Professional Documents

Culture Documents

132 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To Finishing

132 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To Finishing

Uploaded by

Black SoulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

132 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To Finishing

132 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To Finishing

Uploaded by

Black SoulCopyright:

Available Formats

132 K. M.

Faridul Hasan: Study on the Changes of GSM (Gm/m2) of Grey Knitted Fabric from Pretreatment to Finishing

Table 11(b). GSM change from stage to stage

Required value of GSM for

GSM Change in processing stages Changing Value Difference between Process to final stage GSM

finishing from process

Grey to Pretreatment 230- Grey to Finishing 260-230=30

Pretreatment to Dyeing 236- Pretreatment to Finishing 260-221=39

Dyeing to Soaping 236- Dyeing to Finishing 260-236=24

Soaping to Finishing 260-234=26

Soaping to Fixing &Softening 237-

Fixing &Softening to Finishing 260-237=23

Fixing &Softening to Stentering 237- Stentering to Finishing 260-229=31

Stentering to Compacting 258- Compacting to Finishing(Required) 260-258=2

Compacting to Finished stage 260- Finishing(Required) to Finishing (Actual) 260-260 =2

GSM change For Double Lacoste fabric (Third sample): During overall wet processing & finishing process of Double

Lacoste fabric, GSM is changed to a greater extent as shown in table-12(a) & 12(b). GSM is mainly changed in Pretreatment,

Dyeing, Stentering & in Compacting stages. During Pretreatment overall impurities are removed by using scouring &

Bleaching Agent for why GSM is extremely reduced than grey fabric. During Antipilling Protruding fibres are removed by

using Enzyme for why GSM is reduced. During Dyeing A lot of dyes are used for Combination shade for why GSM is

increased. During soaping extra unfixed color is cut for why GSM is reduced. During Stentering GSM is reduced. During

Compacting GSM is increased to a greater extent due to increase Overfeed% .After Compacting GSM is increased by

absorbing moisture (3-5%).

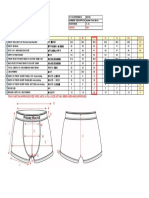

Table 12(a). GSM change For Double Lacoste Fabric

Treatment Obtained

Fabric name Buyer & Colour M/c no. Lot no. Count Brand of yarn

observation stage GSM

Grey Fabric 230

Pre-treatment 221

Double Lacoste ZARA; Lavenda HT-6 28 26/1 KAMYA-YRN Dyeing 236

Soaping 234

Fixing & Softening 235

Stentering 225

Compacting 258

Final/finished 260

Table 12(b). GSM change from stage to stage

Required value of GSM for

GSM Change in processing stages Changing Value Difference between Process to final stage GSM

finishing from process

Grey to Pretreatment 230- Grey to Finishing 260-230=30

Pretreatment to Dyeing 236- Pretreatment to Finishing 260-221=39

Dyeing to Soaping 236- Dyeing to Finishing 260-236=24

Soaping to Finishing 260-234=26

Soaping to Fixing &Softening 235-

Fixing &Softening to Finishing 260-235=25

Fixing &Softening to Stentering 235- Stentering to Finishing 260-225=35

Stentering to Compacting 258- Compacting to Finishing(Required) 260-258=2

Compacting to Finished stage 260- Finishing(Required) to Finishing (Actual) 260-260 =2

Comparison with all the samples for GSM change of double Lacoste fabric: Comparing with all the four test sample it

is found that the difference among all the separate samples GSM is very little, which could be negligible. So it is clear that my

different test data results are near about similar as shown in bellow graph-1. So we can take these variation of data from

different stages as experimentally approved data to assume any GSM related issues in different stages of knit dyeing factory.

You might also like

- Ebook PDF Understanding Motor Controls 4th EditionDocument41 pagesEbook PDF Understanding Motor Controls 4th Editionedward.howard1020% (1)

- BIM Technical Standards - MEP Color Mapping - GSADocument4 pagesBIM Technical Standards - MEP Color Mapping - GSASebastian RaduNo ratings yet

- Mapiful - How To Make Your Home More YouDocument35 pagesMapiful - How To Make Your Home More YouElina100% (1)

- Use Cases For Example ATM SystemDocument54 pagesUse Cases For Example ATM SystemGayatri SharmaNo ratings yet

- G-125, G-100 Parts Drawing PDFDocument1 pageG-125, G-100 Parts Drawing PDFRuben E. Aguilar Lazarte100% (2)

- Traction Therapy Unit BTL-16 PlusDocument1 pageTraction Therapy Unit BTL-16 PlusAnita WidayantiNo ratings yet

- International Journal of Textile Science 2015, 4 (6) : 119-136 131Document1 pageInternational Journal of Textile Science 2015, 4 (6) : 119-136 131Black SoulNo ratings yet

- 130 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To FinishingDocument1 page130 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To FinishingBlack SoulNo ratings yet

- International Journal of Textile Science 2015, 4 (6) : 119-136 133Document1 pageInternational Journal of Textile Science 2015, 4 (6) : 119-136 133Black SoulNo ratings yet

- Ebook Ebook PDF Soil Mechanics 4Th Ed 2017 Edition All Chapter PDF Docx KindleDocument41 pagesEbook Ebook PDF Soil Mechanics 4Th Ed 2017 Edition All Chapter PDF Docx Kindlewalter.schroeder558100% (29)

- Technical Data SL246/40: PrimcoDocument4 pagesTechnical Data SL246/40: PrimcoMirceaNo ratings yet

- Forbo Flooring Systems CATALOGUE 2014 PDFDocument380 pagesForbo Flooring Systems CATALOGUE 2014 PDFWassim DjennaneNo ratings yet

- Product Manual: Characters of Mold Silicone RubberDocument3 pagesProduct Manual: Characters of Mold Silicone RubbershennoNo ratings yet

- Technical Data SL257/40: PrimcoDocument3 pagesTechnical Data SL257/40: PrimcoMirceaNo ratings yet

- Saex SamDocument1 pageSaex SamAventusNo ratings yet

- LG Multi V Catalogue - LowDocument178 pagesLG Multi V Catalogue - LowyelectromechanicalNo ratings yet

- Matt PaperDocument1 pageMatt PaperPrince DankwaNo ratings yet

- CCBP - ST-01 - Boundary Wall Details - 15.05.2021Document1 pageCCBP - ST-01 - Boundary Wall Details - 15.05.2021Deepanshu GargNo ratings yet

- Technical Data SL277/47: PrimcoDocument3 pagesTechnical Data SL277/47: PrimcoMirceaNo ratings yet

- Change Font Brochure DesignDocument2 pagesChange Font Brochure DesignForeverNo ratings yet

- Ar 312 Ese 2020-21Document4 pagesAr 312 Ese 2020-21IqRa JaVedNo ratings yet

- 2023 2 Bnseptember Medium UpdtdDocument124 pages2023 2 Bnseptember Medium UpdtdChristian OvalleNo ratings yet

- 002 - Atterberg LimitDocument6 pages002 - Atterberg LimitJolayemi Emmanuel OlatayoNo ratings yet

- Kraft Paper: Supplier Referance Mill GSM Excise Vat/ CST Freight Payment Grace DaysDocument13 pagesKraft Paper: Supplier Referance Mill GSM Excise Vat/ CST Freight Payment Grace DaysSunil Patel100% (1)

- Characteristics (Typical Figures) Agip Arum HT 220Document1 pageCharacteristics (Typical Figures) Agip Arum HT 220AMAZING AGNo ratings yet

- Updated Timetable GRAphics+tex+fashionDocument3 pagesUpdated Timetable GRAphics+tex+fashionNasreen AdtaniNo ratings yet

- Transfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesDocument2 pagesTransfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesSupport RFZ2 EngineeringNo ratings yet

- Screeds Mykl Calculator 2015Document6 pagesScreeds Mykl Calculator 2015chinna_p_123No ratings yet

- Load EstimationDocument2 pagesLoad Estimationsherefnagm1981No ratings yet

- Shell Valiant Grease R 2: Plastic Compatible Lithium Soap GreaseDocument1 pageShell Valiant Grease R 2: Plastic Compatible Lithium Soap GreaseDinukaDeshanNo ratings yet

- Simple Steps BrochureDocument4 pagesSimple Steps BrochureDreamtech PressNo ratings yet

- WM WM GM GM MM MM RM GM RM: Target Finish 4 Okt 2019Document1 pageWM WM GM GM MM MM RM GM RM: Target Finish 4 Okt 2019AndriNo ratings yet

- Brakel Eura Excellent: Highly Insulated Louvred VentilatorDocument4 pagesBrakel Eura Excellent: Highly Insulated Louvred VentilatorhjduarteNo ratings yet

- Environmental Effects On Crack Growth in Polymers: JC Arnold, University of Wales, Swansea, UKDocument35 pagesEnvironmental Effects On Crack Growth in Polymers: JC Arnold, University of Wales, Swansea, UKNguyễn Trung HiệpNo ratings yet

- Visualisation Challenge DashboardDocument81 pagesVisualisation Challenge DashboardTNo ratings yet

- A-2 Test Data For Materials Description A B C: Column AS Column AT Column AUDocument3 pagesA-2 Test Data For Materials Description A B C: Column AS Column AT Column AUJitu PatelNo ratings yet

- SBCG/CGR Campo Grande, Brazil Voryrwy24: .Ceiling - RequiredDocument1 pageSBCG/CGR Campo Grande, Brazil Voryrwy24: .Ceiling - RequiredIury AlencarNo ratings yet

- Col Lapsk: Abstract of Concrete Mix Design of M30 GradeDocument3 pagesCol Lapsk: Abstract of Concrete Mix Design of M30 GradeLeelaKrishna QNo ratings yet

- June 2022 ConsolidatedDocument1 pageJune 2022 ConsolidatedAswin Raj RNo ratings yet

- Flyer ChameleoBoost ConsolDocument26 pagesFlyer ChameleoBoost ConsolAnchita MitraNo ratings yet

- QA in Highway Sector-Part-3Document10 pagesQA in Highway Sector-Part-3boomiNo ratings yet

- International Journal of Textile Science 2015, 4 (6) : 119-136 125Document1 pageInternational Journal of Textile Science 2015, 4 (6) : 119-136 125Black SoulNo ratings yet

- Ficha Tecnica SasobitDocument16 pagesFicha Tecnica SasobitFernandoAntonioAlvarezPachecoNo ratings yet

- 3 Stack 00001Document1 page3 Stack 00001karioke moha100% (1)

- Prevention of Soot Fires Oct 01Document2 pagesPrevention of Soot Fires Oct 01petermorgan74931No ratings yet

- Mabanol Argon Fleet Plus 20W-50: High Performance Universal Engine OilDocument1 pageMabanol Argon Fleet Plus 20W-50: High Performance Universal Engine OilEdgard RinconNo ratings yet

- Bearing Course Ashraf SaadDocument70 pagesBearing Course Ashraf SaadKarim SamhyNo ratings yet

- Sr-Area Tabulation DP VS ApDocument2 pagesSr-Area Tabulation DP VS ApMartin Lenin SantosNo ratings yet

- Sale Invoice: Lals PharmaDocument2 pagesSale Invoice: Lals Pharmamujahididrees.pakNo ratings yet

- 09 - Update SummaryDocument58 pages09 - Update SummaryErickson MalicsiNo ratings yet

- Council Construction Specifications Part 264Document1 pageCouncil Construction Specifications Part 264Tanmay VegadNo ratings yet

- Familiya Graphika Wholesale Pricelist 2023..Document19 pagesFamiliya Graphika Wholesale Pricelist 2023..ginojezzamae21No ratings yet

- 134 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To FinishingDocument1 page134 K. M. Faridul Hasan: Study On The Changes of GSM (GM/M) of Grey Knitted Fabric From Pretreatment To FinishingBlack SoulNo ratings yet

- Bituminous Macadam: Property T ST Code R Quirem NTDocument4 pagesBituminous Macadam: Property T ST Code R Quirem NTSOORAJ CHANDRA R SNo ratings yet

- International Journal of Textile Science 2015, 4 (6) : 119-136 129Document1 pageInternational Journal of Textile Science 2015, 4 (6) : 119-136 129Black SoulNo ratings yet

- CBR Tanah Timbun Lapangan 6Document1 pageCBR Tanah Timbun Lapangan 6Nurul Hasanah ArwiiNo ratings yet

- Rev CSP 8 AnoDocument10 pagesRev CSP 8 Anodaniel_licifsNo ratings yet

- Built-Up Rate VO2Document2 pagesBuilt-Up Rate VO2HikersNo ratings yet

- Inbound 5974541720865119750Document2 pagesInbound 5974541720865119750Eddie ArellanoNo ratings yet

- Drawing Name: Meters 1: 125Document1 pageDrawing Name: Meters 1: 125Rizkan ToyibNo ratings yet

- MICROLUBE GL 261 GL 262 EN enDocument4 pagesMICROLUBE GL 261 GL 262 EN enVendy KurniawanNo ratings yet

- W23-4055 BTS Girls Jersey TrousersDocument4 pagesW23-4055 BTS Girls Jersey TrousersBlack SoulNo ratings yet

- RVM231PB64 A Body Width MeshDocument1 pageRVM231PB64 A Body Width MeshBlack SoulNo ratings yet

- RVM231PB64 A Body 30-9-22Document1 pageRVM231PB64 A Body 30-9-22Black SoulNo ratings yet

- PSF Vertbaudet 70013-0990 94642 Dors Bien D 20211029Document15 pagesPSF Vertbaudet 70013-0990 94642 Dors Bien D 20211029Black SoulNo ratings yet

- RVM231PB64 A Body Width Out MeshDocument1 pageRVM231PB64 A Body Width Out MeshBlack SoulNo ratings yet

- Mens Boxer A BodyDocument1 pageMens Boxer A BodyBlack SoulNo ratings yet

- Aero Mid-Rise Comp Shorts - Style #WA6684bDocument16 pagesAero Mid-Rise Comp Shorts - Style #WA6684bBlack SoulNo ratings yet

- BLS Nov2021 JP04 BlissDocument34 pagesBLS Nov2021 JP04 BlissBlack SoulNo ratings yet

- Ga21fwf005jkt Measurment ChartDocument1 pageGa21fwf005jkt Measurment ChartBlack SoulNo ratings yet

- Style File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/BLS NOV2021 JP04 BLISS - PDS Global InfoDocument10 pagesStyle File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/BLS NOV2021 JP04 BLISS - PDS Global InfoBlack SoulNo ratings yet

- Updated GA21SSM036BTT 031615091276 - TfileDocument7 pagesUpdated GA21SSM036BTT 031615091276 - TfileBlack SoulNo ratings yet

- Style File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/116560 - SPORTS MASTER - PDS Global InfoDocument6 pagesStyle File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/116560 - SPORTS MASTER - PDS Global InfoBlack SoulNo ratings yet

- 028 Ga21ssm028btl Measurment GermanyDocument1 page028 Ga21ssm028btl Measurment GermanyBlack SoulNo ratings yet

- Measurement Charts OptitexDocument9 pagesMeasurement Charts OptitexBlack SoulNo ratings yet

- Baum Trading Size Specfication: A B C D E F I J M N O P QDocument1 pageBaum Trading Size Specfication: A B C D E F I J M N O P QBlack SoulNo ratings yet

- Itihasher OntoraleDocument226 pagesItihasher OntoraleBlack SoulNo ratings yet

- Effect of Different Machines On Different Structural FabricsDocument1 pageEffect of Different Machines On Different Structural FabricsBlack SoulNo ratings yet

- Preferences (3D - Illustrative Rendering) - OptitexDocument3 pagesPreferences (3D - Illustrative Rendering) - OptitexBlack SoulNo ratings yet

- PSF VERTBAUDET 70004-0438 79425 BODY SUIT A 54255 202103091616080711 MfileDocument23 pagesPSF VERTBAUDET 70004-0438 79425 BODY SUIT A 54255 202103091616080711 MfileBlack SoulNo ratings yet

- BLC Nov2021 JP04Document77 pagesBLC Nov2021 JP04Black SoulNo ratings yet

- Style Front Page: Fabric DetailsDocument10 pagesStyle Front Page: Fabric DetailsBlack SoulNo ratings yet

- Sec 3 Welding Imperfections (Defects)Document31 pagesSec 3 Welding Imperfections (Defects)Abdullah100% (1)

- Task 1 - PCK8Document8 pagesTask 1 - PCK8Andrea SantosNo ratings yet

- Sop-10 Dose Rate MeasurementDocument3 pagesSop-10 Dose Rate MeasurementOSAMANo ratings yet

- OISD ChecklistDocument3 pagesOISD ChecklistLoganathan DharmarNo ratings yet

- CatalogDocument20 pagesCatalogDorin ȘuvariNo ratings yet

- Worksheet 9 - ClimateChangeDocument1 pageWorksheet 9 - ClimateChangeVanessa MondejarNo ratings yet

- Online Reading Resources Among EFL (English Foreign Language) Students: Do They Promote Reading Habit? Estika SatrianiDocument10 pagesOnline Reading Resources Among EFL (English Foreign Language) Students: Do They Promote Reading Habit? Estika SatrianiArman JufryNo ratings yet

- ONX 620 QuickStart Guide v10Document133 pagesONX 620 QuickStart Guide v10Haiward RinconNo ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger DesignCharito Sollera AlbaricoNo ratings yet

- Graph Writing Vocabulary IndexDocument37 pagesGraph Writing Vocabulary IndexKamal deep singh SinghNo ratings yet

- Chicago Fed Survey April 2023Document2 pagesChicago Fed Survey April 2023Robert GarciaNo ratings yet

- Europe & ThailandDocument1 pageEurope & ThailandTipitaka TripitakaNo ratings yet

- Usg Epsilon1 enDocument53 pagesUsg Epsilon1 enTonatiuh RamirezNo ratings yet

- Hard Math For Middle SchoolDocument184 pagesHard Math For Middle SchoolJani TandaNo ratings yet

- PHP Security CPanelDocument5 pagesPHP Security CPanelManiMegalaiNo ratings yet

- Karoora 2012 L-3 (2013)Document9 pagesKaroora 2012 L-3 (2013)FiraolNo ratings yet

- Activity Proposal For Capacity Building For TeachersLNHS 2021Document4 pagesActivity Proposal For Capacity Building For TeachersLNHS 2021ian100% (2)

- Bed 2nd Sem ResultDocument1 pageBed 2nd Sem ResultAnusree PranavamNo ratings yet

- Technical Note 156 Correction Factors For Combustible Gas LEL Sensorsnr 02 16Document3 pagesTechnical Note 156 Correction Factors For Combustible Gas LEL Sensorsnr 02 16napoleon5976No ratings yet

- Astronomy - 12 - 15 - 18 - 5 - 6 KeyDocument11 pagesAstronomy - 12 - 15 - 18 - 5 - 6 Keykalidindi_kc_krishnaNo ratings yet

- Service ManualDocument283 pagesService ManualcoquerasNo ratings yet

- Common Australian Phrases and SlangDocument9 pagesCommon Australian Phrases and SlangAidan Donovan100% (1)

- 5E Lesson Plan Template: Replace These Directions With Your WorkDocument4 pages5E Lesson Plan Template: Replace These Directions With Your Workapi-583088531No ratings yet

- Oblicon Reviewer Q and ADocument13 pagesOblicon Reviewer Q and ARussel SirotNo ratings yet

- Geologia 2Document194 pagesGeologia 2agvega69109No ratings yet

- Gloss 1Document8 pagesGloss 1api-3723109No ratings yet

- Sansulin R Suspensi Injeksi 100 IU, ML - Rekombinan Insulin Manusia - DKI0708100443A1 - 2016Document2 pagesSansulin R Suspensi Injeksi 100 IU, ML - Rekombinan Insulin Manusia - DKI0708100443A1 - 2016Yessi VirginiaNo ratings yet