Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanCopyright:

Available Formats

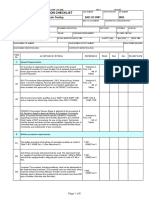

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Supplemental Support Fabrication and Installation

SAIC-J-6031 24-Jul-18 INST

Visual Inspection (Before Installation)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements

Schedule G

A1 New and Unused - Instrumentation materials shall be new and unused.

Sec. 2.1

As Designed - Instrumentation materials shall be in accordance with the

Schedule G

A2 Saudi Aramco-approved project-specific design drawings, diagrams,

Sec. 2

schedules, lists, databases and associated documents.

Identification - Instrumentation materials shall be identified by using tags,

Schedule Q

stamps, color coding, stencils or labels. The location and the method of

A3 Att. lV

identification shall not affect the function or quality of the item being

Sec. 4.2

identified.

Free of Damage - Instrumentation materials shall be free of damage. All

Schedule Q

incoming materials shall be visually inspected for damage and

A4 Att. IV

conformance to all applicable inspection releases with Material Test

Sec. 3.3

Report (MTR).

QC Before Installation - Instrumentation materials shall conform to all Schedule Q

A5 applicable requirements, standards and specifications prior to release to Att. IV

be used as part of the work. Sec. 3.3

Traceability - Instrumentation materials shall be traceable from the Schedule Q

A6 manufacturer and supplier through delivery, storage, fabrication, erection, Att. IV

installation, repair, modification and use. Sec. 4.3

B Inspection Before Installation

All strut components must be supplied by a single manufacturer. SAES-P-104

B1

(Unistrut Spec. Guide 1.02 B.2) Sec. 8.10.1

Channel erector system components (Unistrut or similar) used to support

conduits, cable trays, enclosures, lighting fixtures and other electrical SAES-P-104

B2

equipment shall be made of steel or iron, either hot-dip galvanized Sec. 8.10.1

(preferably), or zinc electroplated as supplied by the manufacturer.

Commentary Note 8.10:

Plant structural members used as supports for conduit and other electrical

SAES-P-104

B3 equipment are outside the scope of this Section. Attachment hardware

Sec. 8.10.1

(clamps, bolts, nuts, etc.) must however, comply with the requirements of

this Section.

Process piping shall not be used to support conduits, except with the

Proponent's approval. If process piping is used to support conduits, SAES-P-104

B4

adequate corrosion protection at the interface between the piping and Sec. 8.10.1

support fittings shall be provided.

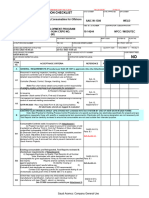

Saudi Aramco: Company General Use

Channel erector system components (Unistrut or similar) used to support

conduits, cable trays, enclosures, lighting fixtures and other electrical

equipment in severe corrosive environments shall be:

(A) as specified in Paragraph 8.10.1, and, in addition, protected by the

methods outlined in Paragraphs 8.9.2 (a) or (b),

1. Either hot-dip galvanized (preferably), or zinc electroplated

as supplied by the manufacturer.

2. and in addition

a) Factory-coating with PVC (minimum thickness of PVC:

40 mils) per NEMA RN 1.

b.) Field-coating prior to installation in accordance with

SAES-H-101 APCS-22(offshore), or APCS-26(onshore).

c). By heat-shrinkable tubes or wrap-arounds, where the SAES-P-104

B5 geometric configuration permits it. Sec. 8.9.2

(B) stainless steel

(C) fiberglass

a) Uncoated plugs and other bare metal shall be coated with PVC

patching compound, or with SAES-H-101 APCS-22 (offshore), or APCS-

SAES-P-104

B6 26 (onshore).

Sec. 8.9.2.a) & b)

b) After installation, any bare metal must be touched up using either of the

above coatings, without sandblasting.

C Installation Inspection

The edges of all tightly contacting surfaces shall be completely seal SAES-M-001

C1

welded. Sec.7.1.13.3

Continuous seal-welding shall be used in places that are not self-draining

or where crevice corrosion is likely to occur. If seal-welding is not 12-SAMSS-007

C2

practical, alternative methods of sealing shall be used with the approval of Sec.6.2.6.8

the Saudi Aramco Representative.

The complete assembly shall be checked to ensure alignment and level SAEP-1636

C3

after tightening of the bolts. Sec. 5

D Installation of Grounding

All exposed non-current-carrying metallic parts that could become

SAES-J-902

D1 energized with hazardous potentials must be reliably connected to the

Sec.17.2.1

equipment grounding circuits.

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract)

2. Schedule Q - Quality Requirements (Pro Forma Contract)

3. SAES-J-902 - Electrical Systems for Instrumentation, 1 January 2018

4. SAES-P-104 - Wiring Methods and Materials, 1 January 2018

5. SAES-M-001 - Structural Design Criteria for Non-Building Structures, 8 March 2017

6. 12-SAMSS-007 - Fabrication of Structural and Miscellaneous Steel, 1 January 2018

7. NFPA 70 - National Electric Code 2017 Edition

ATTACHMENTS:

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

Saudi Aramco: Company General Use

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection:

T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco StandardsDocument23 pagesSaudi Aramco Standardsbalaji100% (3)

- 002-PDS-CON-005 Method Statement For Demoilition of Pipelines Asphalt, Concrete, Houses and FenceDocument22 pages002-PDS-CON-005 Method Statement For Demoilition of Pipelines Asphalt, Concrete, Houses and FenceMalik ZamanNo ratings yet

- Method Statement For Water Heaters InstallationDocument9 pagesMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For Fire Alarm System InstallationDocument4 pagesMethod Statement For Fire Alarm System Installationamg00780% (5)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- SAIC-P-3005 Rev 7 FinalDocument2 pagesSAIC-P-3005 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalik100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- SAIC-P-3602 Rev 3Document3 pagesSAIC-P-3602 Rev 3DipuNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-P-3008 Rev 3Document9 pagesSAIC-P-3008 Rev 3YaserNo ratings yet

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDocument2 pagesSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88No ratings yet

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingDocument1 pageSACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- SAIC-P-3017 Rev 7 FinalDocument14 pagesSAIC-P-3017 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- ARAMCO RT Inpection Check List - SAIC-RT-2001Document15 pagesARAMCO RT Inpection Check List - SAIC-RT-2001Anonymous hBBam1nNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic P 3423Document7 pagesSaic P 3423spravin231No ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingDocument2 pagesSACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingArshad ImamNo ratings yet

- SAIC-P-3008 Rev 7 FinalDocument10 pagesSAIC-P-3008 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saic P 3315Document2 pagesSaic P 3315Arshad ImamNo ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- Saic W 1308Document21 pagesSaic W 1308mathew.genesis.inspNo ratings yet

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstDocument16 pagesSaudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstnadeemNo ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- SACIC-T-5705 OSP Ductbank-Maintenance & Service Hole Hardware - Material ReceivingDocument3 pagesSACIC-T-5705 OSP Ductbank-Maintenance & Service Hole Hardware - Material ReceivingArshad ImamNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- CamScanner 10-13-2021 23.17Document2 pagesCamScanner 10-13-2021 23.17nisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khan100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Introduction To SAP QMDocument53 pagesIntroduction To SAP QMSudhagar100% (1)

- Module & Sesion Plan IIDocument23 pagesModule & Sesion Plan IIGODNo ratings yet

- Specification 01286 SPE EPC 302 210 0001 IFB0-01Document27 pagesSpecification 01286 SPE EPC 302 210 0001 IFB0-01minakirolosNo ratings yet

- Acceptance Test Reports of Ready Mixed Concrete: Who Should Get Them?Document4 pagesAcceptance Test Reports of Ready Mixed Concrete: Who Should Get Them?ZELALEMNo ratings yet

- Jis G 3472-2013Document19 pagesJis G 3472-2013HongHaiDuong100% (1)

- ITP Steel StructureDocument2 pagesITP Steel StructureEndy0% (1)

- IMS-MG-002-VER 00 - Quarterly Tenant Area Fire & Electrical Safety InspectionDocument9 pagesIMS-MG-002-VER 00 - Quarterly Tenant Area Fire & Electrical Safety InspectionDINESH KUMARNo ratings yet

- Supplier PPAP Manual 2Document25 pagesSupplier PPAP Manual 2roparn100% (1)

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument19 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianNo ratings yet

- Inspection and Test Plan: Linolium Sheet InstallationDocument1 pageInspection and Test Plan: Linolium Sheet Installationmoytabura96No ratings yet

- Convention C081 - Labour Inspection Convention, 1947 (No. 81)Document8 pagesConvention C081 - Labour Inspection Convention, 1947 (No. 81)Elmir ƏzimovNo ratings yet

- HEP InspectionDocument13 pagesHEP InspectionKurt CobainNo ratings yet

- Information and Procedures For Obtaining An Asme Certificate of Accreditation As An Authorized Inspection AgencyDocument2 pagesInformation and Procedures For Obtaining An Asme Certificate of Accreditation As An Authorized Inspection AgencyJamesNo ratings yet

- Material Receiving Inspection ReportDocument1 pageMaterial Receiving Inspection ReportktwfaevlmhtfbdgeojNo ratings yet

- P-QAC-PLN-910-39451-Rev BDocument23 pagesP-QAC-PLN-910-39451-Rev BAslaouiNo ratings yet

- Industrial Visit Report Abhishek GurjarDocument21 pagesIndustrial Visit Report Abhishek GurjarAbhishek GurjarNo ratings yet

- Method Statement For PEX Pipes and Fittings InstallationDocument9 pagesMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Especificación Técnica N 0000-ESP-J-14Document8 pagesEspecificación Técnica N 0000-ESP-J-14Inf Ormation Servic Emp ResarialNo ratings yet

- Company Profile PT. Serayu Teknologi IndonesiaDocument24 pagesCompany Profile PT. Serayu Teknologi Indonesiaamanullah-azzamNo ratings yet

- Objasnjenje PED TPEDDocument18 pagesObjasnjenje PED TPEDAnonymous xiMSmvmC6ENo ratings yet

- No Requirements Applicable Status: Section 1 - AdministrationDocument4 pagesNo Requirements Applicable Status: Section 1 - AdministrationJoachim100% (2)

- TAPPI TIP 0402 22 Insp Digester BatchDocument9 pagesTAPPI TIP 0402 22 Insp Digester Batcha_parratNo ratings yet

- Gen2 - Inspector's GuideDocument26 pagesGen2 - Inspector's Guidekędzierzawy100% (1)

- Engineering Encyclopedia: Maintenance and Repair of Heat ExchangersDocument69 pagesEngineering Encyclopedia: Maintenance and Repair of Heat ExchangersAfzaalUmairNo ratings yet

- Zf2515 Zoi 4bzw Nach0umt3muccnDocument26 pagesZf2515 Zoi 4bzw Nach0umt3muccnraulNo ratings yet

- Al Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation of Telephone & Data SystemDocument7 pagesAl Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation of Telephone & Data Systemmidhun muraliNo ratings yet