Professional Documents

Culture Documents

Illiade-179 Total Fat Content in Food 2019.10.14

Illiade-179 Total Fat Content in Food 2019.10.14

Uploaded by

AnnaRusuCopyright:

Available Formats

You might also like

- 4.5.05 AOAC of Fi Cial Method 2003.05 Crude Fat in Feeds, Ce Real Grains, and For AgesDocument2 pages4.5.05 AOAC of Fi Cial Method 2003.05 Crude Fat in Feeds, Ce Real Grains, and For AgesGiuseppe AV100% (2)

- Lab Food Analaysis-FatDocument9 pagesLab Food Analaysis-FatSHAFIKANOR366160% (5)

- Quiz 11-12 IntroDocument2 pagesQuiz 11-12 IntroFelix Echabaudis Espinoza100% (6)

- Aacc 30-10Document2 pagesAacc 30-10Елена СтариноваNo ratings yet

- 991.20 Nitrogeno en LecheDocument2 pages991.20 Nitrogeno en LechedcardonasterNo ratings yet

- Lab Report Exp 2Document12 pagesLab Report Exp 2Syuhada Aminuddin0% (2)

- Intensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALFrom EverandIntensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALRating: 5 out of 5 stars5/5 (1)

- ISO AOACDocument4 pagesISO AOACmidosy1996No ratings yet

- Lab Manual Experiment 5Document11 pagesLab Manual Experiment 5ShafikaNo ratings yet

- AN3460 PDF FeedDocument7 pagesAN3460 PDF Feedabanoub ebaidNo ratings yet

- Method Acid Hydrolysis AnkomDocument2 pagesMethod Acid Hydrolysis AnkomThamrongsak HannarongNo ratings yet

- Mbpracticas LabDocument6 pagesMbpracticas LabRosa VelásquezNo ratings yet

- Crude Fat Determination - Soxhlet Method - 1998Document3 pagesCrude Fat Determination - Soxhlet Method - 1998david_stephens_29No ratings yet

- Aplication Fat Extraction FoodDocument6 pagesAplication Fat Extraction FoodKu BonNo ratings yet

- AN3414 PDF FeedDocument13 pagesAN3414 PDF Feedabanoub ebaidNo ratings yet

- Determination of FatDocument5 pagesDetermination of FatLaksilu Viduraga Peiris100% (1)

- AN3480 CF in Feed PDFDocument6 pagesAN3480 CF in Feed PDFabanoub ebaidNo ratings yet

- Determination of Total Fat and Free Fat ContentDocument13 pagesDetermination of Total Fat and Free Fat ContentCesar Augusto Torres LinaresNo ratings yet

- Experiment 8 Determination of Total Fat in Foods by Rose Gottleib MethodDocument3 pagesExperiment 8 Determination of Total Fat in Foods by Rose Gottleib MethodRadwan AjoNo ratings yet

- AN0320 General S&H8000 PDFDocument7 pagesAN0320 General S&H8000 PDFabanoub ebaidNo ratings yet

- Dairy Techmology CentrifugationDocument11 pagesDairy Techmology CentrifugationM Umer SaeedNo ratings yet

- Lab 8 Ash Fat and Protein Addendum - 2018-5Document14 pagesLab 8 Ash Fat and Protein Addendum - 2018-5najwa0% (1)

- 34) Extraction of Bitumen From Paving MixturesDocument6 pages34) Extraction of Bitumen From Paving MixturesPn EkanayakaNo ratings yet

- Mlvss & Mlss Is-3025 - 18Document2 pagesMlvss & Mlss Is-3025 - 18Anuraj20No ratings yet

- SOP AMBL 105A TotalSolidsDocument5 pagesSOP AMBL 105A TotalSolidsWijianto WijiantoNo ratings yet

- Clarifying and Bacteria Removal Separators enDocument40 pagesClarifying and Bacteria Removal Separators enPiperea F. Bogdan100% (1)

- Fat AnalysisDocument11 pagesFat AnalysisSooraj NairNo ratings yet

- Crude Fat Determination - Soxhlet Method - 1998 PDFDocument3 pagesCrude Fat Determination - Soxhlet Method - 1998 PDFRosa EsparzaNo ratings yet

- M. Mujeeb Ullah, Nutr-401 PracticalDocument16 pagesM. Mujeeb Ullah, Nutr-401 PracticalAli RazaNo ratings yet

- Fat Determination SoxhletDocument9 pagesFat Determination SoxhletwanizalilNo ratings yet

- Physical and Chemical Methods of Testing Waste Water - Is 3025 - Part 15Document2 pagesPhysical and Chemical Methods of Testing Waste Water - Is 3025 - Part 15madhuwadiNo ratings yet

- Is-3025-Part-15-1984-Tests of Water For Total Residue (Total Solids - Dissolved and Suspended)Document2 pagesIs-3025-Part-15-1984-Tests of Water For Total Residue (Total Solids - Dissolved and Suspended)Sachin PawarNo ratings yet

- Theoretical Framework FatsDocument5 pagesTheoretical Framework FatsScribdTranslationsNo ratings yet

- 4534-Exp 1 Fat Oil by Soxhlet ExtractionDocument7 pages4534-Exp 1 Fat Oil by Soxhlet ExtractionAhmed AliNo ratings yet

- Soxhlet Extraction Method 1Document12 pagesSoxhlet Extraction Method 1Ziauddeen NoorNo ratings yet

- AN0305-Soxtec™ 8000Document6 pagesAN0305-Soxtec™ 8000abanoub ebaidNo ratings yet

- EXTRACTIVESDocument7 pagesEXTRACTIVESBryan Roncal LlajarunaNo ratings yet

- Lab - ManualDocument9 pagesLab - ManualLuna DanNo ratings yet

- Raw Milk Processing Presented in ClassDocument56 pagesRaw Milk Processing Presented in Classihovka3No ratings yet

- CHA 393 Sec 1 ReadyDocument14 pagesCHA 393 Sec 1 Readymajoxa9560No ratings yet

- Oils and FatsDocument110 pagesOils and FatsPurely Opaspong100% (1)

- PGDBST 03Document61 pagesPGDBST 03UJJWAL RAJ SINGHNo ratings yet

- Fat TotalDocument15 pagesFat TotalFathy MehayaNo ratings yet

- Total Solid Content Convection Oven ProcedureDocument2 pagesTotal Solid Content Convection Oven ProcedureashNo ratings yet

- Fiber 01Document4 pagesFiber 01Kim-Kim TorresNo ratings yet

- Universiti Kuala Lumpur Malaysian Institute of Chemical & Bioengineering TechnologyDocument7 pagesUniversiti Kuala Lumpur Malaysian Institute of Chemical & Bioengineering TechnologyMahainiIm RuzailyNo ratings yet

- Method 1.0 Sample Preparation Effective 1 January 2021Document5 pagesMethod 1.0 Sample Preparation Effective 1 January 2021oubaha happyNo ratings yet

- Cho 393 Sem ReadyDocument11 pagesCho 393 Sem Readypapey42271No ratings yet

- Practical Manual - Processing of Spices and Plantation CropsDocument26 pagesPractical Manual - Processing of Spices and Plantation CropsDhaya VNo ratings yet

- AOCS Official Method Ca 3d Sedimentos en AceiteDocument4 pagesAOCS Official Method Ca 3d Sedimentos en AceiteCarla Sánchez GallardoNo ratings yet

- Determination of FatDocument6 pagesDetermination of FatnajwaNo ratings yet

- Total Solid in MilkDocument3 pagesTotal Solid in Milkediasianagri100% (1)

- Quality of Ingredient and ProductsDocument36 pagesQuality of Ingredient and Productssudesha t rNo ratings yet

- Anaysis of MilkDocument14 pagesAnaysis of MilkSaman AkramNo ratings yet

- SoxhletExtraction PDFDocument7 pagesSoxhletExtraction PDFJim VelNo ratings yet

- FST306 Laboratory Report 2Document8 pagesFST306 Laboratory Report 2Nisa AzamNo ratings yet

- Determination of Moisture in FoodsDocument9 pagesDetermination of Moisture in Foodsagdwiyanti100% (1)

- Producing Cream on the Dairy Farm - A Collection of Articles on the Methods, Science and Equipment Used in Cream ProductionFrom EverandProducing Cream on the Dairy Farm - A Collection of Articles on the Methods, Science and Equipment Used in Cream ProductionNo ratings yet

- Microstructure of Dairy ProductsFrom EverandMicrostructure of Dairy ProductsMamdouh El-BakryNo ratings yet

- 2-5-1 English Language and LeteratureDocument7 pages2-5-1 English Language and LeteratureJitesh DuaNo ratings yet

- Anglais 23leçonsDocument24 pagesAnglais 23leçonsJérôme100% (2)

- Skill Development BrochureDocument2 pagesSkill Development BrochureJaimon C UthupNo ratings yet

- Unit 4 Plant and Inorganic NutrientsDocument29 pagesUnit 4 Plant and Inorganic NutrientsDita PerdanaNo ratings yet

- Antimicrobial Interventions For BeefDocument16 pagesAntimicrobial Interventions For BeefFrankPapa100% (1)

- Mosaic Uk 2009 Brochure Jun10Document24 pagesMosaic Uk 2009 Brochure Jun10stooge1983No ratings yet

- INSTITUTO CAMBRIDGE de Cultura Inglesa - Noviembre-Diciembre 2021Document3 pagesINSTITUTO CAMBRIDGE de Cultura Inglesa - Noviembre-Diciembre 2021LUCIA JESUS OJEDA CARCAMONo ratings yet

- Grammar Unit 7 1 Complete The Sentences With The Correct Form of The Verbs in BracketsDocument6 pagesGrammar Unit 7 1 Complete The Sentences With The Correct Form of The Verbs in BracketsCristina GarciaNo ratings yet

- Fridge - Freezer Instruction Book: Instructions For Use 3Document14 pagesFridge - Freezer Instruction Book: Instructions For Use 3nazimaghabayovNo ratings yet

- ProPoints TakeawayDocument10 pagesProPoints TakeawaychloeNo ratings yet

- Unit 3 - Do You Like NoodlesDocument154 pagesUnit 3 - Do You Like NoodlesHoàng Khắc HuyNo ratings yet

- Dokumen 1Document12 pagesDokumen 1Wulani HaryonoNo ratings yet

- Marc Maron On Whole Foods - From Attempting Normal by Marc MaronDocument7 pagesMarc Maron On Whole Foods - From Attempting Normal by Marc MaronRandom House Publishing Group100% (2)

- Third English ManualDocument102 pagesThird English ManualBelem LGNo ratings yet

- Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E Ticketing Service Electronic Reservation Slip (Personal User)puru42No ratings yet

- Pressure Cookers USP Cards - Eng - v5 PDFDocument20 pagesPressure Cookers USP Cards - Eng - v5 PDFJeffNo ratings yet

- Anglais CM1/CM2 1Document19 pagesAnglais CM1/CM2 1Bachir SaharaNo ratings yet

- StoichiometryDocument54 pagesStoichiometryRaymark AdoptanteNo ratings yet

- FODMAPDocument4 pagesFODMAParcp49No ratings yet

- B1-C1 Scattergories GameDocument11 pagesB1-C1 Scattergories GameSena baltaoğluNo ratings yet

- Duivenboekje 44pg Eng LR PDFDocument44 pagesDuivenboekje 44pg Eng LR PDFJega Alin100% (1)

- F-2013152 R-102 Product Overview A4Document2 pagesF-2013152 R-102 Product Overview A4Salalah Fire Safety Technical Services CompanyNo ratings yet

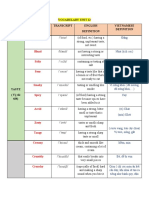

- Bitter: Vocabulary Unit 12 Vocabulary Transcript English VietnameseDocument4 pagesBitter: Vocabulary Unit 12 Vocabulary Transcript English VietnamesePan PerterNo ratings yet

- BRM Project FinalDocument45 pagesBRM Project FinalLalit TradaNo ratings yet

- Resume 2Document1 pageResume 2api-491898211No ratings yet

- Reading Comprehension ActivitiesDocument3 pagesReading Comprehension ActivitiesLea May MagnoNo ratings yet

- Dabur India - SWOT Analysis - BrandGuide - MBA Skool-Study - Learn.shareDocument7 pagesDabur India - SWOT Analysis - BrandGuide - MBA Skool-Study - Learn.shareBhavikk KotadiaNo ratings yet

- Science Adventure 2 - Lesson 2Document4 pagesScience Adventure 2 - Lesson 2Alena LetinaNo ratings yet

- What Are Diverticulosis and Diverticulitis?Document8 pagesWhat Are Diverticulosis and Diverticulitis?Zilvia EhrlichNo ratings yet

Illiade-179 Total Fat Content in Food 2019.10.14

Illiade-179 Total Fat Content in Food 2019.10.14

Uploaded by

AnnaRusuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Illiade-179 Total Fat Content in Food 2019.10.14

Illiade-179 Total Fat Content in Food 2019.10.14

Uploaded by

AnnaRusuCopyright:

Available Formats

ILIADe 179:2019 | CLEN Method

Determination of Total Fat Content in Food Products

Version 14 October 2019

Determination of Total Fat Content in Food Products

1. Scope

The value of fat content obtained with this procedure shall be used in the calculation of milk

fat content required for the attribution of Meursing additional code (method described in

Regulation (EC) No. 900/2008,modified by Regulation (EU) No. 2015/824).

This method can be applied for the analysis of food, where oils and fats cannot be extracted

without a previous hydrolysis, except for the case where specific methods apply, such as

milk, butter or cheese.

It has been tested also on nutritional supplements containing skimmed milk together with

egg white powder and thickeners such as carrageenan and xanthan gum. In these cases

results should be carefully regarded, as for “fat content” in this procedure is meant all

substances extractable with this procedure.

2. Principle

The sample is hydrolysed in a hot cup with hydrochloric acid. It is then accurately filtered

together with a filter aid that should retain all the fat. After washing and drying, the residue

is extracted by petroleum ether in a Soxhlet extractor or equivalent system, and weighed.

3. Reagents and materials

3.1. Hydrochloric acid 4 N.

3.2. Filtration system: it is composed of a filter and a filtration aid, an auxiliary material,

which mainly serves in the filtration process to confer porosity and incompressibility of

the solid deposit that accumulates in the filtration medium, aiding the retention of the

fatty matter. The choice of the filters should be done finding the best compromise

between loose of fat and speed of filtration while filtration aid has to be chosen in

order to retain all the fat during filtration and totally release it during Soxhlet

extraction.

Suggestions may be:

• cellulose filters for rapid filtration plus diatomaceous earth treated with sodium

carbonate and calcined, trade name Celite of the type 503 or similar;

• glass fibre membrane filtres plus cellulose (microcrystalline; ca. 0.038 mm);

• glass filter discs filled with quartz sand (40 - 100 mesh) or ca.50 g quartz sand

(0,3-0,9 mm)and ca.5 g Celite type 545.

3.3. Anhydrous Sodium sulphate.

3.4. Petroleum ether (40°C – 60°C), with non-volatile substances less than 0.001 % m/m.

3.5. Cellulose thimbles or glass thimbles or glass tubes.

4. Apparatus

4.1. Analytical balance with precision of 0.1 mg.

4.2. Desiccator provided with a perforated plate for rapid cooling, containing active drying

material.

4.3. Ventilated oven (better if with vapours sucking, to remove ether).

4.4. Hydrolysis dedicated equipment: hydrolysis system or heating mantles/plates

equipped with a reflux system, or another adapted heating system.

4.5. Soxhlet extractor or equivalent extraction system (manual, semi-automatic or

automatic).

5. Procedure

The sample should be finely homogenised in a mortar or through a blender. Weigh in a

250 ml flask or a beaker a quantity of sample not less than 1 g. The ideal is to weigh a sample

quantity as to have a TFC of approximately 1 g (Sample Amount to be weighed = 100 /

percentage of presumed TFC). The limiting factor is, however, the maximum quantity of

sample in order not to have problems of incomplete extraction.

Different procedures can be followed to perform both the acid hydrolysis and Soxhlet or

equivalent extraction. Conditions such as quantity and/or concentration of HCl, temperature

or heating time for hydrolysis, drying duration and temperature, duration and conditions for

extraction and for final drying of extract must be clearly defined in in-house documents and

tested for satisfactory recovery of fat (98%) on certified materials or within the specifications

of the certified reference materials used to check the accuracy of the method.

Procedures indicated in this document are general suggestions.

5.1. Acid hydrolysis

For example, acid hydrolysis can be performed by addition of 4 N HCl normally in a flask or a

beaker at boiling temperature (it can be under reflux or on a hot plate or in a dedicated

equipment), leaving it for at least 30 minutes. Filter through filter system and wash the filter

several times with deionized water until neutral pH of filtrate. Place the filter system to dry

and then introduce it in the extraction thimble together with two strokes of anhydrous

sodium sulphate.

5.2. Soxhlet (or equivalent) extraction

Weigh with precision of 0.0001 g the extraction glass or collection flask (depending on

whether a Soxhlet or equivalent extraction system is used or a manual extraction is

performed) after reaching a stable weight (treating in ventilated oven and cooling in a

desiccator) Place extractor glasses or collection flask and extraction thimbles in the Soxhlet

system and perform the extraction with petroleum ether and final drying of extractor

glass/collection flask with usual procedure, allow to cool in the desiccator at room

temperature and weigh to the nearest 1 mg, provided constant mass was obtained (relative

percentage difference between two subsequent weightings should be ≤ 0.002).

W II − W I

Relative percentage difference % = ⋅ 100

Av

where:

WII = weight of extraction glass or collection flask after half an hour treatment in oven

(in grams)

WI = Previous weight of extraction glass or collection flask (in grams)

Av = average between WII and WI

Blank test should not exceed 0.01 g for manual and 0.005 g for automatic extraction.

6. Calculation

Total fat content in sample, expressed in % m/m, is given by the following formula:

A− B

TFC = ⋅100

C

where:

A = final weight of recipient containing extracted fat (in grams).

B = initial weight of empty recipient (in grams).

C = sample weight (in grams).

7. Expression of results

Results are given with one decimal place (i.e. a maximum of 3 significant digits, with one

decimal).

8. Precision

Nine CLEN inter laboratory tests were carried out between 2002 and 2019, including the

determination of total fat content, with the participation of the EU Customs laboratories.

For products as butter biscuits or chocolate bars, total fat content repeatability (r) and

reproducibility (R):

content range 1.5-50% (m/m): r = 0.7% (m/m) R = 1.5% (m/m)

You might also like

- 4.5.05 AOAC of Fi Cial Method 2003.05 Crude Fat in Feeds, Ce Real Grains, and For AgesDocument2 pages4.5.05 AOAC of Fi Cial Method 2003.05 Crude Fat in Feeds, Ce Real Grains, and For AgesGiuseppe AV100% (2)

- Lab Food Analaysis-FatDocument9 pagesLab Food Analaysis-FatSHAFIKANOR366160% (5)

- Quiz 11-12 IntroDocument2 pagesQuiz 11-12 IntroFelix Echabaudis Espinoza100% (6)

- Aacc 30-10Document2 pagesAacc 30-10Елена СтариноваNo ratings yet

- 991.20 Nitrogeno en LecheDocument2 pages991.20 Nitrogeno en LechedcardonasterNo ratings yet

- Lab Report Exp 2Document12 pagesLab Report Exp 2Syuhada Aminuddin0% (2)

- Intensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALFrom EverandIntensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALRating: 5 out of 5 stars5/5 (1)

- ISO AOACDocument4 pagesISO AOACmidosy1996No ratings yet

- Lab Manual Experiment 5Document11 pagesLab Manual Experiment 5ShafikaNo ratings yet

- AN3460 PDF FeedDocument7 pagesAN3460 PDF Feedabanoub ebaidNo ratings yet

- Method Acid Hydrolysis AnkomDocument2 pagesMethod Acid Hydrolysis AnkomThamrongsak HannarongNo ratings yet

- Mbpracticas LabDocument6 pagesMbpracticas LabRosa VelásquezNo ratings yet

- Crude Fat Determination - Soxhlet Method - 1998Document3 pagesCrude Fat Determination - Soxhlet Method - 1998david_stephens_29No ratings yet

- Aplication Fat Extraction FoodDocument6 pagesAplication Fat Extraction FoodKu BonNo ratings yet

- AN3414 PDF FeedDocument13 pagesAN3414 PDF Feedabanoub ebaidNo ratings yet

- Determination of FatDocument5 pagesDetermination of FatLaksilu Viduraga Peiris100% (1)

- AN3480 CF in Feed PDFDocument6 pagesAN3480 CF in Feed PDFabanoub ebaidNo ratings yet

- Determination of Total Fat and Free Fat ContentDocument13 pagesDetermination of Total Fat and Free Fat ContentCesar Augusto Torres LinaresNo ratings yet

- Experiment 8 Determination of Total Fat in Foods by Rose Gottleib MethodDocument3 pagesExperiment 8 Determination of Total Fat in Foods by Rose Gottleib MethodRadwan AjoNo ratings yet

- AN0320 General S&H8000 PDFDocument7 pagesAN0320 General S&H8000 PDFabanoub ebaidNo ratings yet

- Dairy Techmology CentrifugationDocument11 pagesDairy Techmology CentrifugationM Umer SaeedNo ratings yet

- Lab 8 Ash Fat and Protein Addendum - 2018-5Document14 pagesLab 8 Ash Fat and Protein Addendum - 2018-5najwa0% (1)

- 34) Extraction of Bitumen From Paving MixturesDocument6 pages34) Extraction of Bitumen From Paving MixturesPn EkanayakaNo ratings yet

- Mlvss & Mlss Is-3025 - 18Document2 pagesMlvss & Mlss Is-3025 - 18Anuraj20No ratings yet

- SOP AMBL 105A TotalSolidsDocument5 pagesSOP AMBL 105A TotalSolidsWijianto WijiantoNo ratings yet

- Clarifying and Bacteria Removal Separators enDocument40 pagesClarifying and Bacteria Removal Separators enPiperea F. Bogdan100% (1)

- Fat AnalysisDocument11 pagesFat AnalysisSooraj NairNo ratings yet

- Crude Fat Determination - Soxhlet Method - 1998 PDFDocument3 pagesCrude Fat Determination - Soxhlet Method - 1998 PDFRosa EsparzaNo ratings yet

- M. Mujeeb Ullah, Nutr-401 PracticalDocument16 pagesM. Mujeeb Ullah, Nutr-401 PracticalAli RazaNo ratings yet

- Fat Determination SoxhletDocument9 pagesFat Determination SoxhletwanizalilNo ratings yet

- Physical and Chemical Methods of Testing Waste Water - Is 3025 - Part 15Document2 pagesPhysical and Chemical Methods of Testing Waste Water - Is 3025 - Part 15madhuwadiNo ratings yet

- Is-3025-Part-15-1984-Tests of Water For Total Residue (Total Solids - Dissolved and Suspended)Document2 pagesIs-3025-Part-15-1984-Tests of Water For Total Residue (Total Solids - Dissolved and Suspended)Sachin PawarNo ratings yet

- Theoretical Framework FatsDocument5 pagesTheoretical Framework FatsScribdTranslationsNo ratings yet

- 4534-Exp 1 Fat Oil by Soxhlet ExtractionDocument7 pages4534-Exp 1 Fat Oil by Soxhlet ExtractionAhmed AliNo ratings yet

- Soxhlet Extraction Method 1Document12 pagesSoxhlet Extraction Method 1Ziauddeen NoorNo ratings yet

- AN0305-Soxtec™ 8000Document6 pagesAN0305-Soxtec™ 8000abanoub ebaidNo ratings yet

- EXTRACTIVESDocument7 pagesEXTRACTIVESBryan Roncal LlajarunaNo ratings yet

- Lab - ManualDocument9 pagesLab - ManualLuna DanNo ratings yet

- Raw Milk Processing Presented in ClassDocument56 pagesRaw Milk Processing Presented in Classihovka3No ratings yet

- CHA 393 Sec 1 ReadyDocument14 pagesCHA 393 Sec 1 Readymajoxa9560No ratings yet

- Oils and FatsDocument110 pagesOils and FatsPurely Opaspong100% (1)

- PGDBST 03Document61 pagesPGDBST 03UJJWAL RAJ SINGHNo ratings yet

- Fat TotalDocument15 pagesFat TotalFathy MehayaNo ratings yet

- Total Solid Content Convection Oven ProcedureDocument2 pagesTotal Solid Content Convection Oven ProcedureashNo ratings yet

- Fiber 01Document4 pagesFiber 01Kim-Kim TorresNo ratings yet

- Universiti Kuala Lumpur Malaysian Institute of Chemical & Bioengineering TechnologyDocument7 pagesUniversiti Kuala Lumpur Malaysian Institute of Chemical & Bioengineering TechnologyMahainiIm RuzailyNo ratings yet

- Method 1.0 Sample Preparation Effective 1 January 2021Document5 pagesMethod 1.0 Sample Preparation Effective 1 January 2021oubaha happyNo ratings yet

- Cho 393 Sem ReadyDocument11 pagesCho 393 Sem Readypapey42271No ratings yet

- Practical Manual - Processing of Spices and Plantation CropsDocument26 pagesPractical Manual - Processing of Spices and Plantation CropsDhaya VNo ratings yet

- AOCS Official Method Ca 3d Sedimentos en AceiteDocument4 pagesAOCS Official Method Ca 3d Sedimentos en AceiteCarla Sánchez GallardoNo ratings yet

- Determination of FatDocument6 pagesDetermination of FatnajwaNo ratings yet

- Total Solid in MilkDocument3 pagesTotal Solid in Milkediasianagri100% (1)

- Quality of Ingredient and ProductsDocument36 pagesQuality of Ingredient and Productssudesha t rNo ratings yet

- Anaysis of MilkDocument14 pagesAnaysis of MilkSaman AkramNo ratings yet

- SoxhletExtraction PDFDocument7 pagesSoxhletExtraction PDFJim VelNo ratings yet

- FST306 Laboratory Report 2Document8 pagesFST306 Laboratory Report 2Nisa AzamNo ratings yet

- Determination of Moisture in FoodsDocument9 pagesDetermination of Moisture in Foodsagdwiyanti100% (1)

- Producing Cream on the Dairy Farm - A Collection of Articles on the Methods, Science and Equipment Used in Cream ProductionFrom EverandProducing Cream on the Dairy Farm - A Collection of Articles on the Methods, Science and Equipment Used in Cream ProductionNo ratings yet

- Microstructure of Dairy ProductsFrom EverandMicrostructure of Dairy ProductsMamdouh El-BakryNo ratings yet

- 2-5-1 English Language and LeteratureDocument7 pages2-5-1 English Language and LeteratureJitesh DuaNo ratings yet

- Anglais 23leçonsDocument24 pagesAnglais 23leçonsJérôme100% (2)

- Skill Development BrochureDocument2 pagesSkill Development BrochureJaimon C UthupNo ratings yet

- Unit 4 Plant and Inorganic NutrientsDocument29 pagesUnit 4 Plant and Inorganic NutrientsDita PerdanaNo ratings yet

- Antimicrobial Interventions For BeefDocument16 pagesAntimicrobial Interventions For BeefFrankPapa100% (1)

- Mosaic Uk 2009 Brochure Jun10Document24 pagesMosaic Uk 2009 Brochure Jun10stooge1983No ratings yet

- INSTITUTO CAMBRIDGE de Cultura Inglesa - Noviembre-Diciembre 2021Document3 pagesINSTITUTO CAMBRIDGE de Cultura Inglesa - Noviembre-Diciembre 2021LUCIA JESUS OJEDA CARCAMONo ratings yet

- Grammar Unit 7 1 Complete The Sentences With The Correct Form of The Verbs in BracketsDocument6 pagesGrammar Unit 7 1 Complete The Sentences With The Correct Form of The Verbs in BracketsCristina GarciaNo ratings yet

- Fridge - Freezer Instruction Book: Instructions For Use 3Document14 pagesFridge - Freezer Instruction Book: Instructions For Use 3nazimaghabayovNo ratings yet

- ProPoints TakeawayDocument10 pagesProPoints TakeawaychloeNo ratings yet

- Unit 3 - Do You Like NoodlesDocument154 pagesUnit 3 - Do You Like NoodlesHoàng Khắc HuyNo ratings yet

- Dokumen 1Document12 pagesDokumen 1Wulani HaryonoNo ratings yet

- Marc Maron On Whole Foods - From Attempting Normal by Marc MaronDocument7 pagesMarc Maron On Whole Foods - From Attempting Normal by Marc MaronRandom House Publishing Group100% (2)

- Third English ManualDocument102 pagesThird English ManualBelem LGNo ratings yet

- Irctcs E Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E Ticketing Service Electronic Reservation Slip (Personal User)puru42No ratings yet

- Pressure Cookers USP Cards - Eng - v5 PDFDocument20 pagesPressure Cookers USP Cards - Eng - v5 PDFJeffNo ratings yet

- Anglais CM1/CM2 1Document19 pagesAnglais CM1/CM2 1Bachir SaharaNo ratings yet

- StoichiometryDocument54 pagesStoichiometryRaymark AdoptanteNo ratings yet

- FODMAPDocument4 pagesFODMAParcp49No ratings yet

- B1-C1 Scattergories GameDocument11 pagesB1-C1 Scattergories GameSena baltaoğluNo ratings yet

- Duivenboekje 44pg Eng LR PDFDocument44 pagesDuivenboekje 44pg Eng LR PDFJega Alin100% (1)

- F-2013152 R-102 Product Overview A4Document2 pagesF-2013152 R-102 Product Overview A4Salalah Fire Safety Technical Services CompanyNo ratings yet

- Bitter: Vocabulary Unit 12 Vocabulary Transcript English VietnameseDocument4 pagesBitter: Vocabulary Unit 12 Vocabulary Transcript English VietnamesePan PerterNo ratings yet

- BRM Project FinalDocument45 pagesBRM Project FinalLalit TradaNo ratings yet

- Resume 2Document1 pageResume 2api-491898211No ratings yet

- Reading Comprehension ActivitiesDocument3 pagesReading Comprehension ActivitiesLea May MagnoNo ratings yet

- Dabur India - SWOT Analysis - BrandGuide - MBA Skool-Study - Learn.shareDocument7 pagesDabur India - SWOT Analysis - BrandGuide - MBA Skool-Study - Learn.shareBhavikk KotadiaNo ratings yet

- Science Adventure 2 - Lesson 2Document4 pagesScience Adventure 2 - Lesson 2Alena LetinaNo ratings yet

- What Are Diverticulosis and Diverticulitis?Document8 pagesWhat Are Diverticulosis and Diverticulitis?Zilvia EhrlichNo ratings yet