Professional Documents

Culture Documents

7/25/11 DESIGN NO. - SECTION 15411 Hangers and Supports Part 1 - General 1.01 Description of Work

7/25/11 DESIGN NO. - SECTION 15411 Hangers and Supports Part 1 - General 1.01 Description of Work

Uploaded by

JhoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7/25/11 DESIGN NO. - SECTION 15411 Hangers and Supports Part 1 - General 1.01 Description of Work

7/25/11 DESIGN NO. - SECTION 15411 Hangers and Supports Part 1 - General 1.01 Description of Work

Uploaded by

JhoCopyright:

Available Formats

7/25/11 DESIGN NO.

_____

SECTION 15411

HANGERS AND SUPPORTS

PART 1 - GENERAL

1.01 DESCRIPTION OF WORK

A. Extent of hangers and support Work is indicated by the

requirements of this Section.

1.02 SUBMITTALS

A. Submit catalog cuts for each different type of hanger

and rod, support and accessory.

B. Submit method of support and hanging for Engineers

approval prior to installation.

C. Submit manufacturer technical data of insert and rod

for approval.

1.03 QUALITY ASSURANCE

A. No-Hub piping shall be installed and supported in full

compliance with Local Law 100 of 1989.

B. Cast-Iron Soil Pipe Institute (CISIP) Designation B10-

1985 and Designation 301-1985.

C. Manufacturers Standardization Society of The Valve and

Fittings Industry (MSS) Compliance: Comply with:

MSS SP-58 Pipe Hangers and Supports - Materials, Design

and Manufacture.

MSS SP-69 Pipe Hangers and Supports - Selection and

Application.

MSS SP-89 Pipe Hangers and Supports - Fabrication and

Installation Practices.

PART 2 - PRODUCTS

2.01 MATERIALS

A. Pipe Hangers and Supports

1. Hangers for horizontal piping (insulated and

uninsulated) one inch and smaller, supported from

above shall be of malleable iron, adjustable

NYCSCA HANGERS AND SUPPORTS 15411 - 1

7/25/11 DESIGN NO. _____

swivel ring type and shall comply with MSS SP-69

Type 6. Hangers shall be Anvil International Fig.

104 or the approved equal of Carpenter & Paterson,

Inc, Hilti, Inc, or Cooper B-Line, Inc.

2. Hangers for horizontal piping (insulated and

uninsulated) and insulated copper tubing larger

than one inch, shall be of carbon steel,

adjustable clevis type and shall conform to MSS

SP-69 Type 1. Hangers shall be Anvil

International Fig. 260, Fig. 260 ISS or the

approved equal of Carpenter & Paterson, Inc,

Hilti, Inc, or Cooper B-Line, Inc.

3. Hangers for uninsulated horizontal copper tubing

one inch and smaller, supported from above shall

be of malleable iron with copper finish,

adjustable ring type, complying with MSS SP-69

Type 6, or with MSS SP 69 Type 15 if with

Turnbuckle Adjuster. Hangers shall be Anvil

International Fig. CT-109 for adjustable ring type

and Fig.114 for Turnbuckle Adjuster, or the

approved equal of Carpenter & Paterson, Inc,

Hilti, Inc, or Cooper B-Line, Inc.

4. Hangers for uninsulated horizontal copper tubing

larger than one inch shall be of carbon steel with

copper finish adjustable clevis type, complying

with MSS SP 69 Type 1. Hangers shall be Anvil

International Fig. CT-65 or the approved equal of

Carpenter & Paterson, Inc, Hilti, Inc, or Cooper

B-Line, Inc.

5. Support for horizontal pipe runs on roof shall be

heavy-duty pipe rollers. Rollers assembly shall

consist of galvanized steel channel track,

galvanized steel fittings, washers and nuts,

painted cast iron roller and locking devices to

maintain pipe location. Assembly shall allow both

vertical and horizontal adjustment. Heavy-duty

pipe roller support shall be with integral base

plate and shall be of the Pate Company, Custom

Curb Inc. (Eastern Plant), Miro Industries, Cooper

B-Line, Inc. or Portable Pipe Hangers. The support

for the gas piping installed horizontally on the

roof shall be anchored or secured to the concrete

deck. The base plate of the pipe roller support

NYCSCA HANGERS AND SUPPORTS 15411 - 2

7/25/11 DESIGN NO. _____

shall be secured to the concrete deck using

stainless steel anchors. A 12" galvanized steel

with integral base plate or a pipe support base

made of polycarbonate plastic with bored holes for

securing same to the concrete decking are

acceptable

6. Supports for vertical piping and copper tubing

shall be double bolt riser clamps, complying with

MSS SP 69 Type 8 with each end having equal

bearing on the building structure located as

hereinafter specified. Supports shall be Anvil

International Fig. 261 for steel pipe and Fig. CT-

121 for copper tubing or the approved equal of

Carpenter & Paterson, Inc, Hilti, Inc or Cooper B-

Line, Inc. If piping is insulated, riser clamp

shall be placed under insulation.

7. Where piping is run near the floor and is

supported from the floor, such supports except as

otherwise noted shall be of pipe standards with

base flange and adjustable top yoke complying with

MSS-SP-69 Type 38. Support shall be similar to

Carpenter & Paterson, Inc Figure 247 or the

approved equal of Anvil International, Hilti, Inc

or Cooper B-Line, Inc.

8. Storm drainage leader piping running exposed along

the outside face of building wall shall be

supported by offset pipe clamp of carbon steel;

Anvil International Fig. 103 or the approved equal

of Carpenter & Paterson, Inc, Hilti Inc or Cooper

B-Line, Inc.

9. Trapeze type hangers shall be made of 2"x2"x1/4"

carbon steel angle iron with drilled holes and

1/2" hangers rods. In lieu of an angle iron, a

strut assembly may also be used for the trapeze

kind of hanger support.

10. Bracing for cast iron No-Hub vertical piping (all

sizes) and horizontal piping 6" and larger shall

be made up of riser clamps, clevis hangers or two

four bolt cast iron socket clamps Anvil

International Fig. 595 with cast iron socket clamp

washers, Anvil International Fig. 594, or the

1

NYCSCA HANGERS AND SUPPORTS 15411 - 3

7/25/11 DESIGN NO. _____

approved equal of Carpenter & Paterson, Inc,

Hilti, Inc or Cooper B-Line, Inc.

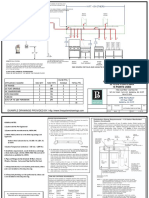

Refer to "No-Hub Pipe BRACING" Detail

11. Sway bracing for horizontal No-Hub cast iron

piping shall be made up of double bolt riser

clamp, complying with MSS SP 69 Type 8, galvanized

steel 12" long shields, conforming to MSS SP 69

2

Type 40, and 1" x 1/8" steel plate. Riser clamp

shall be Anvil International Fig. 261 and shields

shall be Anvil International Fig. 167 or the

approved equal of Carpenter & Paterson, Inc, or

Hilti, Inc. or Cooper B-Line, Inc.

Refer to "SWAY BRACING" Detail.

12. At all points of support, a galvanized steel

shield shall be provided between the hanger and

pipe insulation complying with MSS SP 69 Type 40.

Shields shall be Anvil International Fig. 167,

Carpenter & Paterson, Inc. Figure 265P or the

approved equal of Hilti, Inc or Cooper B-Line,

Inc.

B. Expansion bolts for use in existing and new reinforced

concrete slabs shall be as follows:

1. “Trubolt” as manufactured by ITW Ramset/Red Head

2. "Kwik Bolts" as manufactured by Hilti, Inc.

3. “Power Stud” as manufactured by Powers Fasteners,

Inc.

C. Inserts for use in new conventional reinforced poured

concrete slabs shall be as follows:

1. Insert No. 650 made by Carpenter & Paterson Inc.

2. Insert Fig. 281 made by ITT Anvil International.

3. Insert No. 100 made by C. H. Leibfried Mfg. Corp.

4. Insert No. 96900 Series made by Hilti, Inc.

5. Insert No. B2500 and N2500 Series made by Cooper

B-Line, Inc.

NYCSCA HANGERS AND SUPPORTS 15411 - 4

7/25/11 DESIGN NO. _____

D. Inserts for use in new composite metal decks shall be

as follows:

Inserts shall be “Bang-It” steel deck insert as

manufactured by Powers Fasteners or HCI-MD Cast-In

Anchor for Metal Deck as manufactured by Hilti, Inc.

Metal Deck ceiling bolts (T-bars), Carpenter &

Paterson, Fig. 143 may be used in lieu of the above

specified deck inserts with the approval of the

Engineer of Record.

E. Fasteners, as required, shall be as follows:

1. Lag screws or Long screws.

2. Long Expansion bolts

3. Bolts and nuts

PART 3 - EXECUTION

3.01 INSTALLATION

A. Supports shall be adequate to securely support the

piping and its contents, to prevent vibration and to

provide proper allowance for expansion and contraction

of the piping.

B. All piping running close to or on walls shall be

supported by means of hanger suspended from heavy angle

iron wall brackets. No wall hooks will be permitted.

C. Hanger rods shall be of ample size to support the pipe

and its contents and shall have machine cut American

Standard V-threads. At a minimum hanger rod size

shall be the same as that recommended by the hanger

manufacturer for each sized hanger. Hangers shall be

recessed to approved beam clamps, concrete inserts,

steel plates or other approved devices. Expansion

shields and bolts shall not be used in the ceilings of

cinder concrete, but may be used where the shields and

bolts are horizontal.

D. Where more than two pipes run parallel, the Contractor

may install trapeze type hangers, constructed of 2" x

NYCSCA HANGERS AND SUPPORTS 15411 - 5

7/25/11 DESIGN NO. _____

2" x 1/4" angle iron or channel strut “ kindorph” and

1/2" hanger rods. Provide holes in the trapeze angle

iron as required to accommodate rods for the

individual supports. Burning of holes in angle

supports is not acceptable. Provide individual

supports for piping, where necessary to provide proper

pitch. Trapeze type hanger when used with uninsulated

copper tubing shall have copper finish. Spacing of

trapeze type hangers shall be as required by the

smallest size pipe/tube supported by trapeze hanger.

E. At all points of support of insulated piping and tubing

a galvanized metal shield shall be installed between

the hanger and pipe insulation. The use of the

galvanized metal shield shall be eliminated if the

Anvil Fig 260 ISS is utilized. Installation of Anvil

Fig 260 ISS: position the pipe on the saddle, notch

section of the insulation to fit around the saddle,

square cut the adjoining insulation section and butt

the mating end to the notched section, finish taping

according to standard methods, No galvanized metal

shield is required.

F. No piping shall be supported from other pipes,

ductwork, electric conduit, hung ceiling, cinder

concrete or work of other trades.

G. When support method is not shown on Drawings, pipes

laid underground shall be firmly bedded on solid

ground under the body of the pipe. Where suitable

bearing cannot be obtained because the ground has been

disturbed by excavating, or for any other reason, the

pipe shall be supported by concrete piers or by

approved brackets secured to the walls. Piers and/or

steel brackets shall be installed at not more that 5'-

0" intervals. New piping passing under cinder

concrete areas shall be supported by hangers secured

by means of beam clamps fastened to existing floor

beams. Where pipe support spacing is excessive

between existing steel, beam clamps shall be fastened

to structural members that are installed by this

Contractor and approved by the Authority. Removed

fireproofing around beams shall be replaced to

original condition.

H. Overhead horizontal drains, vents, supply or other

piping shall be supported by adjustable wrought iron,

NYCSCA HANGERS AND SUPPORTS 15411 - 6

7/25/11 DESIGN NO. _____

steel or malleable iron hangers. Double locknuts

shall be installed all hangers. The metal decks shall

not be used for support of piping or equipment.

I. Intervals of supports for horizontal piping shall be as

follows:

1. Hub and Spigot Cast iron soil and vent pipe - At

5' intervals and 18" behind each hub or joint.

2. No-Hub Cast iron soil and vent pipe: - At 5'

intervals and within 12" of each joint.

3. Threaded pipe (1¼” or less) - At 8' intervals

4. Threaded pipe (1½” or over) - At 12' intervals

5. Copper tubing (1¼” in. or less) - At 6' intervals

6. Copper tubing (1½” in. or over). At 10' intervals

7. Other Materials--As required for structural

stability, service and as further stipulated in

specifications and Drawings.

J. Intervals of supports for vertical piping shall be as

follows:

1. All Cast iron soil and vent pipe: At base and at

each story height, but in no case at intervals

greater than 20'.

2. Threaded pipe: At every other story height, but in

no case at intervals greater than 25'.

3. Copper tubing (Hard Temper): At each story height.

4. Other materials: As for structural stability and

service.

5. Cast iron storm drainage leader piping exposed

along outside face of building wall: At base and

at 5' intervals and 18" behind each hub or joint.

K. Inserts and Expansion Bolts

NYCSCA HANGERS AND SUPPORTS 15411 - 7

7/25/11 DESIGN NO. _____

1. Piping and equipment, hung from ceilings shall be

properly supported from the ceiling slabs by means

of required number of inserts. Provide inserts

before the pouring of the slabs and expansion

bolts after concrete is placed and completely

cured.

2. Inserts for new conventional reinforced poured

concrete slabs shall be designed for insertion of

heavy nuts suitable for screwing up to and

including 3/4" rods. Inserts shall not be primed.

Install inserts so that hangers will appear true

and uniform. Install inserts before the pouring of

the concrete.

3. For composite metal deck, consisting of metal deck

and conventional poured reinforced concrete, steel

deck inserts or Metal deck ceiling bolts (T-bars)

shall be used. Steel deck inserts shall be of a

type that is supported by the concrete slab and

not by the metal deck. Inserts size shall conform

to the size of the hanger rod. Install inserts

before the pouring of the concrete.

4. Expansion bolts shall be installed in snug fitting

smoothly drilled holes in accordance with the

manufacturer's installation instructions.

Expansion bolts shall be installed so that the

load acts on the bolts in shear and withdrawal.

Expansion bolts shall be carefully located in

order to eliminate the risk of damage to concrete,

steel reinforcement, and other embedded items.

Install in concrete after concrete is placed and

completely cured.

5. The Contractor shall take every precaution to

furnish and set all sleeves, wood boxes or other

devices that are required for proper installation

of his work, before concrete is poured.

The Contractor is responsible for coordination

with other trades and maintaining location of

sleeves and inserts during concrete pour.

L. Methods of Fastening: The following rule, except where

otherwise specified, shall be observed throughout the

entire work: Where fastenings are made to wood, use

NYCSCA HANGERS AND SUPPORTS 15411 - 8

7/25/11 DESIGN NO. _____

long screws or lag screw; to brickwork, cement, stone

and marble, approved long expansion bolts; to fire-

proof block work, approved toggle bolts, and to iron

work, approved bolts and nuts. The use of wood plugs

and nailing will not be permitted. Sundries used in

connection with galvanized iron shall be galvanized.

Those in connection with brass work shall be of brass,

finished to match the connecting work.

M. Cleaning, painting and installation of hangers and

supports shall be done before the application of

fireproofing material. All hanger and support

assemblies in their entirety shall be rust proofed and

painted. For material and method of painting, refer to

Section 09900 - Painting.

N. Gas piping installed on the roof: The support shall be

anchored or secured to the concrete deck.

3.02 NO-HUB PIPING - ADDITIONAL REQUIREMENTS

A. Sway bracing shall be provided at changes in direction

greater than 45° for pipe sizes 4” and larger.

B. On horizontal piping, additional hangers shall be

provided at each horizontal branch connection.

C. Horizontal piping 6" and larger shall be braced to

prevent joint separation.

D. Vertical piping shall be braced at each joint to assure

maintaining alignment.

E. Vertical piping shall be secured at base of stack to

building structure with socket clamp and rods or

1 trapeze hangers.

Refer to "No-Hub Pipe Bracing (for vertical piping)

Detail".

END OF SECTION

Notes to Specifiers (Delete from Specifications)

1. When No-Hub piping is specified include the stated details

on Contract Drawings.

NYCSCA HANGERS AND SUPPORTS 15411 - 9

7/25/11 DESIGN NO. _____

2. New York City plumbing code PC. 308.6 Sway bracing. Rigid

support sway bracing shall be provided at changes in

direction greater than 45 degrees for pipe sizes 4 inches and

larger.

* * *

HC/SK/BN

7/25/11

NYCSCA HANGERS AND SUPPORTS 15411 - 10

7/25/11 DESIGN NO. _____

LIST OF SUBMITTALS

SUBMITTAL DATE SUBMITTED DATE APPROVED

Product Data:

1. Pipe hangers _____________ _____________

2. Expansion bolts _____________ ______________

3. Inserts ______________ ______________

Shop Drawings: ______________ _____________

1. Method of Supports

* * *

NYCSCA HANGERS AND SUPPORTS 15411 - 11

You might also like

- Fuse Box Diagram Volkswagen Passat (B8 2015-2019)Document2 pagesFuse Box Diagram Volkswagen Passat (B8 2015-2019)slhkrh1905No ratings yet

- Kitchen Ansul Design #008 Pyro Chem Spray BoothDocument6 pagesKitchen Ansul Design #008 Pyro Chem Spray BoothJhoNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- ASHRAE Journal - Doubling-Down On NOT Balancing Variable Flow Hydronic SystemsDocument6 pagesASHRAE Journal - Doubling-Down On NOT Balancing Variable Flow Hydronic SystemsJhoNo ratings yet

- Katherine Byrne, Tuberculosis and The Victorian: Literary ImaginationDocument5 pagesKatherine Byrne, Tuberculosis and The Victorian: Literary ImaginationMaria Eliza GiuboruncaNo ratings yet

- NYC Water Tank Insp FaqDocument4 pagesNYC Water Tank Insp FaqJhoNo ratings yet

- 23 05 29 - HVAC Hangers and SupportsDocument9 pages23 05 29 - HVAC Hangers and SupportsperezismaelNo ratings yet

- Ontario Water Main StandardsDocument15 pagesOntario Water Main Standardsrhunter2010No ratings yet

- ReligionsDocument4 pagesReligionsPia Flores67% (3)

- Pipe Hangers and Supports PDFDocument13 pagesPipe Hangers and Supports PDFfaizan abbasiNo ratings yet

- SECTION 15140 Non-Continuous Hangers and Pipe Supports Part 1-General 1.1 SCOPEDocument2 pagesSECTION 15140 Non-Continuous Hangers and Pipe Supports Part 1-General 1.1 SCOPEJulian RiverosNo ratings yet

- Specification For Support and HangerDocument6 pagesSpecification For Support and Hangerdee1985No ratings yet

- Fire Protection Specifications - NgacDocument44 pagesFire Protection Specifications - Ngacmon MagbualNo ratings yet

- 22 05 29 - Plumbing Hangers and SupportsDocument17 pages22 05 29 - Plumbing Hangers and SupportsReda El-DahshoryNo ratings yet

- Piping Systems and AccessoriesDocument16 pagesPiping Systems and AccessoriesYoussef100% (1)

- Section 15060 - Hangers and SupportsDocument9 pagesSection 15060 - Hangers and SupportsLuciano SalituriNo ratings yet

- Supports, Hangers, Anchors and Sleeves For PlumbingDocument11 pagesSupports, Hangers, Anchors and Sleeves For Plumbingabdullah sahibNo ratings yet

- SECTION 15060 Hangers and Supports General 1.1Document8 pagesSECTION 15060 Hangers and Supports General 1.1fatREVITNo ratings yet

- Underground Chilled Water System August 132014Document12 pagesUnderground Chilled Water System August 132014umair186No ratings yet

- CS UT 252 Conduit PipelineDocument8 pagesCS UT 252 Conduit PipelineGilson VieiraNo ratings yet

- Section 221116 - Domestic Water Piping-PexDocument16 pagesSection 221116 - Domestic Water Piping-PexChase GietterNo ratings yet

- Hanger & Support - SpecificationDocument6 pagesHanger & Support - SpecificationParwez KhanNo ratings yet

- Pipe Hangers and Supports PDFDocument13 pagesPipe Hangers and Supports PDFKaraJet Kara Sanat100% (1)

- Division 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentDocument14 pagesDivision 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentAhmed EbrahimNo ratings yet

- Untitled 1Document1 pageUntitled 1Waqar KhanNo ratings yet

- STD 15080Document4 pagesSTD 15080dineshinnaci123No ratings yet

- Fire Protection ServicesDocument10 pagesFire Protection ServicesHeyaStanNo ratings yet

- Plumbing SpecificationsDocument38 pagesPlumbing SpecificationsAbdulaziz Al-FarsiNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- 15510Document13 pages15510mahaboobptmNo ratings yet

- Pipe and Pipe FittingsDocument21 pagesPipe and Pipe FittingsAdamNo ratings yet

- Astm Grating 655.10010039Document3 pagesAstm Grating 655.10010039Frederick CartojanoNo ratings yet

- Section 230516 - Expansion Fittings and Loops For Hvac PipingDocument5 pagesSection 230516 - Expansion Fittings and Loops For Hvac PipingChase GietterNo ratings yet

- 15510Document13 pages15510uddinnadeemNo ratings yet

- MechanicalDocument173 pagesMechanicalapi-38592580% (1)

- Ntent Ummary Erformance Equirements Reference Standards Ubmittals ArrantiesDocument5 pagesNtent Ummary Erformance Equirements Reference Standards Ubmittals ArrantiesLui TCC BariaNo ratings yet

- Fuel Handling SystemDocument4 pagesFuel Handling SystemRoel FranciscoNo ratings yet

- Hangers and Supports For Hvac Piping and EquipmentDocument10 pagesHangers and Supports For Hvac Piping and EquipmentAmeen Mohamed Ali SanadNo ratings yet

- 15-1-6 - Chilled Water Piping SystemDocument10 pages15-1-6 - Chilled Water Piping Systemfarshan296015No ratings yet

- SF - Domestic Water PipingDocument16 pagesSF - Domestic Water PipingJahat AtencioNo ratings yet

- Division 33 - UtilitiesDocument18 pagesDivision 33 - UtilitiesMisba UddinNo ratings yet

- 1110-1.14-DC-F-0704-Rev01_SPECS_ SECTION_15312 - FIRE PROTECTION BRACKETSDocument3 pages1110-1.14-DC-F-0704-Rev01_SPECS_ SECTION_15312 - FIRE PROTECTION BRACKETSمحمد إسلام عبابنهNo ratings yet

- Steam and Steam Condensate PDocument14 pagesSteam and Steam Condensate PDanny BoysieNo ratings yet

- 15070-Hangers and SupportDocument11 pages15070-Hangers and SupportAdamNo ratings yet

- BG180 Rev 2Document15 pagesBG180 Rev 2Anonymous cossY9FNo ratings yet

- Ductile Iron CastingsDocument6 pagesDuctile Iron CastingsSusan Sue Berrospi MerinoNo ratings yet

- Steel Water Pipe Specs 06Document7 pagesSteel Water Pipe Specs 06Astri NgentNo ratings yet

- 23 - 05 - 29 - Hangers and Support For HVAC Piping and EquipmentDocument8 pages23 - 05 - 29 - Hangers and Support For HVAC Piping and EquipmentVo Kien CuongNo ratings yet

- Victaulic FP SpecDocument12 pagesVictaulic FP SpecpedroluischoqueNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Water Agencies' StandardsDocument16 pagesWater Agencies' StandardsYakdhan YaseenNo ratings yet

- Specifications of Sanitary and Plumbing Works Part 1 ProductDocument12 pagesSpecifications of Sanitary and Plumbing Works Part 1 ProductderekNo ratings yet

- Division 15 - Mechanical 15000 - Basic Mechanical RequirementsDocument24 pagesDivision 15 - Mechanical 15000 - Basic Mechanical RequirementsNagiahTNo ratings yet

- The Piping Guide by David Sherwood - 1991Document267 pagesThe Piping Guide by David Sherwood - 1991bavarian_sheep100% (1)

- Cement-Mortar Lined & Coated Steel Pipe - 2Document6 pagesCement-Mortar Lined & Coated Steel Pipe - 2dwi sutiknoNo ratings yet

- Sewer Pipes and FittingsDocument8 pagesSewer Pipes and FittingsMaan Valencia - RevillaNo ratings yet

- Tyton Joint Pipe & Fittings: 2008 EDITIONDocument39 pagesTyton Joint Pipe & Fittings: 2008 EDITIONdeema saleemNo ratings yet

- Valves For Steam ServiceDocument17 pagesValves For Steam ServiceqaiserNo ratings yet

- SECTION 16110 Raceways, Boxes and Fittings: Part 1 - General Related DocumentsDocument10 pagesSECTION 16110 Raceways, Boxes and Fittings: Part 1 - General Related DocumentsAhmed GamalNo ratings yet

- Book V - Mechanical 24Document1 pageBook V - Mechanical 24Gowshalya PerinbanayakamNo ratings yet

- Fire Supperssion StandpipesDocument15 pagesFire Supperssion StandpipesMohammad Sadik0% (1)

- Hangers and Supports For Plumbing Piping and EquipmentDocument11 pagesHangers and Supports For Plumbing Piping and EquipmentEN LeedNo ratings yet

- S-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesDocument22 pagesS-0000-1360-0005 - TECHNICAL SPECIFICATION FOR PipesPaul NieNo ratings yet

- Expansion Compensation For PlumbingDocument6 pagesExpansion Compensation For Plumbingabdullah sahibNo ratings yet

- 22 05 16-Expansion Fittings and Loops For Plumbing PipingDocument8 pages22 05 16-Expansion Fittings and Loops For Plumbing PipingMahmoud GwailyNo ratings yet

- Belimo High-Torque-Application GuideDocument24 pagesBelimo High-Torque-Application GuideJhoNo ratings yet

- An Inside Look at The Technical Advances of Bioheat 2020Document36 pagesAn Inside Look at The Technical Advances of Bioheat 2020JhoNo ratings yet

- Belimo Dual Actuators - Uglk1074 - Datasheet - En-UsDocument2 pagesBelimo Dual Actuators - Uglk1074 - Datasheet - En-UsJhoNo ratings yet

- HVAC SpecDocument84 pagesHVAC SpecJhoNo ratings yet

- SystemAir Heat Pump AHU With Heat Recovery Wheel Installatio ManulDocument32 pagesSystemAir Heat Pump AHU With Heat Recovery Wheel Installatio ManulJhoNo ratings yet

- Heat Pump RTU SCADocument49 pagesHeat Pump RTU SCAJhoNo ratings yet

- Kitchen Ansul #009 Ansul 6 GallonDocument5 pagesKitchen Ansul #009 Ansul 6 GallonJhoNo ratings yet

- Ciaq 3d Printing Exposure Research 10 4 17.pptxv2 0Document11 pagesCiaq 3d Printing Exposure Research 10 4 17.pptxv2 0JhoNo ratings yet

- 06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkDocument16 pages06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkJhoNo ratings yet

- California State University: Commissioning Guideline For CSU Capital ProjectsDocument24 pagesCalifornia State University: Commissioning Guideline For CSU Capital ProjectsJhoNo ratings yet

- Code Notes Standpipe SystemsDocument11 pagesCode Notes Standpipe SystemsJhoNo ratings yet

- Ansul Design #007 Kidde Booth SystemDocument8 pagesAnsul Design #007 Kidde Booth SystemJhoNo ratings yet

- ASHRAE Journal - VAV System Duct Main DesignDocument5 pagesASHRAE Journal - VAV System Duct Main DesignJhoNo ratings yet

- Federal SP-Duplex-End-Suction-UnitDocument10 pagesFederal SP-Duplex-End-Suction-UnitJhoNo ratings yet

- Kitchen ANSUL-system-requirements Sequence of OperationDocument1 pageKitchen ANSUL-system-requirements Sequence of OperationJhoNo ratings yet

- Kitchen Ansul UL 300 & NFPA 17A PYROCHEM TANDEM TANK SYSTEMDocument7 pagesKitchen Ansul UL 300 & NFPA 17A PYROCHEM TANDEM TANK SYSTEMJhoNo ratings yet

- Kitchen Ansul #009 ANSUL 6 GALLONDocument5 pagesKitchen Ansul #009 ANSUL 6 GALLONJhoNo ratings yet

- Construction Fence-permit-ApplicationDocument4 pagesConstruction Fence-permit-ApplicationJhoNo ratings yet

- Kitchen Ansul Design #10 PROTEX 300Document6 pagesKitchen Ansul Design #10 PROTEX 300JhoNo ratings yet

- Kitchen Ansul System Design BUCKEYE TANDEM TANK SYSTEMDocument4 pagesKitchen Ansul System Design BUCKEYE TANDEM TANK SYSTEMJhoNo ratings yet

- Kitchen Ansul ANSUL 3 GALDocument5 pagesKitchen Ansul ANSUL 3 GALJhoNo ratings yet

- Kitchen Ansul System With Mechanical Gas Valve Wiring BUCKEYE BFR 10Document4 pagesKitchen Ansul System With Mechanical Gas Valve Wiring BUCKEYE BFR 10JhoNo ratings yet

- Attachment A - Scope of WorkDocument12 pagesAttachment A - Scope of WorkJhoNo ratings yet

- 12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkDocument367 pages12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkJhoNo ratings yet

- Perception On CatcallingDocument19 pagesPerception On CatcallingJasmin Delos ReyesNo ratings yet

- Principal 5svbk8Document56 pagesPrincipal 5svbk8badillojdNo ratings yet

- Digital Media MemoryDocument10 pagesDigital Media Memorywkurlinkus7386No ratings yet

- VBA Water 6.09 Temperature Pressure Relief Valve Drain LinesDocument2 pagesVBA Water 6.09 Temperature Pressure Relief Valve Drain LinesgaryNo ratings yet

- Module 2: Most Essential Learning Competencies (Melcs)Document5 pagesModule 2: Most Essential Learning Competencies (Melcs)Teresita EspinosaNo ratings yet

- The Sophia Sun: in This Issue..Document32 pagesThe Sophia Sun: in This Issue..Gi3iBq7uAANo ratings yet

- Unit 5 - Futher PractiseDocument34 pagesUnit 5 - Futher PractiseNgọc Hoa LêNo ratings yet

- Drill Daily Check SheetDocument3 pagesDrill Daily Check SheetNikhil MadaneNo ratings yet

- Department of Business Administration: Submitted ToDocument15 pagesDepartment of Business Administration: Submitted Topinky271994No ratings yet

- Model QuestionsDocument27 pagesModel Questionskalyan555No ratings yet

- Leakage Management TechnologiesDocument380 pagesLeakage Management TechnologiesWengineerNo ratings yet

- Liebherr Brochure Boom Pumps enDocument20 pagesLiebherr Brochure Boom Pumps enVikash PanditNo ratings yet

- How To Use Survey MonkeyDocument122 pagesHow To Use Survey MonkeyAlfie AbiabiNo ratings yet

- Submarine Cable Installation ContractorsDocument19 pagesSubmarine Cable Installation Contractorswiji_thukulNo ratings yet

- Cit 15 SyllabusDocument5 pagesCit 15 Syllabusapi-235716776No ratings yet

- Every Office Has OneDocument2 pagesEvery Office Has OneVeronicaGelfgrenNo ratings yet

- Requirement and Specifications: Chapter - 3Document17 pagesRequirement and Specifications: Chapter - 3Chandrashekhar KuriNo ratings yet

- Cabbash Vms BrochureDocument22 pagesCabbash Vms BrochureOghosa OsahenrhumwenNo ratings yet

- Measuring Strain in RocksDocument2 pagesMeasuring Strain in Rocksdarebusi1No ratings yet

- Multimedia Chapter 1 and 2Document22 pagesMultimedia Chapter 1 and 2tsegab bekeleNo ratings yet

- CSA Standard W178.2-01: Certification of Welding InspectorsDocument2 pagesCSA Standard W178.2-01: Certification of Welding InspectorsramalingamNo ratings yet

- Cronin 1992Document15 pagesCronin 1992Marcela GonzálezNo ratings yet

- Guided Reading Lesson PlanDocument4 pagesGuided Reading Lesson Planapi-311848745No ratings yet

- 2-2-Schedules NH-167K-05-08-2022Document187 pages2-2-Schedules NH-167K-05-08-2022hallmarkvenugopalNo ratings yet

- Action ResearchDocument6 pagesAction Researchbenita valdezNo ratings yet

- GA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0Document1 pageGA 132 VSD - 150 Psi - Air Cooled - 2015 Rev 0esteban muñozNo ratings yet

- UF - 455 - G Presentation Sheet 2011Document4 pagesUF - 455 - G Presentation Sheet 2011Carlos Perez TrujilloNo ratings yet