Professional Documents

Culture Documents

Installation Instructions: Oil Pressure Gauge-Engine and Transmission

Installation Instructions: Oil Pressure Gauge-Engine and Transmission

Uploaded by

HanCopyright:

Available Formats

You might also like

- MBC7X 652292Document18 pagesMBC7X 652292Gesiel SoaresNo ratings yet

- Kenwood KD 65F InstructionManualDocument11 pagesKenwood KD 65F InstructionManualdjr01749No ratings yet

- C6 Remove Fuel PumpDocument7 pagesC6 Remove Fuel PumpHan100% (2)

- PRODUCT SIZING ACTUATOR TrainingDocument43 pagesPRODUCT SIZING ACTUATOR TrainingNyoman RakaNo ratings yet

- AP MK8 MK9 Installation ManualDocument48 pagesAP MK8 MK9 Installation ManualMorseunitedNo ratings yet

- Fuel Injection Equipment (Diesel) (9166A056AFH02043)Document4 pagesFuel Injection Equipment (Diesel) (9166A056AFH02043)HanNo ratings yet

- Shop Manual PC650Document801 pagesShop Manual PC650Han100% (1)

- Soot Blower PDFDocument283 pagesSoot Blower PDFHatem Jafoura93% (14)

- Atra-4l80e-Rebuild (GM) Part 1Document50 pagesAtra-4l80e-Rebuild (GM) Part 1highvoltkv100% (4)

- 1NZ-FE Engine Control SystemDocument12 pages1NZ-FE Engine Control Systemjuan83% (12)

- 2 / " Electrical Gauges: MountingDocument2 pages2 / " Electrical Gauges: MountingDamien DrakeNo ratings yet

- MAC E-Power e-MMMT User ManualDocument14 pagesMAC E-Power e-MMMT User ManualJosé Luis MorenoNo ratings yet

- C653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageDocument2 pagesC653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageAyub SetiawanNo ratings yet

- ABS Sensor TestsDocument4 pagesABS Sensor TestsLuisFelipeCalixtoChavezNo ratings yet

- Battery IsolatorDocument4 pagesBattery IsolatorOrganic MechanicNo ratings yet

- DC Faulth LocatorDocument12 pagesDC Faulth LocatorRudi HermansahNo ratings yet

- Installation Instructions: Electric Gauges 2-1/16" and 2-5/8"Document2 pagesInstallation Instructions: Electric Gauges 2-1/16" and 2-5/8"HanNo ratings yet

- Hfe Classe Audio Cap-80 101 ServiceDocument19 pagesHfe Classe Audio Cap-80 101 Servicehesso1No ratings yet

- Technical Bulletin: Meritor WABCO ABS Sensor TestsDocument4 pagesTechnical Bulletin: Meritor WABCO ABS Sensor TestsfranzstolenNo ratings yet

- Inverter - Solaredge - Installation-Manual - SE3800A-US InstallationDocument7 pagesInverter - Solaredge - Installation-Manual - SE3800A-US InstallationAl0% (1)

- SU10000RT3UPM - Owner's ManualDocument104 pagesSU10000RT3UPM - Owner's ManualRuben3012No ratings yet

- Air Fuel Ratio GaugesDocument6 pagesAir Fuel Ratio GaugesadrianNo ratings yet

- Installation Data Manual Model 510 Pressure TransmitterDocument6 pagesInstallation Data Manual Model 510 Pressure TransmitterJimmy F HernandezNo ratings yet

- Service Manual: Color TelevisionDocument16 pagesService Manual: Color TelevisionYoyneer SalinasNo ratings yet

- Encoder General Install0409Document11 pagesEncoder General Install0409Johny GarganoNo ratings yet

- Stator Mod-Floating Ground Honda Wave100 XRM110Document7 pagesStator Mod-Floating Ground Honda Wave100 XRM110poscopmpc100% (2)

- Channel Master CM 3000A Suburban Outdoor Amplified Omnidirectional SMARTennaDocument4 pagesChannel Master CM 3000A Suburban Outdoor Amplified Omnidirectional SMARTennaDavid WardNo ratings yet

- DZB200M&JDocument41 pagesDZB200M&Jvijayrockz06No ratings yet

- 52Mm Short Sweep Electric Gauge: Installation GuideDocument4 pages52Mm Short Sweep Electric Gauge: Installation GuideSkiZoSnaKeNo ratings yet

- LCD LCT3201AD Service ManualDocument88 pagesLCD LCT3201AD Service ManualrhigniteNo ratings yet

- PBM Power PointDocument32 pagesPBM Power PointCarlos Quispe100% (1)

- Fuel Level Sensor Wiring Harness ReplacementDocument3 pagesFuel Level Sensor Wiring Harness ReplacementgrafpapNo ratings yet

- Cable Wire Tracer Tracker Kit Tone Probe MS6812Document10 pagesCable Wire Tracer Tracker Kit Tone Probe MS6812ristanintanNo ratings yet

- Victron Manual-Blue-Smart-IP22-Charger - (1) - (3) - 120VACDocument33 pagesVictron Manual-Blue-Smart-IP22-Charger - (1) - (3) - 120VACsimoneNo ratings yet

- H1AC1 Installation GuideDocument12 pagesH1AC1 Installation GuideWillNo ratings yet

- MN 01045Document8 pagesMN 01045jose-fumeroNo ratings yet

- User Manual: High Velocity AC Motor DrivesDocument38 pagesUser Manual: High Velocity AC Motor DrivesKumar HarendraNo ratings yet

- Haier: Color Television & DVDDocument29 pagesHaier: Color Television & DVDWilinton PissoNo ratings yet

- W 403Document84 pagesW 403Sebastian QuaroneNo ratings yet

- Akai Lct42z6tm LPL Usa (12!20!06) LCDDocument77 pagesAkai Lct42z6tm LPL Usa (12!20!06) LCDDiego Di NubilaNo ratings yet

- Chasis CY-PH2529TOP PDFDocument25 pagesChasis CY-PH2529TOP PDFDaniel AvecillaNo ratings yet

- 98 Manalx 09Document5 pages98 Manalx 09ralphNo ratings yet

- Service Nickel-Cadmium Batteries and Electrolytes Used: A. How To Measure VoltageDocument17 pagesService Nickel-Cadmium Batteries and Electrolytes Used: A. How To Measure Voltagejames kuriaNo ratings yet

- Manual Gp4303d A Gp4185d ADocument11 pagesManual Gp4303d A Gp4185d ADiego AsiconaNo ratings yet

- Video Cassette Recorder: Service ManualDocument72 pagesVideo Cassette Recorder: Service Manualmavicky89No ratings yet

- Im 10Document2 pagesIm 10RafatNo ratings yet

- F21 24E1 ManualDocument28 pagesF21 24E1 ManualJose JamNo ratings yet

- Anytone At310m ManualDocument12 pagesAnytone At310m Manual9w2nrNo ratings yet

- Faria Diesel Tach Installation Is0030fDocument2 pagesFaria Diesel Tach Installation Is0030fMichael TrimNo ratings yet

- Sens Battery ChargerDocument17 pagesSens Battery ChargervjNo ratings yet

- Panasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38Document110 pagesPanasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38drunk65100% (1)

- CTV 21d TXT Mega PH Tda9351 SMDocument37 pagesCTV 21d TXT Mega PH Tda9351 SMMersija CelikNo ratings yet

- Manual de Uso Mastech Mas838Document11 pagesManual de Uso Mastech Mas838Mario Carrasco DiazNo ratings yet

- HMS-2000-4T Quick Installation Guide: 1. AccessoriesDocument2 pagesHMS-2000-4T Quick Installation Guide: 1. AccessoriesOscar Fernando Roque PardoNo ratings yet

- Body Electrical SystemDocument59 pagesBody Electrical SystemLeonardo Gómez Berniga100% (1)

- Service Manual: VC-A560U (A) VC-A560U/A560U (B) VC-H960U/H960U (B) VC-H961UDocument78 pagesService Manual: VC-A560U (A) VC-A560U/A560U (B) VC-H960U/H960U (B) VC-H961UHugo ZuñigaNo ratings yet

- VDP Electric GaugesDocument2 pagesVDP Electric GaugesasadiqbalansariNo ratings yet

- Manual TV TRCDocument14 pagesManual TV TRCPedro MoraNo ratings yet

- DS19730Document12 pagesDS19730Joel Roberto MolinaNo ratings yet

- Philips 21pt9457 Chassis Sk4.0l-Ca PDFDocument56 pagesPhilips 21pt9457 Chassis Sk4.0l-Ca PDFJuan Garcia HernandezNo ratings yet

- 50UX58BDocument88 pages50UX58Bnip27No ratings yet

- Service Manual: LCT2662 ModelDocument76 pagesService Manual: LCT2662 ModelLyne SosiakNo ratings yet

- China Chassis KLX-2129TOPDocument32 pagesChina Chassis KLX-2129TOPDomingo CordovaNo ratings yet

- Service Manual: Colour TelevisionDocument15 pagesService Manual: Colour TelevisionArte Y MecatrónicaNo ratings yet

- Haier Htaf21sDocument15 pagesHaier Htaf21sch3o10836266No ratings yet

- Fitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7Document4 pagesFitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7HanNo ratings yet

- 2" Voltmeter 12 & 24 VDC Systems: CautionDocument2 pages2" Voltmeter 12 & 24 VDC Systems: CautionHanNo ratings yet

- KP15 Pressure Transmitter: Low & Absolute Pressure MeasurementDocument5 pagesKP15 Pressure Transmitter: Low & Absolute Pressure MeasurementHanNo ratings yet

- InteliLite NT Datasheet en HTDocument4 pagesInteliLite NT Datasheet en HTHanNo ratings yet

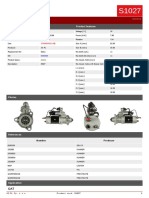

- S1027 PDFDocument2 pagesS1027 PDFHanNo ratings yet

- QSK23-G5: EPA Tier 2Document3 pagesQSK23-G5: EPA Tier 2HanNo ratings yet

- MODEL 560 Operating Manual: DSE Model 560 Automatic Start Engine Management and Instrumentation System Operators ManualDocument35 pagesMODEL 560 Operating Manual: DSE Model 560 Automatic Start Engine Management and Instrumentation System Operators ManualHanNo ratings yet

- Dvigatel Cummins Nta855 g4Document2 pagesDvigatel Cummins Nta855 g4HanNo ratings yet

- Fuel Supply LineDocument2 pagesFuel Supply LineHanNo ratings yet

- Installation Instructions: Electric Gauges 2-1/16" and 2-5/8"Document2 pagesInstallation Instructions: Electric Gauges 2-1/16" and 2-5/8"HanNo ratings yet

- Product CardDocument1 pageProduct CardHanNo ratings yet

- VDO Gauge - VL Hourmeter 12 - 24Document2 pagesVDO Gauge - VL Hourmeter 12 - 24HanNo ratings yet

- Datcon Tachometer Installation Instructions PDFDocument2 pagesDatcon Tachometer Installation Instructions PDFHan100% (1)

- Materials and Equipment Standard: IPS-M-EL-138Document36 pagesMaterials and Equipment Standard: IPS-M-EL-138ali rabieeNo ratings yet

- 'Bowden's Hobby CircuitsDocument8 pages'Bowden's Hobby Circuitsempeeno1No ratings yet

- ITC Lecture 01Document21 pagesITC Lecture 01Momena MalikNo ratings yet

- Inbound 4313559213763842860Document6 pagesInbound 4313559213763842860Gabriel PopaNo ratings yet

- Up-Date TI 2017 Site AdaroDocument51 pagesUp-Date TI 2017 Site AdaroCavandraNo ratings yet

- 38 TMSS 03 R0Document0 pages38 TMSS 03 R0renjithas2005No ratings yet

- Tupi BV: Cosco (Dalian)Document5 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- GR Yaris Service Intervals-Gryaris - Co.ukDocument1 pageGR Yaris Service Intervals-Gryaris - Co.ukFrancesco LunettaNo ratings yet

- 1990453Document3 pages1990453Mohan PreethNo ratings yet

- Requirement For 33KV Panel and 220KV Bay ExtensionDocument2 pagesRequirement For 33KV Panel and 220KV Bay ExtensionericmNo ratings yet

- Alphaspectro DatasheetDocument2 pagesAlphaspectro DatasheetP RambabuNo ratings yet

- DS3695 Multipoint RS485 RS422 Transceivers RepeatersDocument17 pagesDS3695 Multipoint RS485 RS422 Transceivers RepeatersJuan Gil Roca100% (1)

- Fingerprint Access Wiring Schematic Diagram ADocument1 pageFingerprint Access Wiring Schematic Diagram Aenamul whabNo ratings yet

- Design and Simulation of LUO Converter Topologies For Photovoltaic ApplicationsDocument8 pagesDesign and Simulation of LUO Converter Topologies For Photovoltaic ApplicationsAbdallah SayeghNo ratings yet

- Automatic Folding Door - GILGEN FFMDocument2 pagesAutomatic Folding Door - GILGEN FFMBochra Hkilani ZoghlamiNo ratings yet

- .Catálogo PRESSOSTATO SUCO 2Document10 pages.Catálogo PRESSOSTATO SUCO 2Fernando MoraesNo ratings yet

- Testsection PDFDocument33 pagesTestsection PDFAndrea AlvesNo ratings yet

- Case History: Power Plant Equipment PreservationDocument2 pagesCase History: Power Plant Equipment PreservationDurga PrasadNo ratings yet

- Samsung - MX j730 Xa RDocument54 pagesSamsung - MX j730 Xa RYeisonamrNo ratings yet

- AC3 Specification SheetDocument4 pagesAC3 Specification SheetWiwa Hernandez DonosoNo ratings yet

- SWWRCatalogRiggers PDFDocument146 pagesSWWRCatalogRiggers PDFThanhdong DoNo ratings yet

- Casio Sa-40Document12 pagesCasio Sa-40Georges TaradauxNo ratings yet

- AT24C16BDocument20 pagesAT24C16Blucio perezNo ratings yet

- SIBA NH Knife BladeDocument43 pagesSIBA NH Knife BladejagambulNo ratings yet

- Itm Lecture - 1Document24 pagesItm Lecture - 1amanrajsinghars31No ratings yet

- MAC Quantum ProfileDocument2 pagesMAC Quantum ProfileJanly CtvNo ratings yet

Installation Instructions: Oil Pressure Gauge-Engine and Transmission

Installation Instructions: Oil Pressure Gauge-Engine and Transmission

Uploaded by

HanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions: Oil Pressure Gauge-Engine and Transmission

Installation Instructions: Oil Pressure Gauge-Engine and Transmission

Uploaded by

HanCopyright:

Available Formats

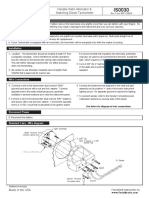

Installation Instructions

Oil Pressure Gauge-

Engine and Transmission

CAUTION: Disconnect the battery during 4. Connect a wire to the gauge stud marked “S”

installation. Tighten nuts on the backclamp only (signal) and secure with a nut and lock washer.

slightly more than you can tighten with your fingers. Connect the other end of the wire to the stud on the

Six inch-pounds of torque is sufficient. Over sending unit and secure with a nut and lock washer.

tightening may result in damage to the instrument and

may void your warranty. 5. Connect a wire to the stud marked “GND” (ground)

and secure with a nut and lock washer. Connect the

1. Engines or transmissions equipped with a low oil other end of the wire to the boat’s electrical ground,

pressure switch that activates a warning light require generally available in several locations at or near the

an appropriate “T” pipe fitting to accommodate both instrument panel.

pressure sender and warning light. Most oil pressure

sending units have 1/8”NPT pipe threads and are 6. Connect a wire to the gauge stud marked “ I ”

usually mounted in the engine’s block. If the block or (ignition) and secure with a nut and lock washer.

transmission case has a larger pipe size, an appropriate Connect the other end of the wire to a 12VDC circuit

bushing may be used without affecting pressure- that is activated by the ignition switch.

sensing accuracy.

7. Connect the blade terminal adjacent to the twist-out

2. Be certain to use stranded, insulated wire not lighter light assembly to the positive “+” side of the

than 18AWG that is approved for marine use. It is instrument lighting circuit. No separate ground is

recommended that insulated wire terminals, preferably required for the light. Reconnect the battery.

ring type, be used on all connections to the gauge and

the sender, except the light, which requires a 1/4” NOTE: To change light bulb, twist the black socket

female blade terminal. assembly one-eighth turn counterclockwise until it

pops out. The bulb pulls straight out of socket

3. Cut a 2-1/16” diameter hole in the dash and mount assembly. It is a GE No. 161 instrument lamp.

the gauge with the backclamp supplied.

IS0007E ECR2951 10/2002

Choosing the Proper Sender

Senders are designated by the following descriptions and must be selected in combinations of one each

from A, B, & C.

(For example: Single station, American resistance, Standard ground)

Single

A Station a

Dual

American

B Resistanceb

European

Standard

C Ground c

Floating

Notes:

a. Station: It is the sender that is unique in a dual station application. The gauge is the same in either single or dual

applications.

b. Resistance: Choose your sender to electrically match your gauge not just the manufacturer. Some sender

manufacturers make both resistance types; and, some instrument manufacturers may use either resistance type

depending on the gauge. There is usually no visual way alone to determine the resistance type.

c. Ground: Standard ground is the most common having battery negative (-) connected directly to the engine block.

Sending units may have one (1) terminal (signal). In a floating ground system, the battery negative is not connected

to the engine block so merely threading in the sender does not supply ground. Floating ground senders will have

two (2) terminals (signal & ground). Both sender terminals may be wired to the appropriate gauge terminal or the

sender’s ground may be wired directly to the battery negative. A floating ground sender may be used in a standard

ground system but not vice versa.

For technical assistance, contact Faria® Marine Instruments Customer Service between 8:30 a.m. and 5:00 p.m. Eastern

time weekdays at (860) 848-9271 or (800) 473-2742.

IS0007E ECR2951 10/2002

You might also like

- MBC7X 652292Document18 pagesMBC7X 652292Gesiel SoaresNo ratings yet

- Kenwood KD 65F InstructionManualDocument11 pagesKenwood KD 65F InstructionManualdjr01749No ratings yet

- C6 Remove Fuel PumpDocument7 pagesC6 Remove Fuel PumpHan100% (2)

- PRODUCT SIZING ACTUATOR TrainingDocument43 pagesPRODUCT SIZING ACTUATOR TrainingNyoman RakaNo ratings yet

- AP MK8 MK9 Installation ManualDocument48 pagesAP MK8 MK9 Installation ManualMorseunitedNo ratings yet

- Fuel Injection Equipment (Diesel) (9166A056AFH02043)Document4 pagesFuel Injection Equipment (Diesel) (9166A056AFH02043)HanNo ratings yet

- Shop Manual PC650Document801 pagesShop Manual PC650Han100% (1)

- Soot Blower PDFDocument283 pagesSoot Blower PDFHatem Jafoura93% (14)

- Atra-4l80e-Rebuild (GM) Part 1Document50 pagesAtra-4l80e-Rebuild (GM) Part 1highvoltkv100% (4)

- 1NZ-FE Engine Control SystemDocument12 pages1NZ-FE Engine Control Systemjuan83% (12)

- 2 / " Electrical Gauges: MountingDocument2 pages2 / " Electrical Gauges: MountingDamien DrakeNo ratings yet

- MAC E-Power e-MMMT User ManualDocument14 pagesMAC E-Power e-MMMT User ManualJosé Luis MorenoNo ratings yet

- C653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageDocument2 pagesC653 and C653A Alternators: This Symbol Is Used To Indicate Presence of Hazards That Can Cause Minor Property DamageAyub SetiawanNo ratings yet

- ABS Sensor TestsDocument4 pagesABS Sensor TestsLuisFelipeCalixtoChavezNo ratings yet

- Battery IsolatorDocument4 pagesBattery IsolatorOrganic MechanicNo ratings yet

- DC Faulth LocatorDocument12 pagesDC Faulth LocatorRudi HermansahNo ratings yet

- Installation Instructions: Electric Gauges 2-1/16" and 2-5/8"Document2 pagesInstallation Instructions: Electric Gauges 2-1/16" and 2-5/8"HanNo ratings yet

- Hfe Classe Audio Cap-80 101 ServiceDocument19 pagesHfe Classe Audio Cap-80 101 Servicehesso1No ratings yet

- Technical Bulletin: Meritor WABCO ABS Sensor TestsDocument4 pagesTechnical Bulletin: Meritor WABCO ABS Sensor TestsfranzstolenNo ratings yet

- Inverter - Solaredge - Installation-Manual - SE3800A-US InstallationDocument7 pagesInverter - Solaredge - Installation-Manual - SE3800A-US InstallationAl0% (1)

- SU10000RT3UPM - Owner's ManualDocument104 pagesSU10000RT3UPM - Owner's ManualRuben3012No ratings yet

- Air Fuel Ratio GaugesDocument6 pagesAir Fuel Ratio GaugesadrianNo ratings yet

- Installation Data Manual Model 510 Pressure TransmitterDocument6 pagesInstallation Data Manual Model 510 Pressure TransmitterJimmy F HernandezNo ratings yet

- Service Manual: Color TelevisionDocument16 pagesService Manual: Color TelevisionYoyneer SalinasNo ratings yet

- Encoder General Install0409Document11 pagesEncoder General Install0409Johny GarganoNo ratings yet

- Stator Mod-Floating Ground Honda Wave100 XRM110Document7 pagesStator Mod-Floating Ground Honda Wave100 XRM110poscopmpc100% (2)

- Channel Master CM 3000A Suburban Outdoor Amplified Omnidirectional SMARTennaDocument4 pagesChannel Master CM 3000A Suburban Outdoor Amplified Omnidirectional SMARTennaDavid WardNo ratings yet

- DZB200M&JDocument41 pagesDZB200M&Jvijayrockz06No ratings yet

- 52Mm Short Sweep Electric Gauge: Installation GuideDocument4 pages52Mm Short Sweep Electric Gauge: Installation GuideSkiZoSnaKeNo ratings yet

- LCD LCT3201AD Service ManualDocument88 pagesLCD LCT3201AD Service ManualrhigniteNo ratings yet

- PBM Power PointDocument32 pagesPBM Power PointCarlos Quispe100% (1)

- Fuel Level Sensor Wiring Harness ReplacementDocument3 pagesFuel Level Sensor Wiring Harness ReplacementgrafpapNo ratings yet

- Cable Wire Tracer Tracker Kit Tone Probe MS6812Document10 pagesCable Wire Tracer Tracker Kit Tone Probe MS6812ristanintanNo ratings yet

- Victron Manual-Blue-Smart-IP22-Charger - (1) - (3) - 120VACDocument33 pagesVictron Manual-Blue-Smart-IP22-Charger - (1) - (3) - 120VACsimoneNo ratings yet

- H1AC1 Installation GuideDocument12 pagesH1AC1 Installation GuideWillNo ratings yet

- MN 01045Document8 pagesMN 01045jose-fumeroNo ratings yet

- User Manual: High Velocity AC Motor DrivesDocument38 pagesUser Manual: High Velocity AC Motor DrivesKumar HarendraNo ratings yet

- Haier: Color Television & DVDDocument29 pagesHaier: Color Television & DVDWilinton PissoNo ratings yet

- W 403Document84 pagesW 403Sebastian QuaroneNo ratings yet

- Akai Lct42z6tm LPL Usa (12!20!06) LCDDocument77 pagesAkai Lct42z6tm LPL Usa (12!20!06) LCDDiego Di NubilaNo ratings yet

- Chasis CY-PH2529TOP PDFDocument25 pagesChasis CY-PH2529TOP PDFDaniel AvecillaNo ratings yet

- 98 Manalx 09Document5 pages98 Manalx 09ralphNo ratings yet

- Service Nickel-Cadmium Batteries and Electrolytes Used: A. How To Measure VoltageDocument17 pagesService Nickel-Cadmium Batteries and Electrolytes Used: A. How To Measure Voltagejames kuriaNo ratings yet

- Manual Gp4303d A Gp4185d ADocument11 pagesManual Gp4303d A Gp4185d ADiego AsiconaNo ratings yet

- Video Cassette Recorder: Service ManualDocument72 pagesVideo Cassette Recorder: Service Manualmavicky89No ratings yet

- Im 10Document2 pagesIm 10RafatNo ratings yet

- F21 24E1 ManualDocument28 pagesF21 24E1 ManualJose JamNo ratings yet

- Anytone At310m ManualDocument12 pagesAnytone At310m Manual9w2nrNo ratings yet

- Faria Diesel Tach Installation Is0030fDocument2 pagesFaria Diesel Tach Installation Is0030fMichael TrimNo ratings yet

- Sens Battery ChargerDocument17 pagesSens Battery ChargervjNo ratings yet

- Panasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38Document110 pagesPanasonic NV Gs6, Gs17, Gs18, Gs21, Gs25, Gs28, Gs35, Gs38drunk65100% (1)

- CTV 21d TXT Mega PH Tda9351 SMDocument37 pagesCTV 21d TXT Mega PH Tda9351 SMMersija CelikNo ratings yet

- Manual de Uso Mastech Mas838Document11 pagesManual de Uso Mastech Mas838Mario Carrasco DiazNo ratings yet

- HMS-2000-4T Quick Installation Guide: 1. AccessoriesDocument2 pagesHMS-2000-4T Quick Installation Guide: 1. AccessoriesOscar Fernando Roque PardoNo ratings yet

- Body Electrical SystemDocument59 pagesBody Electrical SystemLeonardo Gómez Berniga100% (1)

- Service Manual: VC-A560U (A) VC-A560U/A560U (B) VC-H960U/H960U (B) VC-H961UDocument78 pagesService Manual: VC-A560U (A) VC-A560U/A560U (B) VC-H960U/H960U (B) VC-H961UHugo ZuñigaNo ratings yet

- VDP Electric GaugesDocument2 pagesVDP Electric GaugesasadiqbalansariNo ratings yet

- Manual TV TRCDocument14 pagesManual TV TRCPedro MoraNo ratings yet

- DS19730Document12 pagesDS19730Joel Roberto MolinaNo ratings yet

- Philips 21pt9457 Chassis Sk4.0l-Ca PDFDocument56 pagesPhilips 21pt9457 Chassis Sk4.0l-Ca PDFJuan Garcia HernandezNo ratings yet

- 50UX58BDocument88 pages50UX58Bnip27No ratings yet

- Service Manual: LCT2662 ModelDocument76 pagesService Manual: LCT2662 ModelLyne SosiakNo ratings yet

- China Chassis KLX-2129TOPDocument32 pagesChina Chassis KLX-2129TOPDomingo CordovaNo ratings yet

- Service Manual: Colour TelevisionDocument15 pagesService Manual: Colour TelevisionArte Y MecatrónicaNo ratings yet

- Haier Htaf21sDocument15 pagesHaier Htaf21sch3o10836266No ratings yet

- Fitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7Document4 pagesFitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7HanNo ratings yet

- 2" Voltmeter 12 & 24 VDC Systems: CautionDocument2 pages2" Voltmeter 12 & 24 VDC Systems: CautionHanNo ratings yet

- KP15 Pressure Transmitter: Low & Absolute Pressure MeasurementDocument5 pagesKP15 Pressure Transmitter: Low & Absolute Pressure MeasurementHanNo ratings yet

- InteliLite NT Datasheet en HTDocument4 pagesInteliLite NT Datasheet en HTHanNo ratings yet

- S1027 PDFDocument2 pagesS1027 PDFHanNo ratings yet

- QSK23-G5: EPA Tier 2Document3 pagesQSK23-G5: EPA Tier 2HanNo ratings yet

- MODEL 560 Operating Manual: DSE Model 560 Automatic Start Engine Management and Instrumentation System Operators ManualDocument35 pagesMODEL 560 Operating Manual: DSE Model 560 Automatic Start Engine Management and Instrumentation System Operators ManualHanNo ratings yet

- Dvigatel Cummins Nta855 g4Document2 pagesDvigatel Cummins Nta855 g4HanNo ratings yet

- Fuel Supply LineDocument2 pagesFuel Supply LineHanNo ratings yet

- Installation Instructions: Electric Gauges 2-1/16" and 2-5/8"Document2 pagesInstallation Instructions: Electric Gauges 2-1/16" and 2-5/8"HanNo ratings yet

- Product CardDocument1 pageProduct CardHanNo ratings yet

- VDO Gauge - VL Hourmeter 12 - 24Document2 pagesVDO Gauge - VL Hourmeter 12 - 24HanNo ratings yet

- Datcon Tachometer Installation Instructions PDFDocument2 pagesDatcon Tachometer Installation Instructions PDFHan100% (1)

- Materials and Equipment Standard: IPS-M-EL-138Document36 pagesMaterials and Equipment Standard: IPS-M-EL-138ali rabieeNo ratings yet

- 'Bowden's Hobby CircuitsDocument8 pages'Bowden's Hobby Circuitsempeeno1No ratings yet

- ITC Lecture 01Document21 pagesITC Lecture 01Momena MalikNo ratings yet

- Inbound 4313559213763842860Document6 pagesInbound 4313559213763842860Gabriel PopaNo ratings yet

- Up-Date TI 2017 Site AdaroDocument51 pagesUp-Date TI 2017 Site AdaroCavandraNo ratings yet

- 38 TMSS 03 R0Document0 pages38 TMSS 03 R0renjithas2005No ratings yet

- Tupi BV: Cosco (Dalian)Document5 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- GR Yaris Service Intervals-Gryaris - Co.ukDocument1 pageGR Yaris Service Intervals-Gryaris - Co.ukFrancesco LunettaNo ratings yet

- 1990453Document3 pages1990453Mohan PreethNo ratings yet

- Requirement For 33KV Panel and 220KV Bay ExtensionDocument2 pagesRequirement For 33KV Panel and 220KV Bay ExtensionericmNo ratings yet

- Alphaspectro DatasheetDocument2 pagesAlphaspectro DatasheetP RambabuNo ratings yet

- DS3695 Multipoint RS485 RS422 Transceivers RepeatersDocument17 pagesDS3695 Multipoint RS485 RS422 Transceivers RepeatersJuan Gil Roca100% (1)

- Fingerprint Access Wiring Schematic Diagram ADocument1 pageFingerprint Access Wiring Schematic Diagram Aenamul whabNo ratings yet

- Design and Simulation of LUO Converter Topologies For Photovoltaic ApplicationsDocument8 pagesDesign and Simulation of LUO Converter Topologies For Photovoltaic ApplicationsAbdallah SayeghNo ratings yet

- Automatic Folding Door - GILGEN FFMDocument2 pagesAutomatic Folding Door - GILGEN FFMBochra Hkilani ZoghlamiNo ratings yet

- .Catálogo PRESSOSTATO SUCO 2Document10 pages.Catálogo PRESSOSTATO SUCO 2Fernando MoraesNo ratings yet

- Testsection PDFDocument33 pagesTestsection PDFAndrea AlvesNo ratings yet

- Case History: Power Plant Equipment PreservationDocument2 pagesCase History: Power Plant Equipment PreservationDurga PrasadNo ratings yet

- Samsung - MX j730 Xa RDocument54 pagesSamsung - MX j730 Xa RYeisonamrNo ratings yet

- AC3 Specification SheetDocument4 pagesAC3 Specification SheetWiwa Hernandez DonosoNo ratings yet

- SWWRCatalogRiggers PDFDocument146 pagesSWWRCatalogRiggers PDFThanhdong DoNo ratings yet

- Casio Sa-40Document12 pagesCasio Sa-40Georges TaradauxNo ratings yet

- AT24C16BDocument20 pagesAT24C16Blucio perezNo ratings yet

- SIBA NH Knife BladeDocument43 pagesSIBA NH Knife BladejagambulNo ratings yet

- Itm Lecture - 1Document24 pagesItm Lecture - 1amanrajsinghars31No ratings yet

- MAC Quantum ProfileDocument2 pagesMAC Quantum ProfileJanly CtvNo ratings yet