Professional Documents

Culture Documents

JSV C500 Metal Gate Solid Wedge 8pg 01122020 7 MSGV Specification

JSV C500 Metal Gate Solid Wedge 8pg 01122020 7 MSGV Specification

Uploaded by

Rhandell DionisioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSV C500 Metal Gate Solid Wedge 8pg 01122020 7 MSGV Specification

JSV C500 Metal Gate Solid Wedge 8pg 01122020 7 MSGV Specification

Uploaded by

Rhandell DionisioCopyright:

Available Formats

AWWA C500 METAL SEATED IRON BODY

BRONZE MOUNTED SOLID WEDGE GATE VALVE

1. SCOPE 5. MATERIALS

1.01 This specification covers design, manufacture, and testing 5.01 Valve body, bonnet, wedge and 2-inch operating nut or

of 3-inch through 108-inch, Metal Seated Gate Valves, handwheel shall be ductile iron ASTM-A536 65-45-12.

suit-able for water or wastewater service as set forth in 5.02 Valves shall have bronze seat rings.

the American Water Works (AWWA) C500 Standard, most 5.03 Valves shall have Garlock fiber braded Teflon impregnated,

recent published version. or equal, non-asbestos packing or o-rings.

5.04 Valve stuffing box glands shall be bronze; gland followers

shall be ductile iron.

2. STANDARDS 5.05 Valve stem shall be Series 300 Stainless Steel

2.01 Valves 3-inch through 12-inch minimum cold-water 5.06 Valve body and bonnet bolting shall be Series 300 Stainless

working pressure of 200psig; 14-inch through 72-inch Steel, unless otherwise specified.

minimum cold-water working pressure of 150psig. Valves 5.07 Valves, 16-inch and larger, shall have tongue-and-groove

larger than 72-inch cold-water pressure rating on guides constructed of Series 300 Stainless Steel.

application and as agreed between the manufacture and 5.08 Valves, 16-inch and larger, shall have rollers and tracks

customer. Valves larger than 72-inch, where applicable, constructed of Series 300 Stainless Steel.

shall be manufactured in compliance with AWWA C500. 5.09 Valves, 16-inch and larger, shall have bronze

2.02 Valves shall be NSF 61 and NSF 372 Certified for use in self-adjusting scrapers.

drinking water applications. 5.10 Valve, by-pass valves:

2.03 Valves shall be tested in accordance with Testing Section A. Shall be non-rising stem or OS&Y gate valves,

5.1 of the AWWA C500. as specified.

B. Shall comply fully with AWWA C509, C515, or C500

3. CONNECTIONS C. Shall open counterclockwise, unless otherwise specified.

3.01 Valve end-connections shall be: D. Shall have 2-inch operating nut or handwheel,

A. Flange end-connections comply with ANSI B16.1, Class as specified.

125, rated for 250psig, or ANSI B16.42, Class 250 rated

for 350psig. for ductile iron. 6. COATINGS

B. Mechanical Joint - ANSI/AWWA C110/A21.10, ANSI/ 6.01 Valve internal and external coatings shall be NSF-61

AWWA C111/A21.11, or ANSI/AWWA C153/21.53. Certified, 2-Part Thermal Setting Epoxy Paint.

C153/21.53. 6.02 Valve internal and external coatings shall be in accordance

with AWWA C550.

4. DESIGN

4.01 Valves shall be non-rising stem (NRS) or outside screw 7. MANUAL GEARING

and yoke (OS&Y) configurations, as specified. 7.01 Valves 18-inch and larger shall have bevel gearing or spur

4.02 Valve shall have full nominal port diameter; reduced port gearing depending on the application requirements.

not acceptable. Bevel Gears or Spur Gears can be adapted to any size

4.03 Valve shall have a full-port, unobstructed, water way valve upon request.

when in the full-open position. 7.02 Valve gear case fully enclosed, unless otherwise specified

4.04 Valves shall have bronze seating rings, machined and

scraped, if necessary, to seat truly flat against body and

wedge seat rings. 8. OPTIONS

4.05 Valves OS&Y shall have multiple rings of packing and a 8.01 Extension Stems.

stuffing box. 8.02 Position Indicators.

4.06 Valve shall permit repacking under line pressure. 8.03 Valve Boxes.

4.07 Valve stem shall have one-piece, integral thrust collar. 8.04 Indicator Posts.

Valve stems shall rotate freely in the valve bonnet recess 8.05 Electric Motor Operators.

4.08 Valve direction of open shall be counterclockwise; unless 8.06 Limit Switches.

otherwise specified.

4.09 Valve 2-inch operating nut or handwheel shall have cast

the word “OPEN” and an arrow indicating the direction 9. MANUFACTURER

to open. 9.01 Valves shall be hydrostatically seat tested and shell tested

4.10 Valves 16-inch and larger shall be provided with per AWWA C500 to show structural integrity. When

tongue- and-groove guides. The guides shall be on both requested, the manufacturer shall provide test certificates,

sides of the wedge and in the body to keep the wedge dimensional drawings, parts list drawings, and operation

centered between the seats throughout its length and maintenance manuals.

of travel. 9.02 Metal Seated Solid Wedge Gate Valve Series 3000

4.11 Valves 16-inch and larger shall have rollers, tracks, and manufactured by J&S Valve, Inc. Huffman, TX, USA or

a self-adjusting scrapers on both sides allowing valves to preapproved equal. (10062019 jb sb rl)

be installed in the vertical or horizontal position. Tracks

shall be U-shaped stainless steel to cover the entire side

surface of the body to prevent any build-up and foreign

matter in the valve body.

4.12 Valves 16-inch and larger shall be supplied with a by-pass

valve, when specified.

4.13 Valves, 30-inch and larger, shall be 3-piece body design;

bonnet, body spacer, body.

4.14 Valve castings shall be marked with the requirements of

AWWA C500 and MSS-SP25.

JANDSVALVE.COM 6

You might also like

- Sebm032405 - PC27 30 35 40 50MR 2Document618 pagesSebm032405 - PC27 30 35 40 50MR 2Зуфар Гатауллин100% (4)

- WA380-6 S/N H60051 - UpDocument1,489 pagesWA380-6 S/N H60051 - UpRAMON TEIXIDOR100% (1)

- Section 05110 - Butterfly ValvesDocument6 pagesSection 05110 - Butterfly Valvesse781No ratings yet

- BUTTERFLY VALVES. An Industry Leader in Underground and In-Plant Applications. STYLE 4500 3 24 STYLE 1450 30 54. Consult Factory For Sizes 60 120Document10 pagesBUTTERFLY VALVES. An Industry Leader in Underground and In-Plant Applications. STYLE 4500 3 24 STYLE 1450 30 54. Consult Factory For Sizes 60 120Tarik JazoulNo ratings yet

- 2500 Valve BrochureDocument12 pages2500 Valve BrochureJurie_sk3608No ratings yet

- Val-Matic Rubber-Seated Ball Valve: Operation, Maintenance and Installation ManualDocument12 pagesVal-Matic Rubber-Seated Ball Valve: Operation, Maintenance and Installation ManualDhim131267No ratings yet

- Material Specification For FLANGED RUBBER SEATED BUTTERFLY VALVESDocument4 pagesMaterial Specification For FLANGED RUBBER SEATED BUTTERFLY VALVESMASOUDNo ratings yet

- Bonetti WBY CatalogueDocument16 pagesBonetti WBY CatalogueisluqueNo ratings yet

- Milliken AWWA Swing Check ValveDocument8 pagesMilliken AWWA Swing Check ValveDiego Fernando PerdomoNo ratings yet

- Resilient Seated Gate and Tapping Valves Oct 08Document10 pagesResilient Seated Gate and Tapping Valves Oct 08arsiajanNo ratings yet

- AWWA Metal Seated Ball Valve: Part 1 - GeneralDocument3 pagesAWWA Metal Seated Ball Valve: Part 1 - Generalchannu rolliNo ratings yet

- PRV Specs PDFDocument2 pagesPRV Specs PDFslpaul25_142058724No ratings yet

- American ValveDocument12 pagesAmerican Valveviller_lpNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Series 44 Ball Valves: Worcester ControlsDocument8 pagesSeries 44 Ball Valves: Worcester ControlsRubenn54No ratings yet

- 08 - SpeckDocument5 pages08 - SpeckSezer CetinNo ratings yet

- AC 100 ValvesDocument4 pagesAC 100 Valvesjames_chan2178No ratings yet

- Valves For Steam ServiceDocument17 pagesValves For Steam ServiceqaiserNo ratings yet

- Technical Notes For Gate & Globe Valves General: MaterialDocument6 pagesTechnical Notes For Gate & Globe Valves General: Materialashish.mathur1No ratings yet

- Basic Type of Valves PDFDocument2 pagesBasic Type of Valves PDFMohamed MustafaNo ratings yet

- Gate, Globe and Check Valves: A B C D E F G - F 1 0 - 0 0 6 4 C - 0 2 T YDocument9 pagesGate, Globe and Check Valves: A B C D E F G - F 1 0 - 0 0 6 4 C - 0 2 T Yrawatbs2020No ratings yet

- Project Standard Specification: Valves Page 1/8Document8 pagesProject Standard Specification: Valves Page 1/8adel rihanaNo ratings yet

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- Specification For Acmv ValvesDocument5 pagesSpecification For Acmv ValvescashloverNo ratings yet

- 609 Awwa C504-MR - Rev00 (9-Feb-18)Document51 pages609 Awwa C504-MR - Rev00 (9-Feb-18)Muhammad Ridwan100% (1)

- 220523-General-Duty Valves For Plumbing PipingDocument9 pages220523-General-Duty Valves For Plumbing PipingAttef BedaweNo ratings yet

- GWC Cast SteelDocument32 pagesGWC Cast SteelApresia KiranaNo ratings yet

- Project Standard Specification: Valves 15100 - Page 1/7Document7 pagesProject Standard Specification: Valves 15100 - Page 1/7adel rihanaNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Chapter 5Document18 pagesChapter 5arsiajanNo ratings yet

- VOLK Valves API 6D CatalogDocument20 pagesVOLK Valves API 6D CatalogJuan PabloNo ratings yet

- ValvesDocument6 pagesValvesstevegazeleyNo ratings yet

- Standard Technical Specification-Bfv (SS) PDFDocument5 pagesStandard Technical Specification-Bfv (SS) PDFpl_arunachalam79No ratings yet

- Standard Technical Specification-Bfv (SS) PDFDocument5 pagesStandard Technical Specification-Bfv (SS) PDFpl_arunachalam79No ratings yet

- Metraflex Valves SpecDocument2 pagesMetraflex Valves SpecCARLOSNo ratings yet

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonNo ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- ValvesDocument11 pagesValvesAdamNo ratings yet

- 2sc-Pco - Dual Solenoid Control ValveDocument3 pages2sc-Pco - Dual Solenoid Control Valveshan07011984No ratings yet

- Flow Control Worcester ControlsDocument8 pagesFlow Control Worcester Controlsviller_lpNo ratings yet

- CVC Steel FullDocument28 pagesCVC Steel FullSergio Bacca SantiagoNo ratings yet

- The Royal Atlantis WSP Usa IBI Project No 38188 IFC - 22 March 2017Document7 pagesThe Royal Atlantis WSP Usa IBI Project No 38188 IFC - 22 March 2017MY PCNo ratings yet

- Literature For Blow-Off ValveDocument16 pagesLiterature For Blow-Off Valvevon18100% (1)

- GWC Valve International Cast Steel ValvesDocument32 pagesGWC Valve International Cast Steel ValvesGWC Valve International100% (1)

- Valves NotesDocument34 pagesValves Notestramperoargentina100% (1)

- A2361 Resilient Wedge Gate VALVES, 350psi: Product SpecificationsDocument3 pagesA2361 Resilient Wedge Gate VALVES, 350psi: Product SpecificationsAli OsmanNo ratings yet

- Underground Chilled Water System August 132014Document12 pagesUnderground Chilled Water System August 132014umair186No ratings yet

- Types of Ball Valves (Floating, Trunnion)Document11 pagesTypes of Ball Valves (Floating, Trunnion)swapnil PATILNo ratings yet

- Types of Ball Valves (Floating, Trunnion)Document11 pagesTypes of Ball Valves (Floating, Trunnion)swapnil PATIL100% (1)

- Double Block Valves (Orion)Document8 pagesDouble Block Valves (Orion)marcoo8No ratings yet

- Aquestia OCV TERMINALDocument12 pagesAquestia OCV TERMINALSony Nd AshaNo ratings yet

- CVS Series E 1 6 Inch March 2021 1Document16 pagesCVS Series E 1 6 Inch March 2021 1iqmpslabNo ratings yet

- Why Are Butterfly Valves A Good Alternative To Ball ValvesDocument5 pagesWhy Are Butterfly Valves A Good Alternative To Ball ValvesHuy Nguyễn Võ XuânNo ratings yet

- Technical Bulletin: Valtek Mark One Control ValvesDocument20 pagesTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzNo ratings yet

- Gate ValveDocument27 pagesGate ValveYogesh Kumar Bhatnagar0% (1)

- StockhamCastSteelCV 807 PDFDocument24 pagesStockhamCastSteelCV 807 PDFchabibNo ratings yet

- Válvula de Retención - Clase 600 - CAMERONDocument9 pagesVálvula de Retención - Clase 600 - CAMERONiMaJeniDeasNo ratings yet

- Section 5: American Ductile Iron Mechanical Joint FittingsDocument27 pagesSection 5: American Ductile Iron Mechanical Joint FittingsRaul AltamiranoNo ratings yet

- Ball Valve - Training Material (Compatibility Mode)Document115 pagesBall Valve - Training Material (Compatibility Mode)kart_rl82% (11)

- Johnston C201 Specification SheetDocument2 pagesJohnston C201 Specification SheetAdel SalamaNo ratings yet

- Three-Way Tipper: Innovative and Efficient in Every DetailDocument16 pagesThree-Way Tipper: Innovative and Efficient in Every DetailAli ShdiefatNo ratings yet

- Parts List 2006SZC - IPL06126Document28 pagesParts List 2006SZC - IPL06126DerekNo ratings yet

- CBLM Servicing Automotive BatteryDocument62 pagesCBLM Servicing Automotive BatteryJayson CayabyabNo ratings yet

- Industry List With EmailDocument141 pagesIndustry List With EmailgidlavinayNo ratings yet

- Grasshopper Classic Manual enDocument16 pagesGrasshopper Classic Manual enGustavs KrievkalnsNo ratings yet

- Duct Sizing ChartDocument1 pageDuct Sizing ChartJEZREEL MENDOZANo ratings yet

- 08 CH-6, Fluid Motion Within Combustion ChamberDocument24 pages08 CH-6, Fluid Motion Within Combustion ChamberAhsan AliNo ratings yet

- Voyager Gold 5w30 5w40 PDFDocument1 pageVoyager Gold 5w30 5w40 PDFAbdelrahmanJamalNo ratings yet

- Wildcatx MANUALDocument187 pagesWildcatx MANUALAlex CachuNo ratings yet

- JD 200 D - Catalogo de PeçasDocument832 pagesJD 200 D - Catalogo de PeçasRodrigo MattosNo ratings yet

- AIRBAGDocument225 pagesAIRBAGPalacios Luna Jose AntonioNo ratings yet

- c300 (Korando) III ChassisDocument148 pagesc300 (Korando) III Chassism.gavrielNo ratings yet

- Manual Bomba de Aceite 1701053Document9 pagesManual Bomba de Aceite 1701053ventas freyreNo ratings yet

- 09 - Assembled ValvesDocument2 pages09 - Assembled ValvesDesign V-Tork ControlsNo ratings yet

- WILO Yonos PARA RKA, RS 25-6Document2 pagesWILO Yonos PARA RKA, RS 25-6Mirela Paul100% (1)

- Anti Lock Braking SystemDocument29 pagesAnti Lock Braking SystemPravin DeshmaneNo ratings yet

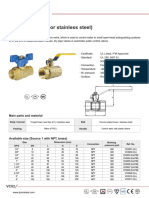

- VC02 Brass Ball Valve Full Port Full BoreDocument2 pagesVC02 Brass Ball Valve Full Port Full Boremahadeva1No ratings yet

- Nissan JulioDocument36 pagesNissan JulioRaúl José GonzálezNo ratings yet

- Volvo: SR2000 - SRO2000 - SR2400 - SRO2400Document6 pagesVolvo: SR2000 - SRO2000 - SR2400 - SRO2400عبدالغني القباطيNo ratings yet

- Tiguan Allspace DimensionsDocument2 pagesTiguan Allspace DimensionsMuhammad IchsanNo ratings yet

- Ships Spares CatalogueDocument35 pagesShips Spares CatalogueChittagong Port AgentNo ratings yet

- Mokveld Product Sheet Axial Control Valve 1Document2 pagesMokveld Product Sheet Axial Control Valve 1Belos SahajiNo ratings yet

- Hyster H2 H3.5 FT Forklift Truck Parts Catalog PDFDocument560 pagesHyster H2 H3.5 FT Forklift Truck Parts Catalog PDFAdrian SobierajczykNo ratings yet

- Massey Ferguson MF 3610 TRACTOR Service Parts Catalogue Manual (Part Number 1637182)Document16 pagesMassey Ferguson MF 3610 TRACTOR Service Parts Catalogue Manual (Part Number 1637182)hujiao6607280No ratings yet

- 05 50 00 IcDocument44 pages05 50 00 IcÜmit KazanNo ratings yet

- SSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Document60 pagesSSP 099 18 Tfsi 132kw 20 Tfsi 162kw Ea888Jose Ramón Orenes ClementeNo ratings yet

- C-9 Engine Systems and Controls: Service TrainingDocument26 pagesC-9 Engine Systems and Controls: Service TrainingJean-Jacques Ouandaogo100% (2)