Professional Documents

Culture Documents

2309-EE-409 Protective Coating

2309-EE-409 Protective Coating

Uploaded by

Muhammad Ibad AlamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2309-EE-409 Protective Coating

2309-EE-409 Protective Coating

Uploaded by

Muhammad Ibad AlamCopyright:

Available Formats

BULK OIL STORAGE

TERMINAL AT TEMA Petrochem Engineering

GTG Services Ghana Services

ELECTRICAL

Standard Specifications for

Doc. No. 2309-EE-409 Protective Coating Revision No. 0

(Electrical)

TABLE OF CONTENT

1.0 SCOPE ............................................................................................................ 2

2.0 CODES AND STANDARDS ............................................................................ 2

3.0 GENERAL ....................................................................................................... 2

4.0 PAINTING........................................................................................................ 4

5.0 INSPECTION................................................................................................... 5

Standard Specifications for Protective Coating (Electrical) Page 1

BULK OIL STORAGE

TERMINAL AT TEMA Petrochem Engineering

GTG Services Ghana Services

ELECTRICAL

Standard Specifications for

Doc. No. 2309-EE-409 Protective Coating Revision No. 0

(Electrical)

1.0 SCOPE

1.1 This specification covers the requirements governing the application of the protective

coating system to be used on the interior and exterior surfaces of electrical

equipment.

2.0 CODES AND STANDARDS

2.1 Protective coating procedures shall generally conform to the following

codes/standards.

NACE National Association of Corrosion Engineers.

NEMA National Electrical Manufacturers Association.

NEC National Electrical Code (US).

IEC International Electrotechnical Commission.

SSPC Steel Structures Painting Council.

BSI British Standards Institution (BS).

VDE Association of German Electrical Engineers.

Relevant Standards as per document 2309-EE-401.

2.2 Any other recognized international standard may be used in lieu of the above, subject

to the approval of Employer / Owner’s Engineer.

2.3 In the event of conflict between this specification and other documents, the

procedures enumerated in this specification only will prevail.

3.0 GENERAL

3.1 The protective coating shall be smooth, uniform and even giving an aesthetically neat

Standard Specifications for Protective Coating (Electrical) Page 2

BULK OIL STORAGE

TERMINAL AT TEMA Petrochem Engineering

GTG Services Ghana Services

ELECTRICAL

Standard Specifications for

Doc. No. 2309-EE-409 Protective Coating Revision No. 0

(Electrical)

image of the equipment coated. There shall not be any air bubbles or marking of

paintings on the surface area of the equipment coated.

3.2 The protective coating offered on the equipment shall be suitable for site conditions

as indicated in Project Information data sheet (Electrical). Contractor / Subcontractor /

Vendor to ensure the same.

3.3 Before painting, the equipment shall undergo the following surface preparation

process :

3.3.1 All oil and grease shall be removed with clean gauze soaked in a suitable solvent.

3.3.2 All rough welds, burrs, weld splatters and other sharp surface projections shall be

grounded smooth.

3.3.3 All bolt holes shall be drilled and smoothened.

3.4 Nameplates and other items in contact with the surface being coated shall be

removed or suitably protected before surface preparation process and painting.

3.5 All containers of coating material shall remain in unopened original manufacturer’s

containers until required for use.

3.6 No painting or additional protective coating is required on the following materials

unless or otherwise specified separately:

a) Stainless steel surfaces.

b) Non-ferrous metal surfaces (e.g. LM6, aluminium / alloys).

c) Galvanised / Plated surfaces.

d) Plastic or plastic coated surfaces not subjected / susceptible to ultra-violet rays.

In case of stainless steel and non-ferrous materials the inner and outer surfaces of

the enclosures shall be cleaned, buffed and polished properly.

Standard Specifications for Protective Coating (Electrical) Page 3

BULK OIL STORAGE

TERMINAL AT TEMA Petrochem Engineering

GTG Services Ghana Services

ELECTRICAL

Standard Specifications for

Doc. No. 2309-EE-409 Protective Coating Revision No. 0

(Electrical)

4.0 PAINTING

4.1 All sheet steel work shall be phosphate in accordance with the following procedure

and in line with relevant standards for phosphating iron and steel.

4.2 Oil, grease and dirt shall be thoroughly removed by emulsion cleaning.

4.3 Rust and scale shall be removed by pickling with dilute acid followed by washing with

running water, rinsing with slightly alkaline hot water and drying.

4.4 After phosphating, rinsing shall be carried out with clean water, followed by final

rinsing with dilute dichromate solution and oven drying.

4.5 The phosphate coating shall be sealed by the application of two coats of ready

mixed, stoving type zinc chromate primer.

4.6 After application of the primer, two coats of finishing synthetic epoxy base paint shall

be applied, with first coat of paint followed by stoving. The second finishing coat shall

be applied after completion of tests.

4.7 Each coat of primer and finishing paint shall be of a slightly different shade to enable

inspection of the painting.

4.8 To the maximum practicable extent, each coat of material shall be applied as a

continuous film of uniform thickness free of pores. Any thin spots or area missed in

the application shall be re-coated and permitted to dry before the next coat is applied.

4.9 Each coat shall be in a proper state of dryness before the application of the

succeeding coat. Material shall be considered for re-coating when an additional coat

can be applied without the development of any detrimental film irregularities.

4.10 The final finished thickness of paint film on steel shall not be less than 100 microns,

and shall not be more than 150 microns. For painting by electrostatic process the

minimum thickness can be 50 microns.

Standard Specifications for Protective Coating (Electrical) Page 4

BULK OIL STORAGE

TERMINAL AT TEMA Petrochem Engineering

GTG Services Ghana Services

ELECTRICAL

Standard Specifications for

Doc. No. 2309-EE-409 Protective Coating Revision No. 0

(Electrical)

4.11 The color shade of the finish coat shall be light grey as per relevant standard on both

outer as well as inner surfaces unless otherwise specified in the system/equipment

data sheet or specifications.

4.12 Finished painted appearance of equipment shall present an aesthetically pleasing

appearance, free from dents and uneven surfaces.

5.0 INSPECTION

5.1 All coated materials and workmanship involved under this specification shall subject

to inspection.

5.2 All parts of the works shall be readily accessible to the Employer / Owner’s Engineer.

Standard Specifications for Protective Coating (Electrical) Page 5

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- To Make Flip Flop Led Flasher Circuit Using Transistor Bc547Document17 pagesTo Make Flip Flop Led Flasher Circuit Using Transistor Bc547ananyabedekar83No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Professional Practice Session 1Document23 pagesProfessional Practice Session 1Dina HawashNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- D00 Cat0003 01Document1 pageD00 Cat0003 01Muhammad Ibad AlamNo ratings yet

- Incident Report FormDocument2 pagesIncident Report FormMuhammad Ibad AlamNo ratings yet

- 2309-EE-404 Emergency Diesel GeneratorDocument36 pages2309-EE-404 Emergency Diesel GeneratorMuhammad Ibad Alam100% (1)

- 2309-EE-401 Electrical Design CriteriaDocument35 pages2309-EE-401 Electrical Design CriteriaMuhammad Ibad AlamNo ratings yet

- 2309-Ee-403 UpsDocument23 pages2309-Ee-403 UpsMuhammad Ibad AlamNo ratings yet

- 1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Document21 pages1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Muhammad Ibad AlamNo ratings yet

- Benzene Reduction SystemDocument1 pageBenzene Reduction SystemMuhammad Ibad AlamNo ratings yet

- 6.25 Transient Analysis Start Up (Pipeline) PDFDocument71 pages6.25 Transient Analysis Start Up (Pipeline) PDFMuhammad Ibad AlamNo ratings yet

- Agustin Vs Edu - DigestDocument2 pagesAgustin Vs Edu - Digestcmv mendozaNo ratings yet

- 07 - Chapter 3 PDFDocument56 pages07 - Chapter 3 PDFSrikanth GandhamNo ratings yet

- Nitish SharmaDocument59 pagesNitish SharmaannnnmmmmmNo ratings yet

- Human Rights in IslamDocument22 pagesHuman Rights in IslamNoor AliNo ratings yet

- Birinci Pozisyon Notalar Ve IsimleriDocument3 pagesBirinci Pozisyon Notalar Ve IsimleriEmre KözNo ratings yet

- Rat ModelDocument1 pageRat Modelapi-483276188No ratings yet

- International Law: Savarkar CaseDocument15 pagesInternational Law: Savarkar CaseArunesh Chandra100% (1)

- Heirs of John Sycip vs. CA G.R. No. 76487 November 9 1990Document3 pagesHeirs of John Sycip vs. CA G.R. No. 76487 November 9 1990Mariel D. Portillo100% (1)

- LEARNING THEORIES Ausubel's Learning TheoryDocument17 pagesLEARNING THEORIES Ausubel's Learning TheoryCleoNo ratings yet

- Level B1 - Threshold: Speaking Mark Scheme - Assessor'sDocument2 pagesLevel B1 - Threshold: Speaking Mark Scheme - Assessor'sdeasaadiah100% (1)

- Week 1 - The Swamp LessonDocument2 pagesWeek 1 - The Swamp LessonEccentricEdwardsNo ratings yet

- Worksheet 1: The Terms of An AgreementDocument2 pagesWorksheet 1: The Terms of An AgreementJulieta ImbaquingoNo ratings yet

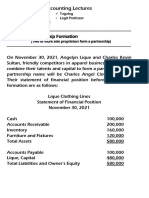

- 8 Lec 03 - Partnership Formation With BusinessDocument2 pages8 Lec 03 - Partnership Formation With BusinessNathalie GetinoNo ratings yet

- M HealthDocument81 pagesM HealthAbebe ChekolNo ratings yet

- Clinical Emergency Management Program: Advanced WorkshopDocument4 pagesClinical Emergency Management Program: Advanced WorkshopNataraj ThambiNo ratings yet

- The Oris Aquis Depth GaugeDocument2 pagesThe Oris Aquis Depth GaugeLord VarioNo ratings yet

- Electric Circuits - M. Navhi and J. A. Edminister PDFDocument113 pagesElectric Circuits - M. Navhi and J. A. Edminister PDFNamratha ThataNo ratings yet

- Tunis Stock ExchangeDocument54 pagesTunis Stock ExchangeAnonymous AoDxR5Rp4JNo ratings yet

- 5 He-Man Vs Skeletor Their Final BattleDocument9 pages5 He-Man Vs Skeletor Their Final BattleRodrigo Sorokin100% (2)

- Electrical Symbols and StandardsDocument12 pagesElectrical Symbols and StandardsSanjay KNo ratings yet

- Grade 2 - 1ST Periodical TestDocument5 pagesGrade 2 - 1ST Periodical TestGAY IBANEZ100% (1)

- Fped 07 00310Document6 pagesFped 07 00310Fariz HidayatNo ratings yet

- T-Systems CPNI Policy Statement - Final 022717 PDFDocument2 pagesT-Systems CPNI Policy Statement - Final 022717 PDFFederal Communications Commission (FCC)No ratings yet

- Intro To ForsciDocument16 pagesIntro To ForsciChloe MaciasNo ratings yet

- Pengkarya Muda - Aliah BiDocument7 pagesPengkarya Muda - Aliah BiNORHASLIZA BINTI MOHAMAD MoeNo ratings yet

- CONSTITUTIONAL - CHANGES - TO - BE - MADE - pdf-SOME IMPORTANT CHANGES TO BE MADE IN THE LANKAN PDFDocument32 pagesCONSTITUTIONAL - CHANGES - TO - BE - MADE - pdf-SOME IMPORTANT CHANGES TO BE MADE IN THE LANKAN PDFThavam RatnaNo ratings yet

- PROCERA: A New Way To Achieve An All-Ceramic CrownDocument12 pagesPROCERA: A New Way To Achieve An All-Ceramic CrownCúc Phương TrầnNo ratings yet

- Lf-74 Wire Feeder: Operator's ManualDocument50 pagesLf-74 Wire Feeder: Operator's ManualLuis Eduardo Cesena De La VegaNo ratings yet