Professional Documents

Culture Documents

Pharma Engineering: Ideal Distillation Setup Based On Required Boil-Up

Pharma Engineering: Ideal Distillation Setup Based On Required Boil-Up

Uploaded by

Ravindra V. Lakhapati0 ratings0% found this document useful (0 votes)

16 views3 pagesThis document provides input and output details for an ideal distillation setup based on a required boil-up of 500 kg/hr. The input details include a reactor capacity of 5 KL, reaction mass volume of 4 KL, and total system volume of 8 KL. The output details specify equipment sizes and capacities, including a vacuum pump capacity of 250 m3/hr, primary condenser area of 24 m2, and hot water tub capacity of 1.5 KL.

Original Description:

Original Title

Ideal Distillation Setup

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides input and output details for an ideal distillation setup based on a required boil-up of 500 kg/hr. The input details include a reactor capacity of 5 KL, reaction mass volume of 4 KL, and total system volume of 8 KL. The output details specify equipment sizes and capacities, including a vacuum pump capacity of 250 m3/hr, primary condenser area of 24 m2, and hot water tub capacity of 1.5 KL.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

16 views3 pagesPharma Engineering: Ideal Distillation Setup Based On Required Boil-Up

Pharma Engineering: Ideal Distillation Setup Based On Required Boil-Up

Uploaded by

Ravindra V. LakhapatiThis document provides input and output details for an ideal distillation setup based on a required boil-up of 500 kg/hr. The input details include a reactor capacity of 5 KL, reaction mass volume of 4 KL, and total system volume of 8 KL. The output details specify equipment sizes and capacities, including a vacuum pump capacity of 250 m3/hr, primary condenser area of 24 m2, and hot water tub capacity of 1.5 KL.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 3

Reach Us Contact US

PHARMA EN

Ideal Distillation Setup B

INPUT Details

Reactor Capacity * 5 KL

Reaction mass Vol. * 4 KL

Required boil-up * 500 Kg/hr

Total System vol. ( Reactor + Receiver +

Condenser vol. + Vacuum pump trap + 8 KL

Line holding capacity) *

Vacuum drop per minute (Leak Test) * 4 Torr

Vacuum * 700 mmHg

Solvent * Methanol

Condenser Utility in * -10 °C

Hot water Set point * 60 °C

Steam inlet pressure to HW tub * 0.51 Kg/cm2

RMA ENGINEERIN

istillation Setup Based on Required Boil-U

OUTPUT Details

Vacuum pump Capacity 250 m3/hr

Line size from pump to system 2 inch

Primary Condenser Area 24 m2

Secondary Condenser Area 8 m2

Vapour Column Size required 8 inch

Vapour passing line b/w primary & secondary condenser 4 inch

Line size required b/w condensers & receiver 2 inch

Vacuum equalization size required b/w condenser & receiver 1 inch

Reactor Jacket Utility line size required 6 inch

Hot water tub capacity required 1.5 KL

Hot water pump capacity required 36 m3/hr

NEERING

equired Boil-Up

UTPUT Details

Motor Capacity required for HW Pump 3.8 HP

Inlet Steam temperature to HW tub 111.6 °C

Specific Enthalpy of Steam 552.98 Kcal/Kg

Specific volume of Steam 1.15 m3/Kg

Plate heat exchanger capacity required for HW tub 2.5 m2

Condensate back to boiler 274 Lts

You might also like

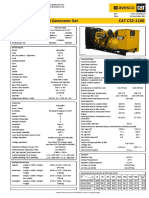

- Cat C32-1100 en PDFDocument1 pageCat C32-1100 en PDFOsanebi Chukwudi LuckyNo ratings yet

- Operating Mannua2Document96 pagesOperating Mannua2Ajay Kumar0% (1)

- Pharma Engg. Ideal Distillation SetupDocument3 pagesPharma Engg. Ideal Distillation SetuppratikNo ratings yet

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadNo ratings yet

- Boiler: - IBR Boiler 22.75 Liters in CapacityDocument23 pagesBoiler: - IBR Boiler 22.75 Liters in CapacitySachin ParasharNo ratings yet

- Thermal 3TPH 12Kg FO Fired Boiler R0Document6 pagesThermal 3TPH 12Kg FO Fired Boiler R09913489806No ratings yet

- Daily Report May 24Document33 pagesDaily Report May 24prasol thermaxNo ratings yet

- BoilerDocument73 pagesBoilerPraveen S.DNo ratings yet

- 300Kw Chiller: Call Us Now 0808 1691919 For An Instant QuoteDocument1 page300Kw Chiller: Call Us Now 0808 1691919 For An Instant Quotegerald077No ratings yet

- WES CNG PackageDocument20 pagesWES CNG Packagehadmadi nurlatifNo ratings yet

- Boiler TrainingDocument21 pagesBoiler TrainingYadav GaneshNo ratings yet

- Super Critical Technology in NTPCDocument24 pagesSuper Critical Technology in NTPCLakshminarayanNo ratings yet

- Steam AnalysisDocument2 pagesSteam Analysisprathamesh sawantNo ratings yet

- Furnace GA Drawing PDFDocument1 pageFurnace GA Drawing PDFToniNo ratings yet

- Sieve SizingDocument26 pagesSieve SizingreninbabaskiNo ratings yet

- BABCOCK BOILER 1 - 6 Instruction ManualDocument43 pagesBABCOCK BOILER 1 - 6 Instruction Manualashek ullah100% (1)

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- Generator & AuxDocument27 pagesGenerator & AuxK R Kumar RanjanNo ratings yet

- Thermic Fluid Heater Data Sheet - Rev 0Document10 pagesThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiNo ratings yet

- Summary Pocket BookDocument13 pagesSummary Pocket Booksas13No ratings yet

- Booster Korean Steam Generator ManualDocument26 pagesBooster Korean Steam Generator ManualUmar MajeedNo ratings yet

- Hiranmaye Energy LimitedDocument37 pagesHiranmaye Energy LimitedBïműřţã Đåś100% (1)

- 2X70 Power Plant Technical SpecificationDocument53 pages2X70 Power Plant Technical SpecificationChanna BasavaNo ratings yet

- Quotation of ADP40 Stationary Drum Mix Asphalt PlantDocument7 pagesQuotation of ADP40 Stationary Drum Mix Asphalt PlantChandra Prakash Karki100% (1)

- Op Eff 16 12 2023Document45 pagesOp Eff 16 12 2023Sharath BogaNo ratings yet

- Coal Fired Power Plant Project ProposalDocument5 pagesCoal Fired Power Plant Project Proposalsugeng ubel100% (1)

- Classification of Boilers: Emphasis Is On Small Oil/gas Fired Industrial Boilers Up To About 300-400K LB/HDocument90 pagesClassification of Boilers: Emphasis Is On Small Oil/gas Fired Industrial Boilers Up To About 300-400K LB/HAbhishek VermaNo ratings yet

- Ch3 Steam Turbine System - BoilerDocument49 pagesCh3 Steam Turbine System - BoilerAzraqul Ilmi100% (1)

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- Pharma Engg. Vacuum Pump SelectionDocument2 pagesPharma Engg. Vacuum Pump SelectionPANOLI PROJECTNo ratings yet

- Spesifikasi Prototipe AC Bus ListrikDocument2 pagesSpesifikasi Prototipe AC Bus ListrikDaud AbdussalamNo ratings yet

- Dalmia Cement (B) Limited: Description Unit ALR DPM Kadapa ValueDocument10 pagesDalmia Cement (B) Limited: Description Unit ALR DPM Kadapa ValueSenthilkumar PragasamNo ratings yet

- Datos Técnicos Del BWRDocument3 pagesDatos Técnicos Del BWRANANo ratings yet

- Boiler Integrity & EfiiciencyDocument45 pagesBoiler Integrity & EfiiciencySumaira KhanNo ratings yet

- Technical Details of 1 Ton Jute BoilerDocument12 pagesTechnical Details of 1 Ton Jute BoilerPial KhanNo ratings yet

- 1st Appraisal Presentation 2Document17 pages1st Appraisal Presentation 2Talha Jamil MalikNo ratings yet

- 3, 4 - Case Study BoilerDocument38 pages3, 4 - Case Study BoilerAzora GeovaniNo ratings yet

- Co HenDocument40 pagesCo HenHiltonNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj75% (4)

- TCD 70 Data Sheet EngDocument2 pagesTCD 70 Data Sheet EngPerc AleksandarNo ratings yet

- Boilers & Fired Systems: Clean Coal TechnologyDocument47 pagesBoilers & Fired Systems: Clean Coal TechnologyfakharkhiljiNo ratings yet

- Boil Up RateDocument1 pageBoil Up RateNitin KurupNo ratings yet

- Boiler Presentation660 MWDocument32 pagesBoiler Presentation660 MWJayaraman Kamaraj100% (1)

- Boiler Presentation - Shared - Updated 19 - 10 - 20Document51 pagesBoiler Presentation - Shared - Updated 19 - 10 - 20Lokesh ChourasiaNo ratings yet

- Waste Heat Recovery System For Cement PlantDocument6 pagesWaste Heat Recovery System For Cement PlantandrowreganNo ratings yet

- Boilers - An OverviewDocument22 pagesBoilers - An OverviewjsnathNo ratings yet

- Cement Kiln Pyro BalanceDocument40 pagesCement Kiln Pyro BalanceGanapathy SubramaniamNo ratings yet

- CDI - Concept NoteDocument34 pagesCDI - Concept NoteRitche Lim BragaisNo ratings yet

- Steam CalculatorDocument6 pagesSteam Calculatorthermaxteja2016No ratings yet

- Auxiliary BoilerDocument56 pagesAuxiliary BoilerNirdosh AnanthNo ratings yet

- PILLARD - Aktuell - YCC - MR - BoseDocument19 pagesPILLARD - Aktuell - YCC - MR - BosePradeep KumawatNo ratings yet

- Calculated Primary Air Flow and MomentumDocument4 pagesCalculated Primary Air Flow and MomentummadhuNo ratings yet

- 2MW Watertube Steam Boiler DatasheetDocument1 page2MW Watertube Steam Boiler DatasheetAshan MahelaNo ratings yet

- Technical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Document7 pagesTechnical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Chakravarthy BharathNo ratings yet

- Boiler Design DataDocument8 pagesBoiler Design Dataramnath008100% (1)

- YF 80PC QuotationDocument5 pagesYF 80PC QuotationahmedsaydNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- C R A D M P: Reen Lanet HemicalsDocument74 pagesC R A D M P: Reen Lanet HemicalsRavindra V. LakhapatiNo ratings yet

- 1.structured Packing PresentationDocument27 pages1.structured Packing PresentationRavindra V. LakhapatiNo ratings yet

- Scale Up of Paddle DryerDocument4 pagesScale Up of Paddle DryerRavindra V. Lakhapati100% (1)

- Air and Steam StrippingDocument108 pagesAir and Steam StrippingRavindra V. LakhapatiNo ratings yet

- NH3 Steam StripperDocument99 pagesNH3 Steam StripperRavindra V. LakhapatiNo ratings yet

- Design of Gas Induction Reactors PDFDocument32 pagesDesign of Gas Induction Reactors PDFRavindra V. LakhapatiNo ratings yet

- Agitators/Mixers: Agitators / Mixers, Factors To Be Considered For Design AreDocument9 pagesAgitators/Mixers: Agitators / Mixers, Factors To Be Considered For Design AreRavindra V. LakhapatiNo ratings yet