Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanCopyright:

Available Formats

You might also like

- Services Manual SA Leon (Plus) 2 0 1b enDocument176 pagesServices Manual SA Leon (Plus) 2 0 1b enjose luis100% (7)

- Design and Construction of Gas Detection System Using ArduinoDocument7 pagesDesign and Construction of Gas Detection System Using ArduinoSamuel Olusanya100% (1)

- Saep-387 2021Document26 pagesSaep-387 2021ArshadNo ratings yet

- Valvula de Control Trans. 140HDocument13 pagesValvula de Control Trans. 140HRCA09100% (7)

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 00 Saip 78Document10 pages00 Saip 78Shoaib NazirNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerSreni Excel MacrosNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Microsoft Word - A927-000-81-41-46052 - 1Document9 pagesMicrosoft Word - A927-000-81-41-46052 - 1bondsivamaniNo ratings yet

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Ae 036904 001Document1 pageAe 036904 001narutothunderjet216No ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Supplier'S Document Cover Page (For A4/A3 Documents Only)Document5 pagesSupplier'S Document Cover Page (For A4/A3 Documents Only)Tanveer Ahmed QuadriNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Engineering Index : A B C D E F G H J L M E Q WDocument3 pagesSaudi Aramco Engineering Index : A B C D E F G H J L M E Q Wkhuram916No ratings yet

- RFQ Document: Tank Pr. Protect. Devices / Flame ArrstrDocument207 pagesRFQ Document: Tank Pr. Protect. Devices / Flame Arrstrvishal_engrNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- SAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARDocument8 pagesSAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARZahidRafiqueNo ratings yet

- SP-1136 Cathodic Protection DrawingsDocument4 pagesSP-1136 Cathodic Protection Drawingshappale2002No ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- A Esl 102Document49 pagesA Esl 102sccksaNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- EFW WSP 83002 RV D01Document46 pagesEFW WSP 83002 RV D01matmarcantonioNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- Inq - 610 - RF Gate Valves - 0.5 Inch To 1 Inch - SsDocument1 pageInq - 610 - RF Gate Valves - 0.5 Inch To 1 Inch - Ssnaveen_86No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- DOCDocument207 pagesDOCdhaktodesatyajitNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Satr H 2004Document1 pageSatr H 2004ravi ajithNo ratings yet

- Choke Valve CatalogueDocument28 pagesChoke Valve CatalogueAzwan ShahmeeNo ratings yet

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Itp PSV, Dppu ImipDocument1 pageItp PSV, Dppu ImipHendra WidyantoroNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Job Specification For CMSDocument12 pagesJob Specification For CMSTauqueerAhmadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Cooler Drawin API-23 Seal PlanDocument5 pagesCooler Drawin API-23 Seal PlankishorsinghNo ratings yet

- 5-Valve Manifold - Butt WeldDocument1 page5-Valve Manifold - Butt Weldhaisam sarwarNo ratings yet

- Technical Description-Rev BDocument5 pagesTechnical Description-Rev Bbmanojkumar16No ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Circulating Water Pipes and Fittings - Rev 1Document14 pagesCirculating Water Pipes and Fittings - Rev 1Yurizal firmansyahNo ratings yet

- 907 1TDSDocument2 pages907 1TDSJainam Shah100% (1)

- Saudi Aramco Pre-Commissioning FormDocument2 pagesSaudi Aramco Pre-Commissioning Formmahdi_gNo ratings yet

- Saic Q 1046Document1 pageSaic Q 1046Gian CarloNo ratings yet

- Engineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesDocument10 pagesEngineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesMuhammad AsifNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- CamScanner 10-13-2021 23.17Document2 pagesCamScanner 10-13-2021 23.17nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khan100% (1)

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Fabrication of Universal Tapping MachineDocument67 pagesFabrication of Universal Tapping MachineMuhammed Hashirkk0% (1)

- 330C Hyd Sys-OpDocument164 pages330C Hyd Sys-OpTaz Juan G97% (29)

- Camozzi Uk Short Form 2020 150dpiDocument372 pagesCamozzi Uk Short Form 2020 150dpiGiel0824No ratings yet

- Pressurization Unit (Reflex Variosat)Document20 pagesPressurization Unit (Reflex Variosat)anand007krishnanNo ratings yet

- Brochure Ex-P Pressurized Enclosure System Zone1 f850sDocument6 pagesBrochure Ex-P Pressurized Enclosure System Zone1 f850ssaman749No ratings yet

- Daf Ix Ecas4 BlockdiagramDocument46 pagesDaf Ix Ecas4 BlockdiagramMircea Gilca100% (1)

- Nordic Valve Remote Control System CatalogDocument36 pagesNordic Valve Remote Control System Catalogbinh_duyvuNo ratings yet

- 2.3 Principle of Turbine Governing CompressedDocument54 pages2.3 Principle of Turbine Governing Compressedabhaymehta67100% (2)

- Solenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBDocument4 pagesSolenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBYuni MariaNo ratings yet

- Service Manual Multimat 2 T - T&P PDFDocument41 pagesService Manual Multimat 2 T - T&P PDFthsenNo ratings yet

- Knife Gate BrochureDocument7 pagesKnife Gate Brochuresf wNo ratings yet

- Valvula Solenoide Serie 370 AscoDocument5 pagesValvula Solenoide Serie 370 AscoBase SistemasNo ratings yet

- HKV-8 Valve Catalog SPLRDocument128 pagesHKV-8 Valve Catalog SPLRCabrera RodriguezNo ratings yet

- Idoc - Pub - 13 Deluge Valve HD Fire PDFDocument17 pagesIdoc - Pub - 13 Deluge Valve HD Fire PDFĐinh TrọngNo ratings yet

- Microcontroller Based Automatic Sprinkler Irrigation SystemDocument5 pagesMicrocontroller Based Automatic Sprinkler Irrigation SystemIJMERNo ratings yet

- Solenoid ValvesDocument56 pagesSolenoid ValvesxvahnxxNo ratings yet

- Price Book - Section 13 Deluge Valves & AccessoriesDocument16 pagesPrice Book - Section 13 Deluge Valves & AccessoriesJohandry MartínezNo ratings yet

- Fluid Control-ChapC-2 - 2-Solenoid-Valves-Direct-Pilot-Operated-CAT-gbDocument62 pagesFluid Control-ChapC-2 - 2-Solenoid-Valves-Direct-Pilot-Operated-CAT-gbĐặng Trung AnhNo ratings yet

- SMC Electro-Pneumatic RegulatorDocument20 pagesSMC Electro-Pneumatic RegulatorJosue Reyes HernandezNo ratings yet

- AltaBlue™ TT Adhesive Melters Models A4, A10, and A16 Product ManualDocument256 pagesAltaBlue™ TT Adhesive Melters Models A4, A10, and A16 Product ManualKayc SilvaNo ratings yet

- DM - Manual FAN CLUTCH PDFDocument57 pagesDM - Manual FAN CLUTCH PDFedgarrocio100% (1)

- z9611BR - Norgren Process Fluid Control - EN - LRDocument32 pagesz9611BR - Norgren Process Fluid Control - EN - LRShigueo EnamotoNo ratings yet

- General Service Solenoid Valves: ConstructionDocument3 pagesGeneral Service Solenoid Valves: ConstructionAditya B. RyantoNo ratings yet

- Automatic Bottle Washing MachineDocument4 pagesAutomatic Bottle Washing MachineBrightchip TechnologiesNo ratings yet

- E4 Series: The XDB World Solenoid ValveDocument2 pagesE4 Series: The XDB World Solenoid ValveLuis Eduardo Albarracin RugelesNo ratings yet

- Promix 2ke: Repair/PartsDocument72 pagesPromix 2ke: Repair/PartsGEORDINA FLORESNo ratings yet

- Ata 28 - FuelDocument83 pagesAta 28 - Fuelmoabduk1990No ratings yet

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanCopyright:

Available Formats

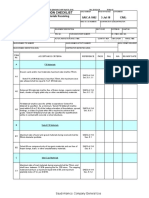

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Control Valve E & I - Material Receiving (Class 600 and

SAIC-J-6703 24-Jul-18 INST

Lower)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Document Review

Schedule Q

A1 Review Quality documentation for Material Receiving. Att. IV, Sec. 4.1 &

6

Schedule Q

A2 Identification Procedure reviewed and implemented.

Att. IV Sec. 4.2

Schedule Q

A3 Documentation for traceability reviewed and implemented.

Att. IV Sec. 4.3

Control Valve Maintenance Support System:

SAES-J-700

A4 The control valve maintenance support system shall be integrated into the

Sec. 7.8

Instrument Asset Management System..

Schedule G

A5 New and Unsed - Instrumentation materials shall be new and unused. Att. lI

Sec. 2.1

As Designed - Instrumentation materials shall be in accordance with the Schedule G

A6 Saudi Aramco-approved project-specific design drawings, diagrams, Att. lI

schedules, lists, databases, and associated documents. Sec. 2

Schedule Q

A7 Free of Damage - Instrumentation materials shall be free of damage.

Att. IV Sec. 3.3

QC Before Installation - Instrumentation materials shall conform to all

Schedule Q

A8 applicable requirements, standards, and specifications prior to release to

Att. IV Sec. 4.3

be used as part of the work.

Identification - Instrumentation materials shall be identified by using tags,

Schedule Q

A9 stamps, color coding, stencils or labels. The location and method of

Att. IV Sec. 4.2

identification shall not affect the function or quality of the materials.

Traceability - Instrumentation materials shall be traceable from the

Schedule Q

A10 manufacturer and supplier through delivery, storage, fabrication, erection,

Att. IV Sec. 4.3

installation, repair, modification and use.

B General Requirements

All control valves shall be selected from the manufacturers listed in SAP SAES-J-700 Sec.

B1

system 4.1

Purchase Order and Instrument specification sheet criteria shall be

Schedule Q

confirmed and compared with instrument stainless steel tags / labels and

B2 Att. IV Sec. 3.0 &

nameplates, and shipment checked for damage, prior to acceptance of the

4.0

shipment

Saudi Aramco: Company General Use

Pneumatic Connections:

All pneumatic connections on the actuator body and ancillaries shall be

NPT threaded per ANSI B1.20.1.

Interconnecting tubing, shall be ASTM A269, Type 316L stainless steel, 34-SAMSS-716

B3

minimum size ¼ inch with wall thickness suitable for the temperature and Sec 7.2.3

pressure specified.

Tube fittings shall be ASTM A269, Type 316L stainless steel

compression type design, made by Swagelok, Parker CPI or equal.

Pneumatic tubing and fittings shall be AISI 316 stainless steel minimum.

Carbon steel, copper, bronze, brass, and AISI 304 stainless steel

materials shall not be used. Fittings shall be as specified on the ISS, but

be limited to Swagelok, Parker A-lock, Hy-Lok, Gyrolock, CPI or other

B4 equivalent manufacturer approved by Saudi Aramco.. The minimum Size 34-SAMSS-711

of pneumatic connectors, fittings, unions and nipples shall be 0.25 inch Sec 6.10.3

NPT provided that the stroke speed requirements are met.

Teflon ribbon shall not be used for sealing threaded connections. All

vents shall be directed downwards to prevent ingress of dust and sand.

Connection of the shaft or stem to the actuator linkages shall be 34-SAMSS-711

B5

adjustable with positive locking and be of an anti-rotating type. Sec 6.10.12

Actuator springs shall be minimum of carbon steel with factory applied 34-SAMSS-711

B6

corrosion resistant coating, unless other wise specified in the P.O. Sec 6.10.9

Materials of actuator cylinders and diaphragm cases shall be steel, cast

34-SAMSS-711

B7 iron or copper free aluminum (i.e., non-metallic, epoxy or fiber glass type

Sec 6.10.14

materials are not acceptable).

Pneumatic Diaphragm Actuators:

SAES-J-700

B8 Spring-return pneumatic diaphragm actuators are preferred and shall be

Sec.7.2

used whenever feasible.

Control valve actuator systems other than pneumatic may be applied if

For applications where instrument air supply cannot practically be made

available, sweet, clean, dry process gas may be considered as the

SAES-J-700

B9 actuating medium. Sour gas shall never be used. Process gas operated

Sec.7.4

actuator systems shall never be used at an indoor location or enclosed

area. Electronic, smart or any positioners with potential ignition sources,

shall not be used for such applications

The following actuator systems may be applied on an exception basis

• Process Gas as Actuating Medium: For applications where instrument

air supply cannot practically be made available, sweet, clean, dry process SAES-J-700

B10

gas may be considered as the actuating medium. Sour gas shall never be Sec.7.4

used. Process gas operated actuator systems shall never be used at an

indoor location or enclosed area.

Actuator materials, specifically the elastomer seals, shall be suitable for

the particular process gas application. All materials in the actuator and SAES-J-700

B11

control instrumentation shall be certified for the particular process gas Sec.7.4

services.

The gas shall be properly conditioned through a fully redundant gas

supply system each with a dedicated inlet and outlet block valve (e.g.,

SAES-J-700

B12 dual regulators, dual liquid knock-out pots with drain valves, dual filtering

Sec.7.4

systems, over-pressure relief valves etc.) connected to a ring header to

enable on-line maintenance on one system at the time.

All enclosures shall be metallic (i.e., non-metallic actuator systems shall

SAES-J-700

B13 not be used in sweet gas services). Grounding of the complete system

Sec.7.4

shall be in accordance with SAES-J-902

C Inspection of Accessories, Positioners, Electro-Pneumatic (I/P) Transducers and Boosters

Digital positioners shall be applied for all new control valves, unless SAES-J-700

C1

otherwise specified. Sec.7.5.1

Saudi Aramco: Company General Use

Handwheels:

A handwheel shall be provided on valves when local manual control is

required by the Proponent. Handwheel installations shall meet the

following requirements: SAES-J-700

C2

a) Neutral position shall be clearly indicated. Sec.8.1

b) Handwheel mechanism shall not add friction to the actuator.

c) Handwheel shall not be used as travel stops.

d) Handwheel shall be fully accessible for operation.

Limit Switches: 34-SAMSS-711

C3

Limit switches shall be actuated by mechanical switch or proximity sensor. Sec.6.11.8

Limit Switches: 34-SAMSS-711

C4

Limit switch enclosures shall be hermetically sealed. Sec.6.11.8

Limit Switches:

34-SAMSS-711

C5 Switch contact outputs shall be minimum, Single-pole, Doublethrow

Sec.6.11.8

(SPDT).

Solenoid Valves:

Requirements for solenoid valves shall be specified on the subject control

SAES-J-700

C6 valve ISS. High temperature class "H" coil insulation rated for continuous

Sec.8.3

duty shall be used with viton elastomers unless the

process temperature dictates otherwise

Solenoid Valves:

Solenoid valves shall be selected from manufacturers listed in SAP . SAES-J-700

C7

Commentary Note: Solenoid valves shall not be used for process service Sec.8.3

applications.

Volume Tanks:

Volume tanks shall be mechanically designed to withstand a maximum SAES-J-700

pressure of 862 kPag (125 psig) at 82°C.The volume tank shall be sized Sec.8.4,

C8

to fully stroke the valve through two travel cycles at the minimum available 34-SAMSS-711

air pressure of 415 kPag (60 psig) Volume tanks shall be manufactured in Sec 6.10.4

accordance with ASME VIII D1 (stamped UM/U)

Mechanical Limit Stops:

Limit stops shall be mechanical devices mounted on the valve or actuator.

When mechanical limit stops are required, they shall be of a permanently

SAES-J-700

C9 welded type. Screwed type, if seal-welding at the locking nuts, is

Sec.8.5

acceptable.Limit stop arrangements through: hand wheel mechanism,

jam-nut arrangement, tack welding arrangement or positioner

configuration, are not acceptable.

Valve Position Indicator:

Each control valve shall be provided with a valve position indicator. The

indicating pointer shall be directly connected to the stem or shaft. The SAES-J-700

C10

valve position shall be indicated on a reversible scale, with clearly Sec.8.6

graduated markings at the 50% valve opening position and the words

OPEN and CLOSED at the valve travel limits.

Valve Position Transmitter: For safety related applications, a dedicated

electronic travel position transmitter, providing a proportional valve stem SAES-J-700

C11

or shaft position signal, shall be specified for remote valve position Sec.8.6

indication.

Marking:

The direction of flow shall be cast or steel-stamped on the valve body, or

alternatively a stainless steel arrow shall be permanently fixed to the body

SAES-J-700

C12 by rivets, for all appropriate valves which have been designed or selected

Sec.8.7

for a specific flow direction.

For butterfly valves and other rotary valves, the vane, disk, cam or ball

position shall be indicated by an engraved marking on the shaft end.

Saudi Aramco: Company General Use

Identification: Name plates shall be provided for all control valves. Name

SAES-J-700

C13 plates shall be made of stainless steel and permanently fastened to the

Sec.8.7

valve (i.e., adhesive fastening is not acceptable).

Anti-Static Devices

Control valve designs shall be evaluated for the presence of electrically

isolated metal parts when used in non-conductive fluid services.

Anti-static devices shall be provided to ensure electric continuity between

all isolated parts and the valve body. These shall fulfill the following SAES-J-700

C14

requirements: Sec.9.4

a) Provide a discharge path with an electrical resistance of not greater

than 10 ohms.

b) Be of such a design that the valve cannot be assembled, or

reassembled, without the device.

Accessories:

Manufacturer shall supply the accessories specified on the ISS and 34-SAMSS-711

C15

Purchase Order. Accessories shall be installed on the control valve and Sec. 6.11.1

actuator assembly.

Accessories:

34-SAMSS-711

C16 Accessories shall operate from the power supply specified on the ISS or

Sec. 6.11.2

Purchase Order.

Accessories:

Enclosures of accessories and junction boxes shall be die-cast aluminum

34-SAMSS-711

C17 copper free max. 0.4%, to meet minimum NEMA 4X or IP 65 (IEC-60529)

Sec. 6.11.3

weather proof and shall be certified for Class I, Division 2 (Zone 2)

installations.

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract)

2. Schedule Q - Quality Requirements (Pro Forma Contract), project specific

3. SAES-J-003 - Instrumentation and Control Buildings - Basic Design Criteria, 1 January 2018

4. SAES-J-700 - Control Valves, 1 January 2018

5. 34-SAMSS-711 - Control Valves- General Services, 11 October 2017

6. 34-SAMSS-716 - Pneumatic Actuators On-Off Service, 13 June 2018

ATTACHMENTS:

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

5. Remarks - This spec. is not applicable for ON /OFF Valves.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

Saudi Aramco: Company General Use

Quality Record Approved:

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Services Manual SA Leon (Plus) 2 0 1b enDocument176 pagesServices Manual SA Leon (Plus) 2 0 1b enjose luis100% (7)

- Design and Construction of Gas Detection System Using ArduinoDocument7 pagesDesign and Construction of Gas Detection System Using ArduinoSamuel Olusanya100% (1)

- Saep-387 2021Document26 pagesSaep-387 2021ArshadNo ratings yet

- Valvula de Control Trans. 140HDocument13 pagesValvula de Control Trans. 140HRCA09100% (7)

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 00 Saip 78Document10 pages00 Saip 78Shoaib NazirNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerSreni Excel MacrosNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Microsoft Word - A927-000-81-41-46052 - 1Document9 pagesMicrosoft Word - A927-000-81-41-46052 - 1bondsivamaniNo ratings yet

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Ae 036904 001Document1 pageAe 036904 001narutothunderjet216No ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Supplier'S Document Cover Page (For A4/A3 Documents Only)Document5 pagesSupplier'S Document Cover Page (For A4/A3 Documents Only)Tanveer Ahmed QuadriNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Engineering Index : A B C D E F G H J L M E Q WDocument3 pagesSaudi Aramco Engineering Index : A B C D E F G H J L M E Q Wkhuram916No ratings yet

- RFQ Document: Tank Pr. Protect. Devices / Flame ArrstrDocument207 pagesRFQ Document: Tank Pr. Protect. Devices / Flame Arrstrvishal_engrNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- SAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARDocument8 pagesSAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARZahidRafiqueNo ratings yet

- SP-1136 Cathodic Protection DrawingsDocument4 pagesSP-1136 Cathodic Protection Drawingshappale2002No ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- A Esl 102Document49 pagesA Esl 102sccksaNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- EFW WSP 83002 RV D01Document46 pagesEFW WSP 83002 RV D01matmarcantonioNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- Inq - 610 - RF Gate Valves - 0.5 Inch To 1 Inch - SsDocument1 pageInq - 610 - RF Gate Valves - 0.5 Inch To 1 Inch - Ssnaveen_86No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- DOCDocument207 pagesDOCdhaktodesatyajitNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Satr H 2004Document1 pageSatr H 2004ravi ajithNo ratings yet

- Choke Valve CatalogueDocument28 pagesChoke Valve CatalogueAzwan ShahmeeNo ratings yet

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Itp PSV, Dppu ImipDocument1 pageItp PSV, Dppu ImipHendra WidyantoroNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Job Specification For CMSDocument12 pagesJob Specification For CMSTauqueerAhmadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Cooler Drawin API-23 Seal PlanDocument5 pagesCooler Drawin API-23 Seal PlankishorsinghNo ratings yet

- 5-Valve Manifold - Butt WeldDocument1 page5-Valve Manifold - Butt Weldhaisam sarwarNo ratings yet

- Technical Description-Rev BDocument5 pagesTechnical Description-Rev Bbmanojkumar16No ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Circulating Water Pipes and Fittings - Rev 1Document14 pagesCirculating Water Pipes and Fittings - Rev 1Yurizal firmansyahNo ratings yet

- 907 1TDSDocument2 pages907 1TDSJainam Shah100% (1)

- Saudi Aramco Pre-Commissioning FormDocument2 pagesSaudi Aramco Pre-Commissioning Formmahdi_gNo ratings yet

- Saic Q 1046Document1 pageSaic Q 1046Gian CarloNo ratings yet

- Engineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesDocument10 pagesEngineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesMuhammad AsifNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- CamScanner 10-13-2021 23.17Document2 pagesCamScanner 10-13-2021 23.17nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khan100% (1)

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Fabrication of Universal Tapping MachineDocument67 pagesFabrication of Universal Tapping MachineMuhammed Hashirkk0% (1)

- 330C Hyd Sys-OpDocument164 pages330C Hyd Sys-OpTaz Juan G97% (29)

- Camozzi Uk Short Form 2020 150dpiDocument372 pagesCamozzi Uk Short Form 2020 150dpiGiel0824No ratings yet

- Pressurization Unit (Reflex Variosat)Document20 pagesPressurization Unit (Reflex Variosat)anand007krishnanNo ratings yet

- Brochure Ex-P Pressurized Enclosure System Zone1 f850sDocument6 pagesBrochure Ex-P Pressurized Enclosure System Zone1 f850ssaman749No ratings yet

- Daf Ix Ecas4 BlockdiagramDocument46 pagesDaf Ix Ecas4 BlockdiagramMircea Gilca100% (1)

- Nordic Valve Remote Control System CatalogDocument36 pagesNordic Valve Remote Control System Catalogbinh_duyvuNo ratings yet

- 2.3 Principle of Turbine Governing CompressedDocument54 pages2.3 Principle of Turbine Governing Compressedabhaymehta67100% (2)

- Solenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBDocument4 pagesSolenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBYuni MariaNo ratings yet

- Service Manual Multimat 2 T - T&P PDFDocument41 pagesService Manual Multimat 2 T - T&P PDFthsenNo ratings yet

- Knife Gate BrochureDocument7 pagesKnife Gate Brochuresf wNo ratings yet

- Valvula Solenoide Serie 370 AscoDocument5 pagesValvula Solenoide Serie 370 AscoBase SistemasNo ratings yet

- HKV-8 Valve Catalog SPLRDocument128 pagesHKV-8 Valve Catalog SPLRCabrera RodriguezNo ratings yet

- Idoc - Pub - 13 Deluge Valve HD Fire PDFDocument17 pagesIdoc - Pub - 13 Deluge Valve HD Fire PDFĐinh TrọngNo ratings yet

- Microcontroller Based Automatic Sprinkler Irrigation SystemDocument5 pagesMicrocontroller Based Automatic Sprinkler Irrigation SystemIJMERNo ratings yet

- Solenoid ValvesDocument56 pagesSolenoid ValvesxvahnxxNo ratings yet

- Price Book - Section 13 Deluge Valves & AccessoriesDocument16 pagesPrice Book - Section 13 Deluge Valves & AccessoriesJohandry MartínezNo ratings yet

- Fluid Control-ChapC-2 - 2-Solenoid-Valves-Direct-Pilot-Operated-CAT-gbDocument62 pagesFluid Control-ChapC-2 - 2-Solenoid-Valves-Direct-Pilot-Operated-CAT-gbĐặng Trung AnhNo ratings yet

- SMC Electro-Pneumatic RegulatorDocument20 pagesSMC Electro-Pneumatic RegulatorJosue Reyes HernandezNo ratings yet

- AltaBlue™ TT Adhesive Melters Models A4, A10, and A16 Product ManualDocument256 pagesAltaBlue™ TT Adhesive Melters Models A4, A10, and A16 Product ManualKayc SilvaNo ratings yet

- DM - Manual FAN CLUTCH PDFDocument57 pagesDM - Manual FAN CLUTCH PDFedgarrocio100% (1)

- z9611BR - Norgren Process Fluid Control - EN - LRDocument32 pagesz9611BR - Norgren Process Fluid Control - EN - LRShigueo EnamotoNo ratings yet

- General Service Solenoid Valves: ConstructionDocument3 pagesGeneral Service Solenoid Valves: ConstructionAditya B. RyantoNo ratings yet

- Automatic Bottle Washing MachineDocument4 pagesAutomatic Bottle Washing MachineBrightchip TechnologiesNo ratings yet

- E4 Series: The XDB World Solenoid ValveDocument2 pagesE4 Series: The XDB World Solenoid ValveLuis Eduardo Albarracin RugelesNo ratings yet

- Promix 2ke: Repair/PartsDocument72 pagesPromix 2ke: Repair/PartsGEORDINA FLORESNo ratings yet

- Ata 28 - FuelDocument83 pagesAta 28 - Fuelmoabduk1990No ratings yet