Professional Documents

Culture Documents

Weld Inspection of Small-Diameter Pipes: Cobra

Weld Inspection of Small-Diameter Pipes: Cobra

Uploaded by

LEONARDOUS7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Inspection of Small-Diameter Pipes: Cobra

Weld Inspection of Small-Diameter Pipes: Cobra

Uploaded by

LEONARDOUS7Copyright:

Available Formats

MANUAL WELD SCANNER

COBRA

FEATURES

■■ Covers pipes from 0.84 in. to 4.5 in. OD.

■■ Operates within 12 mm (0.5 in.) clear-

ance (on all standard pipes) permitting

inspections in limited access areas

■■ Can hold two phased array probes for

complete weld coverage in one pass

■■ Can be configured to make one-sided

inspections for pipe-to-component

evaluations

■■ Design provides stable and constant

pressure around the full circumference

of the pipe.

■■ Urethane wheels provide smooth radial

movement and limited axial drift

■■ Compact, lightweight, and portable

■■ Wedges and probes can be quickly and

easily changed.

Weld Inspection of Small-Diameter Pipes ■■ Distance between probes can be ad-

The COBRA manual scanner is able to inspect pipes as small as 0.84 in. OD to 4.5 in. OD. justed from 0 mm to 45 mm

This scanner uses the OmniScan® MX flaw detector with the 16:128 module, and the MXU

■■ Can be manipulated from one side of a

software to inspect circumferential welds on small-diameter pipes.

pipe.

With its very slim design, this manual This Olympus solution uses low-profile

■■ Spring-loaded scanner can be used on fer-

scanner inspects pipes in limited access phased array probes with optimized eleva-

romagnetic and nonferromagnetic pipes.

areas where minimal clearance is required. tion focusing, which improves the detection

Adjacent obstructions such as piping, sup- of small defects in thin-wall pipes. Specially ■■ Waterproof, rust-free, and CE compliant

ports, and structures can be as close as 12 designed low-profile wedges that fit each

mm (0.5 in.). This spring-loaded scanner pipe diameter covered by the scanner, are ■■ Encoder resolution of 32 steps/mm

is designed to hold onto carbon steel and also offered to complete the solution. The

stainless steel pipes of different diameters. COBRA scanner ensures stable, constant,

The COBRA scanner is characterized by and strong pressure thus providing good

its smooth-rolling encoded movement UT signals and precise encoding around

enabling precise data acquisition. The scan- the full circumference of the pipe. This

ner can hold two phased array probes for complete solution package is small and

a complete inspection of the weld in one lightweight for easy transport. The scanner

pass. For pipe-to-component inspections, is also waterproof, rust-free, and CE compli-

the scanner can be quickly configured to ant.

make one-sided inspections with only one

probe.

The COBRA scanner on a 0.84 in. pipe with

two PA probes and an OmniScan MXU 16:128

displaying two PA groups with sectorial scans,

A-scans, and C-scans.

920-206A-EN

CONFIGURATION

The typical configuration for the application uses: the COBRA scanner, two A15 low-profile phased array probes with SA15 wedges, the

Y probe adaptor, and the OmniScan MX PA 16:128 with the multigroup option.

ORDERING INFORMATION

Scanner packages

Part number Description PN: COBRA-K-3.5 PN: COBRA-K-4.5

Small pipe scanner with encoder to cover 0.84 in. to 3.5 in.

COBRA

OD pipes; packaged in hard carrying case ✔ ✔

2 flat wedges plus 8 pairs of curved wedges to cover 0.84 in.

COBRA-A-SA15

to 3.5 in. OD pipes ✔ ✔

7.5CCEV35-A15-P-2.5-OM Low-profile phased array probe ✔ (x2) ✔ (x2)

Additional links to enlarge the COBRA scanner’s range to

COBRA-A-EXT

4.5 in. OD pipes ✔

COBRA-A-SA15EXT Two pairs of wedges to cover 3.5 in. to 4.5 in. OD pipes ✔

Y-adaptor (splitter) with OmniScan connectors to support 2

OMNI-A-ADP05

phased array probes

WTR-SPRAYER-4L 4 L manual water pump with irrigation tubes and fittings

WTR-SPRAYER-8L 8 L manual water pump with irrigation tubes and fittings

OMNI-P-PA16128 OmniScan MX 16:128 with MXU 2.0 software

OMNI-SO-MGROUP Multigroup option for MXU 2.0 software

PHASED ARRAY PROBE

Elevation

Freq. Number of Pitch Elevation Corresponding Cable length Connector

Part number curvature radius

(MHz) elements (mm) (mm) wedge (m) type

(mm)

7.5CCEV35-A15-P-2.5-OM 7.5 16 0.5 10 SA15 2.5 OmniScan 35

PHASED ARRAY WEDGES

The wedge part number for this application is SA15-N60S-IH-AODXXXX. This part number comprises the A15 probe type, normal probe

mounting, 60 degree refracted angle, shear wave, irrigation, and scanner mounting holes. The outside diameter curvature (XXXX) is defined

by referring to the different values for standard pipe outside diameters found in the table below (AOD).

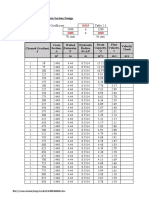

STANDARD WEDGE AOD VALUES AND PIPE OD

Minimum OD Maximum OD

AOD (in.)

(in.) (in.)

0.84 0.800 0.840

1.05 0.840 1.050

1.315 1.050 1.315

1.66 1.315 1.660

1.9 1.660 1.900

2.375 1.900 2.375

2.875 2.375 2.875

3.5 2.875 3.500

4 3.500 4.000

4.5 4.000 4.500

The solution uses low-profile phased array probes The COBRA scanner can also be configured for pipe-to-

with optimized elevation focusing, which improves component weld inspections.

the detection of small defects in thin-wall pipes.

is ISO 9001 certified.

48 Woerd Avenue, Waltham, MA 02453, USA, Tel.: (1) 781-419-3900

12569 Gulf Freeway, Houston, TX 77034, USA, Tel.: (1) 281-922-9300

450 Campbell St. Unit 5, Cobourg, Ontario K9A 4C4, Tel.: (1) 905-377-9611

www.olympus-ims.com

info@olympusNDT.com Scanner_COBRA_EN_200911 • Printed in Canada• Copyright © 2009 by Olympus NDT.

*All specifications are subject to change without notice. All brands are trademarks or registered trademarks of their respective owners.

You might also like

- Collaborative Environmental Governance Frameworks-A Practical Guide (Timothy Gieseke (Author) ) (Z-Library) - 1Document211 pagesCollaborative Environmental Governance Frameworks-A Practical Guide (Timothy Gieseke (Author) ) (Z-Library) - 1kiemwanzNo ratings yet

- Semi Detailed Lesson Plan DIASS (Humss) (Demo)Document5 pagesSemi Detailed Lesson Plan DIASS (Humss) (Demo)Nildy Ponteras100% (4)

- Lab Safety WorksheetDocument2 pagesLab Safety WorksheetTcer Odah25% (4)

- Cobra Scan InspectionDocument58 pagesCobra Scan InspectionMohsin Iam100% (2)

- Flexscan Manual-FinalDocument105 pagesFlexscan Manual-FinalLEONARDOUS7100% (5)

- CVL Consent PDFDocument5 pagesCVL Consent PDFGolam SarwarNo ratings yet

- Scanner COBRA - en PDFDocument2 pagesScanner COBRA - en PDFrupamNo ratings yet

- Scanner COBRA - en PDFDocument2 pagesScanner COBRA - en PDFlucky kakanNo ratings yet

- COBRA - Weld Inspection of Small-Diameter Pipes: FeaturesDocument2 pagesCOBRA - Weld Inspection of Small-Diameter Pipes: FeaturesGhaithNo ratings yet

- Scanner Cobra en 201507Document2 pagesScanner Cobra en 201507Shahbaz KhanNo ratings yet

- Scanner COBRA EN 201805 WebDocument2 pagesScanner COBRA EN 201805 WebkannanNo ratings yet

- Scanner HSMT-Flex - en PDFDocument3 pagesScanner HSMT-Flex - en PDFMadhu BabuNo ratings yet

- GE - Palm Scanner PipeDocument4 pagesGE - Palm Scanner Pipepokeboy19No ratings yet

- Process Pipe and Piping Inspection SolutionsDocument1 pageProcess Pipe and Piping Inspection SolutionsBelaliaNo ratings yet

- PA Caracterization BlockDocument2 pagesPA Caracterization BlockMuallim MursyidNo ratings yet

- Pheonix - Advanced UT ScannerDocument2 pagesPheonix - Advanced UT Scannerpokeboy19No ratings yet

- PBR EDRV220704 ERH EN WebDocument5 pagesPBR EDRV220704 ERH EN Webwael72No ratings yet

- Applus+K2 - Phased Array UT (PAUT)Document3 pagesApplus+K2 - Phased Array UT (PAUT)Gistek MarcoNo ratings yet

- Sultan 234Document12 pagesSultan 234wang710No ratings yet

- TSC Subsea Tool Brochures NodeScanner 0.2Document4 pagesTSC Subsea Tool Brochures NodeScanner 0.2Bimal BosmiaNo ratings yet

- Long Range Ultrasonic To Detect Corrosion in Tank Annular PlatesDocument2 pagesLong Range Ultrasonic To Detect Corrosion in Tank Annular PlatesGistek MarcoNo ratings yet

- Small Diameter Tube and Pipe Inspection With Phased ArrayDocument1 pageSmall Diameter Tube and Pipe Inspection With Phased Arraypon sharonNo ratings yet

- Sitransl lc300 Fi01 en PDFDocument14 pagesSitransl lc300 Fi01 en PDFValiNo ratings yet

- Continuous Level Measurement - Ultrasonic TransmittersDocument3 pagesContinuous Level Measurement - Ultrasonic Transmitterslucio gonzalezNo ratings yet

- INA326 INA327 Instrumentation AmplifierDocument27 pagesINA326 INA327 Instrumentation AmplifierArun KaruppaswamyNo ratings yet

- CompuflowDocument4 pagesCompuflowDavid MoleroNo ratings yet

- Pipeline Corrosion Detection Testing 1700551871Document7 pagesPipeline Corrosion Detection Testing 1700551871shailesh jhaNo ratings yet

- Bliss Anand America - Magnetic Level Gauges - NewDocument25 pagesBliss Anand America - Magnetic Level Gauges - NewNikhil WadhwaNo ratings yet

- Inspección de TuberiasDocument7 pagesInspección de TuberiasharyjbiNo ratings yet

- Spi Mag Model 282L Flow Meter With Procomm ConverterDocument6 pagesSpi Mag Model 282L Flow Meter With Procomm ConverterLeonardo WehmuthNo ratings yet

- Jireh Circ It ScannerDocument2 pagesJireh Circ It ScannerMarcos Kaian Moraes RodriguesNo ratings yet

- Ti 177 CenDocument8 pagesTi 177 CenNirmal KumarNo ratings yet

- Compatible Pigs To Argus Pig Valve (ILI) - PR11Document8 pagesCompatible Pigs To Argus Pig Valve (ILI) - PR11FSAAVEDRAFNo ratings yet

- PRUEFTECHNIK Overview Rotating-Systems 8-Page-Brochure DOK5400ENDocument8 pagesPRUEFTECHNIK Overview Rotating-Systems 8-Page-Brochure DOK5400ENvanloc tranNo ratings yet

- Specifications Sheet Sharck ProbeDocument4 pagesSpecifications Sheet Sharck ProbeKim GraebnerNo ratings yet

- TI096CENDocument4 pagesTI096CENOctavio SilvaNo ratings yet

- Brosur Sokkia LX442 Crossline LaserDocument2 pagesBrosur Sokkia LX442 Crossline LaserGina Rizka AmaliaNo ratings yet

- Ect, Eca, NFT, RFT, Iris: ApplicationsDocument2 pagesEct, Eca, NFT, RFT, Iris: ApplicationsGistek MarcoNo ratings yet

- I 60metricDocument2 pagesI 60metricWayne SeamanNo ratings yet

- Water Jetting Accessory Catalog - Blast-JetDocument102 pagesWater Jetting Accessory Catalog - Blast-JetGhouma ayoubNo ratings yet

- Needle ValvesDocument8 pagesNeedle Valvessrave_k07No ratings yet

- Endress HauserDocument36 pagesEndress HauserCapacitacion TodocatNo ratings yet

- PTC Excavator Mounted Vibrodrivers WEB 09-2015 PDFDocument20 pagesPTC Excavator Mounted Vibrodrivers WEB 09-2015 PDFDaniel FuhrNo ratings yet

- DS1280 S-24WR Series Strobe Revision 01-28-14Document4 pagesDS1280 S-24WR Series Strobe Revision 01-28-14Danny DukeranNo ratings yet

- Catalogo CeaDocument2 pagesCatalogo CeaSergio ZegarraNo ratings yet

- Cat75HYD Metric Fine-Spray EDocument12 pagesCat75HYD Metric Fine-Spray Edavide scamardellaNo ratings yet

- Probe Lu SiemensDocument4 pagesProbe Lu Siemensvhmingenieria9084No ratings yet

- 14 Wireline Catalogue High Expansion Gauge Hanger Product SheetDocument2 pages14 Wireline Catalogue High Expansion Gauge Hanger Product SheetYovaraj KarunakaranNo ratings yet

- Signet 8860 Two-Channel Conductivity Controller: FeaturesDocument2 pagesSignet 8860 Two-Channel Conductivity Controller: FeaturesMagin Idelfonso TorreblancaNo ratings yet

- 4 Product-Data-Sheet-396-396vp-396p-396pvp-396r-396rvp-Tuph-Ph-Orp-Sensors-Rosemount-En-72114Document20 pages4 Product-Data-Sheet-396-396vp-396p-396pvp-396r-396rvp-Tuph-Ph-Orp-Sensors-Rosemount-En-72114Marina SovaNo ratings yet

- 1SXU657176C0201Document108 pages1SXU657176C0201baurzhan.kunkuzhayevNo ratings yet

- Data Sheet LG PenberthyDocument12 pagesData Sheet LG PenberthyHERNANDO CASTAÑONo ratings yet

- Ultra: Sprays Valves Controllers Sensors Central Controls MicroDocument4 pagesUltra: Sprays Valves Controllers Sensors Central Controls MicroWayne SeamanNo ratings yet

- PS Platform: Production Logging With ConfidenceDocument6 pagesPS Platform: Production Logging With ConfidenceMelisa JuradoNo ratings yet

- Cy-100 e CataDocument6 pagesCy-100 e Cataluis fernando noche monroyNo ratings yet

- Medium Pressure Filters Models 15CN, 40CN, 80CN: P A G EDocument7 pagesMedium Pressure Filters Models 15CN, 40CN, 80CN: P A G EHidralteka SandelisNo ratings yet

- CAT-5322 SS-2001 Abort StationDocument2 pagesCAT-5322 SS-2001 Abort StationEliud RodriguezNo ratings yet

- STL DatasheetDocument16 pagesSTL DatasheetCarlos Miguel Barrena TorresNo ratings yet

- VCTDS 0041 EN Web PDFDocument8 pagesVCTDS 0041 EN Web PDFAbdul RahimNo ratings yet

- Eddyfi Technologies Application NoteInspecting Beyond The Curve With IRISDocument2 pagesEddyfi Technologies Application NoteInspecting Beyond The Curve With IRISVikas TiwariNo ratings yet

- EN VEGAKON 61 66 Probes EL 1 3 4 6 8 Level Detection in LiquidDocument16 pagesEN VEGAKON 61 66 Probes EL 1 3 4 6 8 Level Detection in LiquidA GlaumNo ratings yet

- Addressable Photoelectoric Smoke Detector Eva-Py: FeaturesDocument3 pagesAddressable Photoelectoric Smoke Detector Eva-Py: FeaturesIndra HayadiNo ratings yet

- Rotary Cleaning For Straight Pipes: Competitive AdvantagesDocument18 pagesRotary Cleaning For Straight Pipes: Competitive AdvantagesЮрийNo ratings yet

- Conceitos de Phased ArrayDocument23 pagesConceitos de Phased ArrayLEONARDOUS7No ratings yet

- B ScanDocument12 pagesB ScanLEONARDOUS7No ratings yet

- Hydroform: Manual and Semi-Automated Corrosion MappingDocument2 pagesHydroform: Manual and Semi-Automated Corrosion MappingLEONARDOUS7No ratings yet

- Historia Do End Us PhasedDocument3 pagesHistoria Do End Us PhasedLEONARDOUS7No ratings yet

- Operating Instructions For Offline Software of PhascanDocument30 pagesOperating Instructions For Offline Software of PhascanLEONARDOUS7100% (1)

- The Ultrasound Image: Generation and Display: by DR/ Dina MetwalyDocument18 pagesThe Ultrasound Image: Generation and Display: by DR/ Dina MetwalyLEONARDOUS7No ratings yet

- Flyer Medicover EliteDocument5 pagesFlyer Medicover EliteLuciaNo ratings yet

- Box Culvert / U-Drain Section Design: File:///conversion/tmp/scratch/488560866Document9 pagesBox Culvert / U-Drain Section Design: File:///conversion/tmp/scratch/488560866azwanNo ratings yet

- Mission Document 2Document7 pagesMission Document 2alistair_bates_1No ratings yet

- Kosher 149 Complete Secular Book ListDocument434 pagesKosher 149 Complete Secular Book ListPond OfCraftsNo ratings yet

- GUI Based Control System Analysis Using PID Controller For EducationDocument11 pagesGUI Based Control System Analysis Using PID Controller For Educationpascal toguNo ratings yet

- Thesis Supervisor ReportDocument7 pagesThesis Supervisor ReportBestPaperWritingServiceUK100% (1)

- CNS Depressants TametaDocument29 pagesCNS Depressants TametaJhareinne GardeNo ratings yet

- Data Structures Algorithms in Python 1St Edition John Canning Full ChapterDocument67 pagesData Structures Algorithms in Python 1St Edition John Canning Full Chapterchester.gallegos491100% (6)

- Daring To Be Great ForeverDocument2 pagesDaring To Be Great ForeverRhoda Mae CocjinNo ratings yet

- A2 Thinking Skills Problem Solving Corvenian Football League With AnswersDocument3 pagesA2 Thinking Skills Problem Solving Corvenian Football League With AnswersLeeNo ratings yet

- Standards Stat SurveysDocument41 pagesStandards Stat SurveysGerardo LozzNo ratings yet

- Lecture "Channel Coding" Chapter 2: Channel Coding PrinciplesDocument19 pagesLecture "Channel Coding" Chapter 2: Channel Coding PrinciplesLernen Deutsch A1No ratings yet

- Pitch Decks by Alejandro CremadesDocument123 pagesPitch Decks by Alejandro CremadesValeria VillacortaNo ratings yet

- Pure EnergyDocument5 pagesPure EnergyRaj ChaurasiaNo ratings yet

- The Myth of The Neronian Persecution. Brent D. ShawDocument28 pagesThe Myth of The Neronian Persecution. Brent D. ShawDolores MonteroNo ratings yet

- EconomicsDocument136 pagesEconomicsAbdi Teshome100% (1)

- Avenida de Balide - Antigo Comarca Balide, Dili TLF.: (+670) 3310315 11111Document2 pagesAvenida de Balide - Antigo Comarca Balide, Dili TLF.: (+670) 3310315 11111iduyNo ratings yet

- Note On Marsh Crocodile, Presentation On Marsh Crocodile or Marsh Crocodile LifeDocument18 pagesNote On Marsh Crocodile, Presentation On Marsh Crocodile or Marsh Crocodile LifeKirfan 123No ratings yet

- ResumeDocument3 pagesResumejohn DaqueNo ratings yet

- Machine Design Vol 12-2Document26 pagesMachine Design Vol 12-2CikamaksaNo ratings yet

- Democratization of Secondary School in MalaysiaDocument12 pagesDemocratization of Secondary School in MalaysiaKavinesh Kaneson100% (1)

- Plasmonics: The Next Chip-Scale Technology: Presented By-Priyanka M.E. Electronics (Vlsi Design) 17215019Document11 pagesPlasmonics: The Next Chip-Scale Technology: Presented By-Priyanka M.E. Electronics (Vlsi Design) 17215019anon_944553531No ratings yet

- 3 Combine Wiring Diagram Pad BDocument7 pages3 Combine Wiring Diagram Pad BDimas FirmanNo ratings yet

- Logging InnovationDocument8 pagesLogging InnovationAnkit ChourasiaNo ratings yet

- Zeus We Just Wanna Talk (Download)Document8 pagesZeus We Just Wanna Talk (Download)RJ PNo ratings yet

- Preston Corpn. Sdn. Bhd. V Edward Leong (1982) 2 MLJ 22Document14 pagesPreston Corpn. Sdn. Bhd. V Edward Leong (1982) 2 MLJ 22Nurissya DaliaNo ratings yet