Professional Documents

Culture Documents

EN 81-2+A3 Unintended Car Movement Control Operation Manual: Ach Series Hydraulic Lift Control System

EN 81-2+A3 Unintended Car Movement Control Operation Manual: Ach Series Hydraulic Lift Control System

Uploaded by

Cosmo MovieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN 81-2+A3 Unintended Car Movement Control Operation Manual: Ach Series Hydraulic Lift Control System

EN 81-2+A3 Unintended Car Movement Control Operation Manual: Ach Series Hydraulic Lift Control System

Uploaded by

Cosmo MovieCopyright:

Available Formats

ACH SERIES HYDRAULIC LIFT

CONTROL SYSTEM

EN 81-2+A3

UNINTENDED CAR MOVEMENT

CONTROL

OPERATION MANUAL

VERSION: 1.0

AYBEY ELEKTRONİK LTD. STI.

Orhanli Mah. Katip Celebi Cad. No:17B/1 Tuzla-Istanbul / Turkey

Tel: (90) (216) 394 50 55 (pbx) Fax: (90) (216) 394 50 58

e-mail: sales@aybey.com

www.aybey.com

F.7.5.5.2.83.R0 1/3 ACH-A3

ACH SERIES HYDRAULIC LIFT CONTROL SYSTEM

EN 81-2+A3 UNINTENDED CAR MOVEMENT CONTROL

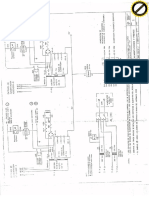

To fulfill the requirements of EN81-2 A3 norm, most of Hydraulic unit manufacturers added

an extra safety valve running in down direction. This extra valve is located between piston and

valve block serially and driven simultaneously with down direction valve.

ACH controller drives down direction valve and down direction A3 valve simultaneously

(depending on hydraulic unit types) via different switches.

ACH also includes automatic (periodic) test function for down A3 valve. User defines test

period as time-dependent or number of start dependent. The test is performed periodically and if a

problem is detected, ACH blocks itself. Beside periodic tests, manual test is also available by using

M6-UCM SERVICES > U2-UCM TEST menu.

TEST PROCEDURES

1.AUTOMATIC (PERIODIC) TEST

At first, test period is defined using P2-AUX. PARAMETERS>B59-UCM CHECK TYPE

menu. Here STARTING COUNT or DAILY CONTROL options are available.

When DAILY CONTROL is selected, first test date and time is set by using M6-UCM

SERVICES>U3-TEST TIME menu. When selected date and time is reached, controller looks for

proper free time slot for test. When lift stays free for 150 seconds then TEST is started. After

completing test, next day is assigned for test date and test time remains the same. So in this way

everyday approximately at the same time test is performed.

When STARTING COUNT is selected, test period is entered to M6-UCM SERVICES >

U4-TEST START menu as number of start. When number of start reaches the multiples of this

number, controller looks for proper free time slot for test. When lift stays free for 150 seconds then

TEST is started.

Tests are performed in two different ways depending on the parameter A05:FLOOR

SELECTOR.

NOTE 1: When B59=2 (Daily Control) is chosen, optional RTC board must be installed and

parameter B44(DATE AND TIME) must be set as 1(ACTIVATED).

NOTE 2: During TEST procedure, ACH Controller passes to Inspection mode and no calls are

accepted.

a) AUTOTEST With Counter System: Controller first moves car in up direction until

down relevelling is needed. Then down valve is energized but A3 valve is not. SECUR.VALVE

TEST message is flashed on the screen for 5 seconds. During 5 seconds if no motion is detected

TEST 1+ message is displayed and down valve is shut off. This shows that A3 valve runs properly.

If any motion is detected, then down valve is shut off, ERROR 68: SECU.VALVE FAULT

is reported and controller blocks itself permanently.

At next step A3 valve is energized but down valve is not. DOWN VALVE TEST message is

flashed on the screen for 5 seconds. During 5 seconds if no motion is detected TEST 2+ message is

displayed and A3 valve is shut off. This shows that Down valve runs properly.

If any motion is detected, then A3 valve is shut off, ERROR 69: DOWN VALVE FAULT is

reported and controller blocks itself permanently.

At the end of test, TEST OK message is displayed and controller exits from VALVE TEST

menu. Car is moved down to floor level.

F.7.5.5.2.83.R0 2/3 ACH-A3

b) AUTOTEST With Encoder System: In this system, as controller has precise position

information no up motion is required at the beginning. Except this point, the similar test procedure

is applied. During test, any motion is detected by monitoring encoder pulses. If more than 20-pulse

decrease is detected then ERROR 68/69 is reported and system is blocked permanently.

2.MANUEL TEST

Manual test is started using M6-UCM SERVICES > U2-UCM TEST menu.

To perform a proper and safe test, following conditions must be confirmed:

1. Be sure that there is nobody inside cabin.

2. Lift must not be used during test.

3. Lift must be in normal mode (not inspection mode) during test.

After starting manual test, all behavior of ACH controller, monitoring and control

procedures, error messages, controller responses are the same with automatic test procedure.

NOTE 1: During TEST procedure ACH Controller passes to Inspection mode and no calls are

accepted.

NOTE 2: Manual test cannot be started when lift is busy.

RESTORING FROM BLOCKED MODE

Enter M6-UCM SERVICES>U1-UCM RESET menu and see CLEAR UCM ERROR message and

push ENT button to confirm. This menu is functional only if the conditions causing UCM are fixed.

UCM DETECTION AND CONTROL

PREOPENING AND DOOR-OPEN RELEVELLING: Cabin is in door zone and moving in slow or

leveling speed. Door is open and Door Bridging circuit bridges safety line. In this case, if any of

door zone limit switches (ML1,ML2) is opened, then ACH Controller accepts this as UCM. Door

bridge is opened and motion is stopped. Valve and contactor supply is cut immediately.

ACH controller passes to out of service mode, reports Error 72:UCM FAULT and blocks itself

permanently. Even if ACH board is restarted, it will stay in blocked mode and error report will flash

on the screen.

During pre-opening or leveling/releveling if a fault occurs on ACH Door Bridging Circuit

and bridging cannot performed, then lift will be stopped and pass to Inspection mode. ACH

controller reports Error 45: BRIDGING ERROR and blocks itself permanently. Even if ACH board

is restarted, it will stay in blocked mode and error report will flash on the screen.

NOTE : UCM conditions occurring in both cases during pre-opening and relevelling with open-

door are supposed to be the same.

F.7.5.5.2.83.R0 3/3 ACH-A3

You might also like

- MultiliftDocument42 pagesMultiliftKevin Singh100% (1)

- 513npe-S FM Naa 200010Document112 pages513npe-S FM Naa 200010DanielNo ratings yet

- GIE Elevator Frequency Converter B1 Instruction Manual: Model: 380V Class: 3.7kW To 90kWDocument157 pagesGIE Elevator Frequency Converter B1 Instruction Manual: Model: 380V Class: 3.7kW To 90kWHector Araujo100% (1)

- Manual Electrico Alam 03Document14 pagesManual Electrico Alam 03Schusterr Barrabas100% (1)

- Class 9 Computer Book Federal Board MergedDocument120 pagesClass 9 Computer Book Federal Board MergedMunib Ahmad50% (2)

- h200 Factsheet DKDocument54 pagesh200 Factsheet DKAhmedNo ratings yet

- KONE - Travel Master 110Document8 pagesKONE - Travel Master 110ratnasekhar_gNo ratings yet

- Vega PliusDocument4 pagesVega PliusMatas DoviltisNo ratings yet

- DRK-S701-ROHS Event Monitoring Device (EMD) Seismic DetectorDocument1 pageDRK-S701-ROHS Event Monitoring Device (EMD) Seismic DetectorGuha ArnabNo ratings yet

- Starting Guide For G11S-UDP Synchronous Motor Software: Date - Revision 14/12/05 - 4Document12 pagesStarting Guide For G11S-UDP Synchronous Motor Software: Date - Revision 14/12/05 - 4freddy garciaNo ratings yet

- SPIDR PosterDocument1 pageSPIDR Postersuper_sumoNo ratings yet

- AC Series Lift Control System: User ManualDocument62 pagesAC Series Lift Control System: User ManualCosmo MovieNo ratings yet

- Fault Enc6 (194) Sheet Unidrive M DriveDocument2 pagesFault Enc6 (194) Sheet Unidrive M DriveEmadNo ratings yet

- Esquemas Fox Sistel PDFDocument19 pagesEsquemas Fox Sistel PDFcristian17283No ratings yet

- Si47 1956a e Opc PMPGDocument1 pageSi47 1956a e Opc PMPGhassanNo ratings yet

- HIDC-N Door Controller Manual-2Document30 pagesHIDC-N Door Controller Manual-2eliomar matuteNo ratings yet

- Uniscroll 2Document2 pagesUniscroll 2Khaled Zakaria100% (1)

- Specification Approval Sheet: Li-Ion 18650 3.6V 2200mah Battery 30023-0 3.6V 2200mahDocument14 pagesSpecification Approval Sheet: Li-Ion 18650 3.6V 2200mah Battery 30023-0 3.6V 2200mahwillseeseewillNo ratings yet

- ST-320 - Installation Manual - EngDocument19 pagesST-320 - Installation Manual - Engimran_21250% (2)

- KoneMontgomery - 47-54 RefacionDocument8 pagesKoneMontgomery - 47-54 RefacionAlex GonzalezNo ratings yet

- A1 KS KE L1: Artigo de Fabrico' 20100017 - Cpu Hidr 40KwDocument10 pagesA1 KS KE L1: Artigo de Fabrico' 20100017 - Cpu Hidr 40KwJose AlmeidaNo ratings yet

- ST-680 - Installation Manual - EngDocument28 pagesST-680 - Installation Manual - EngTam Ka100% (1)

- Ax Man e PDFDocument14 pagesAx Man e PDFAl Fakhamah LiftsNo ratings yet

- Ecn 413 Ecn 425 Ern 421 Ern 487Document11 pagesEcn 413 Ecn 425 Ern 421 Ern 487capricornius100% (1)

- Specification Form UML-11Document1 pageSpecification Form UML-11Gustavo CastilloNo ratings yet

- 2d-8910 - Manual 1Document1 page2d-8910 - Manual 1badis10488No ratings yet

- ECN 413 ECN 425 ERN 487: Product InformationDocument9 pagesECN 413 ECN 425 ERN 487: Product Informationangel martinezNo ratings yet

- ML40P Kullanim KilavuzuDocument23 pagesML40P Kullanim KilavuzumuaadhNo ratings yet

- Micelect Technical Manual LM3D STD Din Ver 01.2004Document1 pageMicelect Technical Manual LM3D STD Din Ver 01.2004Armando100% (1)

- 3.CS.17 - SAR2 Manual Basico Instalacion en r0Document16 pages3.CS.17 - SAR2 Manual Basico Instalacion en r0tamineNo ratings yet

- (VEGA ENG) Manuale Icaro DIP-P Rev07-1Document12 pages(VEGA ENG) Manuale Icaro DIP-P Rev07-1Mustapha BenhamouNo ratings yet

- Schindler MicromaticDocument24 pagesSchindler MicromaticJuan100% (1)

- Tool CatalogueDocument106 pagesTool CatalogueenkelectricalttNo ratings yet

- Variador StepDocument203 pagesVariador Stepgosx13No ratings yet

- Kone Grške KceDocument20 pagesKone Grške KceTIM 4EVANo ratings yet

- IRIS NV Shaft TeachDocument5 pagesIRIS NV Shaft TeachJaydi ZambranoNo ratings yet

- Scanned With CamscannerDocument6 pagesScanned With CamscannerJms QuinteroNo ratings yet

- TKE-GEC-24 - Códigos de Falhas e Alertas-PortuguêsDocument6 pagesTKE-GEC-24 - Códigos de Falhas e Alertas-PortuguêsValdo100% (1)

- MP Eco GoDocument75 pagesMP Eco GoPapa JonesNo ratings yet

- Fältcom ECII Flex: ManualDocument41 pagesFältcom ECII Flex: ManualMohamed HajjiNo ratings yet

- Tabla de-Resistencias-A1000-L1000 YASKAWADocument8 pagesTabla de-Resistencias-A1000-L1000 YASKAWADarwinGiomarPerezMarcanoNo ratings yet

- Model 840 Series Controller: Product Information SheetDocument4 pagesModel 840 Series Controller: Product Information SheetMatti HynniNo ratings yet

- Dielro 101: Manual TécnicoDocument50 pagesDielro 101: Manual Técnicomisubisi100% (1)

- LG RiseDocument29 pagesLG RisePolash UapNo ratings yet

- Ml40P Control Panel Connection, Pit and Floor Wiring SchemesDocument62 pagesMl40P Control Panel Connection, Pit and Floor Wiring Schemeskoceila HAMMADNo ratings yet

- SG10145B Op ManualDocument28 pagesSG10145B Op ManualMohamed Shafik100% (1)

- Fältcom Ecii Se: Manual and Installation InstructionsDocument36 pagesFältcom Ecii Se: Manual and Installation InstructionsCarlos BarrosNo ratings yet

- ForewordDocument199 pagesForeworddavid mauricio0% (2)

- Installation Manual: SYSTEM Inverter Air ConditionersDocument52 pagesInstallation Manual: SYSTEM Inverter Air ConditionersOscar DiazNo ratings yet

- Brugg CTP 6.5 ENDocument6 pagesBrugg CTP 6.5 ENLeandro VialNo ratings yet

- Orona (Input&Output in Ext-5 ARCAIII)Document9 pagesOrona (Input&Output in Ext-5 ARCAIII)Thi HaNo ratings yet

- Konel Evo Pro +a3 CeDocument1 pageKonel Evo Pro +a3 CeSENER AKSOYNo ratings yet

- Driver L7 OMRON PDFDocument299 pagesDriver L7 OMRON PDFmuaadhNo ratings yet

- Esquema EnorDocument43 pagesEsquema Enorhc_elecNo ratings yet

- 3.8.8 - Lista de Parâmetros Unidrive SPDocument26 pages3.8.8 - Lista de Parâmetros Unidrive SPAnonymous ugCWo0Acz3No ratings yet

- Zxk-Can3200c-2012 Wee LRDocument2 pagesZxk-Can3200c-2012 Wee LRjose moralesNo ratings yet

- Hidral Uh DiagramasDocument4 pagesHidral Uh DiagramasSaul Castillo100% (1)

- Manual ECC 230V-07.2015Document16 pagesManual ECC 230V-07.2015coco MP100% (1)

- GMV Hydraulic Unit: Transformer / 250W Line Safety LineDocument1 pageGMV Hydraulic Unit: Transformer / 250W Line Safety LineMohamed SaadNo ratings yet

- N100-Hyundai Brochure 2Document28 pagesN100-Hyundai Brochure 2herororoNo ratings yet

- Elempu Quick1Document4 pagesElempu Quick1Jaime PeñaNo ratings yet

- Technical SupportDocument25 pagesTechnical SupportThomas CutajarNo ratings yet

- Explanation of Control Panel TerminalsDocument1 pageExplanation of Control Panel TerminalsCosmo MovieNo ratings yet

- MFR/PSI Security System: User ManualDocument6 pagesMFR/PSI Security System: User ManualCosmo MovieNo ratings yet

- Km-20 User Manual v17Document32 pagesKm-20 User Manual v17Cosmo MovieNo ratings yet

- Frequently Asked QuestionsDocument1 pageFrequently Asked QuestionsCosmo MovieNo ratings yet

- AC Series Lift Control System: User ManualDocument62 pagesAC Series Lift Control System: User ManualCosmo MovieNo ratings yet

- EN 81-1+A3 Unintended Car Movement Control Operation Manual: Act/Acs Series Electric Lift Control SystemsDocument7 pagesEN 81-1+A3 Unintended Car Movement Control Operation Manual: Act/Acs Series Electric Lift Control SystemsCosmo MovieNo ratings yet

- Design and Implementation of PLC and SCADA Based Monitoring and Control System For Radiological Once Through Ventilation System at BARCDocument17 pagesDesign and Implementation of PLC and SCADA Based Monitoring and Control System For Radiological Once Through Ventilation System at BARCInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- International Journal of Information ManagementDocument16 pagesInternational Journal of Information ManagementdinaNo ratings yet

- Computer Vision White Paper 2020Document10 pagesComputer Vision White Paper 2020Amanda AntoszewskaNo ratings yet

- Template CEP PresentationDocument13 pagesTemplate CEP PresentationHassan KhanNo ratings yet

- C++ LoopDocument6 pagesC++ LoopNica Claudine Garcia MazoNo ratings yet

- Credence Induction SessionDocument33 pagesCredence Induction SessionTushar kathalkarNo ratings yet

- Driver DrowinessDocument20 pagesDriver DrowinessSruthi ReddyNo ratings yet

- JA-100 EndUser Brochure EN PDFDocument5 pagesJA-100 EndUser Brochure EN PDFjanderclanderNo ratings yet

- How To Perfectly Hide IP Address in PC and SmartphoneDocument17 pagesHow To Perfectly Hide IP Address in PC and SmartphoneFulad AfzaliNo ratings yet

- Aws Cheat SheetDocument8 pagesAws Cheat SheetdestiniprestiniNo ratings yet

- Access - Chapter 1 - Creating A Database and TablesDocument5 pagesAccess - Chapter 1 - Creating A Database and Tablesc5cxrp2nwbNo ratings yet

- SciAps X-500 QS ManualDocument20 pagesSciAps X-500 QS ManualQAQC EILNo ratings yet

- IELM 511: Information System Design: Part 1. ISD For Well Structured Data - Relational and Other DBMSDocument32 pagesIELM 511: Information System Design: Part 1. ISD For Well Structured Data - Relational and Other DBMSSarita MoreNo ratings yet

- PMI-2322 - SaleRelease - SecuriCloud General ReleaseDocument4 pagesPMI-2322 - SaleRelease - SecuriCloud General ReleaseНикита РадченкоNo ratings yet

- Evaluation of An Arabic Chatbot Based On Extractive Question-Answering Transfer Learning and Language TransformersDocument25 pagesEvaluation of An Arabic Chatbot Based On Extractive Question-Answering Transfer Learning and Language TransformersChaimaa BouafoudNo ratings yet

- Altfactor - Description of The CompanyDocument6 pagesAltfactor - Description of The CompanyMarius IvanovNo ratings yet

- 60 Power BI Interview Questions and Expert Answers For 2024Document27 pages60 Power BI Interview Questions and Expert Answers For 2024indinjourneyNo ratings yet

- Quick Start Guide 78-101246-02-A0Document29 pagesQuick Start Guide 78-101246-02-A0Samuel GabraNo ratings yet

- MediHub Version 3 User Guide For 1st Time Login and Subsequent Login - 21 Aug 2019 Effective 1 Sep 2019Document16 pagesMediHub Version 3 User Guide For 1st Time Login and Subsequent Login - 21 Aug 2019 Effective 1 Sep 2019Amran SemperitNo ratings yet

- KnowledgebaseDocument283 pagesKnowledgebaseعثمان الاغبزيNo ratings yet

- Scheduling Systems Are Used by Organizations To Allocate and Manage TheirDocument4 pagesScheduling Systems Are Used by Organizations To Allocate and Manage TheirPaolo TenorioNo ratings yet

- Speilo - Prodigi Vu Software GuideDocument120 pagesSpeilo - Prodigi Vu Software GuideJared TeeterNo ratings yet

- Silo - Tips Best Practices For Running Temenos t24 On Microsoft SQL Server and Windows ServerDocument60 pagesSilo - Tips Best Practices For Running Temenos t24 On Microsoft SQL Server and Windows Servernd0906No ratings yet

- AWS Certified Cloud Practitioner - Exam Guide - C02Document22 pagesAWS Certified Cloud Practitioner - Exam Guide - C02Sonal GuptaNo ratings yet

- 09 Texturing MethodsDocument5 pages09 Texturing MethodsthrowawayNo ratings yet

- Lead Nodejs Developer ResumeDocument7 pagesLead Nodejs Developer ResumePeter L. MontezNo ratings yet

- Microsoft Powerbi Connection AdwDocument11 pagesMicrosoft Powerbi Connection AdwAHMED MUFLEHNo ratings yet

- Java Solved Slips For PracticalDocument95 pagesJava Solved Slips For PracticalAjay Ghuge0% (1)