Professional Documents

Culture Documents

Gauge Repeatability and Reproducibility Data Sheet Variable Data Results

Gauge Repeatability and Reproducibility Data Sheet Variable Data Results

Uploaded by

Sharif KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gauge Repeatability and Reproducibility Data Sheet Variable Data Results

Gauge Repeatability and Reproducibility Data Sheet Variable Data Results

Uploaded by

Sharif KhanCopyright:

Available Formats

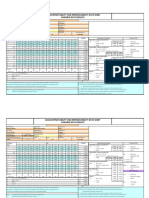

GAUGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET

VARIABLE DATA RESULTS

Part Number Gage Name Appraiser A

3990 5800 4009 Vernier height gauge Vinayak

Part Name Gage Number : Appraiser B

camouflage support bkt AG.001 Vithal

Characteristic Specification Instrument Type : Appraiser C

Height 57.7000 58.3000 0-300 Raju

Characteristic Classification Trials Parts Appraisers Date Performed

Critical 57.7000 58.3000 3 10 3 8-Oct-14

APPRAISER/ PART AVERAGE Measurement Unit Analysis % Tolerance (Tol)

TRIAL # 1 2 3 4 5 6 7 8 9 10 Repeatability - Equipment Variation (EV)

1. A 1 58.3000 58.3000 56.8000 58.5000 58.2000 58.5000 57.8000 59.1000 58.4000 58.4000 58.23000 EV = R x K1 Trials K1 % EV = 100 (EV/Tol)

2 2 58.4000 58.3000 56.8000 58.5000 58.2000 58.5000 57.8000 59.1000 58.4000 58.3000 58.23000 = 0.05667 x 0.5908 2.0000 0.8862 = 100(0.0335/0.6000)

3 3 58.3000 58.3000 56.9000 58.5000 58.2000 58.5000 57.8000 59.1000 58.4000 58.3000 58.23000 = 0.0335 3.0000 0.5908 = 5.5798

4 AVE 58.333 58.300 56.833 58.500 58.200 58.500 57.800 59.100 58.400 58.333 xa= 58.23000 Reproducibility - Appraiser Variation (AV)

5 R 0.100 0.000 0.100 0.000 0.000 0.000 0.000 0.000 0.000 0.100 ra= 0.03000 AV = {(xDIFF x K2)2 - (EV2/nr)}1/2 % AV = 100 (AV/Tol)

6. B 1 58.1000 58.1000 56.9000 58.2000 58.1000 58.9000 57.9000 58.9000 58.1000 58.1000 58.13000 = {(0.13667 x 0.5321)^2 - (0.03348 ^2/(10 x 3))}^1/2 = 100(0.0725/0.6000)

7 2 58.1000 58.1000 56.9000 58.1000 58.1000 58.9000 57.9000 58.9000 58.1000 58.0000 58.11000 = 0.0725 Appraisers 2.0000 3.0000 = 12.0772

8 3 58.0000 58.0000 56.9000 58.1000 58.0000 58.9000 57.9000 58.9000 58.0000 58.1000 58.08000 K2 0.7071 0.5321 n = number of parts

9 AVE 58.067 58.067 56.900 58.133 58.067 58.900 57.900 58.900 58.067 58.067 xb= 58.10667 Repeatability & Reproducibility (R & R) r = number of trials

10 R 0.100 0.100 0.000 0.100 0.100 0.000 0.000 0.000 0.100 0.100 rb= 0.06000 R&R = {(EV2 + AV2)}1/2 Parts K3

11. C 1 58.4000 58.4000 56.7000 58.6000 58.2000 58.6000 58.4000 58.4000 58.3000 58.4000 58.24000 = {(0.0335^2 + 0.0725^2)}^1/2 2.0000 0.7071 % R&R = 100 (R&R/Tol)

12 2 58.3000 58.4000 56.8000 58.6000 58.2000 58.6000 58.4000 58.4000 58.4000 58.3000 58.24000 = 0.0798 3.0000 0.5231 = 100(0.0798/0.6000)

13 3 58.4000 58.3000 56.7000 58.6000 58.3000 58.5000 58.5000 58.4000 58.4000 58.4000 58.25000 Part Variation (PV) 4.0000 0.4467 = 13.3038

14 AVE 58.367 58.367 56.733 58.600 58.233 58.567 58.433 58.400 58.367 58.367 xb= 58.24333 PV = RP x K3 5.0000 0.4030 Gauge system may be acceptable

15 R 0.100 0.100 0.100 0.000 0.100 0.100 0.100 0.000 0.100 0.100 rb= 0.08000 = 1.9778 x 0.3146 6.0000 0.3742

16. PART X= 58.19333 = 0.6222 7.0000 0.3534 % PV = 100 (PV/Tol)

AVE ( Xp ) 58.256 58.244 56.822 58.411 58.167 58.656 58.044 58.800 58.278 58.256 Rp= 1.97778 Tolerance 8.0000 0.3375 = 100(0.6222/0.600000)

17 (ra + rb + rc) / (# OF APPRAISERS) = R= 0.05667 Tol = Upper - Lower 9.0000 0.3249 = 103.7015

18 (Max x - Min x) = xDIFF= 0.13667 = 58.3 - 57.7 10.0000 0.3146

19 R x D4* = UCLR= 0.14620 = 0.6000 NDC = 1.41(PV/R&R)

20 R x D3* = LCLR= 0.00000 = 10.99075

= 11

* D4 =3.27 for 2 trials and 2.58 for 3 trials; D3 = 0 for up to 7 trials. UCLR represents the limit of individual R's. Circle those that are All calculations are based upon predicting 5.15 sigma (99.0% of the area under the normal distribution curve).

beyond this limit. Identify the cause and correct. Repeat these readings using the same appraiser and unit as originally used or dis- K1 is 5.15/d2, where d2 is dependent on the number of trials (m) and the number if parts times the number of is

card values and re-average and recompute R and the limiting value from the remaining observations. operators (g) which assumed to be greater than 15.

AV - If a negative value is calculated under the square root sign, the appraiser variation (AV) defaults to zero (0).

Notes: 1) Use parts for reading from different lot or shift , never from a continous flow. K2 is 5.15/d2, where d2 is dependent on the number of operators (m) and (g) is 1, since there is only one range calculation.

2) Not to be used for checking special characteristics in any part K2 is 5.15/d2, where d2 is dependent on the number of parts (m) and (g) is 1, since there is only one range calculation.

d2 is obtained from Table D3, "Quality Control and Industrial Statistics", A.J. Duncan.

You might also like

- Gauge Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument5 pagesGauge Repeatability and Reproducibility Data Sheet Variable Data ResultsSharif KhanNo ratings yet

- MSA of Sealing Plate DC-12Document2 pagesMSA of Sealing Plate DC-12RahulNo ratings yet

- Msa Data Sheet VariableDocument10 pagesMsa Data Sheet VariableDandik ErwantoNo ratings yet

- GRR # Inner Dia 75.85 +0.046 #3.182503Document2 pagesGRR # Inner Dia 75.85 +0.046 #3.182503rpengworksNo ratings yet

- Guage R&R StudyDocument1 pageGuage R&R StudyMkrp KameswarNo ratings yet

- Gage Repeatability and Reproducibility Data SheetDocument12 pagesGage Repeatability and Reproducibility Data SheetDiiego LozadaNo ratings yet

- G65QS - Canopy Set: PRIME KVA: 63.00 - STANDBY KVA 71.00 2750mmDocument4 pagesG65QS - Canopy Set: PRIME KVA: 63.00 - STANDBY KVA 71.00 2750mmمحمد النذيرNo ratings yet

- SPC Afs No.Document2 pagesSPC Afs No.Dhananjay PatilNo ratings yet

- Msa (25.40)Document1 pageMsa (25.40)Quality VenusNo ratings yet

- Power AnalyzerDocument6 pagesPower AnalyzerdimulescuremusNo ratings yet

- MSA StudyDocument22 pagesMSA StudySandip PandeNo ratings yet

- GR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationDocument4 pagesGR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationRahulNo ratings yet

- Gage R&R-part To Part-ToleranceDocument5 pagesGage R&R-part To Part-ToleranceTiếnTrầnHồVănNo ratings yet

- Repeability and Reproducibility Analysis ReportDocument7 pagesRepeability and Reproducibility Analysis ReportJulio Isaias GarciaNo ratings yet

- REPETIBILIDAD Y REPRODUCIBILIDAD Parte 2Document6 pagesREPETIBILIDAD Y REPRODUCIBILIDAD Parte 2Juan Manuel De La CruzNo ratings yet

- Averages (X Bar Chart) : Gage R AnalysisDocument1 pageAverages (X Bar Chart) : Gage R AnalysisFernando BeltránNo ratings yet

- Chain Test RigDocument6 pagesChain Test RigService MMINo ratings yet

- GR&R (9.50)Document1 pageGR&R (9.50)Quality VenusNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- CHW2204-00-EL-ITR-7301 RevA Factory AcceptanceTest Reports and Certificates For ACBDocument8 pagesCHW2204-00-EL-ITR-7301 RevA Factory AcceptanceTest Reports and Certificates For ACBThẩm Trần Thanh PhongNo ratings yet

- R&R StudyDocument1 pageR&R StudyDr Rajamani R - PSGCTNo ratings yet

- Özgüney: Transformer TestDocument1 pageÖzgüney: Transformer TestmominzadahNo ratings yet

- 1602-A2 Performance Test Certificate R1Document1 page1602-A2 Performance Test Certificate R1adhyharmonypngNo ratings yet

- (A Division of Testing & Calibration India (Opc) Pvt. LTD)Document1 page(A Division of Testing & Calibration India (Opc) Pvt. LTD)santanushee8No ratings yet

- Variablegauge Rand RDocument20 pagesVariablegauge Rand RpruthviNo ratings yet

- E560 CVD03 DSDocument5 pagesE560 CVD03 DSdwie wijayantoNo ratings yet

- 249-317 Tec Aero Tue-C-100-293Document1 page249-317 Tec Aero Tue-C-100-293KiranNo ratings yet

- G440QX - Canopy Set: PRIME KVA: 418.90 - STANDBY KVA 463.70 4500mmDocument4 pagesG440QX - Canopy Set: PRIME KVA: 418.90 - STANDBY KVA 463.70 4500mmsarita_hectorNo ratings yet

- MSA FormatDocument4 pagesMSA FormatSaurabh PhandNo ratings yet

- LAB Session 06 To Draw The Characteristic Curves For Tangy Air CompressorDocument9 pagesLAB Session 06 To Draw The Characteristic Curves For Tangy Air CompressorSikandar DogarNo ratings yet

- Lab Fl14a086cDocument5 pagesLab Fl14a086czyassNo ratings yet

- Ehsan (3050) Lab 01Document7 pagesEhsan (3050) Lab 01Antenna /// Power ElectronicsNo ratings yet

- Hasil Pengujian Differential Relay Transformer F87T: Transformator Bay Test ReportDocument9 pagesHasil Pengujian Differential Relay Transformer F87T: Transformator Bay Test Reportbudifirmansyah. globaltwinstarNo ratings yet

- Measurement System Analysis (MSA) Gauge Repeatability & Reproducibility (GR&R)Document1 pageMeasurement System Analysis (MSA) Gauge Repeatability & Reproducibility (GR&R)Sharif KhanNo ratings yet

- Detail: 76,000 Dwt Bulk Carrier 76,000吨散货轮Document6 pagesDetail: 76,000 Dwt Bulk Carrier 76,000吨散货轮Jagmohan SinghNo ratings yet

- GageRR Analisis RRDocument2 pagesGageRR Analisis RRYli S'cNo ratings yet

- Gage Repeatability and Reproducibility Data Sheet Gage Repeatability and Reproducibility Data Sheet Variable Data Results Variable Data ResultsDocument1 pageGage Repeatability and Reproducibility Data Sheet Gage Repeatability and Reproducibility Data Sheet Variable Data Results Variable Data ResultsRohitNo ratings yet

- Stability Test GT (30 Nov 2021) - Calc 13 Des 2021 2Document37 pagesStability Test GT (30 Nov 2021) - Calc 13 Des 2021 2Mr IlchamNo ratings yet

- Özgüney: Test TransformerDocument1 pageÖzgüney: Test TransformermominzadahNo ratings yet

- Özgüney: Test TransformerDocument1 pageÖzgüney: Test TransformermominzadahNo ratings yet

- Uncertainty Analysis - Performance of Centrifugal VentilatorDocument34 pagesUncertainty Analysis - Performance of Centrifugal VentilatorMohamed AhmeedNo ratings yet

- Lab Reports PCTDocument34 pagesLab Reports PCTaamir.faiazNo ratings yet

- SPC FormatDocument1 pageSPC FormatKishan Royal VirkNo ratings yet

- YSIODocument4 pagesYSIOrex.lopez.tmcclarkbiomedNo ratings yet

- Calibration Certificate PQW-1500Document4 pagesCalibration Certificate PQW-1500VikasNo ratings yet

- Expt 6 The Split Phase MotorDocument4 pagesExpt 6 The Split Phase MotorCapalar KyleNo ratings yet

- Asumsi KlasikDocument6 pagesAsumsi KlasikDina RamadanaNo ratings yet

- Expt 6 The Cage Rotor Induction MotorDocument5 pagesExpt 6 The Cage Rotor Induction MotorRyan De GuzmanNo ratings yet

- SPC 24809 En19 Ø58Document1 pageSPC 24809 En19 Ø58HAMPI JBNo ratings yet

- Performance Analysis of Motor (Direct Method) : Ex - PTDocument7 pagesPerformance Analysis of Motor (Direct Method) : Ex - PTArul Selvan RajaduraiNo ratings yet

- M3AA 180MLA 8 G 400V 50Hz 11kWDocument1 pageM3AA 180MLA 8 G 400V 50Hz 11kWdiablolcNo ratings yet

- 10% To 30% Error - May Be Acceptable Based Upon Importance of ApplicationDocument3 pages10% To 30% Error - May Be Acceptable Based Upon Importance of ApplicationktyeoNo ratings yet

- PAEC2016 - Shear Wall Investigation AnalysisDocument5 pagesPAEC2016 - Shear Wall Investigation AnalysisSayavi Nicole Sayavi NickNo ratings yet

- Exp04Document4 pagesExp04asifasmat14No ratings yet

- Ha04 - 3mva Unit Auxailry Transformer Unit#10Document5 pagesHa04 - 3mva Unit Auxailry Transformer Unit#10Asgher khkattakNo ratings yet

- G R&RDocument12 pagesG R&Rpradeep kumarNo ratings yet

- Abc Pvt. LTD.: Statistical Process Control StudyDocument1 pageAbc Pvt. LTD.: Statistical Process Control StudySAURAV KAUSHALNo ratings yet

- Functional Testing of G60 A Test Results Engro PDFDocument14 pagesFunctional Testing of G60 A Test Results Engro PDFunab84No ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

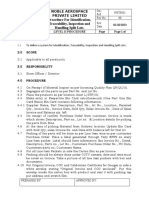

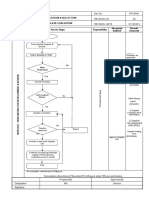

- Procedure For TrainingDocument3 pagesProcedure For TrainingSharif Khan100% (1)

- Procedure For QADocument7 pagesProcedure For QASharif Khan100% (1)

- Procedure For Management ReviewDocument3 pagesProcedure For Management ReviewSharif Khan100% (1)

- Location ChartDocument6 pagesLocation ChartSharif KhanNo ratings yet

- Procedure For Design andDocument4 pagesProcedure For Design andSharif Khan100% (1)

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- Procedure For MaintenanceDocument2 pagesProcedure For MaintenanceSharif KhanNo ratings yet

- Design Review Report: Sr. No. Review CommentsDocument1 pageDesign Review Report: Sr. No. Review CommentsSharif KhanNo ratings yet

- Goods Received and Inspection Report: 2014-2015 GRN RECEIPTSDocument301 pagesGoods Received and Inspection Report: 2014-2015 GRN RECEIPTSSharif KhanNo ratings yet

- Procedure For Identification, Traceablity, Inspection and Handeling Split Lots.Document2 pagesProcedure For Identification, Traceablity, Inspection and Handeling Split Lots.Sharif KhanNo ratings yet

- Procedure For MARKETINGDocument2 pagesProcedure For MARKETINGSharif KhanNo ratings yet

- Iso & Iatf Corelation in StandardsDocument19 pagesIso & Iatf Corelation in StandardsSharif KhanNo ratings yet

- Procedure For Evaluation and SelectionDocument2 pagesProcedure For Evaluation and SelectionSharif KhanNo ratings yet

- Quality PolicyDocument2 pagesQuality PolicySharif KhanNo ratings yet

- HAWk Eye TechnologyDocument59 pagesHAWk Eye Technology91udayNo ratings yet

- Reading Notes From How To Write A Master Thesis PDFDocument1 pageReading Notes From How To Write A Master Thesis PDFQurrat N JamalNo ratings yet

- Indian Standard: Quality Assurance Requirements FOR Measuring EquipmentDocument23 pagesIndian Standard: Quality Assurance Requirements FOR Measuring EquipmentproxywarNo ratings yet

- Chapter # 4 Analysis: DegreeDocument8 pagesChapter # 4 Analysis: DegreeDure KashafNo ratings yet

- Steyerberg Prediction Modeling 7 Steps Jan10Document45 pagesSteyerberg Prediction Modeling 7 Steps Jan10Fajar Rudy QimindraNo ratings yet

- An Analysis of The Factors Affecting TheDocument15 pagesAn Analysis of The Factors Affecting TheMikee Ellen JabonilloNo ratings yet

- Handbook On Project Work For Post Graduate Diploma in Urban Planning and Development (PGDUPDL)Document34 pagesHandbook On Project Work For Post Graduate Diploma in Urban Planning and Development (PGDUPDL)Mahiruddin AnsariNo ratings yet

- To Study The Relationship Between Perceived Stress and Procrastination Among Young AdultsDocument4 pagesTo Study The Relationship Between Perceived Stress and Procrastination Among Young AdultsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Lecture07 HMM SDocument26 pagesLecture07 HMM SHui Ka HoNo ratings yet

- Continous Probability DistributionDocument40 pagesContinous Probability DistributionpaopaoNo ratings yet

- Confusion MatrixDocument3 pagesConfusion Matrixsaranraj7691No ratings yet

- 4 - LM Test and HeteroskedasticityDocument13 pages4 - LM Test and HeteroskedasticityArsalan KhanNo ratings yet

- Short Questions Answers StatisticsDocument17 pagesShort Questions Answers StatisticsAli Hussain100% (2)

- Random VariableDocument51 pagesRandom VariableJash Antoneth TimbangNo ratings yet

- BBA Business AdministartionDocument60 pagesBBA Business AdministartionCool EfxNo ratings yet

- Sample Size Master ThesisDocument8 pagesSample Size Master Thesisphewzeajd100% (2)

- Chap9 Decision TreeDocument51 pagesChap9 Decision TreeJakhongirNo ratings yet

- Lecture Note 4 To 7 OLSDocument29 pagesLecture Note 4 To 7 OLSViktória KónyaNo ratings yet

- Topic Model For LDADocument9 pagesTopic Model For LDAHoang Khanh HungNo ratings yet

- PTSP Unit-3 Important Questions& AnswersDocument36 pagesPTSP Unit-3 Important Questions& AnswersECE N.V.Satyanarayana MurthyNo ratings yet

- XI Annual ExamDocument4 pagesXI Annual ExamAnika MohapatraNo ratings yet

- Optimization of Plant Fertilizer by The Use of Pencil ShavingsDocument2 pagesOptimization of Plant Fertilizer by The Use of Pencil ShavingsJNo ratings yet

- Predictive Analytics CourseDocument3 pagesPredictive Analytics CourseManjulaNo ratings yet

- Design Solution For Effective Public Toilets in CitiesDocument71 pagesDesign Solution For Effective Public Toilets in CitiesAnkit Singh RajputNo ratings yet

- Asian MethodologyDocument5 pagesAsian MethodologyJoyce l. GaytosNo ratings yet

- Brochura PGM en 47edDocument52 pagesBrochura PGM en 47edZene KentishNo ratings yet

- C 41304219Document14 pagesC 41304219विशाल पुडासैनीNo ratings yet

- AS306 Fme Cou HSK Jan13Document2 pagesAS306 Fme Cou HSK Jan13MayWy KyNo ratings yet

- I MIB SyllabusDocument11 pagesI MIB SyllabusdhekabaiNo ratings yet