Professional Documents

Culture Documents

483-Medium Voltage Power Cables15

483-Medium Voltage Power Cables15

Uploaded by

Joseph PoplingerCopyright:

Available Formats

You might also like

- 481-Medium Voltage Power CablesDocument2 pages481-Medium Voltage Power Cablesopplus33% (3)

- 35kv Xlpe Phelps Dodge PDFDocument2 pages35kv Xlpe Phelps Dodge PDFRodney LanagNo ratings yet

- Cable Impedance CalculationsDocument4 pagesCable Impedance CalculationsJoseph PoplingerNo ratings yet

- 484-Medium Voltage Power Cables26.45kVDocument2 pages484-Medium Voltage Power Cables26.45kVJoseph Poplinger0% (1)

- Raychem Link Boxes: Cable ServicesDocument8 pagesRaychem Link Boxes: Cable ServicesGokul VenugopalNo ratings yet

- Technical Specification - Power Cable - WP4Document15 pagesTechnical Specification - Power Cable - WP4nnNo ratings yet

- OKONITEDocument2 pagesOKONITEworkshop Ega SbyNo ratings yet

- Kerpen Catalogo Medium-VoltageDocument43 pagesKerpen Catalogo Medium-VoltageAlfonso GonzálezNo ratings yet

- Technical Specification - Special Screen Cable - WP4Document7 pagesTechnical Specification - Special Screen Cable - WP4nnNo ratings yet

- CablesDocument29 pagesCablesbimaNo ratings yet

- Cables For EE342 CourseDocument7 pagesCables For EE342 Coursemahmab70No ratings yet

- Southern Cable CatalogueDocument46 pagesSouthern Cable CatalogueRaja Mohd AriffNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document30 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- Transmission Line Lecture 1revisedDocument133 pagesTransmission Line Lecture 1revisedLhorie Ladica Valerio100% (2)

- Alcan Abc Cables PDFDocument6 pagesAlcan Abc Cables PDFAHMED YOUSEFNo ratings yet

- Transmission Line Lecture 1revisedDocument133 pagesTransmission Line Lecture 1revisedLhorie Ladica ValerioNo ratings yet

- SC - Low Voltage Catalogue - Copper - 2020Document46 pagesSC - Low Voltage Catalogue - Copper - 2020May OngNo ratings yet

- Power Cables YJV22Document30 pagesPower Cables YJV22dabs_orangejuiceNo ratings yet

- Copper Conductors, XLPE Insulated: DescriptionDocument1 pageCopper Conductors, XLPE Insulated: DescriptionLucian2001No ratings yet

- Surge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage ProtectionDocument4 pagesSurge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage Protectiondave chaudhuryNo ratings yet

- Fire Rated CablesDocument3 pagesFire Rated CablesRoy MonroyNo ratings yet

- Part 9Document5 pagesPart 9pravishnNo ratings yet

- Bahra Cables-Technical SheetsDocument33 pagesBahra Cables-Technical Sheetsmir sadat aliNo ratings yet

- All About Transmission Lines3Document5 pagesAll About Transmission Lines3Stephen Dunifer100% (1)

- Tecnical Specification - AC CABLE DATASHEETDocument7 pagesTecnical Specification - AC CABLE DATASHEETEisac SagimanNo ratings yet

- 01 Power Cables EarthingDocument77 pages01 Power Cables EarthingMADDY RANANo ratings yet

- Line Electrical: PropertiesDocument13 pagesLine Electrical: Propertiesj_andrade_arceNo ratings yet

- Nexans MV Cables UK Brochure - 1Document48 pagesNexans MV Cables UK Brochure - 1Ra'fat HerzallahNo ratings yet

- Section Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Document56 pagesSection Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Terex14253No ratings yet

- N2Xsy: Technical Data ConstructionDocument2 pagesN2Xsy: Technical Data ConstructionAthanasios AntonopoulosNo ratings yet

- Epdu EE-182,183,196,202 Pre Lab 1: British Standard Wire Gauge Is A Set of Wire Sizes Given byDocument3 pagesEpdu EE-182,183,196,202 Pre Lab 1: British Standard Wire Gauge Is A Set of Wire Sizes Given byMaaz HussainNo ratings yet

- 2 Hazard Mechanisms AMDocument29 pages2 Hazard Mechanisms AMroyclhorNo ratings yet

- Arrester DisconnectorDocument37 pagesArrester DisconnectorKush SharmaNo ratings yet

- 30W Linear On 23cm: Sage Wire Line, What IsDocument5 pages30W Linear On 23cm: Sage Wire Line, What IsΑΝΔΡΕΑΣ ΤΣΑΓΚΟΣNo ratings yet

- Energy Hvca Linkboxes Us enDocument8 pagesEnergy Hvca Linkboxes Us enKush SharmaNo ratings yet

- FAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...Document16 pagesFAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...César Díaz LiberonaNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5Document36 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5nnNo ratings yet

- Sheath Bonding MethodDocument26 pagesSheath Bonding Methodوهيبه بكر100% (1)

- Types of Copper Network CablesDocument27 pagesTypes of Copper Network Cablesapi-19713349No ratings yet

- IEC Separable Connectors 36 KV, 630A: Front T-Body / Coupling (Rear) T-Body ConnectorDocument5 pagesIEC Separable Connectors 36 KV, 630A: Front T-Body / Coupling (Rear) T-Body ConnectorDiego AlvesNo ratings yet

- Tds New 1c Cu 35kvDocument2 pagesTds New 1c Cu 35kvButch BuciaNo ratings yet

- 35kv Xlpe Phelps DodgeDocument2 pages35kv Xlpe Phelps DodgeCommercial One100% (2)

- Cable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17Document6 pagesCable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17anamulk-1No ratings yet

- ITECO Submarine Cable CatalogueDocument16 pagesITECO Submarine Cable CatalogueThai AnhNo ratings yet

- EE458Document36 pagesEE458ArishaNo ratings yet

- Terminacion de Cables Aislados PDFDocument11 pagesTerminacion de Cables Aislados PDFMisael Daniel EstevezNo ratings yet

- Betobar 2021Document44 pagesBetobar 2021berliani navitasNo ratings yet

- Insulators: Dr.S.Prabhakar Karthikeyan Smieee, PDF (Cpri) Associate Professor, SELECT VIT University, VelloreDocument31 pagesInsulators: Dr.S.Prabhakar Karthikeyan Smieee, PDF (Cpri) Associate Professor, SELECT VIT University, Velloresahale sheraNo ratings yet

- Olex HV Cable RatingDocument58 pagesOlex HV Cable RatingsimbashumbaNo ratings yet

- Cables and Distribution: Dept. of EEE, JNTUA College of Engineering, Kalikiri Chittoor District, A P, IndiaDocument58 pagesCables and Distribution: Dept. of EEE, JNTUA College of Engineering, Kalikiri Chittoor District, A P, Indiasuneel.thandraNo ratings yet

- Anixter Minimum Bending Radius Wire Wisdom en PDFDocument1 pageAnixter Minimum Bending Radius Wire Wisdom en PDFAndrew Ixara AribowoNo ratings yet

- 110kv Ehv Cable - GtpsDocument2 pages110kv Ehv Cable - GtpsBijaya Kumar MohantyNo ratings yet

- Cables in Deep WaterDocument14 pagesCables in Deep WaterCarlos GarridoNo ratings yet

- Alcan AluminumDocument4 pagesAlcan AluminumAhmed H. HassanNo ratings yet

- Fluke Unilap100xeDocument10 pagesFluke Unilap100xepancaro93No ratings yet

- Surge-Transferred Overvoltages in Earthing/Auxiliary TransformersDocument6 pagesSurge-Transferred Overvoltages in Earthing/Auxiliary TransformersSudhir RavipudiNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Control Cables: PVC Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVDocument2 pagesControl Cables: PVC Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVJoseph PoplingerNo ratings yet

- 484-Medium Voltage Power Cables26.45kVDocument2 pages484-Medium Voltage Power Cables26.45kVJoseph Poplinger0% (1)

- 480-LSOH Installation WiresDocument2 pages480-LSOH Installation WiresJoseph PoplingerNo ratings yet

- Control Cables: XLPE Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVDocument2 pagesControl Cables: XLPE Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVJoseph PoplingerNo ratings yet

- Ampacities For Aluminum & ACSR Overhead Electrical Conductors PDFDocument20 pagesAmpacities For Aluminum & ACSR Overhead Electrical Conductors PDFJoseph PoplingerNo ratings yet

- Art11 PDFDocument29 pagesArt11 PDFJoseph PoplingerNo ratings yet

- Pole and Tower Lines For Electric Power Transmission Von R. D. CoombsDocument60 pagesPole and Tower Lines For Electric Power Transmission Von R. D. CoombsJoseph PoplingerNo ratings yet

- Cable Shield Grounded at One End OnlyDocument4 pagesCable Shield Grounded at One End OnlyJoseph PoplingerNo ratings yet

- Bed Sizes and Mattress DimensionsDocument3 pagesBed Sizes and Mattress DimensionsJoseph PoplingerNo ratings yet

- Making Sense of TimeDocument4 pagesMaking Sense of TimeJoseph PoplingerNo ratings yet

- AL-CU Cables Impedances CalculationsDocument2 pagesAL-CU Cables Impedances CalculationsJoseph PoplingerNo ratings yet

- Line - Cable-Parameter-Calculation-metric MMDocument59 pagesLine - Cable-Parameter-Calculation-metric MMJoseph PoplingerNo ratings yet

- Classic-Handbook, Part 2, Edition 9, June 2015Document68 pagesClassic-Handbook, Part 2, Edition 9, June 2015Joseph PoplingerNo ratings yet

- 3 Phase System Simulation V1Document6 pages3 Phase System Simulation V1Joseph Poplinger100% (1)

- 3-Phase Calculators Result Cells Are Green.: Converting Voltage From Line-To-Neutral To Line-To-LineDocument2 pages3-Phase Calculators Result Cells Are Green.: Converting Voltage From Line-To-Neutral To Line-To-LineJoseph PoplingerNo ratings yet

- 3 Phase System Simulation V2Document50 pages3 Phase System Simulation V2Joseph PoplingerNo ratings yet

- Heat Generation Modeling of Ball Bearing Based On Internal Load DistributionDocument8 pagesHeat Generation Modeling of Ball Bearing Based On Internal Load DistributionMÔNICA SUEDE S. SILVANo ratings yet

- Exercises On Fluids and GravityDocument22 pagesExercises On Fluids and Gravityelty TanNo ratings yet

- Standard TriacDocument4 pagesStandard TriacHector Alberto SanchezNo ratings yet

- A6260 Datasheet PDFDocument12 pagesA6260 Datasheet PDFAlfonzo ParedesNo ratings yet

- Ozone Generators - Life Support Systems MAT LSSDocument1 pageOzone Generators - Life Support Systems MAT LSSqualiman1No ratings yet

- Chapter 12 - Kinetics of Particles - Part 1 and 2Document30 pagesChapter 12 - Kinetics of Particles - Part 1 and 2Ahmed AliNo ratings yet

- Final ScheduleDocument21 pagesFinal Scheduleನವೀನ್ಕುಮಾರ್No ratings yet

- What Is Megger Test and How Is It PerformedDocument4 pagesWhat Is Megger Test and How Is It PerformedYasir JamilNo ratings yet

- Design For Wear Resistance: Raymond G. Bayer, Tribology ConsultantDocument12 pagesDesign For Wear Resistance: Raymond G. Bayer, Tribology Consultanttolentino.jason1222No ratings yet

- Lecture 1 Intro Energy TargetsDocument56 pagesLecture 1 Intro Energy Targets翁宝怡No ratings yet

- Danfoss EKC 361 Manual PDFDocument16 pagesDanfoss EKC 361 Manual PDFphilip penaflorNo ratings yet

- Answer SheetDocument2 pagesAnswer SheetKirsty SebastianNo ratings yet

- Chapter 3 Response of Structures To DynaDocument61 pagesChapter 3 Response of Structures To DynaSayyadh Rahamath BabaNo ratings yet

- CR306Document3 pagesCR306josé fernando sotelo ventosillaNo ratings yet

- S4-4 Damping Paper TakedaDocument26 pagesS4-4 Damping Paper TakedaRonald Omar García RojasNo ratings yet

- Intelligent Coolwex Exclusive Air/Water Heat PumpsDocument13 pagesIntelligent Coolwex Exclusive Air/Water Heat PumpsTimo TNo ratings yet

- Electronics Repair and Troubleshooting: Regulated Power Supply TroubleshootingDocument5 pagesElectronics Repair and Troubleshooting: Regulated Power Supply TroubleshootingIra CervoNo ratings yet

- Esdd 02 006 PDFDocument34 pagesEsdd 02 006 PDFKarthik EvilordNo ratings yet

- (TDB) DVM Chiller For Europe Ver.2.2 - 170223Document66 pages(TDB) DVM Chiller For Europe Ver.2.2 - 170223ORLANDO CASTRONo ratings yet

- Panel Thermo-Hygrostat and Thermostats: Drying KilnsDocument6 pagesPanel Thermo-Hygrostat and Thermostats: Drying KilnsBasman GeorgeNo ratings yet

- Power DiodesDocument46 pagesPower DiodesJay R BallonNo ratings yet

- Brochure TG enDocument8 pagesBrochure TG enpascal_chinNo ratings yet

- Bionics IFM-500 - Test ReportDocument74 pagesBionics IFM-500 - Test ReportRomário CaribéNo ratings yet

- P605-P1100 Power Optimizer Module Add-On DS-000012-EnGDocument4 pagesP605-P1100 Power Optimizer Module Add-On DS-000012-EnGKarunakara ReddyNo ratings yet

- Chapter-3-Ohm's Law, Energy, and PowerDocument33 pagesChapter-3-Ohm's Law, Energy, and PowershahadNo ratings yet

- Lecture On Distribution SystemDocument36 pagesLecture On Distribution Systemimburais100% (1)

- Mass Transfer Slides - CHE304 - Chapter 26Document51 pagesMass Transfer Slides - CHE304 - Chapter 26RehabNo ratings yet

- Room Air Line UpDocument4 pagesRoom Air Line UpJeffrey FortalezaNo ratings yet

- Week 9 - Revision SolutionsDocument11 pagesWeek 9 - Revision SolutionsReacher ElliotNo ratings yet

- Charging by FrictionDocument33 pagesCharging by FrictionlostgirlNo ratings yet

483-Medium Voltage Power Cables15

483-Medium Voltage Power Cables15

Uploaded by

Joseph PoplingerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

483-Medium Voltage Power Cables15

483-Medium Voltage Power Cables15

Uploaded by

Joseph PoplingerCopyright:

Available Formats

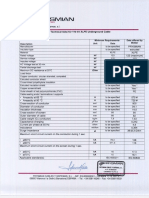

Medium Voltage Power Cables

XLPE Insulated, PVC Sheathed Three-

core Cables for Fixed Installations,

3.6/6 kV; 6/10 kV; 12/20kV; 18/30 kV

APPLICATION:

For indoor or outdoor installation in open air in

tray, trough and conduit or for direct burial in free

draining soil or inside duct where no mechanical

damage is to be expected. Power cable for utilities

medium voltage underground distribution systems

and in commercial buildings, industrial plants,

power stations and substations. For rated voltages

U0/U(Um): 3.6/6(7.2) kV; 6/10(12) kV; 12/20kV

or 18/30 kV at maximum conductor temperatures

of 90 °C for continuous normal operation and

250 °C for short circuit.

STANDARDS:

1. Conforms to Israeli Standard IS 1516-2: ”Power CONSTRUCTION: - 8.7/15 kV cables

cables with extruded insulation and their A copper or aluminium compacted circular - tree-retardant XLPE insulation

accessories for rated voltages from 1 kV conductor has a triple single head extruded - EPR insulation

(Um = 1,2 kV) up to 30 kV (Um = 36 kV) – smooth conductor screen, XLPE (cross-linked - easy strippable insulation screen

Part 2: Cables for rated voltages of 6 kV polyethylene) insulation and bonded insulation - double tape, round wire or flat wire

(Um = 7,2 kV) up to 30 kV (Um = 36 kV)” for screen, all dry nitrogen cured. Each insulated core galvanized steel armour

the types N2XSEY and NA2XSEY. is lapped with a semi-conducting tape and metal - other PVC oversheath colours

2. Conforms to IEC 60502-2 Standard: ”Power screened with copper tape or with solid bare - ST7 black PE oversheath.

cables with extruded insulation and their copper wires uniformly spaced around the cable Consult us on fire retardant and /or halogen

accessories for rated voltages from 1 kV and a counter helix copper tape. The cores are free constructions.

(Um = 1,2 kV) up to 30 kV (Um = 36 kV) – assembled and covered with an extruded inner

Part 2: Cables for rated voltages of 6 kV covering; a surface printed red PVC oversheath PACKAGING

(Um = 7,2 kV) up to 30 kV (Um = 36 kV)”. is extruded over all. Standard supply lengths are given in the tables

3. Conformance to various European standards, The following alternatives are available upon hereunder. Other bobbin lengths or cut to

available upon request. request: length - available upon request.

Reactance @50Hz (5)

conductor (1 sec) (1)

Current Rating (2)

conductors & screen

Max. conductor DC

Nominal insulation

No., Nominal cross

Approximate outer

Approximate cable

Minimum bending

Short Circuit rating

wires in conductor

resistance at 20°C

Charging Current

Minimum No. of

Catalog

Standard supply

sectional area of

Nominal sheath

In ground (4)

Number

Capacitance

thickness

thickness

diameter

In air (3)

lengths

weight

radius

No. x mm2/mm2 mm mm mm kg/km mm Ω/km kA A A A/km Ω/km μF/km m

N2XSEY 3.6/6 (7.2)kV COPPER CONDUCTOR

168 039 3x35/16 6 2.5 2.2 36 2000 540 0.524 5.0 176 179 0.32 0.110 0.28 1000

168 063 3x50/16 6 2.5 2.3 44 3500 660 0.387 7.2 211 211 0.36 0.104 0.32 1000

168 319 3x70/16 12 2.5 2.4 48 4300 720 0.268 10.0 262 258 0.41 0.098 0.36 500

168 392 3x95/16 15 2.5 2.6 51 5300 765 0.193 13.6 319 309 0.47 0.094 0.41 500

168 321 3x120/16 18 2.5 2.7 55 6500 825 0.153 17.2 366 351 0.51 0.091 0.45 500

1683290 3x150/25 18 2.5 2.8 59 7900 885 0.124 21.5 416 395 0.55 0.089 0.49 250

168 341 3x185/25 30 2.5 2.9 63 9300 945 0.0991 26.5 476 446 0.61 0.086 0.54 250

168 351 3x240/25 34 2.6 3.1 68 11600 1020 0.0754 34.3 560 518 0.65 0.084 0.58 250

NA2XSEY 3.6/6 (7.2) kV ALUMINIUM CONDUCTOR

168 040 3x35/16 6 2.5 2.2 36 1550 540 0.868 3.29 137 139 0.32 0.110 0.28 1000

1680630 3x50/16 6 2.5 2.3 44 2600 660 0.641 4.7 163 163 0.36 0.104 0.32 1000

1683180 3x70/16 12 2.5 2.4 48 3050 720 0.443 6.6 204 201 0.41 0.098 0.36 1000

1683920 3x95/16 15 2.5 2.6 51 3600 765 0.320 8.9 247 240 0.47 0.094 0.41 1000

1683200 3x120/16 15 2.5 2.7 55 4350 825 0.253 11.3 285 273 0.51 0.091 0.45 500

1683300 3x150/25 15 2.5 2.8 59 5200 885 0.206 14.1 323 306 0.55 0.089 0.49 500

1683410 3x185/25 30 2.5 2.9 63 5900 945 0.164 17.4 371 347 0.61 0.086 0.54 500

PCD 45-15, October 2007

168 355 3x240/25 30 2.6 3.1 68 7150 1020 0.125 22.6 438 404 0.65 0.084 0.58 500

Tel: (972) 4-8466222

Fax: (972) 4-8466286

e-mail: export@synergy-cables.com

http://www.synergy-cables.com

Medium Voltage Power Cables Medium Voltage Power Cables

Reactance @50Hz (5)

conductor (1 sec) (1)

Current Rating (2)

conductors & screen

Max. conductor DC

Nominal insulation

Specification

No., Nominal cross

Approximate outer

XLPE Insulated, PVC Sheathed Three-

Approximate cable

Minimum bending

Short Circuit rating

wires in conductor

resistance at 20°C

Charging Current

Minimum No. of

Catalog

Standard supply

sectional area of

Nominal sheath

core Cables for Fixed Installations,

In ground (4)

Number

Capacitance

3.6/6 kV; 6/10 kV; 12/20kV; 18/30 kV

thickness

thickness

diameter

In air (3)

lengths

weight

radius

No. x mm2/mm2 mm mm mm kg/km mm Ω/km kA A A A/km Ω/km μF/km m

N2XSEY 6/10 (12) kV COPPER CONDUCTOR SCOPE INSULATION FILLERS AND INNER COVERING

168 032 3x35/16 6 3.4 2.4 44 3000 660 0.524 5.0 178 181 0.42 0.117 0.23 1000

This specification describes XLPE insulated - Directly over the conductor screen shall be - Fillers and a covering shall be applied in the

168 055 3x50/16 6 3.4 2.5 49 3750 735 0.387 7.2 213 213 0.47 0.110 0.25 1000

168 314 3x70/16 12 3.4 2.6 53 4500 795 0.268 10.0 261 0.53 0.104 0.28 500

PVC sheathed three-core cables for fixed applied a homogeneous wall of XLPE screened cores assembly and above it

265

168 393 3x95/16 15 3.4 2.7 57 5850 855 0.193 13.6 322 312 0.60 0.099 0.32 500 installations underground and in the air in insulation. respectively.

168 323 3x120/16 18 3.4 2.8 61 6950 915 0.153 17.2 370 355 0.66 0.096 0.35 500 commercial, industrial and utilities plants. - The thickness and properties of the insulation - Properties of the covering shall be in

168 330 3x150/25 18 3.4 2.9 66 8250 990 0.124 21.5 420 399 0.71 0.093 0.37 250 They are intended for use in three phase shall be in accordance with Israeli Standard accordance with Israeli Standard 1516-2 and

168 337 3x185/25 30 3.4 3.0 70 9800 1050 0.0991 26.5 481 451 0.77 0.090 0.41 250 installations of 3.6/6 kV; 6/10 kV; 12/20kV 1516-2 and IEC 60502-2 Standard. IEC 60502-2 Standard.

1683491 3x240/25 34 3.4 3.2 74 10800 1140 0.0754 34.3 566 523 0.86 0.087 0.46 250

and 18/30kV at maximum conductor - Ethylene propylene rubber insulation, in

NA2XSEY 6/10 (12) kV ALUMINIUM CONDUCTOR

temperatures of 90°C for continuous normal accordance with the referenced standards, OVERSHEATH

168 031 3x35/16 6 3.4 2.4 44 2400 660 0.868 3.29 138 140 0.42 0.117 0.23 1000

168 061 3x50/16 6 3.4 2.5 49 2850 735 0.641 4.7 165 165 0.47 0.110 0.25 1000 operation and 250 °C for short circuit is available upon request. - An extruded red PVC sheath shall be applied

168 316 3x70/16 12 3.4 2.6 53 3200 795 0.443 6.6 206 203 0.53 0.104 0.28 1000 maximum conductor temperature. on the inner covering. Other sheath colours

168 394 3x95/16 15 3.4 2.7 57 3600 855 0.320 8.9 249 242 0.60 0.099 0.32 1000 INSULATION SCREEN available upon request.

168 328 3x120/16 15 3.4 2.8 61 4600 915 0.253 11.3 288 276 0.66 0.096 0.35 500 STANDARDS - The insulation screen shall consist of a non- - Properties of the sheath shall be in accordance

1683340 3x150/25 15 3.4 2.9 66 5350 990 0.206 14.1 326 309 0.71 0.093 0.37 500 with the referenced standards for the ST4

The following standards shall form a part of metallic extruded semi-conducting layer in

168 340 3x185/25 30 3.4 3.0 70 6150 1050 0.164 17.4 375 351 0.77 0.090 0.41 500

this specification to the extent specified herein: combination with semi-conducting tape and type.

1683490 3x240/25 30 3.4 3.2 74 6400 1140 0.125 22.6 442 408 0.86 0.087 0.46 500

N2XSEY 12/20 (24) kV COPPER CONDUCTOR

- Israeli Standard IS 1516-2: ”Power cables a metallic layer. - Alternative materials may be provided if

1683117 3x35/16 6 5.5 2.7 54 3850 810 0.524 5.0 180 184 0.60 0.131 0.16 1000 with extruded insulation and their - The extruded semi-conducting layer shall specified.

1683126 3x50/16 6 5.5 2.8 57 4450 855 0.387 7.2 215 215 0.66 0.123 0.17 500 accessories for rated voltages from 1 kV consist of smooth cross-linked polyolefin

1683172 3x70/16 12 5.5 2.9 61 5350 915 0.268 10.0 268 264 0.74 0.116 0.19 500 (Um = 1,2 kV) up to 30 kV (Um = 36 kV) – compound bonded to the insulation and TESTS

168397 3x95/16 15 5.5 3.0 65 6400 975 0.193 13.6 325 315 0.82 0.110 0.21 500 Part 2: Cables for rated voltages of 6 kV meeting the requirements of Israeli Standard The cable shall be tested in accordance with

1683230 3x120/16 18 5.5 3.1 69 7450 1035 0.153 17.2 374 359 0.90 0.106 0.23 500

(Um = 7,2 kV) up to 30 kV (Um = 36 kV)” 1516-2 and IEC 60502-2 Standard. the Israeli Standard 1516-2 and IEC 60502-2

168332 3x150/25 18 5.5 3.2 72 8600 1080 0.124 21.5 424 403 0.96 0.104 0.25 250

1683445 3x185/25

for the types N2XSEY and NA2XSEY. - The conductor screen, the insulation and the Standard and meet their requirements.

30 5.5 3.4 76 10000 1140 0.0991 26.5 486 456 1.04 0.100 0.27 250

168350 3x240/25 34 5.5 3.5 81 12300 1215 0.0754 34.3 572 528 1.15 0.096 0.30 250 - IEC 60502-2 Standard: ”Power cables with insulation screen shall be applied in a single

NA2XSEY 12/20 (24) kV ALUMINIUM CONDUCTOR extruded insulation and their accessories head triple extrusion process with dry CHARACTERISTICS

1683118 3x35/16 6 5.5 2.7 54 3200 810 3.29 3.29 140 142 0.60 0.131 0.16 1000 for rated voltages from 1 kV (Um = 1,2 kV) nitrogen curing. Mechanical resistance

1683127 3x50/16 6 5.5 2.8 57 3550 855 4.7 4.7 167 167 0.66 0.123 0.17 1000 up to 30 kV (Um = 36 kV)” – “Part 2: Cables - A semi-conducting tape shall be applied on to impacts Low

1683174 3x70/16 12 5.5 2.9 61 4050 915 6.6 6.6 208 205 0.74 0.116 0.19 500

for rated voltages of 6 kV (Um = 7,2 kV) up the extruded semi-conducting insulation Flexibility Semi-flexible

1683980 3x95/16 15 5.5 3.0 65 4650 975 8.9 8.9 251 244 0.82 0.110 0.21 500

to 30 kV (Um = 36 kV)”. screen. Minimum installation

1683231 3x120/16 15 5.5 3.1 69 5250 1035 11.3 11.3 291 279 0.90 0.106 0.23 500

1683320 3x150/25 15 5.5 3.2 72 5850 1080 14.1 14.1 329 312 0.96 0.104 0.25 500 - The metallic screen shall consist of: a) a temperature -5 °C

1683446 3x185/25 30 5.5 3.4 76 6600 1140 17.4 17.4 379 355 1.04 0.100 0.27 500 CONDUCTORS helically applied copper tape or, b) a number Temperature range -15 to +90 °C

1683501 3x240/25 30 5.5 3.5 81 7800 1215 22.6 22.6 446 412 1.15 0.096 0.30 500 - Annealed, high conductivity copper of bare copper wires, uniformly spaced and Weather resistance Good

N2XSEY 18/30 (36) kV COPPER CONDUCTOR compacted circular stranded conductor helically applied on top of the semi-

1683160 3x50/16 6 8 3.2 69 6000 1035 0.387 7.2 217 217 0.77 0.136 0.13 500

according to IEC 60228, Class 2. conducting tape with an open helix applied

1683185 3x70/16 12 8 3.3 73 6900 1095 0.268 10.0 270 266 0.85 0.128 0.15 500

1683201 3x95/16 15 8 3.4 77 8100 1155 0.193 13.6 328 318 0.94 0.121 0.16 250

- Aluminium compacted circular stranded copper tape binding the wires together.

1683226 3x120/16 18 8 3.5 80 9300 1200 0.153 17.2 377 362 1.02 0.117 0.18 250 conductor according to IEC 60228,

1683375 3x150/25 18 8 3.6 83 10500 1245 0.124 21.5 428 407 1.08 0.114 0.19 250 Class 2. CABLING

1683470 3x185/25 30 8 3.7 87 12000 1305 0.0991 26.5 491 460 1.17 0.110 0.20 250 - Three screened cores shall be laid-up.

1683895 3x240/25 34 8 3.9 93 14300 1395 0.0754 34.3 577 534 1.28 0.105 0.22 250 CONDUCTOR SCREEN - The sum of the geometrical cross sectional

NA2XSEY 18/30 (36) kV ALUMINIUM CONDUCTOR

The conductors shall be covered with a layer areas of the metallic screen of each of the

1683161 3x50/16 6 8 3.2 69 5050 1035 0.641 4.7 168 168 0.77 0.136 0.13 500

1683186 3x70/16 12 8 3.3 73 5650 1095 0.443 6.6 210 207 0.85 0.128 0.15 500 of extruded smooth conducting cross-linked cores shall be the one specified in the tables

1683202 3x95/16 15 8 3.4 77 6400 1155 0.320 8.9 254 247 0.94 0.121 0.16 500 polyolefin compound, firmly bonded to the above to provide an earth fault current path.

1683227 3x120/16 15 8 3.5 80 7000 1200 0.253 11.3 294 282 1.02 0.117 0.18 500 insulation and which shall meet the Other cross sectional areas can be supplied

1683376 3x150/25 15 8 3.6 83 7700 1245 0.206 14.1 333 315 1.08 0.114 0.19 500 requirements of Israeli Standard 1516-2 and upon request.

1683471 3x185/25 30 8 3.7 87 8500 1305 0.164 17.4 383 358 1.17 0.110 0.20 250 IEC 60502-2 Standard.

1683896 3x240/25 30 8 3.9 93 9800 1395 0.125 22.6 451 416 1.28 0.105 0.22 250

PCD 33-24/3.02 March 6, 2002

(1) The conductor short circuit rating is based on an initial conductor temperature of 90 °C and a final temperature of 250 °C.

(2) Current rating based upon operation at 90 °C conductor, three-phase a.c. load. The screens are earthed at both ends of the cable. Based on VDE 0276-620.

(3) Cable laid in freely circulating air at 30 °C, protected against direct thermal radiation due to sun, etc.

(4) Cable directly buried at 0.7 m deep in soil at 20 °C, with 1 °K.m/W thermal resistivity. Load factor 0.7.

PCD 45-15, October 2007

(5) Calculated inductive reactance per core. The screens are bonded and earthed at both ends of the cable.

TEMPERATURE RATING FACTORS

Ambient Temperature °C 20 25 30 35 40 45 50 55 60 65

Correction factor air 1.08 1.04 1.00 0.96 0.91 0.87 0.82 0.76 0.71 0.65

Correction factor ground 1.00 0.96 0.93 0.89 0.85 0.80 0.76 - - -

The information given in this page is subject to change without notice.

You might also like

- 481-Medium Voltage Power CablesDocument2 pages481-Medium Voltage Power Cablesopplus33% (3)

- 35kv Xlpe Phelps Dodge PDFDocument2 pages35kv Xlpe Phelps Dodge PDFRodney LanagNo ratings yet

- Cable Impedance CalculationsDocument4 pagesCable Impedance CalculationsJoseph PoplingerNo ratings yet

- 484-Medium Voltage Power Cables26.45kVDocument2 pages484-Medium Voltage Power Cables26.45kVJoseph Poplinger0% (1)

- Raychem Link Boxes: Cable ServicesDocument8 pagesRaychem Link Boxes: Cable ServicesGokul VenugopalNo ratings yet

- Technical Specification - Power Cable - WP4Document15 pagesTechnical Specification - Power Cable - WP4nnNo ratings yet

- OKONITEDocument2 pagesOKONITEworkshop Ega SbyNo ratings yet

- Kerpen Catalogo Medium-VoltageDocument43 pagesKerpen Catalogo Medium-VoltageAlfonso GonzálezNo ratings yet

- Technical Specification - Special Screen Cable - WP4Document7 pagesTechnical Specification - Special Screen Cable - WP4nnNo ratings yet

- CablesDocument29 pagesCablesbimaNo ratings yet

- Cables For EE342 CourseDocument7 pagesCables For EE342 Coursemahmab70No ratings yet

- Southern Cable CatalogueDocument46 pagesSouthern Cable CatalogueRaja Mohd AriffNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document30 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- Transmission Line Lecture 1revisedDocument133 pagesTransmission Line Lecture 1revisedLhorie Ladica Valerio100% (2)

- Alcan Abc Cables PDFDocument6 pagesAlcan Abc Cables PDFAHMED YOUSEFNo ratings yet

- Transmission Line Lecture 1revisedDocument133 pagesTransmission Line Lecture 1revisedLhorie Ladica ValerioNo ratings yet

- SC - Low Voltage Catalogue - Copper - 2020Document46 pagesSC - Low Voltage Catalogue - Copper - 2020May OngNo ratings yet

- Power Cables YJV22Document30 pagesPower Cables YJV22dabs_orangejuiceNo ratings yet

- Copper Conductors, XLPE Insulated: DescriptionDocument1 pageCopper Conductors, XLPE Insulated: DescriptionLucian2001No ratings yet

- Surge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage ProtectionDocument4 pagesSurge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage Protectiondave chaudhuryNo ratings yet

- Fire Rated CablesDocument3 pagesFire Rated CablesRoy MonroyNo ratings yet

- Part 9Document5 pagesPart 9pravishnNo ratings yet

- Bahra Cables-Technical SheetsDocument33 pagesBahra Cables-Technical Sheetsmir sadat aliNo ratings yet

- All About Transmission Lines3Document5 pagesAll About Transmission Lines3Stephen Dunifer100% (1)

- Tecnical Specification - AC CABLE DATASHEETDocument7 pagesTecnical Specification - AC CABLE DATASHEETEisac SagimanNo ratings yet

- 01 Power Cables EarthingDocument77 pages01 Power Cables EarthingMADDY RANANo ratings yet

- Line Electrical: PropertiesDocument13 pagesLine Electrical: Propertiesj_andrade_arceNo ratings yet

- Nexans MV Cables UK Brochure - 1Document48 pagesNexans MV Cables UK Brochure - 1Ra'fat HerzallahNo ratings yet

- Section Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Document56 pagesSection Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Terex14253No ratings yet

- N2Xsy: Technical Data ConstructionDocument2 pagesN2Xsy: Technical Data ConstructionAthanasios AntonopoulosNo ratings yet

- Epdu EE-182,183,196,202 Pre Lab 1: British Standard Wire Gauge Is A Set of Wire Sizes Given byDocument3 pagesEpdu EE-182,183,196,202 Pre Lab 1: British Standard Wire Gauge Is A Set of Wire Sizes Given byMaaz HussainNo ratings yet

- 2 Hazard Mechanisms AMDocument29 pages2 Hazard Mechanisms AMroyclhorNo ratings yet

- Arrester DisconnectorDocument37 pagesArrester DisconnectorKush SharmaNo ratings yet

- 30W Linear On 23cm: Sage Wire Line, What IsDocument5 pages30W Linear On 23cm: Sage Wire Line, What IsΑΝΔΡΕΑΣ ΤΣΑΓΚΟΣNo ratings yet

- Energy Hvca Linkboxes Us enDocument8 pagesEnergy Hvca Linkboxes Us enKush SharmaNo ratings yet

- FAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...Document16 pagesFAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...César Díaz LiberonaNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5Document36 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5nnNo ratings yet

- Sheath Bonding MethodDocument26 pagesSheath Bonding Methodوهيبه بكر100% (1)

- Types of Copper Network CablesDocument27 pagesTypes of Copper Network Cablesapi-19713349No ratings yet

- IEC Separable Connectors 36 KV, 630A: Front T-Body / Coupling (Rear) T-Body ConnectorDocument5 pagesIEC Separable Connectors 36 KV, 630A: Front T-Body / Coupling (Rear) T-Body ConnectorDiego AlvesNo ratings yet

- Tds New 1c Cu 35kvDocument2 pagesTds New 1c Cu 35kvButch BuciaNo ratings yet

- 35kv Xlpe Phelps DodgeDocument2 pages35kv Xlpe Phelps DodgeCommercial One100% (2)

- Cable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17Document6 pagesCable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17anamulk-1No ratings yet

- ITECO Submarine Cable CatalogueDocument16 pagesITECO Submarine Cable CatalogueThai AnhNo ratings yet

- EE458Document36 pagesEE458ArishaNo ratings yet

- Terminacion de Cables Aislados PDFDocument11 pagesTerminacion de Cables Aislados PDFMisael Daniel EstevezNo ratings yet

- Betobar 2021Document44 pagesBetobar 2021berliani navitasNo ratings yet

- Insulators: Dr.S.Prabhakar Karthikeyan Smieee, PDF (Cpri) Associate Professor, SELECT VIT University, VelloreDocument31 pagesInsulators: Dr.S.Prabhakar Karthikeyan Smieee, PDF (Cpri) Associate Professor, SELECT VIT University, Velloresahale sheraNo ratings yet

- Olex HV Cable RatingDocument58 pagesOlex HV Cable RatingsimbashumbaNo ratings yet

- Cables and Distribution: Dept. of EEE, JNTUA College of Engineering, Kalikiri Chittoor District, A P, IndiaDocument58 pagesCables and Distribution: Dept. of EEE, JNTUA College of Engineering, Kalikiri Chittoor District, A P, Indiasuneel.thandraNo ratings yet

- Anixter Minimum Bending Radius Wire Wisdom en PDFDocument1 pageAnixter Minimum Bending Radius Wire Wisdom en PDFAndrew Ixara AribowoNo ratings yet

- 110kv Ehv Cable - GtpsDocument2 pages110kv Ehv Cable - GtpsBijaya Kumar MohantyNo ratings yet

- Cables in Deep WaterDocument14 pagesCables in Deep WaterCarlos GarridoNo ratings yet

- Alcan AluminumDocument4 pagesAlcan AluminumAhmed H. HassanNo ratings yet

- Fluke Unilap100xeDocument10 pagesFluke Unilap100xepancaro93No ratings yet

- Surge-Transferred Overvoltages in Earthing/Auxiliary TransformersDocument6 pagesSurge-Transferred Overvoltages in Earthing/Auxiliary TransformersSudhir RavipudiNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Control Cables: PVC Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVDocument2 pagesControl Cables: PVC Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVJoseph PoplingerNo ratings yet

- 484-Medium Voltage Power Cables26.45kVDocument2 pages484-Medium Voltage Power Cables26.45kVJoseph Poplinger0% (1)

- 480-LSOH Installation WiresDocument2 pages480-LSOH Installation WiresJoseph PoplingerNo ratings yet

- Control Cables: XLPE Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVDocument2 pagesControl Cables: XLPE Insulated, PVC Sheathed Multicore Cables For Fixed Wiring, 0.6/1 KVJoseph PoplingerNo ratings yet

- Ampacities For Aluminum & ACSR Overhead Electrical Conductors PDFDocument20 pagesAmpacities For Aluminum & ACSR Overhead Electrical Conductors PDFJoseph PoplingerNo ratings yet

- Art11 PDFDocument29 pagesArt11 PDFJoseph PoplingerNo ratings yet

- Pole and Tower Lines For Electric Power Transmission Von R. D. CoombsDocument60 pagesPole and Tower Lines For Electric Power Transmission Von R. D. CoombsJoseph PoplingerNo ratings yet

- Cable Shield Grounded at One End OnlyDocument4 pagesCable Shield Grounded at One End OnlyJoseph PoplingerNo ratings yet

- Bed Sizes and Mattress DimensionsDocument3 pagesBed Sizes and Mattress DimensionsJoseph PoplingerNo ratings yet

- Making Sense of TimeDocument4 pagesMaking Sense of TimeJoseph PoplingerNo ratings yet

- AL-CU Cables Impedances CalculationsDocument2 pagesAL-CU Cables Impedances CalculationsJoseph PoplingerNo ratings yet

- Line - Cable-Parameter-Calculation-metric MMDocument59 pagesLine - Cable-Parameter-Calculation-metric MMJoseph PoplingerNo ratings yet

- Classic-Handbook, Part 2, Edition 9, June 2015Document68 pagesClassic-Handbook, Part 2, Edition 9, June 2015Joseph PoplingerNo ratings yet

- 3 Phase System Simulation V1Document6 pages3 Phase System Simulation V1Joseph Poplinger100% (1)

- 3-Phase Calculators Result Cells Are Green.: Converting Voltage From Line-To-Neutral To Line-To-LineDocument2 pages3-Phase Calculators Result Cells Are Green.: Converting Voltage From Line-To-Neutral To Line-To-LineJoseph PoplingerNo ratings yet

- 3 Phase System Simulation V2Document50 pages3 Phase System Simulation V2Joseph PoplingerNo ratings yet

- Heat Generation Modeling of Ball Bearing Based On Internal Load DistributionDocument8 pagesHeat Generation Modeling of Ball Bearing Based On Internal Load DistributionMÔNICA SUEDE S. SILVANo ratings yet

- Exercises On Fluids and GravityDocument22 pagesExercises On Fluids and Gravityelty TanNo ratings yet

- Standard TriacDocument4 pagesStandard TriacHector Alberto SanchezNo ratings yet

- A6260 Datasheet PDFDocument12 pagesA6260 Datasheet PDFAlfonzo ParedesNo ratings yet

- Ozone Generators - Life Support Systems MAT LSSDocument1 pageOzone Generators - Life Support Systems MAT LSSqualiman1No ratings yet

- Chapter 12 - Kinetics of Particles - Part 1 and 2Document30 pagesChapter 12 - Kinetics of Particles - Part 1 and 2Ahmed AliNo ratings yet

- Final ScheduleDocument21 pagesFinal Scheduleನವೀನ್ಕುಮಾರ್No ratings yet

- What Is Megger Test and How Is It PerformedDocument4 pagesWhat Is Megger Test and How Is It PerformedYasir JamilNo ratings yet

- Design For Wear Resistance: Raymond G. Bayer, Tribology ConsultantDocument12 pagesDesign For Wear Resistance: Raymond G. Bayer, Tribology Consultanttolentino.jason1222No ratings yet

- Lecture 1 Intro Energy TargetsDocument56 pagesLecture 1 Intro Energy Targets翁宝怡No ratings yet

- Danfoss EKC 361 Manual PDFDocument16 pagesDanfoss EKC 361 Manual PDFphilip penaflorNo ratings yet

- Answer SheetDocument2 pagesAnswer SheetKirsty SebastianNo ratings yet

- Chapter 3 Response of Structures To DynaDocument61 pagesChapter 3 Response of Structures To DynaSayyadh Rahamath BabaNo ratings yet

- CR306Document3 pagesCR306josé fernando sotelo ventosillaNo ratings yet

- S4-4 Damping Paper TakedaDocument26 pagesS4-4 Damping Paper TakedaRonald Omar García RojasNo ratings yet

- Intelligent Coolwex Exclusive Air/Water Heat PumpsDocument13 pagesIntelligent Coolwex Exclusive Air/Water Heat PumpsTimo TNo ratings yet

- Electronics Repair and Troubleshooting: Regulated Power Supply TroubleshootingDocument5 pagesElectronics Repair and Troubleshooting: Regulated Power Supply TroubleshootingIra CervoNo ratings yet

- Esdd 02 006 PDFDocument34 pagesEsdd 02 006 PDFKarthik EvilordNo ratings yet

- (TDB) DVM Chiller For Europe Ver.2.2 - 170223Document66 pages(TDB) DVM Chiller For Europe Ver.2.2 - 170223ORLANDO CASTRONo ratings yet

- Panel Thermo-Hygrostat and Thermostats: Drying KilnsDocument6 pagesPanel Thermo-Hygrostat and Thermostats: Drying KilnsBasman GeorgeNo ratings yet

- Power DiodesDocument46 pagesPower DiodesJay R BallonNo ratings yet

- Brochure TG enDocument8 pagesBrochure TG enpascal_chinNo ratings yet

- Bionics IFM-500 - Test ReportDocument74 pagesBionics IFM-500 - Test ReportRomário CaribéNo ratings yet

- P605-P1100 Power Optimizer Module Add-On DS-000012-EnGDocument4 pagesP605-P1100 Power Optimizer Module Add-On DS-000012-EnGKarunakara ReddyNo ratings yet

- Chapter-3-Ohm's Law, Energy, and PowerDocument33 pagesChapter-3-Ohm's Law, Energy, and PowershahadNo ratings yet

- Lecture On Distribution SystemDocument36 pagesLecture On Distribution Systemimburais100% (1)

- Mass Transfer Slides - CHE304 - Chapter 26Document51 pagesMass Transfer Slides - CHE304 - Chapter 26RehabNo ratings yet

- Room Air Line UpDocument4 pagesRoom Air Line UpJeffrey FortalezaNo ratings yet

- Week 9 - Revision SolutionsDocument11 pagesWeek 9 - Revision SolutionsReacher ElliotNo ratings yet

- Charging by FrictionDocument33 pagesCharging by FrictionlostgirlNo ratings yet