Professional Documents

Culture Documents

Method of Statement For: Hot Works

Method of Statement For: Hot Works

Uploaded by

Hussam WaleedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method of Statement For: Hot Works

Method of Statement For: Hot Works

Uploaded by

Hussam WaleedCopyright:

Available Formats

ENI - IRAQ

ZUBAIR MISHRIF DGS ELECTRICAL INTEGRATION

METHOD OF STATEMENT FOR HOT WORKS

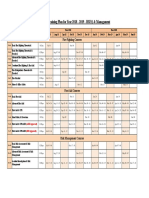

Issue For Hussam Alfio Silvio

EX-CO 00 01/09/20 Silvio Belloni

Comments Waleed Tringali Belloni

Validity Rev.

Status number Prepared Checked Approved Contractor Company

Date Description

by by by Approval Approval

Revision Index

Company logo and business name Project name Company Document ID

ZUBAIR MISHRIF 251010DJPCTB556

DGS ELECTRICAL

INTEGRATION

eni iraq b.v. Job N.

Contractor logo and business name Contractor Document ID

19C016-9H913

CONSORTIUM TOZZI SUD - ALBILAL GROUP

Contract N. 4600038271

Vendor logo and business name Vendor Document ID

N/A N/a

Order N.

Facility Name Location Scale Sheet of Sheets

ZUBAIR MISHRIF DGS ONSHORE N/A 1 of 9

Document Title Supersedes N.

METHOD OF STATEMENT FOR HOT WORKS Superseded by N.

Plant Area Plant Unit

N/A N/A

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

Revision Index Sheet of Sheets

CONTRACTOR

COMPANY Document

Document Validity 2/9

Identification Rev.

Identification Status

CONSORTIUM TOZZI SUD – 251010DJPCTB556

ALBILAL GROUP 19C016-9H913

EX-CO 01

REVISION HISTORY

Rev. Date No. of Description

sheets

EX-CO 00 30/08/2020 8 Issue For Comments

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

Revision Index Sheet of Sheets

CONTRACTOR

COMPANY Document

Document Validity 3/9

Identification Rev.

Identification Status

CONSORTIUM TOZZI SUD – 251010DJPCTB556

ALBILAL GROUP 19C016-9H913

EX-CO 01

Table of Contents

1. Objective............................................................................................................................................................ 3

2. Purpose.............................................................................................................................................................. 4

3. Scope................................................................................................................................................................. 4

4. Definitions and Abbreviations......................................................................................................................... 4

5. Reference Documents:..................................................................................................................................... 4

5.1. Project Documents:..................................................................................................................................4

5.2. Project HSE Major Document:..................................................................................................................5

6. Responsibility.................................................................................................................................................... 5

6.1. CONSTRUCTION Manager.........................................................................................................................6

6.2. Site Engineer.............................................................................................................................................6

6.3. HSE Manager............................................................................................................................................6

6.4. QA/QC Manager.......................................................................................................................................6

6.5. Worker......................................................................................................................................................6

7. Machinery, Equipment’s & Tool....................................................................................................................... 6

8. Work Sequence................................................................................................................................................. 7

8.1. Welding, Cutting and Grinding Preparation..............................................................................................7

8.2. Welding, Cutting and Grinding Procedure................................................................................................8

9. Risk Assessment.............................................................................................................................................. 9

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

Revision Index Sheet of Sheets

CONTRACTOR

COMPANY Document

Document Validity 4/9

Identification Rev.

Identification Status

CONSORTIUM TOZZI SUD – 251010DJPCTB556

ALBILAL GROUP 19C016-9H913

EX-CO 01

1. Objective

The Method statement has issued as a Guide to Employees to ensure that all activities required for

the hot works, would be carried out in compliance with Contractual and Health & Safety

Requirements.

2. Purpose

The purpose of this document is to identify the Hot works is any work that produces open flames, hot

slag or sparks. The Fire Code defines Hot Work as cutting, welding, brazing, soldering, grinding, ther-

mal spraying, thawing pipe, installation of torch applied roof systems, or any other similar situation

and all these activities to been performed in line with proper methodology and correct sequence

according to the approved documentation and requirements.

3. Scope

Hot Works is any work that produces open flames, hot slag or sparks, Hot Work as cutting, welding,

grinding and thermal spraying and the Main activities describe into this document are:

Welding.

Cutting and grinding.

4. Definitions and Abbreviations

Definitions:

Company ENI Iraq B.V.

Contractor Consortium TOZZI SUD Albilal group

QA/QC Quality Assurance, Quality Control

HSE Health, Safety and Environment

ITP Inspection and Test Plan

QCP Quality Control Plan

ITR Inspection Test Record

IMTE Inspection, Measuring and Test Equipment

MAR Material Approval Request

N/A Not Applicable

NCR Non-Conformance Report

TP Third Party (Laboratory)

RA Risk Assessment

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

Revision Index Sheet of Sheets

CONTRACTOR

COMPANY Document

Document Validity 5/9

Identification Rev.

Identification Status

CONSORTIUM TOZZI SUD – 251010DJPCTB556

ALBILAL GROUP 19C016-9H913

EX-CO 01

5. Reference Documents:

1.

5.1. Project Documents:

251010DADMTB028 Main Substation -Formwork & Details - Plan at level +3.500 TOC

251010DADMTB029 Main Substation -Formwork & Details - Plan at level +9.300 TOC

251010DADMTB535 Main Substation Finishing -Transversal Sections

251010DADMTB536 Main substation Finishing - Thermal and Fire Insulation - Typical Section

251010DADMTB040 Main Substation Finishing Layout and Details - First floor

251010DADMTB041 Main Substation Finishing Layout and Details - Roof

251010DADMTB043 Main Substation Finishing - External Views from West and from South

251010DADMTB044 Main Substation Finishing - Longitudinal Sections

5.2. Project HSE Major Document:

251010DFPATB360 HSE Plan

251010DFPCTB427 HSE Risk Management Procedure

251010DFMSTB431 Working at height procedure

251010DFPCTB436 Noise Control

251010DFPCTB438 Manual Handling

251010DFPLTB439 Environmental management plan

251010DFPCTB444 Heat Stress

251010DFPLTB453 Hazardous Materials Management Plan

251010DFPLTB455 Waste Management Plan

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

Revision Index Sheet of Sheets

CONTRACTOR

COMPANY Document

Document Validity 6/9

Identification Rev.

Identification Status

CONSORTIUM TOZZI SUD – 251010DJPCTB556

ALBILAL GROUP 19C016-9H913

EX-CO 01

6. Responsibility

6.1. CONSTRUCTION Manager

Defines the required working/construction methodology in written work procedures/MOS

and implements such documents to ensure that each single activity will be executed under

controlled conditions to meet the specification requirements.

Shall cooperate with the project QA/QC Manager, HSE Manager and Security Manager.

Get approved documentation before performing any work at site and he is in charge. Ensure

the correct application.

Directly reports to Site Project Manager.

6.2. Site Engineer

Ensure that all works are carried out according to approved shop drawings.

Ensure all safety equipment proper tools & tackles are available at the point of use.

Aware of all procedures, work method, instruction, quality requirements for the timely completion of

the job and explains to the task to workers for execution of the job with applicable code of practice.

6.3. HSE Manager

Ensure the compliance with the HSE System requirements.

Develop safety culture.

Monitor and control each site activity and related risk associated.

Directly reports to Site Project Manager.

6.4. QA/QC Manager

Responsible to adhere to the Quality System requirements.

Ensure that all necessary requests for inspection and testing are processed and put forward

to the company Engineer for notification.

Monitor the quality of works and ensure that fulfilment of specified requirement and that all

quality records related to work are completed.

Directly reports to Site Project Manager.

6.5. Worker

Qualified and trained person assigned to a specific task.

He has to perform his task in line with the related PTW without any deviation.

He has to act in respect of HSE System requirements.

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

Revision Index Sheet of Sheets

CONTRACTOR

COMPANY Document

Document Validity 7/9

Identification Rev.

Identification Status

CONSORTIUM TOZZI SUD – 251010DJPCTB556

ALBILAL GROUP 19C016-9H913

EX-CO 01

7. Machinery, Equipment’s & Tool

Equipment Remarks

Mobile Scaffold Quantities will be decided as per the work

Small Cars for the Crew requirements

Tools Remarks

Measuring tape and Levelling Tools

Welding Machine

Quantities will be decided as

Portable Grinding Machine

per the work requirements

Spirit level, Right angle

Safety tools (warning tape, flags, gloves …etc.)

8. Work Sequence

8.1. Welding, Cutting and Grinding Preparation

Following tasks shall be carried out prior to the hot works:

• Prior to beginning any burning, cutting, heating, welding or other hot work activities, the area

must be prepared so that the potential for fire is reduced or eliminated. When the work area

has been prepared, those workers who will perform the work must obtain a hot work permit.

• The area in and around the proposed hot work area must be cleaned to remove trash and

debris.

• Cardboard boxes and other combustible material must be moved to a distance of at least 35

feet from the proposed hot work area.

• All flammable or combustible materials must be removed from the area.

• Any electrical conduit, piping or machinery that could be damaged as a result of the hot work

must be protected with a fire-retardant material such as A-cloth, tarps or welding blankets.

• All equipment in the hot work area should be locked out.

• Holes in the floor and walls must be covered to prevent sparks from falling through unnoticed

onto people or combustible materials below.

• Maintain a fire watch when doing this kind of work and have a charged fire extinguisher readily

available.

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

Revision Index Sheet of Sheets

CONTRACTOR

COMPANY Document

Document Validity 8/9

Identification Rev.

Identification Status

CONSORTIUM TOZZI SUD – 251010DJPCTB556

ALBILAL GROUP 19C016-9H913

EX-CO 01

• Ensure any sprinkler system in the area is operable and is set properly to prevent inadvertent

release, i.e., set high enough so heat from the hot work does not set off the sprinkler system.

8.2. Welding, Cutting and Grinding Procedure

Procedure for welding, cutting and grinding procedure shall be as below:

• Identify the materials and equipments in the site .

• Refer the drawing and ensure the proper locations and dimensions by concerned engineer.

• Arrange all tools, materials and equipments orderly near to the work area.

• Measure length required, making due all allowance to be used. Cutting and measured length to

ensure that the ends are cut properly.

• Prepare the part of the rebar to be welded to the right angle, level and the size in accordance

with procedure Specification. The surfaces to be welded shall be smooth, uniform and free from

tears, scale, slag, grease and other materials that might affect the quality of welding. power

tools or hand tools will be used for cleaning, grinding or both.

• The two parts shall be tack welded together minimum in four positions at ninety degrees. after

tacking, the alignment shall be checked to confirm the integrity of the alignment has been

preserved. During the welding process the tacks shall be removed by grinding.

• The welding process will commence, ensuring that the correct filler metal, electrical current,

polarity, voltage, amperage and number of passes is in accordance with the welding procedure.

All slag or foreign matter shall be removed from each pass of welding, including the repair of

any visible defects, such as crack, cavities, etc., prior to commencing the succeeding passes.

Any such impurities shall be removed using a grinder.

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

COMPANY Document Identification CONTRACTOR Document Revision Index Sheet of Sheets

Identification

251010DJPCTB556 19C016-9H913 Validity 9/9

Rev.

Status

CONSORTIUM TOZZI SUD –

ALBILAL GROUP EX-CO 00

9. Risk Assessment

This document is property of eni Iraq B.V.

It shall neither be shown to Third Parties not used for purposes other than those for which it has been sent.

You might also like

- Common JCI CBAHI Survey QuestionsDocument371 pagesCommon JCI CBAHI Survey Questionsshadi alshadafan100% (4)

- Work Method Statement For Constructing New RC Plinth & Top Up SlabDocument9 pagesWork Method Statement For Constructing New RC Plinth & Top Up SlabMohd Hafizi Azlan100% (1)

- Permit To Work: Construction & Commissioning Procedures ManualDocument16 pagesPermit To Work: Construction & Commissioning Procedures ManualALADINHENo ratings yet

- JHA - Manual TorquingDocument6 pagesJHA - Manual TorquingMohamadSyahmiNo ratings yet

- Safe Work Methode For HDD BoringDocument1 pageSafe Work Methode For HDD Boringiwansalma100% (3)

- Method Statement For: Tiling WorkDocument5 pagesMethod Statement For: Tiling WorkHussam Waleed100% (3)

- Initiation Rites in MozambiqueDocument10 pagesInitiation Rites in MozambiqueIvan Emilio Muapavele50% (4)

- Blasting and Painting Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsDocument52 pagesBlasting and Painting Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsYo Wee Liam100% (1)

- Jsa Nitrogen Purging PDFDocument2 pagesJsa Nitrogen Purging PDFBISWA RANJAN SAHOONo ratings yet

- Cont HSE Alignment Kickoff Meeting F0228Document2 pagesCont HSE Alignment Kickoff Meeting F0228NAGARJUNA75% (4)

- 6.0 Method Statement and Risk AssessmentsDocument11 pages6.0 Method Statement and Risk Assessmentskumar sNo ratings yet

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli Hassan100% (1)

- MOS For Road ConstructionDocument7 pagesMOS For Road ConstructionHussam WaleedNo ratings yet

- Nursing Care PlanDocument3 pagesNursing Care Planjovanney100% (10)

- Grating Decking and Floor Removal FormDocument2 pagesGrating Decking and Floor Removal FormMohamed Abd ElhaleemNo ratings yet

- Hose Test Method StatementDocument6 pagesHose Test Method StatementRavi ValiyaNo ratings yet

- Abrasive Blasting Inspection Checklist - Rev 00Document1 pageAbrasive Blasting Inspection Checklist - Rev 00okba labdiNo ratings yet

- Blinding and Deblinding Rev1Document42 pagesBlinding and Deblinding Rev1Mayur NaikNo ratings yet

- (HSE Plan) : ProjectDocument32 pages(HSE Plan) : ProjectRIDONo ratings yet

- No.21 Manual HandlingDocument6 pagesNo.21 Manual HandlingAbdul Hakam Mohamed Yusof100% (1)

- Hempel Paint - MSDSDocument14 pagesHempel Paint - MSDSbaseet gazaliNo ratings yet

- Shell Capability Assessment Close Out DocumentsDocument6 pagesShell Capability Assessment Close Out DocumentsNwekeNwokomaAugustineNo ratings yet

- Cold Cutting PDFDocument9 pagesCold Cutting PDFAshraf BottaniNo ratings yet

- Dabel - Awoba Fence. Jha.Document14 pagesDabel - Awoba Fence. Jha.Trevor Emb100% (1)

- STFC Objectives and Targets SHE PlanDocument2 pagesSTFC Objectives and Targets SHE PlanThato KebuangNo ratings yet

- PPE PolicyDocument3 pagesPPE PolicyTolbert OkiringNo ratings yet

- Standard Operationg Procedure For Excavation For Lean Meg Pump FoundationsDocument10 pagesStandard Operationg Procedure For Excavation For Lean Meg Pump FoundationsBhargav BbvsNo ratings yet

- 021 - Energy Isolation, Lockout and Tagout ProcedureDocument22 pages021 - Energy Isolation, Lockout and Tagout ProcedureemmyNo ratings yet

- Ripen Offshore Calmbuoy Cleaning and Painting Works ProcedureDocument6 pagesRipen Offshore Calmbuoy Cleaning and Painting Works ProcedureAdamu Jebo100% (1)

- Commissioning and Decommissioning of Pipelines, District Isolation TestDocument13 pagesCommissioning and Decommissioning of Pipelines, District Isolation TestSevet Gnow DrachirNo ratings yet

- Hot Work ProcedureDocument12 pagesHot Work ProcedureEr AjenkNo ratings yet

- OPAL Road Safety Standard - HSEManagers ForumDocument15 pagesOPAL Road Safety Standard - HSEManagers ForumPVG SafetyNo ratings yet

- SOP Excavation and PermittingDocument4 pagesSOP Excavation and PermittingTengku & Wan ResourcesNo ratings yet

- HSE MASTER LIST Rev 20Document5 pagesHSE MASTER LIST Rev 20Agung Tri SugihartoNo ratings yet

- Hydro Test Checklist: Megha Engineering and Infrastructures LTDDocument1 pageHydro Test Checklist: Megha Engineering and Infrastructures LTDjithin shankarNo ratings yet

- Internal Audit Schedule (Example)Document1 pageInternal Audit Schedule (Example)baronnet88No ratings yet

- Safety Engineer PDFDocument3 pagesSafety Engineer PDFخلف الله التوم50% (2)

- Method Statement Hot InsulationDocument14 pagesMethod Statement Hot InsulationSaleem AkhtarNo ratings yet

- Part 4 ExcavationDocument6 pagesPart 4 ExcavationHana Seiadi100% (1)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Manual For SIEP-led HSE AuditingDocument60 pagesManual For SIEP-led HSE AuditingClive NicliNo ratings yet

- Health, Safety & Environmental (HSE) 1/3/2022 Management SystemDocument13 pagesHealth, Safety & Environmental (HSE) 1/3/2022 Management SystemNZ NZ100% (1)

- Lifting OperationDocument9 pagesLifting OperationRadit DuaSatuDuaNo ratings yet

- 07 Method Sytatement For Drilling MachineDocument5 pages07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- MS For Pipe Demolation at MT-OffshoreDocument5 pagesMS For Pipe Demolation at MT-OffshoreahmadNo ratings yet

- HSE-PRO-09-D01 0.2 - Interested Party Needs and Expectations 2020 HSE (NEW ONE)Document7 pagesHSE-PRO-09-D01 0.2 - Interested Party Needs and Expectations 2020 HSE (NEW ONE)Soufian BahmadNo ratings yet

- Hot WorkDocument20 pagesHot WorkmarceloNo ratings yet

- Document Title: HSE Standard Manual Sec. C.005 Confined Space Entry COPI Doc No.: ID-G-BU-00000-00000-00372Document11 pagesDocument Title: HSE Standard Manual Sec. C.005 Confined Space Entry COPI Doc No.: ID-G-BU-00000-00000-00372riskha100% (1)

- Petrofac Limited Hsseia StandardDocument15 pagesPetrofac Limited Hsseia Standardrodman823No ratings yet

- Shovel ChecklistDocument2 pagesShovel Checklistjamal motaNo ratings yet

- Improvement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Document10 pagesImprovement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Ravi Shankar TurlapatiNo ratings yet

- Mset Engineering SDN BHD: Door End Closure Replacement MLNG (PL 291)Document3 pagesMset Engineering SDN BHD: Door End Closure Replacement MLNG (PL 291)BhisamS SallehNo ratings yet

- Safety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksDocument1 pageSafety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksRísês ÃfrözNo ratings yet

- Cleaning Chlorination Water Tank Risk AnalysisDocument2 pagesCleaning Chlorination Water Tank Risk AnalysisRamyNo ratings yet

- Daily LPG Cylinder Leakage TestDocument2 pagesDaily LPG Cylinder Leakage TestLwandziso Dlamini100% (1)

- HIRA 013 Working Over Water.Document2 pagesHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- Pre-Mobilisation Assurance Checklist BackupDocument7 pagesPre-Mobilisation Assurance Checklist BackupNazrin SHONo ratings yet

- 47.HDEC-HSE-F0047 Pressure Test PermitDocument1 page47.HDEC-HSE-F0047 Pressure Test PermitRonn CaiNo ratings yet

- QCS 2014.docx TRAINING REQUIREMENTSDocument1 pageQCS 2014.docx TRAINING REQUIREMENTSRehan hassan janjuaNo ratings yet

- Planning and Procedures: Pdo Hse Management System Manual (CP-122)Document10 pagesPlanning and Procedures: Pdo Hse Management System Manual (CP-122)AHMEDNABTNo ratings yet

- GTSC Egypt Training Plan For Year 2018 - 2019 - HSEQ & ManagamentDocument11 pagesGTSC Egypt Training Plan For Year 2018 - 2019 - HSEQ & ManagamentAR El Patron KadryNo ratings yet

- Safra PineDocument3 pagesSafra PineTanzeel Liaqat100% (4)

- HSE Management Summary.Document2 pagesHSE Management Summary.min thantNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- 251010DFMSTB430 Exde01 15Document15 pages251010DFMSTB430 Exde01 15hussein aliNo ratings yet

- Temporary Security FenceDocument21 pagesTemporary Security FenceHussam Waleed100% (1)

- ZMDEI-AB-200110-MOS-HW-Sewage WorksDocument24 pagesZMDEI-AB-200110-MOS-HW-Sewage WorksHussam WaleedNo ratings yet

- Method Statement Asphalt PavingDocument3 pagesMethod Statement Asphalt PavingHussam WaleedNo ratings yet

- MOS For Bituminous Protective Coating Water ProofingDocument5 pagesMOS For Bituminous Protective Coating Water ProofingHussam WaleedNo ratings yet

- MOS of Installation Rise FloorDocument13 pagesMOS of Installation Rise FloorHussam WaleedNo ratings yet

- MOS For Epoxy PaintingDocument3 pagesMOS For Epoxy PaintingHussam WaleedNo ratings yet

- MOS For Bulk EarthworksDocument3 pagesMOS For Bulk EarthworksHussam WaleedNo ratings yet

- Dental Surgeon ResumeDocument4 pagesDental Surgeon Resumeafmsheushbqoac100% (1)

- PR 048 UND 12 Long Form Health Certificate Application EditableDocument4 pagesPR 048 UND 12 Long Form Health Certificate Application Editablelisa marieNo ratings yet

- An Orgasm Is Who Defines What An Orgasm Is?: Sexual and Relationship TherapyDocument8 pagesAn Orgasm Is Who Defines What An Orgasm Is?: Sexual and Relationship Therapytharuka1000No ratings yet

- Imagine Corporala - Scala ApreciereDocument13 pagesImagine Corporala - Scala ApreciereDan ManoleNo ratings yet

- MODULE 1 Introduction To Process Safety EngineeringDocument33 pagesMODULE 1 Introduction To Process Safety EngineeringCyberR.DomingoNo ratings yet

- Commu. II UNIT 4Document9 pagesCommu. II UNIT 4bashaNo ratings yet

- Case Analysis Colorectal CancerDocument4 pagesCase Analysis Colorectal CancerKhie-An Ocampo0% (1)

- Digital Detox - WorksheetDocument12 pagesDigital Detox - WorksheetFabiana Alejandra RuizNo ratings yet

- Consent in Pediatric Urology First Edition Prasad Godbole Duncan PDFDocument284 pagesConsent in Pediatric Urology First Edition Prasad Godbole Duncan PDFMarcela Osorio DugandNo ratings yet

- Disease of SorghumDocument29 pagesDisease of SorghumVikas BhardwajNo ratings yet

- Normal Value For Urine TestDocument2 pagesNormal Value For Urine TestMarcellino NernereNo ratings yet

- Emotional Intelligence What Is Emotional Intelligence ?Document7 pagesEmotional Intelligence What Is Emotional Intelligence ?shanNo ratings yet

- Stoller Alpha-1AntitrypsinDeficiency 2017Document8 pagesStoller Alpha-1AntitrypsinDeficiency 2017FrancoNo ratings yet

- Surpreme Compound MSDSDocument11 pagesSurpreme Compound MSDSskimmereNo ratings yet

- Assessment of Incidence, Management And.3Document6 pagesAssessment of Incidence, Management And.3FERNANDO ALVESNo ratings yet

- Literature Review PyramidDocument6 pagesLiterature Review Pyramidaflshvifm100% (1)

- Normal 5fc8e5cc9d923Document3 pagesNormal 5fc8e5cc9d923sidra darNo ratings yet

- Perceived Stress and Coping Levels of College Students During PandemicDocument10 pagesPerceived Stress and Coping Levels of College Students During PandemicPsychology and Education: A Multidisciplinary JournalNo ratings yet

- The Silent Patient by Alex Michaelides A Summary Noble Publishing Full ChapterDocument49 pagesThe Silent Patient by Alex Michaelides A Summary Noble Publishing Full Chapterrobert.burns554100% (7)

- Sexual Orientation Scale 2020Document10 pagesSexual Orientation Scale 2020MaqboolNo ratings yet

- Heart Attack Detection and AlerDocument3 pagesHeart Attack Detection and Alerprabhujaya97893No ratings yet

- L100 2843 REV C ISR G3 100 4T G3 Operators ManualDocument36 pagesL100 2843 REV C ISR G3 100 4T G3 Operators ManualcsNo ratings yet

- Endocrine SystemDocument12 pagesEndocrine SystemGiselle AlindoganNo ratings yet

- Yohan DirgantaraDocument7 pagesYohan DirgantaraSteffi SantosoNo ratings yet

- Test Bank For Essentials of Assistive Technologies 1st Edition Albert M Cook DownloadDocument5 pagesTest Bank For Essentials of Assistive Technologies 1st Edition Albert M Cook Downloadazurawinifredupaa8mNo ratings yet

- Obsessive-Compulsive and Related Disorders DSM - V Ocd and Related DisordersDocument2 pagesObsessive-Compulsive and Related Disorders DSM - V Ocd and Related DisordersJaaaaaaaaNo ratings yet

- Inter Hospital Transfer SopDocument2 pagesInter Hospital Transfer SopNATARAJAN RAJENDRANNo ratings yet