Professional Documents

Culture Documents

2reee Si.: It Is

2reee Si.: It Is

Uploaded by

jai2009Copyright:

Available Formats

You might also like

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- 5-116 Final PDFDocument342 pages5-116 Final PDFLeonardo Avila100% (1)

- H2000 5 10t Service and Operation Manual PDFDocument111 pagesH2000 5 10t Service and Operation Manual PDFJavier Ignacio Briones CapiccelliNo ratings yet

- Crude Pump Installation Manual SULZER PDFDocument992 pagesCrude Pump Installation Manual SULZER PDFRamesh mudunuri100% (1)

- MHI PresentationDocument45 pagesMHI Presentationluriah100% (2)

- United States Patent (10) Patent N0.2 US 6,583,656 B1Document10 pagesUnited States Patent (10) Patent N0.2 US 6,583,656 B1SaurabhABCNo ratings yet

- Z 2 Ezzx: United States PatentDocument7 pagesZ 2 Ezzx: United States Patentjai2009No ratings yet

- US9409477Document8 pagesUS9409477stanleymathers1999No ratings yet

- Us 5184465Document9 pagesUs 5184465Zhu LeeNo ratings yet

- United States Patent (10) Patent No.: US 6,712,734 B1: Loeffler (45) Date of Patent: Mar. 30, 2004Document7 pagesUnited States Patent (10) Patent No.: US 6,712,734 B1: Loeffler (45) Date of Patent: Mar. 30, 2004pmurphNo ratings yet

- Disc TurbineDocument9 pagesDisc TurbineRonan RojasNo ratings yet

- United States Patent (10) Patent No.: US 6,425,338 B1Document18 pagesUnited States Patent (10) Patent No.: US 6,425,338 B1samNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,165,759 B2Document8 pagesUnited States Patent: (12) (10) Patent No.: US 7,165,759 B2Vijay KotiNo ratings yet

- United States Patent (10) Patent No.: US 6,257,859 B1: K0da Et Al. (45) Date of Patent: Jul. 10, 2001Document10 pagesUnited States Patent (10) Patent No.: US 6,257,859 B1: K0da Et Al. (45) Date of Patent: Jul. 10, 2001SelvamNo ratings yet

- T.R. A AletteDocument9 pagesT.R. A AletteMarco Raneo PezzanoNo ratings yet

- US5323724Document11 pagesUS5323724Iuri DudinovNo ratings yet

- Patent US5611555 - Tilting SystemDocument20 pagesPatent US5611555 - Tilting SystemGabriel NunesNo ratings yet

- United States Patent (19) 11 Patent Number: 6,111,492: Fink (45) Date of Patent: Aug. 29, 2000Document8 pagesUnited States Patent (19) 11 Patent Number: 6,111,492: Fink (45) Date of Patent: Aug. 29, 2000ahmadNo ratings yet

- US20070262197A1Document24 pagesUS20070262197A1slamet wardoyoNo ratings yet

- Will O: (12) United States Patent (10) Patent No.: US 6,752,138 B2Document7 pagesWill O: (12) United States Patent (10) Patent No.: US 6,752,138 B2Khant Wai YanNo ratings yet

- United States Patent: Forward-Reverse and BrakeDocument6 pagesUnited States Patent: Forward-Reverse and Brakejai2009No ratings yet

- Heeeeeeeeee: United States PatentDocument17 pagesHeeeeeeeeee: United States PatentJohn WuNo ratings yet

- Patent Us 6212218Document11 pagesPatent Us 6212218Saulo UainerNo ratings yet

- Boat Reversing Marinegear-SCG025-Servicemanual-OriginalDocument16 pagesBoat Reversing Marinegear-SCG025-Servicemanual-OriginalAfranio Martins de Melo Franco JúniorNo ratings yet

- US5918832Document8 pagesUS5918832engine wangNo ratings yet

- MM TR 72 127 12542Document2 pagesMM TR 72 127 12542harisya denggayanaNo ratings yet

- US5060765Document12 pagesUS5060765marcglebNo ratings yet

- Us 7092801Document11 pagesUs 7092801pmurphNo ratings yet

- Transmision US3650349Document8 pagesTransmision US3650349Dejan ZdravkovskiNo ratings yet

- Us6843149 PDFDocument10 pagesUs6843149 PDFDana CucuNo ratings yet

- United States PatentDocument10 pagesUnited States PatentendhylakausuNo ratings yet

- United States Patent (10) Patent No.: US 6,767,161 B1: 107, Pasadena, CA (US) 91105 Janet E. A: 19: Taberg OSRDocument12 pagesUnited States Patent (10) Patent No.: US 6,767,161 B1: 107, Pasadena, CA (US) 91105 Janet E. A: 19: Taberg OSRSpring SuperbNo ratings yet

- 2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingDocument19 pages2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingCường Nguyễn QuốcNo ratings yet

- Us4873881 PDFDocument9 pagesUs4873881 PDFMartinito MacraméNo ratings yet

- US20130119673A1Document88 pagesUS20130119673A1Paulina Marin TellezNo ratings yet

- United States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Document14 pagesUnited States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Dagger HashimotoNo ratings yet

- United States Patent: - 3 C.T. V. V6 TaseDocument9 pagesUnited States Patent: - 3 C.T. V. V6 TaseMuhammad NazeerNo ratings yet

- Type Certificute: Republic of Indonesia Ministry of Transportation Directorate General of Civi AviationDocument10 pagesType Certificute: Republic of Indonesia Ministry of Transportation Directorate General of Civi AviationDepartemen KegelapanNo ratings yet

- US8946961Document9 pagesUS8946961naturist_medNo ratings yet

- Twinshaft Propulsion Arrangement For Tugboat PDFDocument6 pagesTwinshaft Propulsion Arrangement For Tugboat PDFRajesh CNo ratings yet

- 2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingDocument13 pages2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- United States Patent (10) Patent No.: US 6,965,821 B1: Balanayagam Et Al. (45) Date of Patent: Nov. 15, 2005Document5 pagesUnited States Patent (10) Patent No.: US 6,965,821 B1: Balanayagam Et Al. (45) Date of Patent: Nov. 15, 2005Cata StefanNo ratings yet

- Meccanismo T.R.Document6 pagesMeccanismo T.R.Marco Raneo PezzanoNo ratings yet

- United States Patent (10) Patent No.: US 7,520,989 B2: Ostergaard (45) Date of Patent: Apr. 21, 2009Document35 pagesUnited States Patent (10) Patent No.: US 7,520,989 B2: Ostergaard (45) Date of Patent: Apr. 21, 2009Cristian GomezNo ratings yet

- Us6041759 PDFDocument8 pagesUs6041759 PDFscaniaNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Document6 pagesUnited States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Keval Kamani100% (1)

- Us7216511 PDFDocument15 pagesUs7216511 PDFCatanescu Alexandru-LaurentiuNo ratings yet

- US4321507Document10 pagesUS4321507autocheck.tlNo ratings yet

- 59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Document22 pages59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Qwerty UiopNo ratings yet

- Peng's 1995-1997 US Patent #5642275Document18 pagesPeng's 1995-1997 US Patent #5642275fangzpengNo ratings yet

- United States Patent (19) : Berg (45) Date of Patent: Dec. 1, 1998Document9 pagesUnited States Patent (19) : Berg (45) Date of Patent: Dec. 1, 1998454No ratings yet

- Cilindro PatenteDocument6 pagesCilindro PatentebreinerNo ratings yet

- Decoder EncoderDocument8 pagesDecoder EncoderEmer nelsonNo ratings yet

- United States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: RegDocument24 pagesUnited States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: Reg155No ratings yet

- United States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002back1949No ratings yet

- United States Patent (19) : Propulsion System ControlDocument12 pagesUnited States Patent (19) : Propulsion System ControlgorgiNo ratings yet

- Aircraft Brake and Method With Electromechanical Actuator ModulesDocument8 pagesAircraft Brake and Method With Electromechanical Actuator ModulesHassanNo ratings yet

- Tesla PDFDocument8 pagesTesla PDFSINGLE KIFNo ratings yet

- US8075772 失效Document35 pagesUS8075772 失效Steven CHENNo ratings yet

- Pantente EngancheDocument7 pagesPantente EngancheJorge SequeraNo ratings yet

- Uinl O: (12) Ulllted States Patent (10) Patent N0.: US 7,762,776 B2Document11 pagesUinl O: (12) Ulllted States Patent (10) Patent N0.: US 7,762,776 B2Surya Chala PraveenNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- 2015 GongBian AdvancesinMechanicalEngineering SCI Q4Document16 pages2015 GongBian AdvancesinMechanicalEngineering SCI Q4jai2009No ratings yet

- Differential 4Document1 pageDifferential 4jai2009No ratings yet

- Differential 1Document1 pageDifferential 1jai2009No ratings yet

- IndexDocument123 pagesIndexjai2009No ratings yet

- Differential 6Document1 pageDifferential 6jai2009No ratings yet

- Differential 2Document1 pageDifferential 2jai2009No ratings yet

- An Overview On Designing An Environmental Friendly Electrode Manufacturing Process (EFEMP)Document7 pagesAn Overview On Designing An Environmental Friendly Electrode Manufacturing Process (EFEMP)jai2009No ratings yet

- Paper302161 2166Document6 pagesPaper302161 2166jai2009No ratings yet

- Furnace and Induction TemperingDocument9 pagesFurnace and Induction Temperingjai2009No ratings yet

- BAF SEM I Economics1Document45 pagesBAF SEM I Economics1jai2009No ratings yet

- Zhaozhong Yang, Liwei Wang, Caoyang ShiDocument6 pagesZhaozhong Yang, Liwei Wang, Caoyang Shijai2009No ratings yet

- Research ArticleDocument21 pagesResearch Articlejai2009No ratings yet

- Comparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel FiberDocument10 pagesComparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel Fiberjai2009No ratings yet

- O ... ... - g:SE:SDocument8 pagesO ... ... - g:SE:Sjai2009No ratings yet

- US2669330Document14 pagesUS2669330jai2009No ratings yet

- Z 2 Ezzx: United States PatentDocument7 pagesZ 2 Ezzx: United States Patentjai2009No ratings yet

- United States Patent (19 (45 Oct. 8, 1974: Higuchi Et Al. Forward-Reverse Clutch ControlDocument6 pagesUnited States Patent (19 (45 Oct. 8, 1974: Higuchi Et Al. Forward-Reverse Clutch Controljai2009No ratings yet

- Naszeeleb!: N: First EistDocument7 pagesNaszeeleb!: N: First Eistjai2009No ratings yet

- Crawler Bulldozers and Their Use at QuarDocument18 pagesCrawler Bulldozers and Their Use at Quarjai2009No ratings yet

- Survey Study On Effective Usage of Online Mode Payment Option in Pandemic PeriodDocument7 pagesSurvey Study On Effective Usage of Online Mode Payment Option in Pandemic Periodjai2009No ratings yet

- US4076107Document7 pagesUS4076107jai2009No ratings yet

- United States Patent (19) 11 Patent Number: 6,038,858: Mies (45) Date of Patent: Mar. 21, 2000Document14 pagesUnited States Patent (19) 11 Patent Number: 6,038,858: Mies (45) Date of Patent: Mar. 21, 2000jai2009No ratings yet

- United States Patent: Forward-Reverse and BrakeDocument6 pagesUnited States Patent: Forward-Reverse and Brakejai2009No ratings yet

- Troyke catalogWEBDocument11 pagesTroyke catalogWEBTudosa PetruNo ratings yet

- 412CRO412CROCH63Document468 pages412CRO412CROCH63252nd PAS100% (1)

- Manual de Servicio TR70 2006Document508 pagesManual de Servicio TR70 2006Fredy TorresNo ratings yet

- 6113 e enDocument28 pages6113 e enPenyair SufiNo ratings yet

- Cummins: Fault Code: 363 PID: P0251, S251 SPN: 1076 FMI: 7Document6 pagesCummins: Fault Code: 363 PID: P0251, S251 SPN: 1076 FMI: 7Enrrique LaraNo ratings yet

- Renr2343 02 Vol1 Outside 052110Document4 pagesRenr2343 02 Vol1 Outside 052110Gustavo PereiraNo ratings yet

- Hypro D30 Dia PumpDocument1 pageHypro D30 Dia PumpJorge MartinezNo ratings yet

- Gas TurbineDocument38 pagesGas TurbineJaya sankarNo ratings yet

- Rig Inspection - ModuspecDocument536 pagesRig Inspection - Moduspecwideawake.wa91No ratings yet

- AstraDocument188 pagesAstrayousif boss100% (1)

- Mobile Crane Product AdvantagesDocument8 pagesMobile Crane Product AdvantagesMarcelo Marques AraujoNo ratings yet

- Manual 0583-PP-7130 A 7132Document261 pagesManual 0583-PP-7130 A 7132gabrielgonzaloverga2No ratings yet

- Parts Manual TB035 PG3-102Z5Document307 pagesParts Manual TB035 PG3-102Z5KrunoslavNo ratings yet

- Tom Two Mark QuestionDocument23 pagesTom Two Mark QuestionTamil SelvanNo ratings yet

- Exercise - FANUCDocument175 pagesExercise - FANUCsubbu.v1987100% (1)

- BMW E90 Front Wheel Bearing Removal InstructionsDocument2 pagesBMW E90 Front Wheel Bearing Removal InstructionsdmnuNo ratings yet

- Normal Proc. BO 105 PDFDocument24 pagesNormal Proc. BO 105 PDFhariadymarpaung100% (1)

- Guides Nitro Nitro Tuning GuideDocument3 pagesGuides Nitro Nitro Tuning Guideabra77No ratings yet

- V1800 Parts Manual - V180A 50000 and Up PDFDocument18 pagesV1800 Parts Manual - V180A 50000 and Up PDFEduardo NuñezNo ratings yet

- International 2500 Tractor Series B Parts Manual TC-175 - 4/1974Document219 pagesInternational 2500 Tractor Series B Parts Manual TC-175 - 4/1974VarvayanisNo ratings yet

- Solid State Drives 2 Marks and 16Document34 pagesSolid State Drives 2 Marks and 16Dhamu DharanNo ratings yet

- Rapid Mixer Granulators RMGDocument4 pagesRapid Mixer Granulators RMGShahadat HossainNo ratings yet

- Introduction To Mechanism and KinematicsDocument24 pagesIntroduction To Mechanism and Kinematicsboonjie100% (1)

- Bomba Electrica 2000gpm@170psi (Curva)Document1 pageBomba Electrica 2000gpm@170psi (Curva)Fire ChileNo ratings yet

- 8 Inch SS 50 HZ CatalogueDocument12 pages8 Inch SS 50 HZ CataloguewagayeNo ratings yet

- Scilab ManualDocument44 pagesScilab ManualMeer Mustafa AliNo ratings yet

2reee Si.: It Is

2reee Si.: It Is

Uploaded by

jai2009Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2reee Si.: It Is

2reee Si.: It Is

Uploaded by

jai2009Copyright:

Available Formats

|H||||||||||||| USOO5168899A

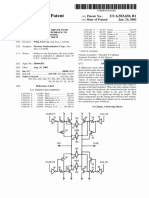

United States Patent (19) 11 Patent Number: 5,168,899

Cerrone et al. (45) Date of Patent: Dec. 8, 1992

(54) INCHING VALVE FOR POWER-SHIFT 56) References Cited

TRANSMISSIONS, PARTICULARLY FOR U.S. PATENT DOCUMENTS

LIFT TRUCKS

3,696,897 10/1972 Kitano et al. ................. 192/13 RX

3,853,210 12/1974 Kitano et al. ................. 92/13 RX

75) Inventors: Carmine Cerrone, Nichelino; 3,948,366 4/1976 Kitano et al. ................. 192/13 RX

Gabriele Mussa, Turin, both of Italy 4,150,737 4/1979 Patton ............................... 192/13 R

73) Assignee: Graziano Transmissioni S.p.A., Italy Primary Examiner-Gerald A. Michalsky

Attorney, Agent, or Firm-Armstrong & Kubovcik

(21) Appl. No.: 714,219 57 ABSTRACT

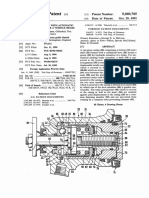

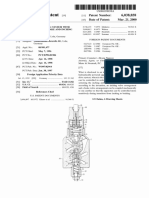

(22) Filed: Jun. 12, 1991 The stem of an inching valve for a power-shift transmis

sion, particularly for lift trucks, is controlled by a hy

(30) Foreign Application Priority Data draulically-operated piston whose axis is distinct from

and parallel to the axis of the stem and which is con

Jun. 15, 1990 IT Italy ............................... 67438 A/90 nected to the stem by means of a mechanical transmis

sion. The risk of contamination of the fluid used for

51) Int. Cl. ..................... F15B 13/042; F16D 67/04 operating the piston (which is the fluid of the vehicle's

52 U.S. Cl. ................................. 137/625.66; 91/433; braking circuit) by the oil used in the power-shift trans

192/12 C; 192/13 R mission is thus avoided.

58) Field of Search ................. 137/625.66; 192/12 C,

192/13 R; 91/433 2 Claims, 1 Drawing Sheet

7C2 ZZZZ-1 ASK

Ee

(NY72

SGS

2REEE

Nix

E6%

Si. it is

Nayyyyyy Zy

see N

(647.

SSSSSSSS

N

a

C-1

N

777 ZZMI/ 2,444,

1. / 3425f 24. 33

27 30

U.S. Patent Dec. 8, 1992 5,168,899

5,168,899

1. 2

INCHING VALVE FOR POWER-SHIFT DESCRIPTION OF THE PREFERRED

EMBODIMENT

TRANSMISSIONS, PARTICULARLY FOR LIFT

TRUCKS The object of the present invention is to provide a

5 valve of the aforesaid type which does not have the

BACKGROUND aforementioned disadvantage.

According to the invention, this object is achieved by

1. Field of the Invention virtue of a valve of the type specified above, character

The present invention relates to an inching valve for ised in that the hydraulically-operated auxiliary piston

power-shift transmissions, particularly for lift trucks. 10 for controlling the position of the stem of the inching

2. Description of Related Art valve is arranged on an axis distinct from and parallel to

Inching valves associated with power-shift transmis the axis of the stem of the inching valve and is opera

sions (which use several multiple-disc clutches engage tively connected to the stem by means of a mechanical

able selectively to obtain the various gear ratios) are transmission.

well known in the art and are used to achieve a slow 15 This arrangement makes it virtually impossible for

forward speed of the lift truck, for example, during the the transmission oil to leak into the region reserved for

the brake fluid and vice versa.

stage when it approaches a load to be lifted, even when The hydraulically-operated piston for controlling the

the internal combustion engine of the truck is kept run position of the stem of the inching valve is preferably

ning at full speed to enable the lifting device to be raised 20 arranged above the axis of the stem of the inching valve.

rapidly. The contamination of the brake fluid by the transmis

In more conventional solutions, the stem of the inch sion oil (which has more dangerous consequences than

ing valve is controlled by the operator by means of a the contamination of the transmission oil by the brake

pedal which is connected to the stem through a me fluid since it renders the braking system of the vehicle

chanical transmission. More recent solutions provide 25 inefficient) is thus made absolutely impossible as the

for the hydraulic control of the stem of the inching aforesaid leakage is opposed by gravity.

valve. In this case also, the operator controls the valve Further characteristics of the invention will become

by means of a pedal but the action of the pedal is trans clear from the description which follows with reference

mitted to the valve stem by means of a hydraulic device. to the appended drawing, provided purely by way of

30 non-limiting example.

With this technique, the piston which controls the stem In the drawing, a hydraulically-operated inching

of the inching valve is operated by the same fluid as is valve for a power-shift transmission system of a lift

used in the vehicle's braking circuit. In this case, the truck is generally indicated 1. The valve 1 comprises a

pedal which controls the inching valve is also the brake body 2 including two parts 3, 4 fixed together by screws

pedal of the vehicle. 35 (not shown in the drawing).

With inching valves produced in accordance with The part 2 has a cylindrical through-hole with a

this known technique, however, there is a risk of the smaller-diameter portion 5 and a larger-diameter por

circuit for the brake fluid being contaminated from the tion 6. The stem 7 of the inching valve is slidable in the

hydraulic circuit of the power-shift transmission. Typi smaller-diameter portion 5 and has an intermediate por

cally, the fluid used in the power-shift transmission, 40 tion of narrow diameter which, together with the wall

which is also intended to pass through the inching of the hole 5, defines an annular chamber 8.

valve, is a lubricating oil which is incompatible with the The left-hand end of the stem 7 (with reference to the

fluid normally used in the braking circuit. The seals drawing) is acted upon by a helical spring 9 interposed

used for the conventional mineral oil which flows 45 between the stem 7 and a closure plug 10 inserted in the

through the inching valve are not compatible with the hole 5. The opposite end of the stem 7 is in contact with

the end of a second stern 11 whose function will be

fluid used in the braking circuit, and vice versa. Some explained below.

times, some of the mineral oil from the transmission The chamber 8 puts an inlet 12 connected to the

enters the circuit reserved for the brake fluid and mixes supply duct for the pressurised fluid (the mineral oil

with that fluid, causing the rapid deterioration of the 50 used in the power-shift transmission) into communica

seals of the master cylinder and wheel cylinders of the tion with an outlet 13 connected to the part of the hy

vehicle's brakes. draulic circuit of the transmission which is downstream

of the valve. Essentially, the pressurised fluid supplied

SUMMARY OF THE INVENTION downstream of the valve is intended selectively to oper

In particular, the invention relates to an inching valve 55 ate a series of multiple-disc clutches provided in the

comprising a valve body; a valve stem movable be gearbox in order to actuate the various gear ratios de

sired.

tween rest position in which an inlet of the valve con The chamber 8 also communicates with a chamber 14

nected to a pressurized-fluid supply duct communicates defined between the stem 7 and the plug 10 through a

with an outlet connected to the circuit downstream of 60 duct 7a formed in the stem 7.

the valve, and an operative position in which the inlet is The stem 7 can be moved to the right (still with refer

isolated and the outlet communicates with a discharge, ence to the drawing) towards an operative position in

and a hydraulically-operated piston for controlling the which communication between the inlet 12 and the

position of the valve stem. chamber 8 is cut off, whilst the chamber 8 puts the

BRIEF DESCRIPTION OF THE DRAWING

65 outlet 13 into communication with a discharge aperture

15 connected to a discharge reservoir. In this position,

The single drawing shows a longitudinal section of a therefore, the pressurised fluid downstream of the valve

valve according to the invention. is discharged through the chamber 8 and the outlet 15,

5,168,899

3 4.

releasing pressure from the multiple-disc clutches of the ning of the present description, this fluid is different

gearbox. The pressure exerted on the multiple-disc from that of the power-shift transmission. Typically, the

clutches can thus be controlled with the desired preci latter is a conventional mineral oil, whilst the fluid in

sion by controlling the position of the stem 7 so that the the braking circuit is of the type normally used for that

advance of the vehicle can be controlled as desired even purpose. The arrangement described above prevents

when the engine is running fast because the lifting de the contamination of each of the two fluids by the other

vice of the lift truck is in operation. The operator and thus prevents the deterioration of the respective

achieves this, on the one hand, by keeping the engine seals. Seals designed for one of the aforesaid fluids are in

running fast by means of the vehicle's accelerator and, fact unsuitable for the other and may deteriorate in the

at the same time, by pressing the pedal which controls O event of contamination.

the inching valve, the speed of advance of the vehicle The device described above operates as follows:

being slower the more the valve-control pedal is as already indicated, the drawing shows the valve in the

pressed. rest condition in which the pressurised fluid arriving

In the device according to the invention, the position at the inlet 12 is sent through the chamber 8 to the

of the stem 7 of the inching valve is controlled by a 15 outlet 13 connected to the power-shift transmission.

piston 16 which is slidable in a hole 17 formed in the The operator can therefore selectively engage the

part 4. As can be seen in the drawings, this hole has an multiple-disc clutches of the transmission by operat

axis 18 distinct from and parallel to the axis 19 of the ing the usual selectors so as to make the vehicle ad

stem 7. Moreover, when the valve is fitted in the vehi vance. When he wishes to control the advance of the

cle, the hole 17 is above the axis 19. The piston 16 has a 20

vehicle, whilst keeping the internal combustion en

rod 20 which projects from the part 4 and is connected gine at a fast running speed, the operator acts on the

by a rigid connection member 21 to an auxiliary piston brake pedal to send pressurised fluid to the aperture

22 which is slidable in a narrow end portion 23 of a 36, the pressure of the fluid being greater the more

cylindrical hole 24 formed in the part 4 as a coaxial the pedal is pressed. The supply of pressurised fluid to

extension of the hole 6. A cup-shaped sleeve 25 is slid 25

the aperture 36 causes the piston 16 to move to the

able on the piston 22. A helical spring 26 is interposed right (with reference to the drawing) and hence the

between the end wall of the cup-shaped sleeve 25 and an connection member 21 and the piston 22 connected

annular abutment surface of the hole 24 so as to urge the thereto to move to the right against the action of the

sleeve 25 towards the left with reference to the draw

ing. The sleeve 25 consequently urges the piston 22 30 spring 26. The movement of the piston 22 to the right

towards the left, by means of a resilient ring 27, so as to causes the sleeve 25 to move to the right. The spring

hold an annular abutment 22a of the connection mem 30a forces the sleeve 28 to follow the movement of

ber 21 against the outer surface of the element 4. In this the sleeve 25 to the right. Once the resilient ring 31

condition, the left-hand end surface of the sleeve 25 comes into contact with the piston 11a, further move

(with reference to the drawing) is in contact with the 35 ment of the piston 22 to the right causes a correspond

corresponding end surface of a further sleeve 28 which ing movement of the stem 11. When the stem 11

is slidable in the hole 6. A chamber 29 defined between moves to the right, the stem 7 also moves to the right,

the end wall of the sleeve 28 and the end wall of the following the movement of the stem 11, under the

sleeve 25 communicates with a discharge aperture 30 action of the spring 9. As indicated above, the move

through notches formed in the end edge of the sleeve ment of the stem 7 to the right closes the inlet 12 and

28. The stem 11 has a piston 11a which is slidable in the the aperture 13 is put into communication with the

sleeve 28. A helical spring 30a is interposed between the discharge aperture 15 through the chamber 8.

piston 11a and the end wall of the sleeve 28 and tends to The basic characteristic of the device according to

hold the stem 11 against the stem 7. The piston 11a can the invention lies in the fact that, unlike conventional

move to the left relative to the sleeve 28 from this posi 45 solutions, the axis 18 of the operating piston 16 is dis

tion until it reaches the end position defined by a resil tinct from and parallel to the axis 19 of the stem 7 of the

ient ring 31 mounted in the end opening of the sleeve 28. inching valve. This avoids the danger of the fluid in the

The chamber 29 which communicates with the dis braking circuit, which is used for operating the piston

charge aperture 30 also communicates with the cham 16, being contaminated by the transmission oil flowing

ber 33 defined between the piston 22 and the end wall 24 50 in the underlying part of the valve.

through ducts 32 formed in the piston 22. The annular Naturally, the principle of the invention remaining

chamber 34 defined between the wall of the hole 24 and the same, the details of construction and forms of em

the outer surface of the sleeve 25, however, communi bodiment may be varied widely with respect to those

cates with the chamber 14 of the valve through a duct described and illustrated, without thereby departing

not visible in the drawing. 55 from the scope of the present invention.

With reference again to the operating piston 16, this We claim:

piston can be moved to the right (with reference to the 1. An inching valve for vehicle power-shift transmis

drawing) from the rest position shown in the drawing sions, particularly for lift trucks, comprising:

(which corresponds to the engagement of the abutment a first valve stem having end portions of a larger diame

surface 22a with the abutment surface of the part 4) by ter and an intermediate portion of smaller diameter;

the supply of pressurised fluid to a chamber 35 through a valve body having:

an aperture 36 and a supply duct 37. The aperture 36 a first elongated generally cylindrical hole formed in

can be closed by a plug 37 for the storage and transpor the valve body and having a first, smaller diameter

tation of the valve. The supply duct 37 also communi portion and a second, larger diameter portion, said

cates with a bleeder valve 39 of the braking circuit. The 65 first valve stem being slidably mounted in the

aperture 36 is intended to be connected to the braking smaller diameter portion of the first hole and the

circuit of the vehicle and therefore receives pressurised intermediate portion thereof forming therewith a

fluid from the braking circuit. As indicated at the begin first, fluid transfer chamber;

5,168,899

5 6

a second elongated generally cylindrical hole axially sleeve in longitudinal coaxial alignment with and

aligned with the first hole; operatively connectable to the second valve stem;

a third elongated generally cylindrical hole which, in a third fluid chamber formed by portions of side walls

a mounted position of the valve, is arranged above of the second hole and the third, auxiliary piston

and generally parallel to a longitudinal axis of the and the open end of the cup-shaped second sleeve;

first and second holes; a fourth fluid chamber formed by the ends of the first

a first fluid inlet cavity connected to a source of a and second sleeves and communicating with a sec

pressurized power shift transmission fluid and con ond fluid discharge outlet through notches formed

nectable to the first fluid transfer chamber; in an end wall of the first sleeve and with the third

a fluid outlet cavity connected to an hydraulic power 10 fluid chamber through ducts formed in the third,

shift transmission circuit and connectable to said auxiliary piston;

first inlet cavity through said first fluid transfer a fifth fluid chamber formed between the walls of the

chamber; second sleeve and the walls of the second hole and

a first fluid discharge outlet connected to a discharge 15

communicating with the second fluid chamber;

reservoir for the power shift transmission fluid and a rod projecting from said second piston outside the

connectable, through the first fluid transfer cham valve body, and

ber, with said fluid outlet cavity; a rigid connecting member connecting said rod and

a second fluid inlet cavity connected to a source of a said third piston,

pressurized braking circuit fluid and to the third 20

whereby said second, control piston is actuable by entry

hole formed in the valve body and to a bleeder of pressurized braking fluid through said second fluid

valve; inlet, thereby moving said connecting member and said

a plug closing an end of the smaller diameter portion of third auxiliary piston and causing said second valve

the first hole and forming, with an end of the first stem to allow said first vale stem to move into an opera

valve stem proximate thereto, a second fluid chamber 25 tive position whereby the first fluid inlet is closed and

communicating with the first, fluid transfer chamber the fluid outlet is put into communication with the first

through ducts in the first valve stem; fluid discharge aperture through the first fluid transfer

a first spring mounted in the smaller diameter portion of chamber, thereby controlling advance of the vehicle.

the first hole with one end thereof bearing on the plug 2. An inching valve for vehicle power-shift transmis

and the other end thereof bearing on one end of the 30 sions, particularly for lift trucks, comprising:

first valve stem proximate to the plug; a valve body having:

said first valve stem being slidable in the smaller diame a first elongated generally cylindrical hole formed

ter portion of the first hole between a rest position in therein and comprising a smaller diameter portion

which said first fluid inlet communicates, through and a larger diameter portion, a portion of the first

said first fluid transfer chamber, with the fluid outlet, 35 hole comprising a fluid transfer chamber;

and an operative position in which said first fluid inlet a second elongated generally cylindrical hole which,

is closed and the fluid outlet communicates with the in a mounted position of the valve, is arranged

discharge reservoir whereby pressurized fluid can be above and generally parallel to a longitudinal axis

discharged through the first, fluid transfer chamber of the first hole,

and the fluid outlet thereby releasing pressure from 40 a first fluid inlet cavity connected to a source of a

multiple-disc clutches of the transmission; and pressurized power shift transmission fluid and con

means to control the position of the first valve stem nectable to said fluid transfer chamber;

and thereby advance of the vehicle, comprising: a fluid outlet cavity connected to an hydraulic power

a first sleeve slidably mounted in the larger diameter shift transmission circuit and connectable to said

portion of the first hole and having one end thereof 45 first inlet cavity through said fluid transfer cham

forming a closed wall and the other end thereof ber;

partially closed by a resilient ring; a fluid discharge aperture connected to a discharge

a second valve stem having a first piston slidably reservoir for the power shift transmission fluid and

mounted in the first sleeve; connectable with said fluid outlet cavity;

a second spring mounted within the first sleeve and 50 a second fluid inlet cavity connected to a source of a

having one end thereof bearing against the first pressurized braking circuit fluid and to the second

piston and another end thereof bearing against the hole formed in the valve body;

closed end wall of the first sleeve; a valve stem comprising

a second, valve stem control piston slidable in the a first portion mounted within the smaller diameter

third hole under the influence of pressurized brak 55 portion of the first hole, and

ing fluid introduced into the third hole through the a second portion mounted within the larger diameter

second fluid inlet cavity; portion of the first hole,

a second, cup-shaped sleeve slidably mounted within wherein the valve stem is slidable in the first hole

the second hole and having an open end and the between a rest position in which said first fluid inlet

other end formed by a wall having a central aper 60 cavity communicates, through said fluid transfer

ture; chamber, with the fluid outlet cavity, and an opera

a third spring mounted within the second sleeve and tive position in which said first fluid inlet cavity is

having one end thereof bearing against the aper closed and the fluid outlet cavity communicates with

tured wall of the second sleeve and the other end the discharge reservoir;

thereof extending outwardly of the second sleeve 65 a first, valve stem control piston slidable in the second

and bearing against an end wall of the second hole; hole under the influence of pressurized braking fluid

a third, auxiliary piston slidably mounted within the introduced into the second hole through said second

second sleeve and outwardly thereof in the second fluid inlet cavity;

5,168,899

7 8

a second, auxiliary piston slidable in the first hole in a second spring mounted in the second sleeve and

longitudinal coaxial alignment with and operatively having one end thereof bearing against one end of

connectable to the valve stem; said second sleeve and the other end thereof bear

a rod projecting from the first piston outside the valve ing against said third piston, thereby urging said

body, and 5 second portion of said valve stem into abutting

a rigid connecting member connecting said rod and said end-to-end relationship with said first portion of

second piston, said valve stem, and

a closure plug closing one end of the first hole; a third spring mounted between said closure plug and

a first sleeve mounted about said second piston and an end of said first portion of said valve stem and

slidable in a larger diameter portion of the first hole; 10 urging said first portion of said valve sten into

a stop element connected to said first sleeve; abutting end-to-end relationship with said second

a first spring mounted in the first sleeve about said sec portion of said valve stem,

ond piston and having one end thereof bearing whereby, on entry of pressurized braking fluid through

against said stop element and the other end thereof said second fluid inlet, said first piston is actuated

bearing against an end of said first sleeve; 15 thereby moving said connecting member and said sec

a second sleeve mounted about the second portion of ond piston, and whereby actuation of the first piston

said valve stem and slidable in the larger diameter permits said first spring to move said second piston into

portion of the first hole in coaxial alignment with said a position relieving the pressure applied by said second

first sleeve and in abutting relationship with said first spring between said first and second portions of said

sleeve; valve stem and allowing said first portion of said valve

a third piston mounted on said second portion of said stem to move into anx operative position.

valve stem within said second sleeve; k sk

25

30

35

45

SO

55

65

You might also like

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- 5-116 Final PDFDocument342 pages5-116 Final PDFLeonardo Avila100% (1)

- H2000 5 10t Service and Operation Manual PDFDocument111 pagesH2000 5 10t Service and Operation Manual PDFJavier Ignacio Briones CapiccelliNo ratings yet

- Crude Pump Installation Manual SULZER PDFDocument992 pagesCrude Pump Installation Manual SULZER PDFRamesh mudunuri100% (1)

- MHI PresentationDocument45 pagesMHI Presentationluriah100% (2)

- United States Patent (10) Patent N0.2 US 6,583,656 B1Document10 pagesUnited States Patent (10) Patent N0.2 US 6,583,656 B1SaurabhABCNo ratings yet

- Z 2 Ezzx: United States PatentDocument7 pagesZ 2 Ezzx: United States Patentjai2009No ratings yet

- US9409477Document8 pagesUS9409477stanleymathers1999No ratings yet

- Us 5184465Document9 pagesUs 5184465Zhu LeeNo ratings yet

- United States Patent (10) Patent No.: US 6,712,734 B1: Loeffler (45) Date of Patent: Mar. 30, 2004Document7 pagesUnited States Patent (10) Patent No.: US 6,712,734 B1: Loeffler (45) Date of Patent: Mar. 30, 2004pmurphNo ratings yet

- Disc TurbineDocument9 pagesDisc TurbineRonan RojasNo ratings yet

- United States Patent (10) Patent No.: US 6,425,338 B1Document18 pagesUnited States Patent (10) Patent No.: US 6,425,338 B1samNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,165,759 B2Document8 pagesUnited States Patent: (12) (10) Patent No.: US 7,165,759 B2Vijay KotiNo ratings yet

- United States Patent (10) Patent No.: US 6,257,859 B1: K0da Et Al. (45) Date of Patent: Jul. 10, 2001Document10 pagesUnited States Patent (10) Patent No.: US 6,257,859 B1: K0da Et Al. (45) Date of Patent: Jul. 10, 2001SelvamNo ratings yet

- T.R. A AletteDocument9 pagesT.R. A AletteMarco Raneo PezzanoNo ratings yet

- US5323724Document11 pagesUS5323724Iuri DudinovNo ratings yet

- Patent US5611555 - Tilting SystemDocument20 pagesPatent US5611555 - Tilting SystemGabriel NunesNo ratings yet

- United States Patent (19) 11 Patent Number: 6,111,492: Fink (45) Date of Patent: Aug. 29, 2000Document8 pagesUnited States Patent (19) 11 Patent Number: 6,111,492: Fink (45) Date of Patent: Aug. 29, 2000ahmadNo ratings yet

- US20070262197A1Document24 pagesUS20070262197A1slamet wardoyoNo ratings yet

- Will O: (12) United States Patent (10) Patent No.: US 6,752,138 B2Document7 pagesWill O: (12) United States Patent (10) Patent No.: US 6,752,138 B2Khant Wai YanNo ratings yet

- United States Patent: Forward-Reverse and BrakeDocument6 pagesUnited States Patent: Forward-Reverse and Brakejai2009No ratings yet

- Heeeeeeeeee: United States PatentDocument17 pagesHeeeeeeeeee: United States PatentJohn WuNo ratings yet

- Patent Us 6212218Document11 pagesPatent Us 6212218Saulo UainerNo ratings yet

- Boat Reversing Marinegear-SCG025-Servicemanual-OriginalDocument16 pagesBoat Reversing Marinegear-SCG025-Servicemanual-OriginalAfranio Martins de Melo Franco JúniorNo ratings yet

- US5918832Document8 pagesUS5918832engine wangNo ratings yet

- MM TR 72 127 12542Document2 pagesMM TR 72 127 12542harisya denggayanaNo ratings yet

- US5060765Document12 pagesUS5060765marcglebNo ratings yet

- Us 7092801Document11 pagesUs 7092801pmurphNo ratings yet

- Transmision US3650349Document8 pagesTransmision US3650349Dejan ZdravkovskiNo ratings yet

- Us6843149 PDFDocument10 pagesUs6843149 PDFDana CucuNo ratings yet

- United States PatentDocument10 pagesUnited States PatentendhylakausuNo ratings yet

- United States Patent (10) Patent No.: US 6,767,161 B1: 107, Pasadena, CA (US) 91105 Janet E. A: 19: Taberg OSRDocument12 pagesUnited States Patent (10) Patent No.: US 6,767,161 B1: 107, Pasadena, CA (US) 91105 Janet E. A: 19: Taberg OSRSpring SuperbNo ratings yet

- 2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingDocument19 pages2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingCường Nguyễn QuốcNo ratings yet

- Us4873881 PDFDocument9 pagesUs4873881 PDFMartinito MacraméNo ratings yet

- US20130119673A1Document88 pagesUS20130119673A1Paulina Marin TellezNo ratings yet

- United States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Document14 pagesUnited States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Dagger HashimotoNo ratings yet

- United States Patent: - 3 C.T. V. V6 TaseDocument9 pagesUnited States Patent: - 3 C.T. V. V6 TaseMuhammad NazeerNo ratings yet

- Type Certificute: Republic of Indonesia Ministry of Transportation Directorate General of Civi AviationDocument10 pagesType Certificute: Republic of Indonesia Ministry of Transportation Directorate General of Civi AviationDepartemen KegelapanNo ratings yet

- US8946961Document9 pagesUS8946961naturist_medNo ratings yet

- Twinshaft Propulsion Arrangement For Tugboat PDFDocument6 pagesTwinshaft Propulsion Arrangement For Tugboat PDFRajesh CNo ratings yet

- 2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingDocument13 pages2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- United States Patent (10) Patent No.: US 6,965,821 B1: Balanayagam Et Al. (45) Date of Patent: Nov. 15, 2005Document5 pagesUnited States Patent (10) Patent No.: US 6,965,821 B1: Balanayagam Et Al. (45) Date of Patent: Nov. 15, 2005Cata StefanNo ratings yet

- Meccanismo T.R.Document6 pagesMeccanismo T.R.Marco Raneo PezzanoNo ratings yet

- United States Patent (10) Patent No.: US 7,520,989 B2: Ostergaard (45) Date of Patent: Apr. 21, 2009Document35 pagesUnited States Patent (10) Patent No.: US 7,520,989 B2: Ostergaard (45) Date of Patent: Apr. 21, 2009Cristian GomezNo ratings yet

- Us6041759 PDFDocument8 pagesUs6041759 PDFscaniaNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Document6 pagesUnited States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Keval Kamani100% (1)

- Us7216511 PDFDocument15 pagesUs7216511 PDFCatanescu Alexandru-LaurentiuNo ratings yet

- US4321507Document10 pagesUS4321507autocheck.tlNo ratings yet

- 59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Document22 pages59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Qwerty UiopNo ratings yet

- Peng's 1995-1997 US Patent #5642275Document18 pagesPeng's 1995-1997 US Patent #5642275fangzpengNo ratings yet

- United States Patent (19) : Berg (45) Date of Patent: Dec. 1, 1998Document9 pagesUnited States Patent (19) : Berg (45) Date of Patent: Dec. 1, 1998454No ratings yet

- Cilindro PatenteDocument6 pagesCilindro PatentebreinerNo ratings yet

- Decoder EncoderDocument8 pagesDecoder EncoderEmer nelsonNo ratings yet

- United States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: RegDocument24 pagesUnited States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: Reg155No ratings yet

- United States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002back1949No ratings yet

- United States Patent (19) : Propulsion System ControlDocument12 pagesUnited States Patent (19) : Propulsion System ControlgorgiNo ratings yet

- Aircraft Brake and Method With Electromechanical Actuator ModulesDocument8 pagesAircraft Brake and Method With Electromechanical Actuator ModulesHassanNo ratings yet

- Tesla PDFDocument8 pagesTesla PDFSINGLE KIFNo ratings yet

- US8075772 失效Document35 pagesUS8075772 失效Steven CHENNo ratings yet

- Pantente EngancheDocument7 pagesPantente EngancheJorge SequeraNo ratings yet

- Uinl O: (12) Ulllted States Patent (10) Patent N0.: US 7,762,776 B2Document11 pagesUinl O: (12) Ulllted States Patent (10) Patent N0.: US 7,762,776 B2Surya Chala PraveenNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- 2015 GongBian AdvancesinMechanicalEngineering SCI Q4Document16 pages2015 GongBian AdvancesinMechanicalEngineering SCI Q4jai2009No ratings yet

- Differential 4Document1 pageDifferential 4jai2009No ratings yet

- Differential 1Document1 pageDifferential 1jai2009No ratings yet

- IndexDocument123 pagesIndexjai2009No ratings yet

- Differential 6Document1 pageDifferential 6jai2009No ratings yet

- Differential 2Document1 pageDifferential 2jai2009No ratings yet

- An Overview On Designing An Environmental Friendly Electrode Manufacturing Process (EFEMP)Document7 pagesAn Overview On Designing An Environmental Friendly Electrode Manufacturing Process (EFEMP)jai2009No ratings yet

- Paper302161 2166Document6 pagesPaper302161 2166jai2009No ratings yet

- Furnace and Induction TemperingDocument9 pagesFurnace and Induction Temperingjai2009No ratings yet

- BAF SEM I Economics1Document45 pagesBAF SEM I Economics1jai2009No ratings yet

- Zhaozhong Yang, Liwei Wang, Caoyang ShiDocument6 pagesZhaozhong Yang, Liwei Wang, Caoyang Shijai2009No ratings yet

- Research ArticleDocument21 pagesResearch Articlejai2009No ratings yet

- Comparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel FiberDocument10 pagesComparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel Fiberjai2009No ratings yet

- O ... ... - g:SE:SDocument8 pagesO ... ... - g:SE:Sjai2009No ratings yet

- US2669330Document14 pagesUS2669330jai2009No ratings yet

- Z 2 Ezzx: United States PatentDocument7 pagesZ 2 Ezzx: United States Patentjai2009No ratings yet

- United States Patent (19 (45 Oct. 8, 1974: Higuchi Et Al. Forward-Reverse Clutch ControlDocument6 pagesUnited States Patent (19 (45 Oct. 8, 1974: Higuchi Et Al. Forward-Reverse Clutch Controljai2009No ratings yet

- Naszeeleb!: N: First EistDocument7 pagesNaszeeleb!: N: First Eistjai2009No ratings yet

- Crawler Bulldozers and Their Use at QuarDocument18 pagesCrawler Bulldozers and Their Use at Quarjai2009No ratings yet

- Survey Study On Effective Usage of Online Mode Payment Option in Pandemic PeriodDocument7 pagesSurvey Study On Effective Usage of Online Mode Payment Option in Pandemic Periodjai2009No ratings yet

- US4076107Document7 pagesUS4076107jai2009No ratings yet

- United States Patent (19) 11 Patent Number: 6,038,858: Mies (45) Date of Patent: Mar. 21, 2000Document14 pagesUnited States Patent (19) 11 Patent Number: 6,038,858: Mies (45) Date of Patent: Mar. 21, 2000jai2009No ratings yet

- United States Patent: Forward-Reverse and BrakeDocument6 pagesUnited States Patent: Forward-Reverse and Brakejai2009No ratings yet

- Troyke catalogWEBDocument11 pagesTroyke catalogWEBTudosa PetruNo ratings yet

- 412CRO412CROCH63Document468 pages412CRO412CROCH63252nd PAS100% (1)

- Manual de Servicio TR70 2006Document508 pagesManual de Servicio TR70 2006Fredy TorresNo ratings yet

- 6113 e enDocument28 pages6113 e enPenyair SufiNo ratings yet

- Cummins: Fault Code: 363 PID: P0251, S251 SPN: 1076 FMI: 7Document6 pagesCummins: Fault Code: 363 PID: P0251, S251 SPN: 1076 FMI: 7Enrrique LaraNo ratings yet

- Renr2343 02 Vol1 Outside 052110Document4 pagesRenr2343 02 Vol1 Outside 052110Gustavo PereiraNo ratings yet

- Hypro D30 Dia PumpDocument1 pageHypro D30 Dia PumpJorge MartinezNo ratings yet

- Gas TurbineDocument38 pagesGas TurbineJaya sankarNo ratings yet

- Rig Inspection - ModuspecDocument536 pagesRig Inspection - Moduspecwideawake.wa91No ratings yet

- AstraDocument188 pagesAstrayousif boss100% (1)

- Mobile Crane Product AdvantagesDocument8 pagesMobile Crane Product AdvantagesMarcelo Marques AraujoNo ratings yet

- Manual 0583-PP-7130 A 7132Document261 pagesManual 0583-PP-7130 A 7132gabrielgonzaloverga2No ratings yet

- Parts Manual TB035 PG3-102Z5Document307 pagesParts Manual TB035 PG3-102Z5KrunoslavNo ratings yet

- Tom Two Mark QuestionDocument23 pagesTom Two Mark QuestionTamil SelvanNo ratings yet

- Exercise - FANUCDocument175 pagesExercise - FANUCsubbu.v1987100% (1)

- BMW E90 Front Wheel Bearing Removal InstructionsDocument2 pagesBMW E90 Front Wheel Bearing Removal InstructionsdmnuNo ratings yet

- Normal Proc. BO 105 PDFDocument24 pagesNormal Proc. BO 105 PDFhariadymarpaung100% (1)

- Guides Nitro Nitro Tuning GuideDocument3 pagesGuides Nitro Nitro Tuning Guideabra77No ratings yet

- V1800 Parts Manual - V180A 50000 and Up PDFDocument18 pagesV1800 Parts Manual - V180A 50000 and Up PDFEduardo NuñezNo ratings yet

- International 2500 Tractor Series B Parts Manual TC-175 - 4/1974Document219 pagesInternational 2500 Tractor Series B Parts Manual TC-175 - 4/1974VarvayanisNo ratings yet

- Solid State Drives 2 Marks and 16Document34 pagesSolid State Drives 2 Marks and 16Dhamu DharanNo ratings yet

- Rapid Mixer Granulators RMGDocument4 pagesRapid Mixer Granulators RMGShahadat HossainNo ratings yet

- Introduction To Mechanism and KinematicsDocument24 pagesIntroduction To Mechanism and Kinematicsboonjie100% (1)

- Bomba Electrica 2000gpm@170psi (Curva)Document1 pageBomba Electrica 2000gpm@170psi (Curva)Fire ChileNo ratings yet

- 8 Inch SS 50 HZ CatalogueDocument12 pages8 Inch SS 50 HZ CataloguewagayeNo ratings yet

- Scilab ManualDocument44 pagesScilab ManualMeer Mustafa AliNo ratings yet