Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mech

Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mech

Uploaded by

nisha_khanCopyright:

Available Formats

You might also like

- Skywatch 497 Trc497 Sky497 Installation ManualDocument112 pagesSkywatch 497 Trc497 Sky497 Installation ManualEric Dirksen100% (4)

- Lab 12Document13 pagesLab 12Brian PaciaNo ratings yet

- Saudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 MechDocument7 pagesSaudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Operation and Maintenance Manual Shoptek ST45, ST55 & ST75 Rev 01Document76 pagesOperation and Maintenance Manual Shoptek ST45, ST55 & ST75 Rev 01Andres Paul (paultgt)67% (3)

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- Saic-A-2006 Rev 62Document5 pagesSaic-A-2006 Rev 62pradeepthalava97No ratings yet

- SAIC-D-2020 Tank Trim Installation MAS-rlcDocument3 pagesSAIC-D-2020 Tank Trim Installation MAS-rlcAnonymous S9qBDVkyNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- SAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFDocument2 pagesSAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- Saic S 4058Document6 pagesSaic S 4058Engr IrfanNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saic B 2014Document4 pagesSaic B 2014usmanNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldAbdul Khaleem KhanNo ratings yet

- SAIC-L-2015 Rev 7Document7 pagesSAIC-L-2015 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saic F 2008Document4 pagesSaic F 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Intrinsically Safe Circuit - Circuit Final Inspection SAIC-J-6906 24-Jul-18 InstDocument3 pagesSaudi Aramco Inspection Checklist: Intrinsically Safe Circuit - Circuit Final Inspection SAIC-J-6906 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechjunaidNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saic A 1013Document2 pagesSaic A 1013karthi51289No ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- SAIC-A-2026 Rev 6 Pre Test API TankDocument6 pagesSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNo ratings yet

- Saic A 1013Document2 pagesSaic A 1013Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Aerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftFrom EverandAerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- CamScanner 10-13-2021 23.17Document2 pagesCamScanner 10-13-2021 23.17nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khan100% (1)

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Tabal of ContantDocument11 pagesTabal of ContantAlhussain EmbarkNo ratings yet

- Tool Shop CatDocument405 pagesTool Shop Catmuhammad arifNo ratings yet

- Barracuda 7200.9: Core Capacities, Interfaces and Cache Options For Entry-Level and Mainstream ApplicationsDocument2 pagesBarracuda 7200.9: Core Capacities, Interfaces and Cache Options For Entry-Level and Mainstream ApplicationsFrancisco Lopez MoyaNo ratings yet

- Generations of ComputerDocument7 pagesGenerations of Computerlearn2 tamilNo ratings yet

- Watch Wireless Calling Receiver User ManualDocument12 pagesWatch Wireless Calling Receiver User ManualCata GodoyNo ratings yet

- Technical Data Book: Apollo Tyres Truck and BusDocument28 pagesTechnical Data Book: Apollo Tyres Truck and BusPrasannaNo ratings yet

- Everlight Electronics Co., LTD.: Device Number: DHI-092-003 Rev: 1.0 Model No: HI400 Ecn: 1/6Document6 pagesEverlight Electronics Co., LTD.: Device Number: DHI-092-003 Rev: 1.0 Model No: HI400 Ecn: 1/6ihsanjuNo ratings yet

- 16-Quincy QSi 335i 370i 440i 500i Direct Drive Compressor ManualDocument88 pages16-Quincy QSi 335i 370i 440i 500i Direct Drive Compressor Manualrogelio delgadoNo ratings yet

- CASE 580 Super M+Document6 pagesCASE 580 Super M+Dian SikumbangNo ratings yet

- 6 Speed Dual Clutch Gearbox 0DD Hybrid EngDocument103 pages6 Speed Dual Clutch Gearbox 0DD Hybrid EngLakhdar BouchenakNo ratings yet

- Lift OtisDocument43 pagesLift OtisrecomendNo ratings yet

- Users Manual 2975685Document36 pagesUsers Manual 2975685Facundo LedesmaNo ratings yet

- ZsiDocument7 pagesZsimuralimallikaNo ratings yet

- NCEP4090GUDocument6 pagesNCEP4090GUMar GaoNo ratings yet

- Steals & Deals Central Edition 7-23-20Document12 pagesSteals & Deals Central Edition 7-23-20Roger WaynickNo ratings yet

- Squarell Installation Instructions - Light Commercial Vehicles - 201228Document114 pagesSquarell Installation Instructions - Light Commercial Vehicles - 201228andreaviligiardiNo ratings yet

- DB FIT USB Fast Installation TesterDocument2 pagesDB FIT USB Fast Installation Testerpaolo.defalcoNo ratings yet

- Commissioning Procedures WIDocument10 pagesCommissioning Procedures WITara WilcoxNo ratings yet

- 02 U-Cups 2012 1-62Document62 pages02 U-Cups 2012 1-62RPINILLA (EICO S.A.)No ratings yet

- 25MM Pneumatic Sniper RifleDocument22 pages25MM Pneumatic Sniper Riflegopinath16100% (2)

- SnowBear Personal Snowplow 2008 Owner's Manual (English and French)Document45 pagesSnowBear Personal Snowplow 2008 Owner's Manual (English and French)Tom SenbergNo ratings yet

- Photometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15Document1 pagePhotometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15emreNo ratings yet

- 7.air Check 6HP19Document4 pages7.air Check 6HP19sakaxunuNo ratings yet

- VW Passat b8 Component Locations EngDocument376 pagesVW Passat b8 Component Locations EngAndris Priedītis100% (1)

- X-Series: Installation Information Emg Model: B118 Active Balance Control / Abc-X (Active Pickup Input Only)Document4 pagesX-Series: Installation Information Emg Model: B118 Active Balance Control / Abc-X (Active Pickup Input Only)roberto gherloneNo ratings yet

- R20ut3599ej3100 rfpv3 ListDocument12 pagesR20ut3599ej3100 rfpv3 ListIkram BalochNo ratings yet

- Unimix CDocument8 pagesUnimix CCatalin NeacsuNo ratings yet

Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mech

Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mech

Uploaded by

nisha_khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mech

Saudi Aramco Inspection Checklist: Relief Valve Installation SAIC-J-2009 24-Jul-18 Mech

Uploaded by

nisha_khanCopyright:

Available Formats

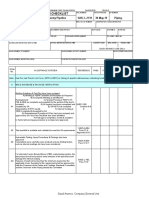

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Relief Valve Installation SAIC-J-2009 24-Jul-18 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General requirements for Installation:

The following requirements are in addition to those of the ASME SEC I,

ASME SEC VIII,and API STD 520 Part II.:

A) Atmospheric Relief

B) Closed System Relief

C) Open Funnel Relief

SAES-J-600

A1 D) Block Valves

Section 9

E) Changeover Valves

F) Access

G) Relief Valve Piping

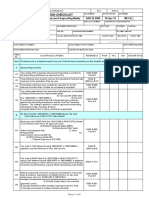

B Specific Requirements for installation

Identified that Relief valve number, data and design conforms to the SAEP-319 Para

B1

description provided on releif valve registration. 1.1

RVs Inlet & outlet piping mating flange alignment is within tolerance:

a) Rotation of flanges,

measured as the offset between elevations of bolt holes on opposite sides SAES-L-350

B2

of a flange centerline, shall not exceed ± 2.4 mm. Para 9.4

b) The tilt of a flange measured at the periphery across any diameter shall

not exceed 1.6 mm from the square position.

Verifies that installed RVs are sealed, in the correct location as per current

verified P&ID, correctly painted and properly piped to a safe location per

SAES-J-600.

a) Approved construction

drawings/ P & ID.

b) SAEP-319 Para

B3

Identification numer stamped on the mating Flange. 5.12

c) Field RV number Tag attached to connecting piping.

d) Die Stamps on the mounting flange for Rupture

Disk/Pins.

Verifies that RV bonnets are vented to a safe location, per SAES-J-600, SAEP-319

B4

and painted green for bellows type RVs, per SAES-B-067. Para 5.12.8

Steam Relief RV installation :

a) RV for steam boilers (open bonnet type) in Section I bears

SAES-J-600

ASME Code "V" stamp

para 4.1.1.2

B5 b) RVs in boiler steam service have initial pop

SAEP-319 Para

pressure set in shop. Final pop pressure

7.6

& blow down setting are made using live steam

Complete RV pressure test report (Appendix M SAEP-319) after final

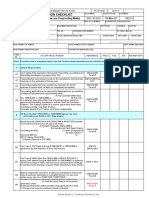

test.

Vacuum relief Rv installation :

a) Tank designed to API 650 STD, RVs installed are Pilot

SAES-J-600

B6 operated or weighted pallet Type.

Para 8.11

b) Tank designed to API 620 STD, RVs

installed are Pilot operated Type, connecting flanges are ASME B 16.5

class 150 flat face type.

Saudi Aramco: Company General Use

Pilot Type Rv installation :

a) A pilot filter is provided.

SAES-J-600

B7 b) A clean gas purge provided on pilot line (For dirty, Para 5.5

corrosive or sour service) or over sized pilot line (3/4" or larger) provided Para 9.4

up to pilot filter.

c) Block Valves are installed on pilot sense lines and are painted orange

colour.

Rupture Disc RV installation:

a) Bears ASME Code Stamp "UD".

b) Approval available for use of Rupture Discs as substitute for RV SAES-J-600

from CSD Supv, Instrument. Unit/ Process & Control System Dept. Para 4.1.1.5

B8 c) Rupture disk is installed in correct location Para 5.6.3

verify the Disk number die stamped on the mounting flange. SAEP-319 Para

d) Pressure gauge is installed between in line RV 7.10.3

and Rupture disk.

e) Isolation valve installed

between the pressure gauge & the area monitored (Area between rupture

disc & RV) is LOCKED OPEN.

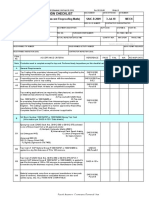

REMARKS:

ATTACHMENTS:

REFERENCE DOCUMENTS:

1. SAES-J-600 -- Pressure Relief Devices, 1 January 2018

2. SAEP-319 -- Pressure Relief Valves - Routine Test, Inspection, Quality Assurance and Regulation, 2 July 2017

3. SAES-L-350 -- Construction of plant Piping,30 January 2018

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Skywatch 497 Trc497 Sky497 Installation ManualDocument112 pagesSkywatch 497 Trc497 Sky497 Installation ManualEric Dirksen100% (4)

- Lab 12Document13 pagesLab 12Brian PaciaNo ratings yet

- Saudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 MechDocument7 pagesSaudi Aramco Inspection Checklist: Relief Valve Testing & Calibration SAIC-J-2008 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Operation and Maintenance Manual Shoptek ST45, ST55 & ST75 Rev 01Document76 pagesOperation and Maintenance Manual Shoptek ST45, ST55 & ST75 Rev 01Andres Paul (paultgt)67% (3)

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- Saic-A-2006 Rev 62Document5 pagesSaic-A-2006 Rev 62pradeepthalava97No ratings yet

- SAIC-D-2020 Tank Trim Installation MAS-rlcDocument3 pagesSAIC-D-2020 Tank Trim Installation MAS-rlcAnonymous S9qBDVkyNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- SAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFDocument2 pagesSAIC-K-2026 Suction Disch Piping Instal-SXS-RLC-f PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- Saic S 4058Document6 pagesSaic S 4058Engr IrfanNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saic B 2014Document4 pagesSaic B 2014usmanNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldAbdul Khaleem KhanNo ratings yet

- SAIC-L-2015 Rev 7Document7 pagesSAIC-L-2015 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saic F 2008Document4 pagesSaic F 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Intrinsically Safe Circuit - Circuit Final Inspection SAIC-J-6906 24-Jul-18 InstDocument3 pagesSaudi Aramco Inspection Checklist: Intrinsically Safe Circuit - Circuit Final Inspection SAIC-J-6906 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechjunaidNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saic A 1013Document2 pagesSaic A 1013karthi51289No ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- SAIC-A-2026 Rev 6 Pre Test API TankDocument6 pagesSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNo ratings yet

- Saic A 1013Document2 pagesSaic A 1013Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Aerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftFrom EverandAerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- CamScanner 10-13-2021 23.17Document2 pagesCamScanner 10-13-2021 23.17nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khan100% (1)

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Tabal of ContantDocument11 pagesTabal of ContantAlhussain EmbarkNo ratings yet

- Tool Shop CatDocument405 pagesTool Shop Catmuhammad arifNo ratings yet

- Barracuda 7200.9: Core Capacities, Interfaces and Cache Options For Entry-Level and Mainstream ApplicationsDocument2 pagesBarracuda 7200.9: Core Capacities, Interfaces and Cache Options For Entry-Level and Mainstream ApplicationsFrancisco Lopez MoyaNo ratings yet

- Generations of ComputerDocument7 pagesGenerations of Computerlearn2 tamilNo ratings yet

- Watch Wireless Calling Receiver User ManualDocument12 pagesWatch Wireless Calling Receiver User ManualCata GodoyNo ratings yet

- Technical Data Book: Apollo Tyres Truck and BusDocument28 pagesTechnical Data Book: Apollo Tyres Truck and BusPrasannaNo ratings yet

- Everlight Electronics Co., LTD.: Device Number: DHI-092-003 Rev: 1.0 Model No: HI400 Ecn: 1/6Document6 pagesEverlight Electronics Co., LTD.: Device Number: DHI-092-003 Rev: 1.0 Model No: HI400 Ecn: 1/6ihsanjuNo ratings yet

- 16-Quincy QSi 335i 370i 440i 500i Direct Drive Compressor ManualDocument88 pages16-Quincy QSi 335i 370i 440i 500i Direct Drive Compressor Manualrogelio delgadoNo ratings yet

- CASE 580 Super M+Document6 pagesCASE 580 Super M+Dian SikumbangNo ratings yet

- 6 Speed Dual Clutch Gearbox 0DD Hybrid EngDocument103 pages6 Speed Dual Clutch Gearbox 0DD Hybrid EngLakhdar BouchenakNo ratings yet

- Lift OtisDocument43 pagesLift OtisrecomendNo ratings yet

- Users Manual 2975685Document36 pagesUsers Manual 2975685Facundo LedesmaNo ratings yet

- ZsiDocument7 pagesZsimuralimallikaNo ratings yet

- NCEP4090GUDocument6 pagesNCEP4090GUMar GaoNo ratings yet

- Steals & Deals Central Edition 7-23-20Document12 pagesSteals & Deals Central Edition 7-23-20Roger WaynickNo ratings yet

- Squarell Installation Instructions - Light Commercial Vehicles - 201228Document114 pagesSquarell Installation Instructions - Light Commercial Vehicles - 201228andreaviligiardiNo ratings yet

- DB FIT USB Fast Installation TesterDocument2 pagesDB FIT USB Fast Installation Testerpaolo.defalcoNo ratings yet

- Commissioning Procedures WIDocument10 pagesCommissioning Procedures WITara WilcoxNo ratings yet

- 02 U-Cups 2012 1-62Document62 pages02 U-Cups 2012 1-62RPINILLA (EICO S.A.)No ratings yet

- 25MM Pneumatic Sniper RifleDocument22 pages25MM Pneumatic Sniper Riflegopinath16100% (2)

- SnowBear Personal Snowplow 2008 Owner's Manual (English and French)Document45 pagesSnowBear Personal Snowplow 2008 Owner's Manual (English and French)Tom SenbergNo ratings yet

- Photometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15Document1 pagePhotometric Standard Compliance: SEGS48P20K - 15, SEGS23P20K - 15emreNo ratings yet

- 7.air Check 6HP19Document4 pages7.air Check 6HP19sakaxunuNo ratings yet

- VW Passat b8 Component Locations EngDocument376 pagesVW Passat b8 Component Locations EngAndris Priedītis100% (1)

- X-Series: Installation Information Emg Model: B118 Active Balance Control / Abc-X (Active Pickup Input Only)Document4 pagesX-Series: Installation Information Emg Model: B118 Active Balance Control / Abc-X (Active Pickup Input Only)roberto gherloneNo ratings yet

- R20ut3599ej3100 rfpv3 ListDocument12 pagesR20ut3599ej3100 rfpv3 ListIkram BalochNo ratings yet

- Unimix CDocument8 pagesUnimix CCatalin NeacsuNo ratings yet