Professional Documents

Culture Documents

Discussion of Result: 36 Asif Shahriar: Physical Change of Various Knitted Fabrics by Stentering & Compacting

Discussion of Result: 36 Asif Shahriar: Physical Change of Various Knitted Fabrics by Stentering & Compacting

Uploaded by

Black SoulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discussion of Result: 36 Asif Shahriar: Physical Change of Various Knitted Fabrics by Stentering & Compacting

Discussion of Result: 36 Asif Shahriar: Physical Change of Various Knitted Fabrics by Stentering & Compacting

Uploaded by

Black SoulCopyright:

Available Formats

36 Asif Shahriar: Physical Change of Various Knitted Fabrics by Stentering & Compacting

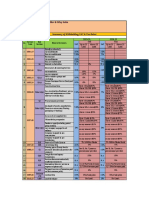

W=5%

240 65 67 245 45 70 240 L=3%

W=4%

240 74 77 250 50 74 240 L=3%

W=3%

Lacost 200 65 67.5 205 40 65 205 L=5%

W=4%

215 72 74.5 220 40 83 220 L=4%

W=5%

220 68 71 225 40 72 225 L=5%

W=5%

220 72 74.5 228 40 84 220 L=6%

W=5%

220 62 64.5 225 40 68 220 L=6%

W=5%

1x1 Rib 160 58 60.5 162 16 58 165 L=6%

W=4%

180 68 70 183 18 68 180 L=4%

W=0%

200 68 69.5 205 17 67 202 L=5%

W=6%

200 68 70 203 18 72 203 L=3%

W=5%

200 62 64 207 18 68 202 L=3%

W=5%

8. Discussion of Result Effect of stenter VS fabric structure: It can be seen in

Table 1 that different types of fabric have different type of

Required GSM VS Finished GSM: nature. For example Single Jersey fabric GSM maintain is

It can be seen in Table 2 that knitting GSM is always less difficult rather than 1x1 RIB and Interlock fabric. Dia

than finished GSM for all types and structures of fabrics, controlling and shrinkage controlling may vary for different

because after knitting fabric need to be dyeing and finishing. structure fabric. Sometime less overfeed needed for other

If dyestuff added in the fabric, its GSM must be increase and fabrics rather than single jersey. This happens because of

after softener added as finishing process GSM also increases. their structural behavior. Single jersey fabric is more flexible

To follow the buyer requirement for GSM we have to look than other structural fabric, so speed of fabric processing also

after the gray GSM very well. If GSM is more than buyer varies.

require GSM, the will not pay for excess weight and factory Effect of Compacting:

will face problem.

Effect of compactor on width: It can be seen in Table 3

Effect of steter: that if tension applied to the fabric widthwise its Dia will be

Effect of stenter on width: It can be seen in Table 1 that increase but shrinkage will be increase. As we have to follow

if tension applied to the fabric widthwise its Dia will be buyer require width, we have to look after the shrinkage as

increase but shrinkage will be increase. As we have to follow well. If width increase shrinkage will be high and higher

buyer require width, we have to look after the shrinkage as shrinkage means lower quality for garments. Compactor

well. If width increase shrinkage will be high and higher usually increases Dia by compaction using blanket, so here

shrinkage means lower quality for garments. So we have to width must be shorter than stenter.

give Over Feed in order to increase dia and for better Effect of compactor on GSM: It can be seen in Table 3

shrinkage. that for following buyer requirement GSM, we have to look

Effect of stenter on GSM: It can be seen in Table 1 that for dia of the fabric and also shrinkage of the fabric. If GSM

for following buyer requirement GSM; we have to look for is less quality of the fabric will also be decrease. Compactor

dia of the fabric and also shrinkage of the fabric. If GSM is usually increase the GSM by compaction with blanket, so

less quality of the fabric will also be decrease. To keep GSM must be good after stentering.

constant GSM Dia, Shrinkage and Overfeed must be Effect of compactor VS fabric structure: It can be seen

perfectly follow-up. in Table 3 that different types of fabric have different type

You might also like

- Internship Report On Tirupur Textile IndustryDocument39 pagesInternship Report On Tirupur Textile IndustryShruthika R91% (33)

- ELNA-TX Instruction ManualDocument48 pagesELNA-TX Instruction Manualathalim1463No ratings yet

- Genshin Impact: at 2021 JustfeelingscraftDocument13 pagesGenshin Impact: at 2021 JustfeelingscraftMayi Romero Chancafe100% (7)

- Easter Gnomes: Crochet Pattern PDFDocument15 pagesEaster Gnomes: Crochet Pattern PDFChic-vic Artesanía75% (4)

- Baby Deer IngDocument14 pagesBaby Deer IngBrigitte Richard100% (4)

- ShibainuDocument7 pagesShibainuPatty Gracino100% (5)

- Using Compactor Machine: International Journal of Textile Science 2019, 8 (2) : 31-37 35Document1 pageUsing Compactor Machine: International Journal of Textile Science 2019, 8 (2) : 31-37 35Black SoulNo ratings yet

- Using Stenter MachineDocument1 pageUsing Stenter MachineBlack SoulNo ratings yet

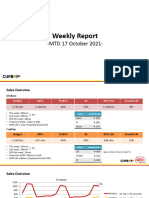

- MTD 17 Oct'21Document9 pagesMTD 17 Oct'21Achmadyani HasimNo ratings yet

- Table CompresDocument24 pagesTable ComprestamfumcknightNo ratings yet

- Maximo# Description Loi Mo TaDocument6 pagesMaximo# Description Loi Mo TaMai Thế ToanNo ratings yet

- LKH40Document1 pageLKH40Lucas SaucedoNo ratings yet

- Physical Change of Various Knitted Fabrics by Stentering & CompactingDocument7 pagesPhysical Change of Various Knitted Fabrics by Stentering & CompactingDeepan DeepuNo ratings yet

- Grey Fabrics December 2020Document888 pagesGrey Fabrics December 2020Makhon AhmedNo ratings yet

- Nonlinear Regression ModelDocument16 pagesNonlinear Regression ModelLaura StephanieNo ratings yet

- Effect of Different Machines On Different Structural FabricsDocument1 pageEffect of Different Machines On Different Structural FabricsBlack SoulNo ratings yet

- Return On Equity Calculations: Yellow Cells Are User Inputs. Please Do Not Change Any Other CellDocument4 pagesReturn On Equity Calculations: Yellow Cells Are User Inputs. Please Do Not Change Any Other CellMohammad YaqoobNo ratings yet

- Ev2712hh 2Document3 pagesEv2712hh 2gilesampion71No ratings yet

- 800 1500lb Globe BellowsDocument1 page800 1500lb Globe BellowsrouquinNo ratings yet

- Muh Fachrul Z Mahanggi - 071001800079 - Tugasekomig4Document5 pagesMuh Fachrul Z Mahanggi - 071001800079 - Tugasekomig4Fahrul mahanggiNo ratings yet

- Electric Travelling Type Trolley (Tested To 25% Overload)Document1 pageElectric Travelling Type Trolley (Tested To 25% Overload)reinpolyNo ratings yet

- Untitled 2Document1 pageUntitled 2engineering tkiNo ratings yet

- Scenrio ManagerDocument5 pagesScenrio Managerrajesh kumarNo ratings yet

- Duct Static SheetDocument6 pagesDuct Static SheetSENTRA ADABNo ratings yet

- Electromagnetic Two Disc, Spring Set BrakeDocument1 pageElectromagnetic Two Disc, Spring Set BrakeAnonymous Ts0uMLFOJNo ratings yet

- C09 KFB e PDFDocument1 pageC09 KFB e PDFAbdulNo ratings yet

- Acotación de SoldaduraDocument9 pagesAcotación de SoldaduraNicolas ArguelloNo ratings yet

- Mittal NC F1.1 Round BarDocument7 pagesMittal NC F1.1 Round BarDominic LeeNo ratings yet

- Area & Price Calculations - The Highland Villas: A-TYPE-TWIN VILLAS (3BHK + Open Ter. + Porch)Document2 pagesArea & Price Calculations - The Highland Villas: A-TYPE-TWIN VILLAS (3BHK + Open Ter. + Porch)Kanu SharmaNo ratings yet

- Tentative Inclusions CFDocument1 pageTentative Inclusions CFAniket JadhavNo ratings yet

- PX447 Rev1Document1 pagePX447 Rev1ZenalMuttaqinNo ratings yet

- Metabical Case Study SolutionDocument7 pagesMetabical Case Study SolutionAshutosh PatkarNo ratings yet

- V Series Boge FilterDocument1 pageV Series Boge FilterMAZENNo ratings yet

- VDS TDS RateDocument3 pagesVDS TDS RateTanvir TanmoyNo ratings yet

- Automotive Aftermarket OutlookDocument13 pagesAutomotive Aftermarket OutlookRittik Kumar NaskarNo ratings yet

- C V - G T - B B - F & R P: Ryogenic Alves Lobe YPE Olted Onnet ULL Educed ORTDocument1 pageC V - G T - B B - F & R P: Ryogenic Alves Lobe YPE Olted Onnet ULL Educed ORTSulist N WahyudieNo ratings yet

- Other Data: Aircraft Recovery ManualDocument4 pagesOther Data: Aircraft Recovery ManualclebersjcNo ratings yet

- S Chedu Le-!: Existing Running Pay Band Existing Grade Pay Existing Grade Pay No. Level in Pay Matrix 5Document3 pagesS Chedu Le-!: Existing Running Pay Band Existing Grade Pay Existing Grade Pay No. Level in Pay Matrix 5Dev MathurNo ratings yet

- CFB MasterDocument26 pagesCFB MasterAshish RohillaNo ratings yet

- PX442 Rev1Document1 pagePX442 Rev1Steev JanotNo ratings yet

- Kumaragiri Price List-01.05.2021Document1 pageKumaragiri Price List-01.05.2021N.M. EESWARANNo ratings yet

- Equal Angles: BS 5950-1: 2000 BS EN 10056-1: 1999Document4 pagesEqual Angles: BS 5950-1: 2000 BS EN 10056-1: 1999Stephen JamesNo ratings yet

- CPVC Rate ComparisionDocument1 pageCPVC Rate ComparisionAkshay GhoshNo ratings yet

- 2022 Automotive Range (Small)Document20 pages2022 Automotive Range (Small)wilfredo hidalgoNo ratings yet

- Gate Valve 1.2 2 WeightDocument1 pageGate Valve 1.2 2 WeightИлья БересневNo ratings yet

- 8DAL474830 - en Conversion Table and Upgrade of Bushing Type GOB - GOM To Type GOBDocument2 pages8DAL474830 - en Conversion Table and Upgrade of Bushing Type GOB - GOM To Type GOBhugo wemerNo ratings yet

- AmRest Investor Call 3Q2022 - 0Document30 pagesAmRest Investor Call 3Q2022 - 0María Alejandra AngaritaNo ratings yet

- Rate AnalysisDocument41 pagesRate AnalysisbkgboqdraftsmanNo ratings yet

- Solution Workshop #2Document12 pagesSolution Workshop #2ScribdTranslationsNo ratings yet

- Bar Bending Schedule For Raft of Box Culvert at Link-A Length 86.18 Raft Width 5.9 Slab Width 4.9 Avg Clear Wall Ht. 1.7 Wall Ht. 3Document2 pagesBar Bending Schedule For Raft of Box Culvert at Link-A Length 86.18 Raft Width 5.9 Slab Width 4.9 Avg Clear Wall Ht. 1.7 Wall Ht. 3GaneshNo ratings yet

- Top 2009 BrandsDocument1 pageTop 2009 BrandsDaniel BallardNo ratings yet

- FactSheet Renta FijaBDocument1 pageFactSheet Renta FijaByaninaNo ratings yet

- Intern ReportDocument13 pagesIntern ReportMorshedul HasanNo ratings yet

- Excel MJ GBDocument1 pageExcel MJ GBVictor ChicaizaNo ratings yet

- Saham AnalisisDocument17 pagesSaham AnalisisPOPT BREBESNo ratings yet

- Exp 2Document12 pagesExp 2tanaygupta1011No ratings yet

- Wear SheetDocument2 pagesWear SheetGiancarloNo ratings yet

- Project Number Sales Order Quotation Budget CUSTOMER CUSTOMER Project # Number OrderDocument18 pagesProject Number Sales Order Quotation Budget CUSTOMER CUSTOMER Project # Number OrderAnonymous 5pURWfNo ratings yet

- TWP Streams Replication 11gr1 130056Document3 pagesTWP Streams Replication 11gr1 130056Kibrom HaftuNo ratings yet

- Water Project 7-7-23Document3 pagesWater Project 7-7-23Hayath WhatsappNo ratings yet

- Calculations of Rain Water Pipe Below Ground Pipe Sizing:: V (M/S) Max. Flow (L/S) Max. Flow (GPM)Document3 pagesCalculations of Rain Water Pipe Below Ground Pipe Sizing:: V (M/S) Max. Flow (L/S) Max. Flow (GPM)Hamdy AdelNo ratings yet

- Nonlinear Regression Model - Quadratic ModelDocument18 pagesNonlinear Regression Model - Quadratic ModelLaura StephanieNo ratings yet

- FiltraciónDocument5 pagesFiltraciónAngel GuerreroNo ratings yet

- Engr. Charity Hope GayatinDocument5 pagesEngr. Charity Hope Gayatinmedwin moralesNo ratings yet

- Knitting Capacity & Booking StatusDocument7 pagesKnitting Capacity & Booking StatussaidurtexNo ratings yet

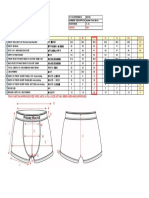

- W23-4055 BTS Girls Jersey TrousersDocument4 pagesW23-4055 BTS Girls Jersey TrousersBlack SoulNo ratings yet

- RVM231PB64 A Body Width MeshDocument1 pageRVM231PB64 A Body Width MeshBlack SoulNo ratings yet

- RVM231PB64 A Body 30-9-22Document1 pageRVM231PB64 A Body 30-9-22Black SoulNo ratings yet

- PSF Vertbaudet 70013-0990 94642 Dors Bien D 20211029Document15 pagesPSF Vertbaudet 70013-0990 94642 Dors Bien D 20211029Black SoulNo ratings yet

- RVM231PB64 A Body Width Out MeshDocument1 pageRVM231PB64 A Body Width Out MeshBlack SoulNo ratings yet

- Mens Boxer A BodyDocument1 pageMens Boxer A BodyBlack SoulNo ratings yet

- Aero Mid-Rise Comp Shorts - Style #WA6684bDocument16 pagesAero Mid-Rise Comp Shorts - Style #WA6684bBlack SoulNo ratings yet

- BLS Nov2021 JP04 BlissDocument34 pagesBLS Nov2021 JP04 BlissBlack SoulNo ratings yet

- Ga21fwf005jkt Measurment ChartDocument1 pageGa21fwf005jkt Measurment ChartBlack SoulNo ratings yet

- Style File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/BLS NOV2021 JP04 BLISS - PDS Global InfoDocument10 pagesStyle File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/BLS NOV2021 JP04 BLISS - PDS Global InfoBlack SoulNo ratings yet

- Updated GA21SSM036BTT 031615091276 - TfileDocument7 pagesUpdated GA21SSM036BTT 031615091276 - TfileBlack SoulNo ratings yet

- Style File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/116560 - SPORTS MASTER - PDS Global InfoDocument6 pagesStyle File: C:/Users/jubayer - sabuj/Desktop/2XU Pattern PDF/COMP DESIGN/116560 - SPORTS MASTER - PDS Global InfoBlack SoulNo ratings yet

- 028 Ga21ssm028btl Measurment GermanyDocument1 page028 Ga21ssm028btl Measurment GermanyBlack SoulNo ratings yet

- Measurement Charts OptitexDocument9 pagesMeasurement Charts OptitexBlack SoulNo ratings yet

- Baum Trading Size Specfication: A B C D E F I J M N O P QDocument1 pageBaum Trading Size Specfication: A B C D E F I J M N O P QBlack SoulNo ratings yet

- Itihasher OntoraleDocument226 pagesItihasher OntoraleBlack SoulNo ratings yet

- Effect of Different Machines On Different Structural FabricsDocument1 pageEffect of Different Machines On Different Structural FabricsBlack SoulNo ratings yet

- Preferences (3D - Illustrative Rendering) - OptitexDocument3 pagesPreferences (3D - Illustrative Rendering) - OptitexBlack SoulNo ratings yet

- PSF VERTBAUDET 70004-0438 79425 BODY SUIT A 54255 202103091616080711 MfileDocument23 pagesPSF VERTBAUDET 70004-0438 79425 BODY SUIT A 54255 202103091616080711 MfileBlack SoulNo ratings yet

- BLC Nov2021 JP04Document77 pagesBLC Nov2021 JP04Black SoulNo ratings yet

- Style Front Page: Fabric DetailsDocument10 pagesStyle Front Page: Fabric DetailsBlack SoulNo ratings yet

- Study On The Changes of GSM (GM/M 2) of Grey Knitted Fabric From Pretreatment To FinishingDocument19 pagesStudy On The Changes of GSM (GM/M 2) of Grey Knitted Fabric From Pretreatment To FinishingSamir RanaNo ratings yet

- Tle Dressmaking9 q2 m9Document8 pagesTle Dressmaking9 q2 m9ALLYSSA MAE PELONIANo ratings yet

- W6 N 1615 Instruction - ManualDocument48 pagesW6 N 1615 Instruction - Manualtanginamooooo42No ratings yet

- TLE 9 READING MATERIALS 13 and 14Document2 pagesTLE 9 READING MATERIALS 13 and 14Jeff LacasandileNo ratings yet

- Simple Skyp Socks PDF v.2.2Document2 pagesSimple Skyp Socks PDF v.2.2hello hiNo ratings yet

- Union VS Sewing Machine Instruction ManualDocument18 pagesUnion VS Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- GATE 2003 - Question Paper TF: Textile Engineering and Fiber ScienceDocument26 pagesGATE 2003 - Question Paper TF: Textile Engineering and Fiber ScienceChandra Deep Mishra0% (1)

- Bucket Hat Pattern by AppleGreen CottageDocument6 pagesBucket Hat Pattern by AppleGreen CottageNguyen100% (1)

- H&M QC Inspection Manual: ContentDocument9 pagesH&M QC Inspection Manual: ContentMark Arvel Pe Singson100% (2)

- Ruffl Ed Collar PatternDocument1 pageRuffl Ed Collar PatternSarang KimNo ratings yet

- Astm-D 3886 - 99 (2015)Document6 pagesAstm-D 3886 - 99 (2015)hiepphuong84No ratings yet

- Acacia Furniture and Upholstery Training ProposalDocument8 pagesAcacia Furniture and Upholstery Training ProposalKhalid OmerNo ratings yet

- BooksDocument10 pagesBooksPundeep ToorNo ratings yet

- HAEJPK 20200320 Underwater Dolphin and TurtleDocument62 pagesHAEJPK 20200320 Underwater Dolphin and Turtlexega13No ratings yet

- Cube Foxy Fox Amigurumi PatternDocument16 pagesCube Foxy Fox Amigurumi PatternyouaremyinoriNo ratings yet

- Train Amigurumi - Free Pattern in EnglishDocument19 pagesTrain Amigurumi - Free Pattern in EnglishTiduj Rácsib100% (8)

- Sewing Machine Operation - SMODocument17 pagesSewing Machine Operation - SMOMujahid ReanNo ratings yet

- PANTSDocument8 pagesPANTSAlicia MyersNo ratings yet

- SRG APPAREL CC - GOTS - Srgapparelsltd - 2021 - 05 - 13 - 11 - 25 - 02Document8 pagesSRG APPAREL CC - GOTS - Srgapparelsltd - 2021 - 05 - 13 - 11 - 25 - 02Ashok LakshmananNo ratings yet

- Garments DefectDocument20 pagesGarments DefectFahima RashidNo ratings yet

- Guitar ENDocument8 pagesGuitar ENSandra Cuenca Figueroa100% (2)

- Pegasus (W&G) 500 I & 500 II Overlocks Instruction ManualDocument23 pagesPegasus (W&G) 500 I & 500 II Overlocks Instruction ManualGuarumo FuentesNo ratings yet

- Crochet Minion For Beginners Amigurumi PDF PatternDocument8 pagesCrochet Minion For Beginners Amigurumi PDF Patternsouji soujanyaNo ratings yet

- Janome Skyline 55 Sewing Machine Instruction ManualDocument92 pagesJanome Skyline 55 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet