Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanCopyright:

Available Formats

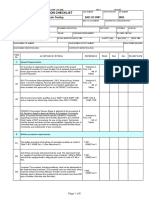

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Instrumentation Workspace Clearances

Civil / Structural Installation - Visual Inspection SAIC-J-6022 24-Jul-18

(before skid installation)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SAES-B-054

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME Sec. 4.2 QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL RE-INSP DATE

No.

A Document Review and Certification

A1 Review Quality Documentation for Material Receiving. Schedule Q Att. IV Sec. 3.3

Identification - Instrumentation materials shall be identified by using tags,

Schedule Q

stamps, color coding, stencils or labels. The location and the method of

A2 Att. lV

identification shall not affect the function or quality of the item being

Sec. 4.2

identified.

Schedule G

A3 New and Unused - Instrumentation materials shall be new and unused.

Sec. 2.1

As Designed - Instrumentation materials shall be in accordance with the

Schedule G

A4 Saudi Aramco-approved project-specific design drawings, diagrams,

Sec. 2

schedules, lists, databases and associated documents.

Free of Damage - Instrumentation materials shall be free of damage. All

incoming materials shall be visually inspected for damage and Schedule Q Att. IV

A5

conformance to all applicable inspection releases with Material Test Sec. 3.3

Report (MTR).

QC Before Installation - Instrumentation materials shall conform to all

Schedule Q Att. IV

A6 applicable requirements, standards and specifications prior to release to

Sec. 3.3

be used as part of the work.

Traceability - Instrumentation materials shall be traceable from the

Schedule Q Att. IV

A7 manufacturer and supplier through delivery, storage, fabrication, erection,

Sec. 4.3

installation, repair, modification and use.

Verify that the contractor or it's Saudi Aramco approved third party

inspector performed the quality activities at the supplier and sub-supplier Schedule Q Att. III

A8

locations as required by the inspection level assigned for the materials Sec. 3.2

and equipment identified in SAER-1972 Inspection Requirements.

Storage, Handling and Preservation

The manufacturer's storage, handling and preservation instructions to be

A9 Schedule Q Att. IV Sec. 6.0

followed.

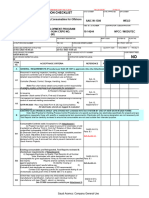

B1 General Workspace Clearance

General: Plant facilities shall be provided with acceptable access and

egress for personnel, materials and equipment by using accessways,

SAES-B-054

B1 ladders, roads, stairways, stile, and walking/working surfaces (decks,

Sec 5.1

floors, grade, platforms, ramps, runways and walkways) based on the

requirements in this standard.

Access Requirements for Equipment Regularly Operated

or Maintained or Operated in an Emergency: For

equipment regularly operated or maintained or operated

in an emergency, such as valve hand wheels,

instrumentation, controls, and their associated manifolds,

the distance, if located outside the handrails, from a fixed

walking/working surface to the operating point shall be

between 500 mm and 1500 mm vertically and a maximum

of 510 mm horizontally. It shall be located away from top

B2 rail, midrails and supports to allow access. SAES-B-054 Sec.5.2

Saudi Aramco: Company General Use

Access Requirements for Equipment Regularly Operated

or Maintained or Operated in an Emergency: Access is

also acceptable for instrumentation, controls and

associated manifolds

if the distance from the outside of a fixed ladder or fixed

B3 stairs to the operating point does not exceed 510 mm. SAES-B-054 Sec. 5.2

Access Requirements for Valves Not Regularly Operated:

Valves not regularly operated shall be accessed from

portable platforms, portable stairs, portable ladders or

temporary scaffolding if access from fixed walking/working

B4 surfaces or fixed stairs is not provided. SAES-B-054 Sec. 5.5

Access/Egress Clearances for Personnel: Minimum clear

width of walking/surfaces, stairways and stiles shall be 760

B5 mm. SAES-B-054 Sec. 5.7.1

Access/Egress Clearances for Personnel: The minimum

clear width for tank stairways shall be per SAES-B-054

B6 Section 7, Paragraph (6.3). SAES-B-054 Sec. 5.7.1.a)

Access/Egress Clearances for Personnel: The minimum

clear width shall be 910 mm where working area is needed

such as in the front of a manhole for servicing trays, the

end of a heat exchanger for servicing the bonnet, channel,

B7 and tube bundle, or around rotating equipment. SAES-B-054 Sec. 5.7.1.b)

Access/Egress Clearances for Personnel: The minimum

clear width of aisles shall be 1020 mm. (An aisle is

personnel walking space around equipment at grade

B8 level.) SAES-B-054 Sec. 5.7.1.c)

Access/Egress Clearances for Personnel: The minimum

headroom above walking/working surfaces shall be 2030

mm, measured to the lowest point of an overhead

B9 obstacle. SAES-B-054 Sec. 5.7.2

Access/Egress Clearances for Personnel: The minimum

vertical clearance under vertical furnaces shall be 2030

B10 mm. SAES-B-054 Sec. 5.7.3

Access/Egress Clearances for Personnel: The vertical

clearance above any stair tread to an overhead

obstruction shall be at least 2030 mm measured from the

B11 leading edge of the tread. SAES-B-054 Sec. 5.7.4

Personnel Ramps: Personnel ramps shall be designed per

SAES-M-001 and SAES-M-100 and shall be constructed

of steel per 12-SAMSS-007.

Exception: The slip resistant walking surface shall not be

B12 steel. SAES-B-054 Sec. 3.1

C Flow Instrument

All instrumentation and associated control equipment shall

be readily accessible from grade, platform, fixed walkway

or a fixed stairway. Local indicating instruments shall be

visible from where related equipment is operated or SAES-J-003 Sec. 10.1.3 ,

C1 primary instruments are tested or calibrated.

D Level Instrument

The selection of process measurement instrumentation

shall consider the following as a minimum: Application

suitability, Reliability, Turndown ratio, Required Accuracy,

D1 Operability and Maintainability SAES-J-100 Section 4.1.1

Selection of instrumentation for ESD service shall meet

D2 requirements of SAES-J-601 in addition to this standard. SAES-J-100 Section 4.1.3

D3 All installation requirements shall follow SAES-J-003. SAES-J-100 Section 4.2.1

Location and Orientation: Connections to the bottom of

vessels shall be avoided whenever possible. However,

when used, bottom vessel connections shall include an

internal nozzle extension to reduce bottom solids from

D4 entering the standpipe. SAES-J-100 Sec. 7.1.3

Saudi Aramco: Company General Use

Location and Orientation: Local receiving instruments shall

D5 be installed 1.40 m above grade level. SAES-J-100 Sec. 7.12.9

D6 Access requirements shall meet SAES-B-054. SAES-J-100 Section 7.5.3

E Temperature Instrument

All temperature instruments, connections and primary

elements shall be located to provide safe access for

E1 installation and maintenance. SAES-J-003 Sec. 10.1.3

Instrumentation requiring frequent access, such as local

controllers, shall be located no more than 1.5 meters

E2 above grade or permanent platform. SAES-J-003 Sec. 10.1.3

F Combustible Gas and Hydrogen Sulfide in Air Detection Systems

Accessibility:

Detectors shall be readily accessible for calibration. If

necessary, access platforms shall be provided as needed,

F1 per SAES-B-054.. SAES-J-505 Sec. 9.2

G Analyzer Shelter

Shelter Location: A minimum walking space of 3 m (10 ft)

from the exterior shelter walls shall be provided around all

shelter sides.

Commentary Note:

The intent is to provide adequate working space around

analyzer shelters to facilitate routine maintenance (the

movement of equipment in and out of the shelter, storage

of gas cylinders, and working space for maintenance

personnel) and to provide a clear path in the event of an

emergency. A minimum of 1 m distance from the analyzer

shelter to structural steel columns is acceptable provided

free access to sample conditioning systems and exit doors

G1 is available SAES-J-510 Sec.12.4.1

Shelter Size: Shelter interior shall be large enough to allow

adequate access and space for maintenance and repair

activities. Analyzers shall have a maximum 600 mm (24 in)

G2 of free space on each side or between individual analyzers SAES-J-510 Sec.12.1.4

Shelter Size: All shelters greater than 10 square meters in

size, shall have at least two exits, located at opposite ends

G3 of the shelter. SAES-J-510 Sec. 12.2.3.2

Shelter Size: Shelters shall be designed for multiple

analyzer use and shall provide one extra analyzer slot with

additional sample system slot on the outside wall of the

G4 shelter for future expansion SAES-J-510 Sec. 12.2.2

Shelter doors shall open outwards, be self-closing, and

shall have steel frames. Doors shall be sized to permit the

G5 removal and installation of equipment SAES-J-510 Sec. 12.2..3

An inspection window shall be installed in each shelter

door. Glass shall be laminated or tempered safety glass

meeting the requirements of ANSI Z 97.1. The window

G6 shall not exceed 0.065 m2 (100 in2) in area SAES-J-510 Sec.12.2.3.3

In addition to the basic construction requirements defined

in 12-SAMSS-014 above, the shelter shall incorporate the

following features: All doors shall be equipped with quick-

opening bars (panic bars) on the inside, which shall

G7 override exterior locks. SAES-J-510 Sec. 12.2.3.4.

H Burner Management, Combustion and Waterside Control Systems for Watertube Boilers

Access shall be allowed to facilitate testing, calibration and

H1 maintenance. SAES-J-602 Sec.4.2.9

The position of local indicating instruments shall enable

them to be observed from grade, platform or walkway

while related equipment is operated or when primary

H2 instruments are being tested or calibrated SAES-J-602 Sec.4.2.10

Saudi Aramco: Company General Use

Instruments and components shall be located so that they

are protected against direct drainage or blowdown of

condensate, water or process fluids from adjacent

H3 equipment. SAES-J-602 Sec4.2.11

All locally mounted instrumentation and associated control

equipment shall be accessible from grade, platform, or

fixed walkway to facilitate testing and maintenance. Where

necessary, provide standoff shielding around

instrumentation to prevent operator contact with high

temperature surfaces, as per requirements in SAES-F-

H4 001. SAES-J-602 Sec.4.2.12

I Process Heaters Safety Systems

The process heater local control/shutdown panel shall be

located so that the power operated fuel gas emergency

isolation valves positions (EIV, also called a ZV) can be

I1 seen from the panel SAES-J-603 Sec. 3.5.2

J Control Valves

Handwheels: A handwheel shall be provided on valves

when local manual control is required by the Proponent.

Handwheel installations shall meet the following

requirements: Handwheel shall be fully accessible for

J1 operation. SAES-J-700 Sec. 8.1

Control valves shall be installed such that they can be

easily removed for maintenance including angle control

valves (i.e., if necessary a piping spool shall be installed to

J2 prevent the need to remove major piping). SAES-J-700 Sec. 9.1

Control valves and their actuating systems shall be

mounted such that all adjustments are accessible (and all

indicators/gauges are readable) from grade, permanent

J3 platform, walkway or fixed ladder. SAES-J-700 Sec. 9.1

J4 Portable platforms and portable ladders shall not be used. SAES-J-700 Sec 9.1

Sufficient clearances shall be provided for the removal of

J5 any part of the control valve or actuator assembly. SAES-J-700 Sec. 9.1

Access space for lifting equipment shall be provided for

J6 valve and actuator assemblies weighing over 50 kg. SAES-J-700 Sec. 9.1

K Control Buildings

The main entrance to the control building, which shall face

away from the process plant or face the plant considered

to have the least risk of fire or explosion, shall be provided

with an air lock to sustain building pressurization. Locks

are not required for emergency exits and service

entrances. Certain emergency exist doors may be

restricted from being opened from outside, but personnel

K1 shall be able to open them from inside. SAES-J-003 Sec.14.3.3.1

The floor plan shall be designed to minimize casual

personnel traffic through the control room. Offices and

equipment rooms should be connected by internal

corridors. For Central Control Buildings, the main entrance

shall open onto a lobby or corridor from which the control

room, offices and other facilities are accessed. For a Local

Control Building, the main entrance may open directly

K2 through an air lock to the control room area. SAES-J-003 Sec14.3.3.2

The computer room (when specified), engineering room

and process interface room (rack room) shall have their

K3 main access through the control room SAES-J-003 Sec14.3.3.3

Emergency exits shall provide easy exit routes from each

room and from the control building in accordance with

K4 SAES-M-100. SAES-J-003 Sec.14.3.3.4

Double doors shall be installed to provide outside access

to the control room, equipment rooms and rack rooms as

required. If the control room is elevated above grade then

loading platforms with stairways shall be provided to

facilitate equipment handling during installation and

maintenance. Equipment access doors shall be kept

locked during normal operation and shall meet the blast

resistance requirements of the structural walls of the

K5 building. SAES-J-003 Sec14.3.3.5

Saudi Aramco: Company General Use

The minimum recommended floor-to-ceiling height is 3

K6 meters. SAES-J-003 Sec.14.5.3.4

In hazardous (Class I, Zone 2 or Class I, Division 2) areas

or areas defined by the building risk assessment of SAES-

B-014, appropriate gas detectors shall be installed in the

pressurization air intake ducts to detect toxic or flammable

gases. Hydrogen sulfide and combustible gas monitors

shall be selected and installed in accordance with SAES-J-

K7 505. SAES-J-003 Sec.14.6.3.3

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract)

2. Schedule Q -- Quality Requirements (Pro Forma Contract), Project Specific

3. SAES-B-054 - Access, Egress, and Materials Handling for Plant Facilities, 28 March 2017

4. SAES-J-003 - Instrumentation and Control Buildings - Basic Design Criteria( 1 January 2018 )

5. SAES-J-100 - Process Measurement( 1 January 2018

6. SAES-J-505 - Combustible Gas and Hydrogen Sulfide in Air Detection Systems, 14 May 2018

7. SAES-J-510 - Process Analyzer Systems (15 September 2016)

8. SAES-J-602 - Burner Management, Combustion and Waterside Control Systems for Watertube Boilers,1 January 2018

9. SAES-J-603 - Process Heaters Safety Systems, 20 October 2015

10. SAES-J-700 - Control Valves, 1 January 2018

ATTACHMENTS:

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of

products or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services,

and whose listing states that the equipment, material or services either meets appropriate designated standards or has been tested and

found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified

organization concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by

whose labeling the manufacturer indicates compliance with appropriate standards or performance in a specified manner.

5. Notes - This check list is for Mechanical Equipment Skid - Non Hazardous locations only (Does not apply for Custom engineered

Package units but only for pre-engineered, pre-assembled and pre- wired skid mounted packaged units)

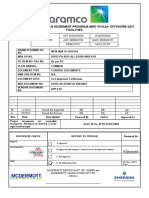

Contractor / Third-Party Saudi Aramco

PMT Representative

Construction Representative*

Name, Initials Work is Complete and Ready for T&I Witnessed QC Record RevWork Verified

and Date: Inspection: Name, Initials an

QC Inspector PID Representative

Performed Work / Rework May

Name, Initials Inspection Proceed Name, Initials T&I Witnessed QC Record RevWork Verified

and Date: and Date:

QC Supervisor Proponent and Others

Name,

Organization, T&I Witnessed QC Record RevWork Verified

Name, Sign and Initials and

Date: Quality Record Approved: Date:

Saudi Aramco: Company General Use

You might also like

- New Scientist International Edition - August 07 2021Document62 pagesNew Scientist International Edition - August 07 2021Thảo HoàngNo ratings yet

- Comptia Security Sy0 601 Exam Objectives (2 0)Document24 pagesComptia Security Sy0 601 Exam Objectives (2 0)tha_flameNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalik100% (1)

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDocument2 pagesSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingDocument1 pageSACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saic P 3315Document2 pagesSaic P 3315Arshad ImamNo ratings yet

- Satr J 6104Document5 pagesSatr J 6104Shahzad HussainNo ratings yet

- SACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingDocument2 pagesSACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstDocument16 pagesSaudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstnadeemNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- ARAMCO RT Inpection Check List - SAIC-RT-2001Document15 pagesARAMCO RT Inpection Check List - SAIC-RT-2001Anonymous hBBam1nNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkNo ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- SAIC-P-3005 Rev 7 FinalDocument2 pagesSAIC-P-3005 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- SAIC-P-3017 Rev 7 FinalDocument14 pagesSAIC-P-3017 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistOmer aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection ChecklistMohammad RizwanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic W 1308Document21 pagesSaic W 1308mathew.genesis.inspNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistpookkoya thangalNo ratings yet

- Saic W 1307Document10 pagesSaic W 1307mathew.genesis.inspNo ratings yet

- SAIC-L-2092 Rev 7Document12 pagesSAIC-L-2092 Rev 7Jaseel KanhirathingalNo ratings yet

- Airman Certification Standards: Instrument Rating - Helicopter (2024): FAA-S-ACS-14From EverandAirman Certification Standards: Instrument Rating - Helicopter (2024): FAA-S-ACS-14No ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- CamScanner 10-13-2021 23.17Document2 pagesCamScanner 10-13-2021 23.17nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khan100% (1)

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Laboratorium Pengujian Teknik Sipil Universitas Bandar LampungDocument1 pageLaboratorium Pengujian Teknik Sipil Universitas Bandar LampungPanji OctaWirawanNo ratings yet

- EXOS Quick Guide - Cheat SheetDocument19 pagesEXOS Quick Guide - Cheat Sheetmaverick2689No ratings yet

- PLC - HMI Lab #4 22W1Document2 pagesPLC - HMI Lab #4 22W1crazyjmprNo ratings yet

- Full Chapter Embracing Modern C Safely 1St Edition Lakos PDFDocument53 pagesFull Chapter Embracing Modern C Safely 1St Edition Lakos PDFjeffery.rosseau147No ratings yet

- Ex5500 PDFDocument7 pagesEx5500 PDFRoberto Chang PalmaNo ratings yet

- AfPS&CS Ch-01Document10 pagesAfPS&CS Ch-01Amelwork AlchoNo ratings yet

- Testbank: Applying Ifrs Standards 4eDocument11 pagesTestbank: Applying Ifrs Standards 4eSyed Bilal AliNo ratings yet

- 3I Grading Rubric For Output PresentationDocument2 pages3I Grading Rubric For Output PresentationBinibining Michelle CenizaNo ratings yet

- Partnership in Class Questions 2015Document3 pagesPartnership in Class Questions 2015Nella KingNo ratings yet

- Glumac Shanghai Office Fall 2016Document4 pagesGlumac Shanghai Office Fall 2016NagaraniNo ratings yet

- Cell Theory Refers To The Idea That: MicrographiaDocument5 pagesCell Theory Refers To The Idea That: MicrographiadeltasixNo ratings yet

- English For ITDocument276 pagesEnglish For ITBao Tram100% (1)

- Philippine Statistics Authority: Date (2021)Document9 pagesPhilippine Statistics Authority: Date (2021)Nah ReeNo ratings yet

- Lienard EquationDocument9 pagesLienard EquationmenguemengueNo ratings yet

- Effective Phone and Door Scripts 0Document6 pagesEffective Phone and Door Scripts 0Kaso MuseNo ratings yet

- Electrical Circuit Lab ManualDocument38 pagesElectrical Circuit Lab Manualecessec67% (3)

- Iklan Transtv - Ani, Adel, Vinda - Kelas ADocument9 pagesIklan Transtv - Ani, Adel, Vinda - Kelas ANur JamilaNo ratings yet

- Chapter 6: The Legal and Political Environment of Global BusinessDocument25 pagesChapter 6: The Legal and Political Environment of Global BusinessMaxineNo ratings yet

- Ultrasonic InterferometerDocument22 pagesUltrasonic InterferometerakshatguptaNo ratings yet

- CS FinalDocument52 pagesCS FinalLucky KhuhaNo ratings yet

- 03 - Literature ReviewDocument9 pages03 - Literature ReviewKhant Wai YanNo ratings yet

- UM 2008 Lightning MechanismDocument22 pagesUM 2008 Lightning Mechanismcik_sya87No ratings yet

- g8 With Answer SheetDocument4 pagesg8 With Answer SheetMICHAEL REYESNo ratings yet

- Christmas Vigil MassDocument106 pagesChristmas Vigil MassMary JosephNo ratings yet

- B94-6 R1995 E1984Document21 pagesB94-6 R1995 E1984zojoNo ratings yet

- Transistor 2n3904 DatasheetDocument2 pagesTransistor 2n3904 DatasheetAlex ZXNo ratings yet

- Drainage Below GroundDocument5 pagesDrainage Below GroundmisharyNo ratings yet

- Analysis of StructureDocument4 pagesAnalysis of StructureCarlson CaliwanNo ratings yet