Welded Tube ManufacturerLe VinhNo ratings yet

- Product Catalog of PFlowDocument7 pagesProduct Catalog of PFlowLe VinhNo ratings yet

- Astm A554Document6 pagesAstm A554Le VinhNo ratings yet

- ASTM A249 Stainless Steel TubesDocument10 pagesASTM A249 Stainless Steel TubesLe VinhNo ratings yet

- Cuelux Manual en 10324Document46 pagesCuelux Manual en 10324joeykeysNo ratings yet

- 917 Coulometer METROHMDocument350 pages917 Coulometer METROHMYến Vũ ThịNo ratings yet

- PDF HSGQ Epon Olt Command User Manual 122018 - CompressDocument41 pagesPDF HSGQ Epon Olt Command User Manual 122018 - Compressdonlot anonymous0% (1)

- K 30iqtDocument32 pagesK 30iqtNimisha RajanNo ratings yet

- EVGA - Product Specs - EVGA GeForce GTX 1650 XC BLACK GAMING, 04G-P4-1151-KR, 4GB GDDR5Document1 pageEVGA - Product Specs - EVGA GeForce GTX 1650 XC BLACK GAMING, 04G-P4-1151-KR, 4GB GDDR5Célio LinharesNo ratings yet

- Lecture Notes On: Random Number GenerationDocument29 pagesLecture Notes On: Random Number GenerationfhyvhufchuNo ratings yet

- Ingenico POS Terminal Download Instructions: Before Initiating A Download Expected Download TimeDocument1 pageIngenico POS Terminal Download Instructions: Before Initiating A Download Expected Download TimeDoNo ratings yet

- NCR MLA MediaInfoLit M2 - L2 The Evolution of Traditional To New Media - v11 RevisedDocument20 pagesNCR MLA MediaInfoLit M2 - L2 The Evolution of Traditional To New Media - v11 RevisedKryzel Lho EspanaNo ratings yet

- 6 Mintzberg's Management RolesDocument12 pages6 Mintzberg's Management Roleshoney guptaNo ratings yet

- Hexagon Documentation Site Export-3Document100 pagesHexagon Documentation Site Export-3Alberto VELOSA ROANo ratings yet

- Telesis TMP7000Document8 pagesTelesis TMP7000Arjuna GamingNo ratings yet

- Long Lead Acid Battery 12v 65ahDocument2 pagesLong Lead Acid Battery 12v 65ahnadeemNo ratings yet

- Steps in Creating Simple Mail MergeDocument5 pagesSteps in Creating Simple Mail MergeRudula AmperNo ratings yet

- SOLANA ECOSYSTEM and Its Dynamism in Recent TimesDocument2 pagesSOLANA ECOSYSTEM and Its Dynamism in Recent TimesEdith OwolabiNo ratings yet

- Ability 6100648Document1 pageAbility 6100648Vedant DesaiNo ratings yet

- Guideline On Writing A First Quantitative Academic Article YYS)Document1 pageGuideline On Writing A First Quantitative Academic Article YYS)Isan Yys SanNo ratings yet

- Key IIS Final VIP David Hai 1Document443 pagesKey IIS Final VIP David Hai 1Hi LightNo ratings yet

- Minimalism - Tubular BellsDocument2 pagesMinimalism - Tubular BellshodiestoeNo ratings yet

- Panel Options LCD Samsung PDFDocument11 pagesPanel Options LCD Samsung PDFJejeNo ratings yet

- Unveil The Mystery of Code Coverage in Low-Power Designs: Achieving Power AwareDocument13 pagesUnveil The Mystery of Code Coverage in Low-Power Designs: Achieving Power AwareNishit GuptaNo ratings yet

- Titus VavDocument46 pagesTitus VavSantiago J. ramos jrNo ratings yet

- Fathur Rahman PDFDocument1 pageFathur Rahman PDFRSCERIA KANDANGANNo ratings yet

- 2017 Driverless CarDocument8 pages2017 Driverless CarLucky pavanNo ratings yet

- PHM Question 555Document3 pagesPHM Question 555Jonathan LukwichiNo ratings yet

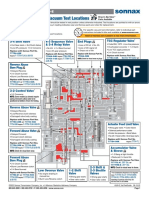

- 4L60-E VacTestGuideDocument4 pages4L60-E VacTestGuideJailton GomesNo ratings yet

- (Download PDF) Natural History New Edition DK Ebook Online Full ChapterDocument24 pages(Download PDF) Natural History New Edition DK Ebook Online Full Chapterhlaselivis100% (6)

- PAT Report Solar System at Sambrial ExchDocument9 pagesPAT Report Solar System at Sambrial ExchBilal AsgharNo ratings yet

- Bu Grading SystemDocument37 pagesBu Grading Systemmanen gajoNo ratings yet

- Super Blood Harvest 3 PDFDocument68 pagesSuper Blood Harvest 3 PDFJoseph McLachlanNo ratings yet

Co Gas Detector: Features

Co Gas Detector: Features

Uploaded by

Le VinhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Co Gas Detector: Features

Co Gas Detector: Features

Uploaded by

Le VinhCopyright:

Available Formats

CO GAS DETECTOR

PRODUCT SPECIFICATION SHEET

FEATURES

• High sensitivity and selectivity to carbon monoxide

• Low sensitivity to alcohol vapor

• Solid state sensor

• Linear 2 to 10 Vdc or 4 to 20mA output

• Compact size (70㎜×122㎜×32㎜)

APPLICATION

Contents

GD250W4NB is IAQ(Indoor Air Quality) sensor, which is

designed to detect carbon monoxide gas in the air. This Application ………………………………………………… 1

model has high accuracy at low concentration, so it is Features …………………………………………………… 1

optimum for parking lot, tunnel and under ground places. Specifications ……………………………………………... 1~2

Also, the advantage of this model is compact size and Dimensions ………………………………………………… 2

easy installation. Installation …………………………………………………. 2

Assembly ……………………………………………. 2

Wiring…………… …………………………………………… 3

Caution ………………………………………………………..4

SPECIFICATIONS

Table 1. Model selection guide

Model Gas Detected Sensing Range Wiring

GD250W4NB Carbon monoxide 0 ~ 250 ppm 3/4 wire

ENS2001R0 KO65 2011 1

GD250W4NB CO GAS DETECTOR

Gas detected : Carbon monoxide (CO) Coverage area : 465 ㎡ (recommended)

Sensor type : Semiconductor Response time : Within 5 minutes.

Detect range : 0~250ppm Warm-up time : Minimum 2 hours

Accuracy : 1) +/-5% FS for 0~100ppm Protection class : IP30

: 2) +/- 10% FS for 100~250ppm

Wiring : 3 or 4 wire compatible

Output signal : 2~10Vdc (default) or 4~20mA (selectable

by jumper) Operating temperature : 0 ~ 50 ℃.

Power supply : 24Vac 50/60Hz, 24Vdc, +/- 20% Operating Humidity : 10 ~ 95%RH (no condensing)

Sensor life : 3years Storage temperature : -20 ~ 60 C.

expectancy

Storage Humidity : 10 ~ 95%RH (no condensing)

DIMENSIONS ASSEMBLY

BASE

PCB ASS’Y

COVER

Fig. 1. dimensions (in mm)

Fig. 2. assembly structure

INSTALLATION

1. Determine the output signal type. ④ Reassemble the cover.

→For DC voltage output(2~10VDC), connect 3. Mount approximately 150㎝(5 feet) above floor.

Jumper to ‘V-out’ which is located in center of the 4. Do not use as a life safety device.

PCB. 5. When the product has wet by dew, use the product

→For current output(4~20㎃), connect Jumper to after completely dry up.

‘I-out’ which is located in center of the PCB. 6. Install the input and output lines far away form other

※ Default is DC voltage output(2~10VDC). system-input lines.

2. Installation procedure 7. Do not use this product for portable.

① Push the bottom of the cover to separate from the

base.

② Connect the input and output lines to the terminal

block. Then, verify the lines correctly fixed to the

terminal.

③ Fix the base by using the screw nails. Do not fix

the base upside down. (Be cautious PCB

assembly not to be damaged.)

ENS2001R0 KO65 2011 2

GD250W4NB CO GAS DETECTOR

WIRING

3-line wiring 4-line wiring

Fig. 3. wiring diagram

Jumper setting method to determine the output signal type

Fig. 4. jumper setting

Caution on wiring

ENS2001R0 KO65 2011 3

GD250W4NB CO GAS DETECTOR

CAUTION

• The standard test condition is 25℃, 50%RH. Sensitivity will be decreased when the sensor is located in

extreme dry condition or places.

• Avoid exposure where silicone adhesives, hair grooming materials or silicone rubber/putty may be

present.

• Avoid exposure to alkaline metals, especially salt-water spray.

• Avoid exposure to highly corrosive materials such as H2S, SOX, Cl2, HCl, etc.

• Sensor drift may occur due to soaking or splashing the sensor with water.

• If water freezes on the sensing surface, the sensing material would crack, altering characteristics.

• If water condenses on the sensor’s surface and remains for an extended period, sensor characteristics

may drift.

• Sensor performance may be affected if exposed to high density of gas for a long period of time,

regardless of the powering condition.

• When stored without powering for a long period, the sensor should be stored in a sealed bag containing

clean air, do not use silica gel.

• Regardless of powering condition, if the sensor is exposed in extreme conditions such as very high

humidity, extreme temperatures, or high contamination levels for a long period of time, sensor

performance will be adversely affected.

• Avoid excessive vibration or strong shock that may cause the sensor or lead wires to break.

HONEYWELL

Honeywell Co., Ltd.

Environmental & Combustion Controls

5 cmd , Sangam IT tower, DMC 1590 B4-4 block,

Sangam-dong, Mapo-gu, Seoul, 121-835, Korea

Tel. 82-2-799-6170/6194

Fax. 82-2-799-6188

ENS2001R0 KO65 2011 4

You might also like

- NCR ATM Service Aid Manual From WWWDocument67 pagesNCR ATM Service Aid Manual From WWWanon_69018194129% (7)

- Fujifilm Finepix S1000fd Service ManualDocument112 pagesFujifilm Finepix S1000fd Service ManualAstronom SuceavaNo ratings yet

- Fujifilm Finepix s8000fdDocument134 pagesFujifilm Finepix s8000fdzilikonNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- COSMO Manual I56-3747Document4 pagesCOSMO Manual I56-3747leandro FigueiredoNo ratings yet

- Operating Manual: Infrared Point Gas Detector GD10-P00Document28 pagesOperating Manual: Infrared Point Gas Detector GD10-P00bango7886No ratings yet

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDocument6 pagesLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaNo ratings yet

- SV - 03678 - en - Na 2Document16 pagesSV - 03678 - en - Na 2eduardodluffy268No ratings yet

- 9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioDocument26 pages9619 LG Flatron L1917S Chassis CL-82 Monitor LCD Manual de ServicioPa PlastireNo ratings yet

- Instruction Manual: Model RSP Sanitary Electronic Pressure TransmitterDocument16 pagesInstruction Manual: Model RSP Sanitary Electronic Pressure TransmitterHectorNo ratings yet

- Smoke Detector ManualDocument4 pagesSmoke Detector ManualKarthik VelNo ratings yet

- JMC Tech DMS ENDocument4 pagesJMC Tech DMS ENVaidas BartkevičiusNo ratings yet

- OXY-Gas - Manual Do UsuarioDocument25 pagesOXY-Gas - Manual Do UsuarioMagno DelmiroNo ratings yet

- Honeywell C7632a B Sensor Co2 PDFDocument4 pagesHoneywell C7632a B Sensor Co2 PDFMarcello PorrinoNo ratings yet

- KB Manual v5Document26 pagesKB Manual v5nathanaelsilva076No ratings yet

- ReadoutDocument11 pagesReadoutsamirmartil676No ratings yet

- Fujifilm Finepix s9000 s9500 SM ET 1Document147 pagesFujifilm Finepix s9000 s9500 SM ET 1newionNo ratings yet

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorDocument14 pagesBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectorluisrruiz_123No ratings yet

- MCD288 DVD Micro Theatre: /all VersionsDocument39 pagesMCD288 DVD Micro Theatre: /all VersionsLeonelHernandezNo ratings yet

- LG LCD Monitor M1917a-K, F, GZD - eDocument33 pagesLG LCD Monitor M1917a-K, F, GZD - evideosonNo ratings yet

- Detector 2151-A05-0182Document2 pagesDetector 2151-A05-0182Tiago SilvaNo ratings yet

- Ecotech Ex22dT50Document13 pagesEcotech Ex22dT50Rujisak MuangsongNo ratings yet

- I4series Datasheet CODS303Document4 pagesI4series Datasheet CODS303b.leite.domNo ratings yet

- 7.1 Method Statement For Termination & GlandingDocument24 pages7.1 Method Statement For Termination & GlandingMedrouaNo ratings yet

- SHD-260LS Combustible Toxic GasDocument25 pagesSHD-260LS Combustible Toxic Gasryan azzaamNo ratings yet

- 300 Series Photoelectric Smoke Detector SystemDocument4 pages300 Series Photoelectric Smoke Detector SystemgeoffffNo ratings yet

- E2s Atex BeaconDocument3 pagesE2s Atex BeaconControlgearNo ratings yet

- SCM-W Datasheet v41Document10 pagesSCM-W Datasheet v41nguyenam2008No ratings yet

- In Touch With The Medium: BEDIA Level - Monitoring - Probes Type PLS 10 Type PLS 30 Type PLS 40Document27 pagesIn Touch With The Medium: BEDIA Level - Monitoring - Probes Type PLS 10 Type PLS 30 Type PLS 40ALEJONo ratings yet

- Ultrasonic Level Transmitter NUS ManualDocument39 pagesUltrasonic Level Transmitter NUS ManualAli Hadi100% (1)

- Fuji Finepix s5200 s5600Document121 pagesFuji Finepix s5200 s5600zilikonNo ratings yet

- Parking Radar: Parking Aid, or As Eye S' For Robo T Projec TsDocument0 pagesParking Radar: Parking Aid, or As Eye S' For Robo T Projec TsBalvendra SinghNo ratings yet

- Bondmaster Pitch-Catch Probe Adaptor: Getting StartedDocument6 pagesBondmaster Pitch-Catch Probe Adaptor: Getting StartedSaadNo ratings yet

- Sony HCD-GNX60Document76 pagesSony HCD-GNX60kalentoneschatNo ratings yet

- Color Monitor Service ManualDocument49 pagesColor Monitor Service ManualAlexandre MagriNo ratings yet

- Oi Kcap300-En eDocument20 pagesOi Kcap300-En ejaime HernandezNo ratings yet

- ElektronikaBa dualCHDocument16 pagesElektronikaBa dualCHedroalNo ratings yet

- CO1224TDocument2 pagesCO1224TJhonny SilvaNo ratings yet

- Fiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Document16 pagesFiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Amila BalasooriyaNo ratings yet

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDocument2 pagesData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaNo ratings yet

- Acw 1709B User Manual 230818Document22 pagesAcw 1709B User Manual 230818armando.wellavNo ratings yet

- WDG-1210 現址式氧氣分析儀Document4 pagesWDG-1210 現址式氧氣分析儀SeanKuoNo ratings yet

- SP Series Magnetostrictive Probe 2016 V2.0Document16 pagesSP Series Magnetostrictive Probe 2016 V2.0Mantenimiento MineriaNo ratings yet

- Installation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92Document22 pagesInstallation, Operating & Maintenance Manual. Electronic Level Switch LIDEC 91-92carlos_sagitarioNo ratings yet

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorDocument15 pagesBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectoryesid rodriguezNo ratings yet

- Conventional Reflective Beam Detector: Technical SpecificationsDocument2 pagesConventional Reflective Beam Detector: Technical SpecificationsdalanruhunaNo ratings yet

- Model 872 Ultrasonic Level Transmitter Two-Wire, Loop PoweredDocument2 pagesModel 872 Ultrasonic Level Transmitter Two-Wire, Loop Poweredandres49mNo ratings yet

- Instruction Manual: Model RSP Sanitary Electronic Pressure TransmitterDocument16 pagesInstruction Manual: Model RSP Sanitary Electronic Pressure Transmittergrincheu70No ratings yet

- S 5800Document114 pagesS 5800elenoremailNo ratings yet

- Mcdonnell & Miller: WarningDocument8 pagesMcdonnell & Miller: WarningALEXANDER VARELANo ratings yet

- 3BLWKB2intden100 ABB KPM KB2 20220406 Fabricca Digital WithSpecs FinalNEWDocument2 pages3BLWKB2intden100 ABB KPM KB2 20220406 Fabricca Digital WithSpecs FinalNEWMajedur Rahman RejaNo ratings yet

- TC100N enDocument15 pagesTC100N enThanosEleftheroudisNo ratings yet

- KM260 Inst EngDocument13 pagesKM260 Inst EngFermalux FermaluxNo ratings yet

- TrackSo Datasheet Installation Guide Solar Radiation Sensor PYRA300VDocument10 pagesTrackSo Datasheet Installation Guide Solar Radiation Sensor PYRA300VGaurav DwivediNo ratings yet

- Do 5519-1Document2 pagesDo 5519-1Ethan PollNo ratings yet

- Operation ManualDocument12 pagesOperation ManualSeaze RooNo ratings yet

- C7232A, B Sensor and Controller: FeaturesDocument8 pagesC7232A, B Sensor and Controller: FeaturesNanû CbralNo ratings yet

- 400 Series Plug-In Smoke Detector: IonizationDocument4 pages400 Series Plug-In Smoke Detector: IonizationJun AntonioNo ratings yet

- DIY Geiger Counter Radiation Detector Kit Ver.2 PDFDocument16 pagesDIY Geiger Counter Radiation Detector Kit Ver.2 PDFLeonardo VelezNo ratings yet

- D116 CatalogDocument8 pagesD116 CatalogLe VinhNo ratings yet

- Hydrant Test Meter: Flowmaster 250Document2 pagesHydrant Test Meter: Flowmaster 250Le VinhNo ratings yet

- ASTM A249 Seamless Tube, ASME SA249 Welded Tube ManufacturerDocument11 pagesASTM A249 Seamless Tube, ASME SA249 Welded Tube ManufacturerLe VinhNo ratings yet

- Product Catalog of PFlowDocument7 pagesProduct Catalog of PFlowLe VinhNo ratings yet

- Astm A554Document6 pagesAstm A554Le VinhNo ratings yet

- ASTM A249 Stainless Steel TubesDocument10 pagesASTM A249 Stainless Steel TubesLe VinhNo ratings yet

- Cuelux Manual en 10324Document46 pagesCuelux Manual en 10324joeykeysNo ratings yet

- 917 Coulometer METROHMDocument350 pages917 Coulometer METROHMYến Vũ ThịNo ratings yet

- PDF HSGQ Epon Olt Command User Manual 122018 - CompressDocument41 pagesPDF HSGQ Epon Olt Command User Manual 122018 - Compressdonlot anonymous0% (1)

- K 30iqtDocument32 pagesK 30iqtNimisha RajanNo ratings yet

- EVGA - Product Specs - EVGA GeForce GTX 1650 XC BLACK GAMING, 04G-P4-1151-KR, 4GB GDDR5Document1 pageEVGA - Product Specs - EVGA GeForce GTX 1650 XC BLACK GAMING, 04G-P4-1151-KR, 4GB GDDR5Célio LinharesNo ratings yet

- Lecture Notes On: Random Number GenerationDocument29 pagesLecture Notes On: Random Number GenerationfhyvhufchuNo ratings yet

- Ingenico POS Terminal Download Instructions: Before Initiating A Download Expected Download TimeDocument1 pageIngenico POS Terminal Download Instructions: Before Initiating A Download Expected Download TimeDoNo ratings yet

- NCR MLA MediaInfoLit M2 - L2 The Evolution of Traditional To New Media - v11 RevisedDocument20 pagesNCR MLA MediaInfoLit M2 - L2 The Evolution of Traditional To New Media - v11 RevisedKryzel Lho EspanaNo ratings yet

- 6 Mintzberg's Management RolesDocument12 pages6 Mintzberg's Management Roleshoney guptaNo ratings yet

- Hexagon Documentation Site Export-3Document100 pagesHexagon Documentation Site Export-3Alberto VELOSA ROANo ratings yet

- Telesis TMP7000Document8 pagesTelesis TMP7000Arjuna GamingNo ratings yet

- Long Lead Acid Battery 12v 65ahDocument2 pagesLong Lead Acid Battery 12v 65ahnadeemNo ratings yet

- Steps in Creating Simple Mail MergeDocument5 pagesSteps in Creating Simple Mail MergeRudula AmperNo ratings yet

- SOLANA ECOSYSTEM and Its Dynamism in Recent TimesDocument2 pagesSOLANA ECOSYSTEM and Its Dynamism in Recent TimesEdith OwolabiNo ratings yet

- Ability 6100648Document1 pageAbility 6100648Vedant DesaiNo ratings yet

- Guideline On Writing A First Quantitative Academic Article YYS)Document1 pageGuideline On Writing A First Quantitative Academic Article YYS)Isan Yys SanNo ratings yet

- Key IIS Final VIP David Hai 1Document443 pagesKey IIS Final VIP David Hai 1Hi LightNo ratings yet

- Minimalism - Tubular BellsDocument2 pagesMinimalism - Tubular BellshodiestoeNo ratings yet

- Panel Options LCD Samsung PDFDocument11 pagesPanel Options LCD Samsung PDFJejeNo ratings yet

- Unveil The Mystery of Code Coverage in Low-Power Designs: Achieving Power AwareDocument13 pagesUnveil The Mystery of Code Coverage in Low-Power Designs: Achieving Power AwareNishit GuptaNo ratings yet

- Titus VavDocument46 pagesTitus VavSantiago J. ramos jrNo ratings yet

- Fathur Rahman PDFDocument1 pageFathur Rahman PDFRSCERIA KANDANGANNo ratings yet

- 2017 Driverless CarDocument8 pages2017 Driverless CarLucky pavanNo ratings yet

- PHM Question 555Document3 pagesPHM Question 555Jonathan LukwichiNo ratings yet

- 4L60-E VacTestGuideDocument4 pages4L60-E VacTestGuideJailton GomesNo ratings yet

- (Download PDF) Natural History New Edition DK Ebook Online Full ChapterDocument24 pages(Download PDF) Natural History New Edition DK Ebook Online Full Chapterhlaselivis100% (6)

- PAT Report Solar System at Sambrial ExchDocument9 pagesPAT Report Solar System at Sambrial ExchBilal AsgharNo ratings yet

- Bu Grading SystemDocument37 pagesBu Grading Systemmanen gajoNo ratings yet

- Super Blood Harvest 3 PDFDocument68 pagesSuper Blood Harvest 3 PDFJoseph McLachlanNo ratings yet