Professional Documents

Culture Documents

Rotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material Steel

Rotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material Steel

Uploaded by

Сергей КолесниковOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material Steel

Rotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material Steel

Uploaded by

Сергей КолесниковCopyright:

Available Formats

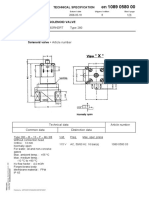

ROTEX®

Torsionally flexible coupling

ROTEX®

Shaft coupling design No. 001 - material steel -

zz Hubs from steel, specifically suitable for drive elements subject

to high loads, e. g. steel mills, elevator drives, spline hubs, etc.)

zz Torsionally flexible, maintenance-free, vibration-damping

zz Axial plug-in, fail-safe

zz Machined allover - good dynamic properties

zz Compact design/low flywheel effect

zz Finish bore acc. to ISO fit H7, feather keyway acc. to DIN

6885 sheet 1 - JS9.

zz Stock programme/basic programme see pages 28 and 29

zz Approved according to EC Standard 94/9/EC

zz Mounting instructions at www.ktr.com

Compenents

1 2 1 1 2 1a 1b

Standard hub Spider Large hub Large hub lengthened

Steel (thread on the keyway)

ROTEX® Steel (St)

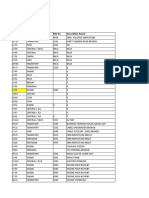

Spider (part 2) 1) Dimensions [mm]

Compo- Rated torque [Nm]

Size Finish bore General Thread for setscrew

nent

92 Sh-A 98 Sh-A 64 Sh-D d (min-max) L l1; l2 E b s DH dH D N G t TA [Nm]

1a 35 11

14 7,5 12,5 16 0-16 13 10 1,5 30 10 30 — M4 5 1,5

1b 50 18,5

1a 66 25

19 10 17 21 0-25 16 12 2 40 18 40 — M5 10 2

1b 90 37

1a 78 30

24 35 60 75 0-35 18 14 2 55 27 55 — M5 10 2

1b 118 50

1a 90 35

28 95 160 200 0-40 20 15 2,5 65 30 65 — M8 15 10

1b 140 60

1 114 45 70 27

38 190 325 405 0-48 24 18 3 80 38 M8 15 10

1b 164 70 80 —

1 126 50 85 28

42 265 450 560 0-55 26 20 3 95 46 M8 20 10

1b 176 75 95 —

1 140 56 95 32

48 310 525 655 0-62 28 21 3,5 105 51 M8 20 10

1b 188 80 105 —

1 160 65 110 37

55 410 685 825 0-74 30 22 4 120 60 M10 20 17

1b 210 90 120 —

1 185 75 115 47

65 625 940 1175 0-80 35 26 4,5 135 68 M10 20 17

1b 235 100 135 —

1 210 85 135 53

75 1280 1920 2400 0-95 40 30 5 160 80 M10 25 17

1b 260 110 160 —

1 245 100 160 62

90 2400 3600 4500 0-110 45 34 5,5 200 100 M12 30 40

1b 295 125 200 —

ROTEX® Sintered steel

Spider (part 2) 1) Dimensions [mm]

Compo- Rated torque [Nm]

Size Finish bore General Thread for setscrew

nent

92 Sh-A 98 Sh-A d L l1; l2 E b s DH dH D N G t TA [Nm]

14 1a 7,5 12,5 unbored 8, 10, 11, 12, 14, 15, 16 35 11 13 10 1,5 30 10 30 - M4 5 1,5

19 1a 10 17 14, 16, 19, 20, 22, 24 66 25 16 12 2 40 18 40 - M5 10 2

= If no material is mentioned in the order, the material is stipulated with the calculation/order.

1) Maximum torque of the coupling TKmax. = rated torque of the coupling TK Nenn. x 2. Selection see page 20/21

ROTEX® 19 – 48 from stainless steel available from stock

–– ROTEX® 19, 28 and 42 – hub material X10CrNiS 18-9 material number 1.4305 (V2A) DIN 17440

–– ROTEX® 24, 38 and 48 – hub material X6CrNiMoTi17-12-2 material number 1.4571 (V4A) DIN 17440

Ordering ROTEX® 38 St 92 Sh-A 1 – Ø 45 1 – Ø 25

example:

Coupling size Material Spider hardness Component Finish bore Component Finish bore

You will find continuously updated data in our online catalogue at www.ktr.com. 31

You might also like

- Honda XL600R 1983 1984 Service ManualDocument254 pagesHonda XL600R 1983 1984 Service Manualjølle jølle100% (1)

- Hino J05E-TH Workshop ManualDocument278 pagesHino J05E-TH Workshop ManualAimHighNo ratings yet

- Price Fitting BesiDocument8 pagesPrice Fitting BesiDevi AndriNo ratings yet

- Bobcat 963 PDFDocument409 pagesBobcat 963 PDFFlores BrayanNo ratings yet

- Ford Tempo Topaz 1984-1994 Repair GuideDocument11 pagesFord Tempo Topaz 1984-1994 Repair GuideFer VN100% (2)

- Data SheetDocument1 pageData SheetramdhanNo ratings yet

- LippedChannel PDFDocument2 pagesLippedChannel PDFShafira Alif FitrahNo ratings yet

- Mobil Renault-K-380-824006Document16 pagesMobil Renault-K-380-824006Joko PurwodadiNo ratings yet

- Katalog Bolt & Nut PDFDocument12 pagesKatalog Bolt & Nut PDFDede SetiawanNo ratings yet

- MCHW 800 PDFDocument31 pagesMCHW 800 PDFShinta AyuningtyasNo ratings yet

- Chain Couplings: E Maximum WidthDocument3 pagesChain Couplings: E Maximum WidthAhmad GhoziNo ratings yet

- Specifications Casting PDFDocument1 pageSpecifications Casting PDFjahangir_alam44_6764No ratings yet

- XS85 To XS145 Specs - March 2011-4Document8 pagesXS85 To XS145 Specs - March 2011-4lucioleo1975No ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexpoNepoleon KaruppiahNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Guide Specifications (Pci Hcs Manual)Document3 pagesGuide Specifications (Pci Hcs Manual)KhaleelNo ratings yet

- SikuDocument2 pagesSikuSuji Rolupat100% (1)

- Tabel Baja WF LRFDDocument16 pagesTabel Baja WF LRFDagus sholehudin0% (1)

- Astm A325-04 STD Specs For Structural Bolts, Steel, Heat TreDocument8 pagesAstm A325-04 STD Specs For Structural Bolts, Steel, Heat TreCharwin Picao100% (1)

- Rampe - Articulated Truck CAT 745CDocument3 pagesRampe - Articulated Truck CAT 745CFarouk AzzouhriNo ratings yet

- 20180131-BROSUR 2018 For U-Ditch 40x60 + CoverDocument16 pages20180131-BROSUR 2018 For U-Ditch 40x60 + CoverArThur BangunNo ratings yet

- Catalogue HalySafeDocument2 pagesCatalogue HalySafeRyza Dwi Mayasari0% (1)

- Concrete Pump: MKW-35SVH MKW-35SM Mkw-35Svh Mkw-35SmDocument2 pagesConcrete Pump: MKW-35SVH MKW-35SM Mkw-35Svh Mkw-35SmPetrNo ratings yet

- BW211D 40SL Data SheetDocument4 pagesBW211D 40SL Data SheetRoqimNo ratings yet

- Peeimoger Compact Ac Gearmotor 001 PDFDocument4 pagesPeeimoger Compact Ac Gearmotor 001 PDFAmpera marzelaNo ratings yet

- Lipped ChannelDocument2 pagesLipped ChannelNabilla ZaheraNo ratings yet

- Brosur Romans 016Document28 pagesBrosur Romans 016Tomi KazuoNo ratings yet

- Astm A325m InnerDocument7 pagesAstm A325m InnerNgiuyen Viet TienNo ratings yet

- HBeam Gunung GarudaDocument2 pagesHBeam Gunung GarudaRenny RevildaNo ratings yet

- Schlosser-Pfeiffer Radialpresse EnglischDocument8 pagesSchlosser-Pfeiffer Radialpresse EnglischHESSGROUPNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- 04.GPD155-F All New Nmax 155 Connected Version Camshaft & ChainDocument1 page04.GPD155-F All New Nmax 155 Connected Version Camshaft & Chainandi yusufNo ratings yet

- Brosur Mitsubishi Fuso FM517 HL OkDocument3 pagesBrosur Mitsubishi Fuso FM517 HL OkRed BorneoNo ratings yet

- Part List Long Arm PC200Document7 pagesPart List Long Arm PC200Andaru GunawanNo ratings yet

- Cks 600 SpecDocument24 pagesCks 600 SpecRajan MullappillyNo ratings yet

- Sensah Catalogue 2023Document34 pagesSensah Catalogue 2023jafrilharis14No ratings yet

- 01.VD01 IND Informasi UmumDocument108 pages01.VD01 IND Informasi UmumBPP Jember Service100% (1)

- Aashto/Pci Standard Products: Appendix BDocument2 pagesAashto/Pci Standard Products: Appendix BJavier CaballeroNo ratings yet

- Mastertop 100 PDFDocument2 pagesMastertop 100 PDFMohiuddin MuhinNo ratings yet

- MPPWD 2014 SOR CH 1 To 5 in ExcelDocument66 pagesMPPWD 2014 SOR CH 1 To 5 in ExcelElvis GrayNo ratings yet

- Studbolt Weight Chart MetricDocument1 pageStudbolt Weight Chart MetricselvakumarNo ratings yet

- Tabel Besi SniDocument57 pagesTabel Besi SniHusein SyarifNo ratings yet

- I.Manual For FSADocument11 pagesI.Manual For FSAVu DangNo ratings yet

- Puddle Arc Vs Thermite WeldingDocument8 pagesPuddle Arc Vs Thermite WeldingBemo RelNo ratings yet

- Ukuran Baut Dan Nut Pada FlangeDocument6 pagesUkuran Baut Dan Nut Pada FlangeaswarNo ratings yet

- MotorGraderL&TKomatsuGD511A 1 TechnicalSpecificationsDocument2 pagesMotorGraderL&TKomatsuGD511A 1 TechnicalSpecificationst1meNo ratings yet

- 17-1 Usage of Recycled Tyre MCRJ Volume 29, No.3, 2019 PDFDocument10 pages17-1 Usage of Recycled Tyre MCRJ Volume 29, No.3, 2019 PDFNor Intang Setyo HNo ratings yet

- Katalog TEKIRO ToolsDocument131 pagesKatalog TEKIRO ToolslukasNo ratings yet

- Steels, Is and Their EquivalentsDocument2 pagesSteels, Is and Their EquivalentsVinit AhluwaliaNo ratings yet

- Sany Truck Mixer 8m3 (Sy5250gjb8-1)Document2 pagesSany Truck Mixer 8m3 (Sy5250gjb8-1)arie sandhiNo ratings yet

- OM 906 LA: Arrangement: R6 Displacement: 6.4 LDocument1 pageOM 906 LA: Arrangement: R6 Displacement: 6.4 LRizqiNo ratings yet

- P 410 B6X4HZ: SpecificationDocument6 pagesP 410 B6X4HZ: SpecificationHec WillNo ratings yet

- Brosur Jembatan (Terbaru) OKkkDocument24 pagesBrosur Jembatan (Terbaru) OKkkdede_anfieldNo ratings yet

- 3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingDocument4 pages3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingPhamLeDanNo ratings yet

- Split Plummer Block Housings SNVDocument84 pagesSplit Plummer Block Housings SNVKharimul AzizNo ratings yet

- Ramset Specifiers Resource Book 09Document244 pagesRamset Specifiers Resource Book 09GarryNo ratings yet

- ICE VIBRO 58B With 595GDocument2 pagesICE VIBRO 58B With 595GKelvin ChewNo ratings yet

- Mechanical - Anchoring - DynaBolt Plus PDFDocument6 pagesMechanical - Anchoring - DynaBolt Plus PDFAnonymous dSFbLxc9No ratings yet

- (Revisi 16 November 2020) : CNP (Southern Pump) Price ListDocument99 pages(Revisi 16 November 2020) : CNP (Southern Pump) Price Listkalimosodo 010% (1)

- Acoplamentos KTR 024 PDFDocument1 pageAcoplamentos KTR 024 PDF3DLAB CAD/CAMNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Company Name: Design Specifications Nozzles Couplings / SupportsDocument21 pagesCompany Name: Design Specifications Nozzles Couplings / Supportsmohsen ranjbarNo ratings yet

- ETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignMuhammad AhsunNo ratings yet

- A55 A56 CylinderDocument1 pageA55 A56 CylinderBiswanath LenkaNo ratings yet

- CSP 50-60Document2 pagesCSP 50-60Сергей КолесниковNo ratings yet

- 8 CSP40Document1 page8 CSP40Сергей КолесниковNo ratings yet

- Gut-Zu-Wissen Folder EN EinzelseitenDocument6 pagesGut-Zu-Wissen Folder EN EinzelseitenСергей КолесниковNo ratings yet

- Certificato ISO9001Document1 pageCertificato ISO9001Сергей КолесниковNo ratings yet

- Bad Harzburg ISO 9001 Certificate 29.08.2016 - EnglDocument1 pageBad Harzburg ISO 9001 Certificate 29.08.2016 - EnglСергей КолесниковNo ratings yet

- Certificato GOST-R 2012Document2 pagesCertificato GOST-R 2012Сергей КолесниковNo ratings yet

- Rotex Flexible Jaw Couplings: Selection of Standard IEC MotorsDocument1 pageRotex Flexible Jaw Couplings: Selection of Standard IEC MotorsСергей КолесниковNo ratings yet

- Буклет клапанаDocument1 pageБуклет клапанаСергей КолесниковNo ratings yet

- Solenoid 1089058003 1089058001 1089058000Document1 pageSolenoid 1089058003 1089058001 1089058000Сергей КолесниковNo ratings yet

- Dichiarazione Di Conformita PED Rev 20-05-02 ENGDocument1 pageDichiarazione Di Conformita PED Rev 20-05-02 ENGСергей КолесниковNo ratings yet

- Atlas Copco: Parts ListDocument214 pagesAtlas Copco: Parts ListСергей КолесниковNo ratings yet

- Электромагнитный клапан соленоидный Burkert 6014Document4 pagesЭлектромагнитный клапан соленоидный Burkert 6014Сергей КолесниковNo ratings yet

- Aerzen High Vaccum Blower HVseries CatalogDocument12 pagesAerzen High Vaccum Blower HVseries CatalogСергей КолесниковNo ratings yet

- Donaldson Filter PDFDocument3 pagesDonaldson Filter PDFСергей КолесниковNo ratings yet

- ) Crli110 Crli140 Crli170 Crli205Document2 pages) Crli110 Crli140 Crli170 Crli205Сергей КолесниковNo ratings yet

- 3RT10656AP36 Datasheet enDocument11 pages3RT10656AP36 Datasheet enСергей КолесниковNo ratings yet

- Grinnell Mechanical Products Plain End Fittings, Ductile Iron & Fabricated Steel General Description Limited Warranty Ordering ProcedureDocument6 pagesGrinnell Mechanical Products Plain End Fittings, Ductile Iron & Fabricated Steel General Description Limited Warranty Ordering ProcedureСергей КолесниковNo ratings yet

- QGS 75-100 Parts Manual - July 24 2020Document202 pagesQGS 75-100 Parts Manual - July 24 2020Сергей КолесниковNo ratings yet

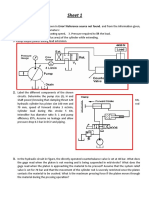

- Example Stationary Compressor, KSV 65: Proportional V/VDocument3 pagesExample Stationary Compressor, KSV 65: Proportional V/VСергей КолесниковNo ratings yet

- MPVLDocument7 pagesMPVLСергей КолесниковNo ratings yet

- Example Stationary Compressor, KSV 120: Proportional V/VDocument3 pagesExample Stationary Compressor, KSV 120: Proportional V/VСергей КолесниковNo ratings yet

- Grinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyDocument4 pagesGrinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyСергей КолесниковNo ratings yet

- Example Stationary Compressor, KSV 85: Proportional V/VDocument3 pagesExample Stationary Compressor, KSV 85: Proportional V/VСергей КолесниковNo ratings yet

- Grinnell Grooved Fittings Ductile Iron and Fabricated Steel Table ofDocument64 pagesGrinnell Grooved Fittings Ductile Iron and Fabricated Steel Table ofСергей КолесниковNo ratings yet

- GRINNELL Model B302 and Model BN302 Grooved End Butterfly Valves With Gear Operators or Lever-Lock Operators General DescriptionDocument6 pagesGRINNELL Model B302 and Model BN302 Grooved End Butterfly Valves With Gear Operators or Lever-Lock Operators General DescriptionСергей КолесниковNo ratings yet

- Grinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataDocument4 pagesGrinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataСергей КолесниковNo ratings yet

- Hobart AM15 Service ManualDocument54 pagesHobart AM15 Service ManualOkabe RintarouNo ratings yet

- Massey Ferguson Mf3120 Parts CatalogueDocument20 pagesMassey Ferguson Mf3120 Parts Cataloguejoseph100% (60)

- Accesorios BticinoDocument10 pagesAccesorios BticinojczaurusNo ratings yet

- Cylinder Head Cover (Bus) Mercedes OM 926 LA: (Europa) (Engine)Document7 pagesCylinder Head Cover (Bus) Mercedes OM 926 LA: (Europa) (Engine)Karthii AjuNo ratings yet

- 03 - 17 - 16 - Wireline Type JarsDocument3 pages03 - 17 - 16 - Wireline Type JarsrezaNo ratings yet

- Price QuotationDocument1 pagePrice QuotationRACCT Construction and TradingNo ratings yet

- FVR Transmission PDFDocument173 pagesFVR Transmission PDFYi Chen100% (1)

- Westinghouse Manual BookDocument27 pagesWestinghouse Manual BookGeraldo CiuffiNo ratings yet

- Derbi Rambla 125 (En)Document258 pagesDerbi Rambla 125 (En)Manualles100% (1)

- Vespa Torque Settings 101: Ftlbs KGMDocument2 pagesVespa Torque Settings 101: Ftlbs KGMwiliwildan04No ratings yet

- Flutek Swing MotorDocument2 pagesFlutek Swing Motorsunil0081No ratings yet

- Pajero III Rear Differential LockDocument8 pagesPajero III Rear Differential Lockleo_corporan100% (1)

- Yamaha Xv16 Road Star 98 Service ManualDocument20 pagesYamaha Xv16 Road Star 98 Service Manualkenneth100% (39)

- BF20 Belt Drive Kit Installation InstructionsDocument51 pagesBF20 Belt Drive Kit Installation InstructionsBryan DixNo ratings yet

- Cni U D 0060 Rev.4 - Shop Drawing For HC Vessel Asabi CL 2704Document7 pagesCni U D 0060 Rev.4 - Shop Drawing For HC Vessel Asabi CL 2704Tĩnh Hồ TrungNo ratings yet

- Pt. Rea Kaltim Plantations Central Enginering Services List Part Direct UserDocument98 pagesPt. Rea Kaltim Plantations Central Enginering Services List Part Direct Usertechnical trainer 011cNo ratings yet

- Traba DiferencialDocument7 pagesTraba DiferencialgenaroNo ratings yet

- MS5002C BreakdownDocument245 pagesMS5002C BreakdownElver Amesquita100% (2)

- Euclid Catalog Front End 760cDocument274 pagesEuclid Catalog Front End 760cjoshNo ratings yet

- Clark Seal & BearingDocument10 pagesClark Seal & BearingRaymond VoldinoNo ratings yet

- Iso 898-1Document1 pageIso 898-1abhineet.gargNo ratings yet

- Installation: SA GBP 201/202Document19 pagesInstallation: SA GBP 201/202Mostafa MatarNo ratings yet

- Vantage Manual Powder Spray Gun G P Y: Gun Part Number Gun Part NumberDocument1 pageVantage Manual Powder Spray Gun G P Y: Gun Part Number Gun Part NumberDaniel VillarrealNo ratings yet

- 320 & 365 Kva PDFDocument156 pages320 & 365 Kva PDFManish AgarwalNo ratings yet

- 6 - Control System 3cDocument40 pages6 - Control System 3cagvassNo ratings yet

- Hydarulic SheetsDocument11 pagesHydarulic Sheetsأحمد عبدالجليلNo ratings yet