Professional Documents

Culture Documents

Tinuvin 928: Technical Data Sheet

Tinuvin 928: Technical Data Sheet

Uploaded by

Carlotta C.Copyright:

Available Formats

You might also like

- Medical Medium Life-Changing Foods: Save Yourself and The Ones You Love With The Hidden Healing Powers of Fruits & Vegetables - Anthony WilliamDocument5 pagesMedical Medium Life-Changing Foods: Save Yourself and The Ones You Love With The Hidden Healing Powers of Fruits & Vegetables - Anthony Williamwecatane12% (17)

- Handbook of Adhesive TechnologyDocument659 pagesHandbook of Adhesive TechnologyCarlotta C.80% (5)

- Uhone Broker GuideDocument28 pagesUhone Broker Guidestech137No ratings yet

- Tinuvin 292 October 2019 R4 IC PPDocument3 pagesTinuvin 292 October 2019 R4 IC PPسلطان ابوالعلاNo ratings yet

- Tinuvin 123: Printing & Packaging Industrial CoatingsDocument2 pagesTinuvin 123: Printing & Packaging Industrial Coatingsfatimah fahira siregarNo ratings yet

- Tinuvin 400 October 2019 R4 IC PPDocument4 pagesTinuvin 400 October 2019 R4 IC PPEmilio HipolaNo ratings yet

- Tinuvin P: Technical Data SheetDocument3 pagesTinuvin P: Technical Data SheetKhoa HuynhNo ratings yet

- Tinuvin 152 October 2019 R4 ICDocument3 pagesTinuvin 152 October 2019 R4 ICEmilio HipolaNo ratings yet

- Tinuvin 400-DW (N) : Technical Data SheetDocument3 pagesTinuvin 400-DW (N) : Technical Data SheetYavuz CelikNo ratings yet

- Thermolite 890F TDS Rev v3Document3 pagesThermolite 890F TDS Rev v3Qwerty RoyalNo ratings yet

- Irganox 1010: Industrial CoatingsDocument3 pagesIrganox 1010: Industrial CoatingsPrototypeNo ratings yet

- BaSO4 SpecDocument2 pagesBaSO4 SpecSubrato SahaNo ratings yet

- Tinuvin 292Document3 pagesTinuvin 292Mohammad Doost Mohammadi100% (1)

- Tinuvin 5248 October 2019 R3 ICDocument4 pagesTinuvin 5248 October 2019 R3 ICMarco EstradaNo ratings yet

- TI - Chimassorb - 944 - EVF - 1028 e - V8-2019Document3 pagesTI - Chimassorb - 944 - EVF - 1028 e - V8-2019Xiaofeng MengNo ratings yet

- Chimassorb 944 TdsDocument3 pagesChimassorb 944 TdsRodrigo Esteban Ramirez CanalesNo ratings yet

- Desmodur Ultra E 15 - en - 86620634 23266676 23505085Document3 pagesDesmodur Ultra E 15 - en - 86620634 23266676 23505085محمد مقلدNo ratings yet

- Tioxide TR28 3Document2 pagesTioxide TR28 3cwqccqNo ratings yet

- Acematt Ts 100 enDocument2 pagesAcematt Ts 100 enSeafar YachtingNo ratings yet

- Mjuwax 2301Document1 pageMjuwax 2301manojNo ratings yet

- Butonal NS 175 TDSDocument2 pagesButonal NS 175 TDSPT. PITAGORAS KONSULTANNo ratings yet

- Tinuvin 770 TdsDocument3 pagesTinuvin 770 TdsCesar MartinezNo ratings yet

- PDFDocument3 pagesPDFMohsen KadivarNo ratings yet

- Denso Marine Piling TapeDocument1 pageDenso Marine Piling TapeFachrurraziNo ratings yet

- R 405 SachtlebenDocument1 pageR 405 Sachtlebenmedo.k016No ratings yet

- MOLYKOTE PA-744 Anti-Friction Coating 80-3214A-01-1Document2 pagesMOLYKOTE PA-744 Anti-Friction Coating 80-3214A-01-1Guillermo FormosoNo ratings yet

- Ca1101 TdsDocument2 pagesCa1101 TdsJosevi Jiménez MerinoNo ratings yet

- Neusilin TDS US2Document1 pageNeusilin TDS US2Rohit RanjanNo ratings yet

- EUR Val TectylMultiPurpose506 CTG TEC ENDocument2 pagesEUR Val TectylMultiPurpose506 CTG TEC ENbouwersNo ratings yet

- Tectyl 506 PDFDocument4 pagesTectyl 506 PDFjaskaran singhNo ratings yet

- Desmodur N 75 MPAX - en - 00832200 17844451 19840310Document4 pagesDesmodur N 75 MPAX - en - 00832200 17844451 19840310rkapadia505No ratings yet

- Tioxide TR25: Product Data SheetDocument2 pagesTioxide TR25: Product Data SheetJose E Batista100% (1)

- Cymel 1158Document2 pagesCymel 1158sidneidecarvalhoNo ratings yet

- Tinuvin 1130Document4 pagesTinuvin 1130Mohammad Doost MohammadiNo ratings yet

- Bpxe 9PPHCNDocument2 pagesBpxe 9PPHCNNarges alikhaniNo ratings yet

- Xylene 9690 Technical Data Sheet: DescriptionDocument4 pagesXylene 9690 Technical Data Sheet: DescriptionKareem El DeebNo ratings yet

- Dupont SurlynDocument2 pagesDupont SurlynpackagingNo ratings yet

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Sorbead H BASF - Data Sheet PDFDocument2 pagesSorbead H BASF - Data Sheet PDFLeo Crisu100% (1)

- Tectyl 502CDocument2 pagesTectyl 502Cmoinu85No ratings yet

- Latex ButonalDocument2 pagesLatex ButonalRicardoNo ratings yet

- Produktinformation Tectyl 506 G TE033 01Document2 pagesProduktinformation Tectyl 506 G TE033 01HDSC ChemicalsNo ratings yet

- Employing Nanoemulsions in Food Packaging: Shelf Life EnhancementDocument26 pagesEmploying Nanoemulsions in Food Packaging: Shelf Life Enhancementarooj sheikhNo ratings yet

- Desmodur N 75 MPAX - en - 00832200 00009990 00034502Document4 pagesDesmodur N 75 MPAX - en - 00832200 00009990 00034502feby nurvinandaNo ratings yet

- Acronal V210 Na AdhesivesDocument3 pagesAcronal V210 Na AdhesivesCanchindoNo ratings yet

- Desmocoll - 05676967 00009951 00046198 PDFDocument3 pagesDesmocoll - 05676967 00009951 00046198 PDFHS AleNo ratings yet

- Desmodur N 75 MPA - en - 00832197 00009989 00054371Document4 pagesDesmodur N 75 MPA - en - 00832197 00009989 00054371VeliYunusKavalciNo ratings yet

- Dispersant Ts-99 Pds enDocument1 pageDispersant Ts-99 Pds enMark WuNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- DURLON RR TANKCAR February 2015Document16 pagesDURLON RR TANKCAR February 2015Hugh Manta100% (1)

- Acronal 4120 AdhesivesDocument2 pagesAcronal 4120 AdhesivesVenu KavetiNo ratings yet

- Bayhydur XP 2655 - en - 06756239 17854696 21037056Document4 pagesBayhydur XP 2655 - en - 06756239 17854696 21037056trường phạmNo ratings yet

- Desmophen A 160 SN: Type Characterization Form Supplied UsesDocument2 pagesDesmophen A 160 SN: Type Characterization Form Supplied UsesFadi MagdyNo ratings yet

- Adisorb UV 944Document3 pagesAdisorb UV 944jdiaz87No ratings yet

- Hoja Técnica Lanco 1890 CDocument2 pagesHoja Técnica Lanco 1890 CBryan GavilanezNo ratings yet

- Dupont Teflon: Teflon S Coatings 958-203 and 958-207Document4 pagesDupont Teflon: Teflon S Coatings 958-203 and 958-207Abdul RafiiNo ratings yet

- PDS Tikkurila Temathane 50Document3 pagesPDS Tikkurila Temathane 50Marcin HryciukNo ratings yet

- BASF MasterSeal NP 472Document2 pagesBASF MasterSeal NP 472HJNo ratings yet

- Desmocoll 540Document2 pagesDesmocoll 540Alberto Ramirez GonzalezNo ratings yet

- Desmodur N 75 BA/X: Aliphatic PolyisocyanateDocument2 pagesDesmodur N 75 BA/X: Aliphatic PolyisocyanateLê TiếnNo ratings yet

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

- Natural Syntheticwaxemulsifications Conference ProceedingsDocument11 pagesNatural Syntheticwaxemulsifications Conference ProceedingsCarlotta C.No ratings yet

- Product Range - Home Care and II Asia PacificDocument19 pagesProduct Range - Home Care and II Asia PacificCarlotta C.100% (1)

- Tridac Iso-8 November 2015Document2 pagesTridac Iso-8 November 2015Carlotta C.No ratings yet

- Polyurethane Types, Synthesis and Applications - A ReviewDocument30 pagesPolyurethane Types, Synthesis and Applications - A ReviewCarlotta C.No ratings yet

- Poligen WE1: Technical InformationDocument4 pagesPoligen WE1: Technical InformationCarlotta C.No ratings yet

- One-Step Synthesis of Polyethylene Microspheres UsDocument5 pagesOne-Step Synthesis of Polyethylene Microspheres UsCarlotta C.No ratings yet

- Degradable Aliphatic PolyestersDocument162 pagesDegradable Aliphatic PolyestersCarlotta C.No ratings yet

- Training Courses On Polyurethane AdhesivesDocument67 pagesTraining Courses On Polyurethane AdhesivesCarlotta C.No ratings yet

- Poly (Urethane) SDocument45 pagesPoly (Urethane) SCarlotta C.No ratings yet

- Wax Characterisation by Instrumental Analysis PDFDocument132 pagesWax Characterisation by Instrumental Analysis PDFCarlotta C.100% (1)

- Biomedical Applications of PolyurethanesDocument48 pagesBiomedical Applications of PolyurethanesCarlotta C.No ratings yet

- From Vegetable Oils To Polyurethanes - Synthetic Routes To Polyols and Main Industrial ProductsDocument43 pagesFrom Vegetable Oils To Polyurethanes - Synthetic Routes To Polyols and Main Industrial ProductsCarlotta C.No ratings yet

- Bio-Based Polymers in The WorldDocument35 pagesBio-Based Polymers in The WorldCarlotta C.No ratings yet

- Surfactants and Emulsifying AgentsDocument6 pagesSurfactants and Emulsifying AgentsCarlotta C.No ratings yet

- Effects of Preparation Parameters On Paraffin Wax MicroemulsionDocument5 pagesEffects of Preparation Parameters On Paraffin Wax MicroemulsionCarlotta C.No ratings yet

- Surfactants, Industrial ApplicationsDocument1 pageSurfactants, Industrial ApplicationsCarlotta C.No ratings yet

- Biobased Polyurethanes From Microalgae: DR Philip B. SellarsDocument30 pagesBiobased Polyurethanes From Microalgae: DR Philip B. SellarsCarlotta C.No ratings yet

- Safe Harbor StatementDocument5 pagesSafe Harbor StatementCarlotta C.No ratings yet

- The Real Green Revolution Organic and Agroecological FarmingDocument151 pagesThe Real Green Revolution Organic and Agroecological FarmingKlausEllegaard11No ratings yet

- Na BR 1168 Hybrid Agv Vna 4Document4 pagesNa BR 1168 Hybrid Agv Vna 4Marco BaptistaNo ratings yet

- Level of Awarenss of Hypertension Among Grade 12 Science Technology Engineering and Mathematics Students of Systems Plus College FoundationDocument35 pagesLevel of Awarenss of Hypertension Among Grade 12 Science Technology Engineering and Mathematics Students of Systems Plus College FoundationMary Grace MendeNo ratings yet

- Makerere Research FormatDocument7 pagesMakerere Research FormatMurice ElaguNo ratings yet

- Vario 18Document92 pagesVario 18Miguel DiazNo ratings yet

- Electrical Workshop EE-113: Prepared By: Engr. Shafaq EjazDocument53 pagesElectrical Workshop EE-113: Prepared By: Engr. Shafaq Ejazshafaq ejazNo ratings yet

- E E E E: For Installation/s IndustrialDocument1 pageE E E E: For Installation/s IndustrialRJ Padilla0% (1)

- BakerHughes BruceWright NewCokerDefoamer CokingCom May2011Document9 pagesBakerHughes BruceWright NewCokerDefoamer CokingCom May2011Anonymous UoHUagNo ratings yet

- BaldwinsDocument2 pagesBaldwinsHarlyn BulayangNo ratings yet

- ALDEN, Dauril. The Significance of Cacao Production PDFDocument34 pagesALDEN, Dauril. The Significance of Cacao Production PDFMarcia MelloNo ratings yet

- Excitation of Plasmons and Interband Transitions by Electrons PDFDocument2 pagesExcitation of Plasmons and Interband Transitions by Electrons PDFRobNo ratings yet

- Salvation Series-Lesson5-EternallifeyourchoiceDocument3 pagesSalvation Series-Lesson5-EternallifeyourchoiceKim M. BaraquelNo ratings yet

- The AlchemistDocument57 pagesThe Alchemistok100% (1)

- Researchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFDocument4 pagesResearchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFTran Huynh NamNo ratings yet

- Hyacinth Blooms in Milton's "Lycidas"Document3 pagesHyacinth Blooms in Milton's "Lycidas"Alex ENo ratings yet

- Writing Handout 4-5Document9 pagesWriting Handout 4-5Rosine ZgheibNo ratings yet

- MCN Q&A With RationaleDocument62 pagesMCN Q&A With RationaleBooger777No ratings yet

- P e - First-Quarter-Exams 1st-SemDocument7 pagesP e - First-Quarter-Exams 1st-SemJieann BalicocoNo ratings yet

- Supplier Response Time: - Measured in Days/Hours - Better The Lowest SRTDocument6 pagesSupplier Response Time: - Measured in Days/Hours - Better The Lowest SRTJebin GeorgeNo ratings yet

- Logistics of Tractor Distribution in An Agriculture-Driven Economy: An Indian Case StudyDocument15 pagesLogistics of Tractor Distribution in An Agriculture-Driven Economy: An Indian Case StudyNiraj PatleNo ratings yet

- Be-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Document2 pagesBe-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Ricardo Frank CordeiroNo ratings yet

- Discussion 1 NPNDocument53 pagesDiscussion 1 NPNFaith TambongNo ratings yet

- A & A Textiles LTDDocument4 pagesA & A Textiles LTDMilton StevensNo ratings yet

- Acoustic Systems in Biology - Neville H. FletcherDocument348 pagesAcoustic Systems in Biology - Neville H. FletcherJosue PazNo ratings yet

- Computer Graphics I UNIT NotesDocument24 pagesComputer Graphics I UNIT Notesgouse1210100% (1)

- HCF and LCMDocument5 pagesHCF and LCMAnkit YadavNo ratings yet

- SR Elite, Aiims S60 & Neet MPL Aits Grand Test - 15 Paper Key (23-04-2023)Document12 pagesSR Elite, Aiims S60 & Neet MPL Aits Grand Test - 15 Paper Key (23-04-2023)vulurakashsharma2005No ratings yet

- BS en 13230 Part 2-2016Document30 pagesBS en 13230 Part 2-2016jasonNo ratings yet

Tinuvin 928: Technical Data Sheet

Tinuvin 928: Technical Data Sheet

Uploaded by

Carlotta C.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tinuvin 928: Technical Data Sheet

Tinuvin 928: Technical Data Sheet

Uploaded by

Carlotta C.Copyright:

Available Formats

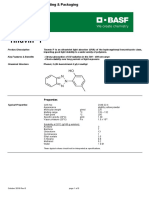

Industrial Coatings, Printing & Packaging, Construction

Technical Data Sheet

Tinuvin® 928

Product Description Tinuvin 928 is UV absorber of the hydroxyphenyl benzotriazole class developed specially

for high performance coating applications.

Key Features & Benefits - Excellent photopermanence

- Excellent spectral coverage

- Designed for use in solvent based & powder coatings

Chemical Structure 2-(2H-Benzotriazol-2-yl)-6-(1-methyl-1-phenylethyl)-4-(1, 1, 3, 3-tetramethylbutyl) phenol

Properties

Typical Properties CAS No: 73936-91-1

Appearance light yellow crystalline powder

Molecular weight 441.6

Melting Data °C 109 - 113

Soluibility at 20 °C (g/100 g solution)

butyldiglycol 35

butanol 17

butyl acetate > 30

butylglycol acetate 9.5

ethylglycol acetate 10

methoxypropyl acetate 9.4

methyoxypropanol 2.9

Solvesso 100 ¹ > 30

Solvesso 150 ¹ > 30

n-hexane > 50

water < 0.01

¹ Registered trademark of Esso

These typical values should not be interpreted as specifications.

October 2019 Rev 4 page 1 of 3

Transmittance Spectrum

in toluene, cell thickness: 1 cm

Explanation:

Top Line: 0.001% Tinuvin 928, corresponds to 0.25% in a 40 µm film

Second Line: 0.002% Tinuvin 928, corresponds to 0.50% in a 40 µm film

Third Line: 0.004% Tinuvin 928, corresponds to 1.0% in a 40 µm film

Bottom Line: 0.006% Tinuvin 928, corresponds to 1.5% in a 40 µm film

Applications

Tinuvin 928 is a UV absorber of the hydroxyphenyl benzotriazole class developed specially for high

performance coating applications. Its characteristic broadband absorption provides efficient

protection to coatings and light sensitive substrates. Its excellent solubility and high thermal and

environmental permanence makes it particularly suitable for coatings exposed to high temperature

curing processes, such as powder and coil coatings, or high environmental stress.

Tinuvin 928 is recommended for applications such as:

• automotive coatings

• powder and coil coatings

• hot melt adhesives

• exterior construction coatings (roofing, etc.)

• construction adhesives and sealants

Tinuvin 928 may be used in combination with a light stabilizer of the sterically hindered amine class

(HALS) such as recommended below. Combinations provide best protection against gloss

reduction, cracking, blistering, delamination, and color change. Light stabilizers may be added in

clear coats, base coats or solid shades. However, according to our experience the optimum

protection is achieved by adding the light stabilizers to the topcoat.

The amount of Tinuvin 928 required for optimum performance should be determined in laboratory

trials covering a concentration range.

Recommend Concentrations

Powder coatings 1.0 – 3.0 % Tinuvin 928

+

0.5 – 2.0 % Tinuvin 144 or Tinuvin 111 FD

Liquid coatings 1–3% Tinuvin 928

+

0.5 – 2 % Tinuvin 292, Tinuvin 249 or Tinuvin 123

(concentrations are based on weight percent binder solids)

October 2019 Rev 4 page 2 of 3

Safety

General The usual safety precautions when handling chemicals must be observed. These include the

measure described in Federal, State and Local health and safety regulations, thorough ventilation

of the workplace, good skin care, and wearing of protective goggles.

Safety Data Sheet All safety information is provided in the Safety Data Sheet for Tinuvin 928.

Storage

Please refer to the “Handling and Storage of Polymer Dispersions” brochure.

Important

The descriptions, designs, and data contained herein are presented for your guidance only.

Because there are many factors under your control which may affect processing or application/use

it is necessary for you to make appropriate tests to determine whether the product is suitable for

your particular purpose prior to use. NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE MADE REGARDING PRODUCTS DESCRIBED OR DESIGNS,

OR INFORMATION SET FORTH, OR THAT THE PRODUCTS, DESIGNS, OR DATA MAY BE

USED WITHOUT INFRINGING THE INTELLECTUAL PROPERTY RIGHTS OF OTHERS. IN NO

CASE SHALL THE DESCRIPTIONS, DATA OR DESIGNS PROVIDED BE PRESUMED TO BE A

PART OF OUR TERMS AND CONDITIONS OF SALE. Further, you expressly understand and

agree that the descriptions, designs, and data furnished by BASF hereunder are given gratis and

BASF assumes no obligation or liability for same or results obtained from use thereof, all such being

given to you and accepted by you at your risk.

Tinuvin is a registered trademark of BASF Group.

© BASF Corporation, 2019

BASF Corporation is fully committed to the Responsible Care®

initiative in the USA, Canada, and Mexico.

For more information on Responsible Care® go to:

U.S.: www.basf.us/responsiblecare_usa

Canada: www.basf.us/responsiblecare_canada

México: www.basf.us/responsiblecare_mexico

BASF Corporation

Dispersions and Resins

11501 Steele Creek Road

Charlotte, North Carolina 28273

Phone: (800) 251 – 0612

Email: CustCare-Charlotte@basf.com

Email: edtech-info@basf.com

www.basf.us/dpsolutions

October 2019 Rev 4 page 3 of 3

You might also like

- Medical Medium Life-Changing Foods: Save Yourself and The Ones You Love With The Hidden Healing Powers of Fruits & Vegetables - Anthony WilliamDocument5 pagesMedical Medium Life-Changing Foods: Save Yourself and The Ones You Love With The Hidden Healing Powers of Fruits & Vegetables - Anthony Williamwecatane12% (17)

- Handbook of Adhesive TechnologyDocument659 pagesHandbook of Adhesive TechnologyCarlotta C.80% (5)

- Uhone Broker GuideDocument28 pagesUhone Broker Guidestech137No ratings yet

- Tinuvin 292 October 2019 R4 IC PPDocument3 pagesTinuvin 292 October 2019 R4 IC PPسلطان ابوالعلاNo ratings yet

- Tinuvin 123: Printing & Packaging Industrial CoatingsDocument2 pagesTinuvin 123: Printing & Packaging Industrial Coatingsfatimah fahira siregarNo ratings yet

- Tinuvin 400 October 2019 R4 IC PPDocument4 pagesTinuvin 400 October 2019 R4 IC PPEmilio HipolaNo ratings yet

- Tinuvin P: Technical Data SheetDocument3 pagesTinuvin P: Technical Data SheetKhoa HuynhNo ratings yet

- Tinuvin 152 October 2019 R4 ICDocument3 pagesTinuvin 152 October 2019 R4 ICEmilio HipolaNo ratings yet

- Tinuvin 400-DW (N) : Technical Data SheetDocument3 pagesTinuvin 400-DW (N) : Technical Data SheetYavuz CelikNo ratings yet

- Thermolite 890F TDS Rev v3Document3 pagesThermolite 890F TDS Rev v3Qwerty RoyalNo ratings yet

- Irganox 1010: Industrial CoatingsDocument3 pagesIrganox 1010: Industrial CoatingsPrototypeNo ratings yet

- BaSO4 SpecDocument2 pagesBaSO4 SpecSubrato SahaNo ratings yet

- Tinuvin 292Document3 pagesTinuvin 292Mohammad Doost Mohammadi100% (1)

- Tinuvin 5248 October 2019 R3 ICDocument4 pagesTinuvin 5248 October 2019 R3 ICMarco EstradaNo ratings yet

- TI - Chimassorb - 944 - EVF - 1028 e - V8-2019Document3 pagesTI - Chimassorb - 944 - EVF - 1028 e - V8-2019Xiaofeng MengNo ratings yet

- Chimassorb 944 TdsDocument3 pagesChimassorb 944 TdsRodrigo Esteban Ramirez CanalesNo ratings yet

- Desmodur Ultra E 15 - en - 86620634 23266676 23505085Document3 pagesDesmodur Ultra E 15 - en - 86620634 23266676 23505085محمد مقلدNo ratings yet

- Tioxide TR28 3Document2 pagesTioxide TR28 3cwqccqNo ratings yet

- Acematt Ts 100 enDocument2 pagesAcematt Ts 100 enSeafar YachtingNo ratings yet

- Mjuwax 2301Document1 pageMjuwax 2301manojNo ratings yet

- Butonal NS 175 TDSDocument2 pagesButonal NS 175 TDSPT. PITAGORAS KONSULTANNo ratings yet

- Tinuvin 770 TdsDocument3 pagesTinuvin 770 TdsCesar MartinezNo ratings yet

- PDFDocument3 pagesPDFMohsen KadivarNo ratings yet

- Denso Marine Piling TapeDocument1 pageDenso Marine Piling TapeFachrurraziNo ratings yet

- R 405 SachtlebenDocument1 pageR 405 Sachtlebenmedo.k016No ratings yet

- MOLYKOTE PA-744 Anti-Friction Coating 80-3214A-01-1Document2 pagesMOLYKOTE PA-744 Anti-Friction Coating 80-3214A-01-1Guillermo FormosoNo ratings yet

- Ca1101 TdsDocument2 pagesCa1101 TdsJosevi Jiménez MerinoNo ratings yet

- Neusilin TDS US2Document1 pageNeusilin TDS US2Rohit RanjanNo ratings yet

- EUR Val TectylMultiPurpose506 CTG TEC ENDocument2 pagesEUR Val TectylMultiPurpose506 CTG TEC ENbouwersNo ratings yet

- Tectyl 506 PDFDocument4 pagesTectyl 506 PDFjaskaran singhNo ratings yet

- Desmodur N 75 MPAX - en - 00832200 17844451 19840310Document4 pagesDesmodur N 75 MPAX - en - 00832200 17844451 19840310rkapadia505No ratings yet

- Tioxide TR25: Product Data SheetDocument2 pagesTioxide TR25: Product Data SheetJose E Batista100% (1)

- Cymel 1158Document2 pagesCymel 1158sidneidecarvalhoNo ratings yet

- Tinuvin 1130Document4 pagesTinuvin 1130Mohammad Doost MohammadiNo ratings yet

- Bpxe 9PPHCNDocument2 pagesBpxe 9PPHCNNarges alikhaniNo ratings yet

- Xylene 9690 Technical Data Sheet: DescriptionDocument4 pagesXylene 9690 Technical Data Sheet: DescriptionKareem El DeebNo ratings yet

- Dupont SurlynDocument2 pagesDupont SurlynpackagingNo ratings yet

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Sorbead H BASF - Data Sheet PDFDocument2 pagesSorbead H BASF - Data Sheet PDFLeo Crisu100% (1)

- Tectyl 502CDocument2 pagesTectyl 502Cmoinu85No ratings yet

- Latex ButonalDocument2 pagesLatex ButonalRicardoNo ratings yet

- Produktinformation Tectyl 506 G TE033 01Document2 pagesProduktinformation Tectyl 506 G TE033 01HDSC ChemicalsNo ratings yet

- Employing Nanoemulsions in Food Packaging: Shelf Life EnhancementDocument26 pagesEmploying Nanoemulsions in Food Packaging: Shelf Life Enhancementarooj sheikhNo ratings yet

- Desmodur N 75 MPAX - en - 00832200 00009990 00034502Document4 pagesDesmodur N 75 MPAX - en - 00832200 00009990 00034502feby nurvinandaNo ratings yet

- Acronal V210 Na AdhesivesDocument3 pagesAcronal V210 Na AdhesivesCanchindoNo ratings yet

- Desmocoll - 05676967 00009951 00046198 PDFDocument3 pagesDesmocoll - 05676967 00009951 00046198 PDFHS AleNo ratings yet

- Desmodur N 75 MPA - en - 00832197 00009989 00054371Document4 pagesDesmodur N 75 MPA - en - 00832197 00009989 00054371VeliYunusKavalciNo ratings yet

- Dispersant Ts-99 Pds enDocument1 pageDispersant Ts-99 Pds enMark WuNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- DURLON RR TANKCAR February 2015Document16 pagesDURLON RR TANKCAR February 2015Hugh Manta100% (1)

- Acronal 4120 AdhesivesDocument2 pagesAcronal 4120 AdhesivesVenu KavetiNo ratings yet

- Bayhydur XP 2655 - en - 06756239 17854696 21037056Document4 pagesBayhydur XP 2655 - en - 06756239 17854696 21037056trường phạmNo ratings yet

- Desmophen A 160 SN: Type Characterization Form Supplied UsesDocument2 pagesDesmophen A 160 SN: Type Characterization Form Supplied UsesFadi MagdyNo ratings yet

- Adisorb UV 944Document3 pagesAdisorb UV 944jdiaz87No ratings yet

- Hoja Técnica Lanco 1890 CDocument2 pagesHoja Técnica Lanco 1890 CBryan GavilanezNo ratings yet

- Dupont Teflon: Teflon S Coatings 958-203 and 958-207Document4 pagesDupont Teflon: Teflon S Coatings 958-203 and 958-207Abdul RafiiNo ratings yet

- PDS Tikkurila Temathane 50Document3 pagesPDS Tikkurila Temathane 50Marcin HryciukNo ratings yet

- BASF MasterSeal NP 472Document2 pagesBASF MasterSeal NP 472HJNo ratings yet

- Desmocoll 540Document2 pagesDesmocoll 540Alberto Ramirez GonzalezNo ratings yet

- Desmodur N 75 BA/X: Aliphatic PolyisocyanateDocument2 pagesDesmodur N 75 BA/X: Aliphatic PolyisocyanateLê TiếnNo ratings yet

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

- Natural Syntheticwaxemulsifications Conference ProceedingsDocument11 pagesNatural Syntheticwaxemulsifications Conference ProceedingsCarlotta C.No ratings yet

- Product Range - Home Care and II Asia PacificDocument19 pagesProduct Range - Home Care and II Asia PacificCarlotta C.100% (1)

- Tridac Iso-8 November 2015Document2 pagesTridac Iso-8 November 2015Carlotta C.No ratings yet

- Polyurethane Types, Synthesis and Applications - A ReviewDocument30 pagesPolyurethane Types, Synthesis and Applications - A ReviewCarlotta C.No ratings yet

- Poligen WE1: Technical InformationDocument4 pagesPoligen WE1: Technical InformationCarlotta C.No ratings yet

- One-Step Synthesis of Polyethylene Microspheres UsDocument5 pagesOne-Step Synthesis of Polyethylene Microspheres UsCarlotta C.No ratings yet

- Degradable Aliphatic PolyestersDocument162 pagesDegradable Aliphatic PolyestersCarlotta C.No ratings yet

- Training Courses On Polyurethane AdhesivesDocument67 pagesTraining Courses On Polyurethane AdhesivesCarlotta C.No ratings yet

- Poly (Urethane) SDocument45 pagesPoly (Urethane) SCarlotta C.No ratings yet

- Wax Characterisation by Instrumental Analysis PDFDocument132 pagesWax Characterisation by Instrumental Analysis PDFCarlotta C.100% (1)

- Biomedical Applications of PolyurethanesDocument48 pagesBiomedical Applications of PolyurethanesCarlotta C.No ratings yet

- From Vegetable Oils To Polyurethanes - Synthetic Routes To Polyols and Main Industrial ProductsDocument43 pagesFrom Vegetable Oils To Polyurethanes - Synthetic Routes To Polyols and Main Industrial ProductsCarlotta C.No ratings yet

- Bio-Based Polymers in The WorldDocument35 pagesBio-Based Polymers in The WorldCarlotta C.No ratings yet

- Surfactants and Emulsifying AgentsDocument6 pagesSurfactants and Emulsifying AgentsCarlotta C.No ratings yet

- Effects of Preparation Parameters On Paraffin Wax MicroemulsionDocument5 pagesEffects of Preparation Parameters On Paraffin Wax MicroemulsionCarlotta C.No ratings yet

- Surfactants, Industrial ApplicationsDocument1 pageSurfactants, Industrial ApplicationsCarlotta C.No ratings yet

- Biobased Polyurethanes From Microalgae: DR Philip B. SellarsDocument30 pagesBiobased Polyurethanes From Microalgae: DR Philip B. SellarsCarlotta C.No ratings yet

- Safe Harbor StatementDocument5 pagesSafe Harbor StatementCarlotta C.No ratings yet

- The Real Green Revolution Organic and Agroecological FarmingDocument151 pagesThe Real Green Revolution Organic and Agroecological FarmingKlausEllegaard11No ratings yet

- Na BR 1168 Hybrid Agv Vna 4Document4 pagesNa BR 1168 Hybrid Agv Vna 4Marco BaptistaNo ratings yet

- Level of Awarenss of Hypertension Among Grade 12 Science Technology Engineering and Mathematics Students of Systems Plus College FoundationDocument35 pagesLevel of Awarenss of Hypertension Among Grade 12 Science Technology Engineering and Mathematics Students of Systems Plus College FoundationMary Grace MendeNo ratings yet

- Makerere Research FormatDocument7 pagesMakerere Research FormatMurice ElaguNo ratings yet

- Vario 18Document92 pagesVario 18Miguel DiazNo ratings yet

- Electrical Workshop EE-113: Prepared By: Engr. Shafaq EjazDocument53 pagesElectrical Workshop EE-113: Prepared By: Engr. Shafaq Ejazshafaq ejazNo ratings yet

- E E E E: For Installation/s IndustrialDocument1 pageE E E E: For Installation/s IndustrialRJ Padilla0% (1)

- BakerHughes BruceWright NewCokerDefoamer CokingCom May2011Document9 pagesBakerHughes BruceWright NewCokerDefoamer CokingCom May2011Anonymous UoHUagNo ratings yet

- BaldwinsDocument2 pagesBaldwinsHarlyn BulayangNo ratings yet

- ALDEN, Dauril. The Significance of Cacao Production PDFDocument34 pagesALDEN, Dauril. The Significance of Cacao Production PDFMarcia MelloNo ratings yet

- Excitation of Plasmons and Interband Transitions by Electrons PDFDocument2 pagesExcitation of Plasmons and Interband Transitions by Electrons PDFRobNo ratings yet

- Salvation Series-Lesson5-EternallifeyourchoiceDocument3 pagesSalvation Series-Lesson5-EternallifeyourchoiceKim M. BaraquelNo ratings yet

- The AlchemistDocument57 pagesThe Alchemistok100% (1)

- Researchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFDocument4 pagesResearchpaper - Dosage Limit Determination of Superplasticizing Admixture and Effect Evaluation On Properties of Concrete PDFTran Huynh NamNo ratings yet

- Hyacinth Blooms in Milton's "Lycidas"Document3 pagesHyacinth Blooms in Milton's "Lycidas"Alex ENo ratings yet

- Writing Handout 4-5Document9 pagesWriting Handout 4-5Rosine ZgheibNo ratings yet

- MCN Q&A With RationaleDocument62 pagesMCN Q&A With RationaleBooger777No ratings yet

- P e - First-Quarter-Exams 1st-SemDocument7 pagesP e - First-Quarter-Exams 1st-SemJieann BalicocoNo ratings yet

- Supplier Response Time: - Measured in Days/Hours - Better The Lowest SRTDocument6 pagesSupplier Response Time: - Measured in Days/Hours - Better The Lowest SRTJebin GeorgeNo ratings yet

- Logistics of Tractor Distribution in An Agriculture-Driven Economy: An Indian Case StudyDocument15 pagesLogistics of Tractor Distribution in An Agriculture-Driven Economy: An Indian Case StudyNiraj PatleNo ratings yet

- Be-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Document2 pagesBe-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Ricardo Frank CordeiroNo ratings yet

- Discussion 1 NPNDocument53 pagesDiscussion 1 NPNFaith TambongNo ratings yet

- A & A Textiles LTDDocument4 pagesA & A Textiles LTDMilton StevensNo ratings yet

- Acoustic Systems in Biology - Neville H. FletcherDocument348 pagesAcoustic Systems in Biology - Neville H. FletcherJosue PazNo ratings yet

- Computer Graphics I UNIT NotesDocument24 pagesComputer Graphics I UNIT Notesgouse1210100% (1)

- HCF and LCMDocument5 pagesHCF and LCMAnkit YadavNo ratings yet

- SR Elite, Aiims S60 & Neet MPL Aits Grand Test - 15 Paper Key (23-04-2023)Document12 pagesSR Elite, Aiims S60 & Neet MPL Aits Grand Test - 15 Paper Key (23-04-2023)vulurakashsharma2005No ratings yet

- BS en 13230 Part 2-2016Document30 pagesBS en 13230 Part 2-2016jasonNo ratings yet