Professional Documents

Culture Documents

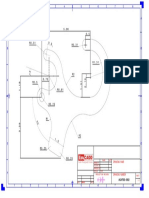

Process Design 1.2: Repeated Batch Fermentation

Process Design 1.2: Repeated Batch Fermentation

Uploaded by

Elzubair EljaaliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Design 1.2: Repeated Batch Fermentation

Process Design 1.2: Repeated Batch Fermentation

Uploaded by

Elzubair EljaaliCopyright:

Available Formats

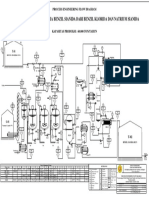

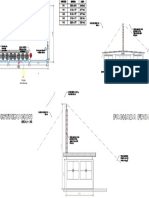

Process Design 1.

2

Repeated Batch

Clostridium Fermentation

acetobutylicum R-201a Total ABE 19.2 g/L

ABE Productivity 0.42 g/L

PCSIR-10 A:B:E 2:95:3

147

25 R-201b

1.01

1191 72.4

Molasses 1

34.9

R-201c 33.05

1.01

3.5

4 CO2

1191 11

0.016

25 P-101 25 R-201d H2

HE-101

39

1.01 3.5 1191 103.7

CSW 5

8 13 34.9

1.5

2 12 1.01

FeSO4.7H2O 1033 P-102

7 HPS T-301

25 6

P-104 1191 P-105 Beer

1.01

V-101

9 121.8 V-102 25

A-101 Stripper

1140

3.5 33.05

H2O 3 1.01 10

P-103 20 22 1140

33.05

98.5% Water Removal

100% Biomass Removal

10 Feed Sterilization CW

1.5

1191

130 P-204 24

23

3.5 R-202

P-205

V-201

1.1 1101

25 111.8

1.01 CO2 1.5

H2

H2O and

37.9

25 27

1.01 26 Biomass

to Waste Water

28

Treatment

F-301

CW

32

3.3

79.5

0.9

Waste Stream (CO2 and Acetone)

37.9 40

25

1.1

29 30

31 Acetone Recovery 4.1

76.5

0.5

99.9% Acetone Recovery

40

P-302

P-301

V-301

CW V-302

34.6 34.6 15.1

HPS 93.45

T-302 25 103.3

20

0.9 1.1 1.5

D-301 20

97

33 34

1.01

HE-301 37

Water Stripper

36

35

43

P-303

Decanter

38 HPS

15.9

T-304 T-303 81.25

33.8

0.5

H2O

97

41 to Waste Water

1.5 Treatment

Purity 99.17%

20

42

18.7

25

P-305 45 1.01

18.7

49 25

47 1.01

P-306 Butanol

V-303 51 Purity 99.05%

50 Overall Recovery

18.7 44 95.62%

128.9

Butanol Recovery HPS

1.5

V-305

46 48

P-307

KEY

Temperature (○C) V-304

Pressure (bar)

Mass Flow (tonne/h)

You might also like

- Poster PresentationDocument1 pagePoster Presentationsayem3070No ratings yet

- Admin HoursDocument5 pagesAdmin Hoursapi-416989971No ratings yet

- Database Access With Visual Basic - NET 3rd PDFDocument445 pagesDatabase Access With Visual Basic - NET 3rd PDFbelkirisNo ratings yet

- Bhatbhateni Supermarket Is ReportDocument12 pagesBhatbhateni Supermarket Is ReportJalie Khata81% (16)

- Process Design 1.2: Repeated Batch FermentationDocument2 pagesProcess Design 1.2: Repeated Batch FermentationElzubair EljaaliNo ratings yet

- Roof Framing Plan Purlin Connections: A' B C D E ADocument1 pageRoof Framing Plan Purlin Connections: A' B C D E ATrisha Marie Bustria MartinezNo ratings yet

- Sapata Sheet 4Document1 pageSapata Sheet 4Dejan AntanasijevicNo ratings yet

- Gambar Kerja Product Sesi 1Document2 pagesGambar Kerja Product Sesi 1Muhamad Eko FebriansyahNo ratings yet

- Cimentaciones EstructurasDocument1 pageCimentaciones EstructurasRené Paricahua SánchezNo ratings yet

- e - Hakko - fx951 - ADocument2 pagese - Hakko - fx951 - ARizky WijayaNo ratings yet

- SC-2100 Feed Gas Slug Catcher V-2401 Inlet Gas SeparatorDocument2 pagesSC-2100 Feed Gas Slug Catcher V-2401 Inlet Gas SeparatorMidha NeerNo ratings yet

- A F C D H E G A F: Denah Lantai Dasar KALA 1:100 Denah Lantai 1 SKALA 1:100Document1 pageA F C D H E G A F: Denah Lantai Dasar KALA 1:100 Denah Lantai 1 SKALA 1:100fadjarwNo ratings yet

- Foundation Plan Roof Framing Plan: K & M Design and StandardsDocument1 pageFoundation Plan Roof Framing Plan: K & M Design and StandardsSabrex MacadatoNo ratings yet

- COLUMNASDocument1 pageCOLUMNASsarai salcedoNo ratings yet

- ỐNG GÓP NẠPDocument1 pageỐNG GÓP NẠPBảo LêNo ratings yet

- Cimentacion Ee GlorindaDocument1 pageCimentacion Ee GlorindaMiquer Sayas HuamanNo ratings yet

- Cuarta PlantaDocument1 pageCuarta PlantaNaomi ArnezNo ratings yet

- Referenece 2Document3 pagesReferenece 2Jasmin De VeraNo ratings yet

- B03a-200-005 Brida Morrison 18Document3 pagesB03a-200-005 Brida Morrison 18Willerman Perez GomezNo ratings yet

- Pefd Fixx 3Document1 pagePefd Fixx 3Rafi Theda PrabawaNo ratings yet

- MARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-Trombone - 2Document1 pageMARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-Trombone - 2Rosinaldo Araújo LimaNo ratings yet

- Tasha Modul3Document1 pageTasha Modul3Aqsal FahrizqaNo ratings yet

- Í ENí+Electrical System-T8 (4DB2)Document34 pagesÍ ENí+Electrical System-T8 (4DB2)kennethpinto275No ratings yet

- CIMENTACIONESDocument1 pageCIMENTACIONESJhocelyn Mirella Dávila CarrascoNo ratings yet

- Saldaña Ejercicio 7-Corte AaDocument1 pageSaldaña Ejercicio 7-Corte Aaalexsaldana.ruagNo ratings yet

- PT Cargas Atmosfericas: Diesel-B5 Diesel-B5 Diesel-B5 Diesel-B5 Diesel-B5 Gasolina Gasolina 90 Gasolina 90Document1 pagePT Cargas Atmosfericas: Diesel-B5 Diesel-B5 Diesel-B5 Diesel-B5 Diesel-B5 Gasolina Gasolina 90 Gasolina 90HERSON EDU NIETO LAPANo ratings yet

- Item DesignationDocument1 pageItem DesignationTahseenNo ratings yet

- 12 CorollaDocument7 pages12 CorollaISAAC SIDIBENo ratings yet

- Plano para MetrarDocument1 pagePlano para MetrarRebeca Noemi Perca MuchoNo ratings yet

- E03 For PitDocument1 pageE03 For Pitsebastian0210_401439No ratings yet

- Reactor R-101 Reactor R-102 Reboiler E-104: UdaraDocument1 pageReactor R-101 Reactor R-102 Reboiler E-104: UdaraNurici Isnaeni Khoiri 2207111420No ratings yet

- Korek 2Document1 pageKorek 2PenerbangNo ratings yet

- Plano 03Document1 pagePlano 03ERICK ORDOÑEZNo ratings yet

- Edc17c11 Part 1 and 2Document1 pageEdc17c11 Part 1 and 2greemaxNo ratings yet

- Detalle de Parapeto de Azotea: Planta 1 N.F.P +0.00Document1 pageDetalle de Parapeto de Azotea: Planta 1 N.F.P +0.00enrique arias avalosNo ratings yet

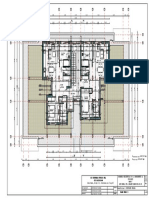

- Etaj 3 Bloc 3Document1 pageEtaj 3 Bloc 3Vladut FaneaNo ratings yet

- 0.nodo Tipo II - Mazocruz CERCO PERIMETRICODocument1 page0.nodo Tipo II - Mazocruz CERCO PERIMETRICOANA PAOLANo ratings yet

- A-1 - Kallupet - DDocument1 pageA-1 - Kallupet - Dismetm365No ratings yet

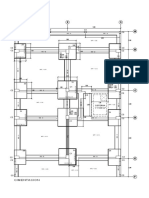

- GROUND FLOOR PLANS 3-ModelDocument1 pageGROUND FLOOR PLANS 3-ModelOmar YassenNo ratings yet

- pj2000213601 15Document1 pagepj2000213601 15karan singh solankiNo ratings yet

- 02 Ar - Denah Lantai 1Document1 page02 Ar - Denah Lantai 1ATHILANo ratings yet

- 1 Cim FebDocument1 page1 Cim FebJhonny Garcia MariñasNo ratings yet

- Cimentacion 1Document1 pageCimentacion 1Edwin Garcia AredoNo ratings yet

- Cimentacion 1 PDFDocument1 pageCimentacion 1 PDFpedro valenciaNo ratings yet

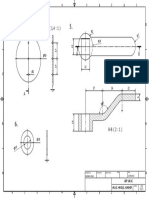

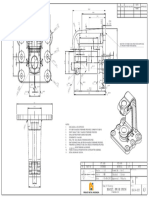

- Mechanical Engineering Design & Drawing 04 6 H: TradeDocument4 pagesMechanical Engineering Design & Drawing 04 6 H: TradeDanı PrasNo ratings yet

- Bodega Moncada 2010-Model4Document1 pageBodega Moncada 2010-Model4miltonjavierhernandezjarquin33No ratings yet

- 4.valve, 5.handle, 6.washerDocument1 page4.valve, 5.handle, 6.washerDamara W. LastaNo ratings yet

- Bracket RWD RR Spring (Machining)Document1 pageBracket RWD RR Spring (Machining)Very BagusNo ratings yet

- Fmy Airport DiagramDocument1 pageFmy Airport Diagramcwhite75No ratings yet

- Base ManuelDocument1 pageBase ManuelAdrien AlchNo ratings yet

- Steam: Size FSCM No DWG No REVDocument1 pageSteam: Size FSCM No DWG No REVNovia Eka RukmanaNo ratings yet

- Politeknik Negeri Bandung Jurusan Teknik Kimia Judul: Benzene 27 APRIL 2017 Nama: Hibah Baskoro Rahman NIM: 161411012 Kelas: 1A-TKI NilaiDocument1 pagePoliteknik Negeri Bandung Jurusan Teknik Kimia Judul: Benzene 27 APRIL 2017 Nama: Hibah Baskoro Rahman NIM: 161411012 Kelas: 1A-TKI NilaiBaskoro RahmanNo ratings yet

- Casa 180 m2Document1 pageCasa 180 m2Joser Fidel CarhuaypiñaNo ratings yet

- Techo Con Rejilla en Ventilacion Techo Con Rejilla en VentilacionDocument1 pageTecho Con Rejilla en Ventilacion Techo Con Rejilla en VentilacionRosa Elizabeth Julca CabanillasNo ratings yet

- ACAT03-002 RevDocument1 pageACAT03-002 RevSK ARIF MAHAMMADNo ratings yet

- Single Cylinder Oscillating Steam EngineDocument1 pageSingle Cylinder Oscillating Steam EngineNiruban Santiagu Fernando100% (1)

- Pieza 1 Dibujo v2 PDFDocument1 pagePieza 1 Dibujo v2 PDFBryam Andre Villanuev GuillenNo ratings yet

- Masters Bedroom Tand BDocument1 pageMasters Bedroom Tand BDELA CRUZ Moses Edelson MNo ratings yet

- SplitOneFile 1666274379Document2 pagesSplitOneFile 1666274379EDWARD STALIM LAZARO HINOJOSANo ratings yet

- MarchasDocument15 pagesMarchasEDWARD STALIM LAZARO HINOJOSANo ratings yet

- Zone 4 - - Rev 00 حصر مبانى-مباني الارضيDocument1 pageZone 4 - - Rev 00 حصر مبانى-مباني الارضيHussam AshourNo ratings yet

- Null 5Document2 pagesNull 5Elzubair EljaaliNo ratings yet

- HEN For Problem 7.3Document1 pageHEN For Problem 7.3Elzubair EljaaliNo ratings yet

- CPLX Tuts SolutionsDocument12 pagesCPLX Tuts SolutionsElzubair EljaaliNo ratings yet

- TUT (4) Q1: Choose The Best AnswerDocument3 pagesTUT (4) Q1: Choose The Best AnswerElzubair EljaaliNo ratings yet

- Fluid Lab Services Fluid Preparation Compositional Analysis PsDocument1 pageFluid Lab Services Fluid Preparation Compositional Analysis PsElzubair EljaaliNo ratings yet

- Hfe ch12 Pivot TablesDocument6 pagesHfe ch12 Pivot TablesElzubair EljaaliNo ratings yet

- In en 924233 08 Ac 101Document10 pagesIn en 924233 08 Ac 101Elzubair EljaaliNo ratings yet

- MSC Business Analytics Course Structure 2019 20Document1 pageMSC Business Analytics Course Structure 2019 20Elzubair EljaaliNo ratings yet

- Com BrownDocument1 pageCom BrownElzubair EljaaliNo ratings yet

- Oil Stabilization With Optimization 1Document16 pagesOil Stabilization With Optimization 1Elzubair EljaaliNo ratings yet

- Page 1 of 4Document4 pagesPage 1 of 4Elzubair EljaaliNo ratings yet

- Tut 1Document3 pagesTut 1Elzubair EljaaliNo ratings yet

- HSE in Short NotesDocument12 pagesHSE in Short NotesElzubair EljaaliNo ratings yet

- الأبعاد والنظم الأساسيةDocument28 pagesالأبعاد والنظم الأساسيةElzubair EljaaliNo ratings yet

- Tut4 Q3Document9 pagesTut4 Q3Elzubair EljaaliNo ratings yet

- Speak Better EnglishDocument25 pagesSpeak Better EnglishElzubair EljaaliNo ratings yet

- Win The Morning Win The Day!Document14 pagesWin The Morning Win The Day!Elzubair EljaaliNo ratings yet

- Material BalanceDocument43 pagesMaterial BalanceElzubair EljaaliNo ratings yet

- CIL Control-2Document8 pagesCIL Control-2Elzubair EljaaliNo ratings yet

- Logbook StandardDocument1 pageLogbook StandardElzubair EljaaliNo ratings yet

- CIL Control-1Document6 pagesCIL Control-1Elzubair EljaaliNo ratings yet

- محمد صلاح 162043Document3 pagesمحمد صلاح 162043Elzubair EljaaliNo ratings yet

- Great Ways To StudyDocument70 pagesGreat Ways To StudyElzubair EljaaliNo ratings yet

- Pro MB (AutoRecovered)Document12 pagesPro MB (AutoRecovered)Elzubair EljaaliNo ratings yet

- متغيرات العمليات الكيميائيةDocument31 pagesمتغيرات العمليات الكيميائيةElzubair EljaaliNo ratings yet

- Ayman Hnyde: Work ExperienceDocument4 pagesAyman Hnyde: Work ExperienceElzubair EljaaliNo ratings yet

- Assignment: Q M CP ( T 1 T 2)Document3 pagesAssignment: Q M CP ( T 1 T 2)Elzubair EljaaliNo ratings yet

- Ricoh Aficio MP4002 Trouble Error CodesDocument26 pagesRicoh Aficio MP4002 Trouble Error CodesNafeesAhmadNo ratings yet

- Class K Commercial Kitchen Fire ExtinguisherDocument1 pageClass K Commercial Kitchen Fire Extinguisher1819 Roy GordonNo ratings yet

- List of GamesDocument7 pagesList of GamesAdrian Joseph BernardinoNo ratings yet

- Acquity Upc: System SpecificationsDocument22 pagesAcquity Upc: System SpecificationsJebtaNo ratings yet

- Commerce Dissertation TopicsDocument4 pagesCommerce Dissertation TopicsHowToWriteMyPaperSingapore100% (1)

- Research Proposal On English Skills Improvement Through The Use of Ipad TechnologyDocument3 pagesResearch Proposal On English Skills Improvement Through The Use of Ipad TechnologyArif AliNo ratings yet

- NO Item QTY Unit Price/Unit Total Price: I Preliminary Works PreparatoriesDocument5 pagesNO Item QTY Unit Price/Unit Total Price: I Preliminary Works Preparatoriesrobert peter rajiminNo ratings yet

- List of Accredited Testing Laboratories NABL-400Document426 pagesList of Accredited Testing Laboratories NABL-400Kishore Nayak kNo ratings yet

- Starlink A Solution To The Digital ConnectivityDocument11 pagesStarlink A Solution To The Digital Connectivityriddheshbore97No ratings yet

- Eligible Participants For CertificateDocument112 pagesEligible Participants For Certificate001srvnNo ratings yet

- Sinopec Cement Industry PDFDocument24 pagesSinopec Cement Industry PDFsyafril sinopec100% (1)

- Release Notes lpfc-14.0.326.12Document3 pagesRelease Notes lpfc-14.0.326.12Ababacar FallNo ratings yet

- Purposive CommunicationDocument8 pagesPurposive CommunicationBorgonia, Khryzlin May C.No ratings yet

- A New Method For Learning Decision Trees From Rules: Amany Abdelhalim, Issa TraoreDocument6 pagesA New Method For Learning Decision Trees From Rules: Amany Abdelhalim, Issa TraoreRV SreehariNo ratings yet

- PH Meter Horiba F51Document114 pagesPH Meter Horiba F51wisang geniNo ratings yet

- Design and Development: Clause 8.3 Auditing and ApplicabilityDocument25 pagesDesign and Development: Clause 8.3 Auditing and ApplicabilityvinayNo ratings yet

- Lecture 4: Use of Standards For Medical Device: Chung Tin, PH.DDocument33 pagesLecture 4: Use of Standards For Medical Device: Chung Tin, PH.Dbarristertoto99 chanNo ratings yet

- Estatus de Publicaciones Manuales PiperDocument68 pagesEstatus de Publicaciones Manuales PiperJesusDavidBlancoNo ratings yet

- ListOfParicipant TrainingDocument8 pagesListOfParicipant TrainingkashemNo ratings yet

- MDSReport 6799005210A4Document3 pagesMDSReport 6799005210A4abinayaNo ratings yet

- MP ILP Product ManualDocument2 pagesMP ILP Product ManualMartin Gomez OrosNo ratings yet

- Kuis4 - Diana Santika Dewi - 18013010010 - Soal1Document2 pagesKuis4 - Diana Santika Dewi - 18013010010 - Soal1Diana SantikaNo ratings yet

- Infineon TC3 PDFDocument2 pagesInfineon TC3 PDFmikipejaNo ratings yet

- Southern Mindanao Colleges: Course Code: Cpe 122Document10 pagesSouthern Mindanao Colleges: Course Code: Cpe 122jumarNo ratings yet

- Espionage Essay - EditedDocument10 pagesEspionage Essay - EditedExpert AnswersNo ratings yet

- Chapter 2 - CS314 - SYSSTRATMGTDocument24 pagesChapter 2 - CS314 - SYSSTRATMGTSophieNo ratings yet

- Week 8Document73 pagesWeek 8sakshampe642No ratings yet