Professional Documents

Culture Documents

WK 421 180 Directional Spool Valves

WK 421 180 Directional Spool Valves

Uploaded by

Рома БлошенкоOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WK 421 180 Directional Spool Valves

WK 421 180 Directional Spool Valves

Uploaded by

Рома БлошенкоCopyright:

Available Formats

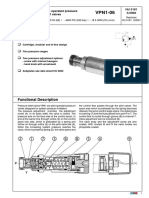

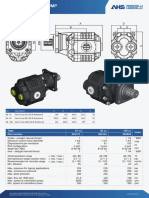

Directional spool valves WK

hand lever operated type WMM6 421 180

rotary knob operated type WMD6

roller operated type WMR6

hydraulically operated type WH6

NS6 up to 31,5 MPa up to 80 dm3/min 11.2015

DATA SHEET - OPERATION MANUAL

APPLICATION

Directional spool valves are intended for change in

direction of fluid flow in a hydraulic system and thus it

allows to change direction of movement of a receiver

- mostly piston rod of a cylinder or hydraulic motor

as well to use functions: on and off.

Directional spool valves can be made in differently

operated design versions:

• hand lever operated type WMM6

• rotary knob operated type WMD6/WMDA6

• roller operated type WMR6/WMU6

• hydraulically operated type WH6

These directional valves are intended for subplate

mounting in any position in hydraulic system.

DESCRIPTION OF OPERATION

General information

4WMM6 E - 32/F ...

Main bore and annular ports P, T, A, B are made in the

housing (1) and are connected to its subplate

connection.

Directional valve is switched by shifting the spool (2)

into one end position. Various control functions are

dependent on shape of the spool (2), which affects the

change in configuration of connections among ports

P, T, A, B in the housing (1). T

Directional spool valve - hand lever operated

type WMM6

The spool (2) is shifted as a result of changing position A P B

of the hand lever (3), by means of pin (4). The spool

return (2) to its rest is secured by springs (6) - version T

…WMM6…/… or the spool (2) is positioned by means 3 5 4 2 1 7 6

of the detent (5) - versions …WMM6…/F. Directional

spool valve may be equipped with throttle insert (7)

placed in port P - version WMM6…/…B.

4WMM6 E - 32/...B... P

Type WMM6/ WMD6/ WMR6/ WH6 -1- WK 421 180 11.2015

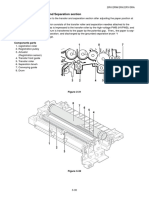

DESCRIPTION OF OPERATION

4WMD6 E -32/F

Directional spool valve - rotary knob operated

type WMD6, WMDA6

T

The spool (2) is shifted by means of rotary knob (3)

through the spindle (4) and by means of the

spring (6). The spool is positioned by means of

detent (5). Directional spool valve may be provided

with orifice (7) placed in port P - version A P B

…WMD6…/FB. T

3 4 5 1 2 7 6

4WMD6 E -32/FB

P

Directional spool valve - roller operated 4WMR6 E -32

type WMR6/WMU6

T

The spool (2) is shifted by means of the pin (3)

with the roller (4) at the end of pin, through the

plunger (5). Spool return (2) to its rest position is

secured by the spring (6). Directional spool valve

may be provided with orifice (7) placed in port P -

version …WMR…/B. A P B

T

4 3 5 1 2 7 6

4WMR6 E -32/B

P

Directional spool valve -hydraulically operated

type WH6

4WH6 E -32

The spool (2) is shifted by means of the pressure

supplied to connections of the caps (3) and thus

T

it allows to move spools (4). Spool return (2) and

its centering in neutral position (3-position

directional valves) or fixing end positions

(2-position directional valves) is secured by the

springs (5) - version …WH6…-12/…;

hydraulically (with oil pressure) - version A P B

…WH6…/O… or by means of detent – version

…WH6…/OF…. In versions: …WH6…/O… and T

…WH6…/OF… the spool position (4) is not fixed 3 4 1 2 6 5

in case of the lack of supply. Directional spool

valve may be provided with orifice (6) placed in

port P - version …WH6…/…B. 4WH6 E -32/B

P

WK 421 180 11.2015 -2- Type WMM6/ WMD6/ WMR6/ WH6

TECHNICAL DATA

Hydraulic fluid mineral oil

Required fluid cleanliness class ISO 4406 class 20/18/15

o

Nominal fluid viscosity 37 mm 2/s at temperature 55 C

Viscosity range 2,8 up to 380 mm 2/s

Fluid temperature range recommended 40 oC up to 55 oC

o

(in a tank) max -20 oC up to +70 C

Ambient temperature range - 20 oC up to +70 oC

Features type WMM6 type WMD6/WMDA6 type WMR6/WMU6 type WH6

ports ports ports ports

Max operating pressure P , A, B T P , A, B T P , A, B T P , A, B T

31,5 MPa 16 MPa 31,5 MPa 16 MPa 31,5 MPa 6 MPa 31,5 MPa 16 MPa

Control pressure _ _ _ min 0,6 - 1 MPa

max 2 0 MPa

pressure in port T

Switching force 0 MPa 15 MPa _ 100 - 200 N _

~ 20 N ~ 30 N

Tightening torque of rotary _ 150 Ncm

_ _

knob

Max angle of control cam _ _ 30 o

_

version with

2 control ports

Weight 1,8 kg

1,4 kg 1,4 kg 1,4 kg

version with

1 control port

1,3 kg

Flow section in 0 (central) spool Q - 6 % nominal section

position spool W - 3 % nominal section

INSTALLATION AND OPERATION REQUIREMENTS

1. Only fully functional and operational valve must be accidental contact with the valve body during

used. operation or to apply suitable covers acc. to

2. During the period of operation must be kept fluid PN - EN ISO 13732 - 1 and PN - EN 4413

viscosity acc. to requirements defined in this Data 5. In order to ensure tightness of the directional valve

Sheet - Operation Manual block, one should take care of dimension of sealing

3. In order to ensure failure free and safe operation the rings and valve operation parameters given in this

following must be checked: Data Sheet - Operation Manual

• proper working of the valve 6. A person that operates the valve must be thoroughly

• cleanliness of the hydraulic fluid familiar with this Data Sheet - Operation Manual.

4. Due to heating of valve body to high temp., the valve

shall be placed in such way to eliminate the risk of

Type WMM6/ WMD6/ WMR6/ WH6 -3- WK 421 180 11.2015

DIAGRAMS

Directional spool valve - hand lever operated

type ...WMM6...-3X/...

Graphic symbols of 3-position Graphic symbols of 2-position

directional spool valves directional spool valves

versions with positions a, 0 versions with positions 0, b

A B A B A B

WMM6...-3X/... a 0 b WMM6...A-3X/... a 0 WMM6...B-3X/... 0 b

P T P T P T

A B A B A B

WMM6...-3X/F... a 0 b WMM6...A-3X/F... a 0 WMM6...B-3X/F... 0 b

P T P T P T

Graphic symbols of spools

working working working working working working

and indirect positions and indirect positions and indirect positions

positions positions positions

a 0 b a 0 b a 0 a 0 0 b 0 b

E EA EB

F FA FB

G GA GB

H HA HB

J JA JB

L LA LB

M MA MB

P PA PB

Q QA QB

R RA RB

T TA TB

U UA UB

V VA VB

W WA WB

NOTES:

Flow sections in 0 (central) position achieved with spools:

Q and W - according to technical data on page 3.

WK 421 180 11.2015 -4- Type WMM6/ WMD6/ WMR6/ WH6

DIAGRAMS

Directional spool valve - hand lever operated

type ...WMM6...-3X/...

Graphic symbols of 2-position

directional spool valves

versions with positions a, b versions with positions a, b

A B A B

WMM6...-3X/... a b a b

WMM6...-3X/...

P T P T

A B A B

WMM6...-3X/F... a b WMM6...-3X/F... a b

P T P T

Graphic symbols of spools

working working working working

and indirect positions and indirect positions

positions positions

a b a b a b a b

A B

a b a b a b a b

D Y

Directional spool valve - rotary knob operated

type ... WMD6...-3X/... ; ...WMDA6...-3X/...

Graphic symbols of 2-position

directional spool valves

versions with positions a, b

A B

WMD6...-3X/F...

WMDA6...-3X/F... a b

P T

Graphic symbols of spools

working working

and indirect positions

positions

a b a b

a b a b

Type WMM6/ WMD6/ WMR6/ WH6 -5- WK 421 180 11.2015

DIAGRAMS

Directional spool valve - rotary knob operated

type ... WMD6...-3X/... ; ...WMDA6...-3X/...

Graphic symbols of 3-position Graphic symbols of 2-position

directional spool valves directional spool valves

versions with positions a, 0 versions with positions 0, b

A B A B WMD6...B-3X/F... A B

WMD6...-3X/F... WMD6...A-3X/F...

WMDA6...-3X/F... a 0 b WMDA6...A-3X/F... a 0 WMDA6...B-3X/F... 0 b

P T P T P T

Graphic symbols of spools

working working working working working working

and indirect positions and indirect positions and indirect positions

positions positions positions

a 0 b a 0 b a 0 a 0 0 b 0 b

E EA EB

F FA FB

G GA GB

H HA HB

J JA JB

L LA LB

M MA MB

P PA PB

Q QA QB

R RA RB

T TA TB

U UA UB

V VA VB

W WA WB

NOTES:

Flow sections in 0 (central) position achieved with spools:

Q and W - according to technical data on page 3.

WK 421 180 11.2015 -6- Type WMM6/ WMD6/ WMR6/ WH6

DIAGRAMS

Directional spool valve - roller operated

type ...WMR6...-3X/... ; ...WMU6...-3X/...

Graphic symbols of 3-position Graphic symbols of 2-position

directional spool valves directional spool valves

A B A B

WMR6...-3X/... WMR6...-3X/...

WMU6...-3X/... a 0 b a b

WMU6...-3X/...

P T P T

Graphic symbols of spools Graphic symbols of spools

working working working working

and indirect positions and indirect positions

positions positions

a 0 b a 0 b a b a b

A

E

F a b a b

G C

H D

NOTES:

Flow sections in 0 (central) position achieved with spools:

Q and W - according to technical data on page 3.

Type WMM6/ WMD6/ WMR6/ WH6 -7- WK 421 180 11.2015

DIAGRAMS

Directional spool valve - hydraulically operated

type ...WH6...-3X/...

Graphic symbols of 3-position Graphic symbols of 2-position

directional spool valves directional spool valves

versions with positions a, 0 versions with positions 0, b

WH6...-3X/...

A B WH6...A-3X/... A B WH6...B-3X/... A B

a a 0 b b a a 0 0 b b

P T P T P T

Graphic symbols of spools

working working working working working working

and indirect positions and indirect positions and indirect positions

positions positions positions

a 0 b a 0 b a 0 a 0 0 b 0 b

E EA EB

F FA FB

G GA GB

H HA HB

J JA JB

L LA LB

M MA MB

P PA PB

Q QA QB

R RA RB

T TA TB

U UA UB

V VA VB

W WA WB

NOTES:

Flow sections in 0 (central) position achieved with spools:

Q and W - according to technical data on page 3.

WK 421 180 11.2015 -8- Type WMM6/ WMD6/ WMR6/ WH6

DIAGRAMS

Directional spool valve - hydraulically operated

type ...WH6...-3X/...

Graphic symbols of 2-position

directional spool valves

versions with positions a , b versions with positions a, b

A B A B

WH6...-3X/... a a b WH6...-3X/... a b b

P T P T

A B

WH6...-3X/O... a a b b

P T

A B

WH6...-3X/OF... a a b b

P T

Graphic symbols of spools

working working working working

and indirect positions and indirect positions

positions positions

a b a b a b a b

A B

a b a b a b a b

D Y

Type WMM6/ WMD6/ WMR6/ WH6 -9- WK 421 180 11.2015

OVERALL AND CONNECTION DIMENSIONS

Directional spool valve - hand lever operated

type ...WMM6...-3X/...

~ 40

20°

~ 40

20 v

OO9,4 - 4 counterbores

5,3 - 4 holes

1

127

~ 27,7

49,5

42

31

23

2

T

A

31,75

B

32,5

S 24

45

0,75

P

40,5 17

~ 32 73 19

141 3

a 0 b

3-position directional valves

a b/0 2-position directional valves

with spools: A,C,D / EA...WA

a/0 b 2-position directional valves

with spools: B, Y / EB...WB 1 - Hand lever

2 - Sealing o-ring 9,2 x 1,8 - 4 pcs/set (P,T,A,B)

3 - Overall dimension of directional spool valve:

•3-position directional spool valve springs cent ered

4 •3-position directional spoo l valve pos itioned with d etent

(spool diagrams: E,F,G,H,J,L,M,Q,R,T,U,V,W - according

to page 4)

•2-position directional spoo l valve pos itioned with retu rn

spring

5

O

M5 depth 10 - 4 holes

7,6 (max) - 4 holes (P,T,A,B)

•2-position directional spoo l valve positioned with d etent

(positions a, 0 - spool diagrams: EA,FA,GA,HA,JA,LA,

MA,PA,QA,RA,TA,UA,VA,WA - according to page 4)

T (positions 0, b - spool diagrams: EB,FB,GB,HB,JB,LB,

MB,PB,QB,RB,TB,UB,VB,WB - according to page 4)

45 (min)

A B

31,75

32,5

26,55

(positions a, b - spool diagrams: A,C,D,B,Y- according

P to page 5)

4 - Positions of hand lever for different versions of

16,25

0,75

5,95

10,3 directional spool valves

5 - Porting pattern - configuration of connection holes in

19

27,8

40,5

17 r 0,01/100 mm

0,63

subplate in accordance with the standard ISO 4401

designation ISO 4401-03-02-0-94 (CETOP 03)

fixing screws M5 x 50 -10.9 in accordance with

73 (min) PN - EN ISO 4762 - 4 pcs/set - must be ordered

6 separatel; tightening; torque Md = 9 Nm

6 - Subplate surface required

WK 421 180 11.2015 - 10 - Type WMM6/ WMD6/ WMR6/ WH6

OVERALL AND CONNECTION DIMENSIONS

Directional spool valve - rotary knob operated

type ... WMD6...-3X/... ; ...WMDA6...-3X/...

7

2,8 (stroke)

6

2,8 (stroke)

OO 9,4 - 4 counterbores

5,3 - 4 holes

5

46

57

S 24

42

23

1 2 12

185 3

205 4

~ 27,7

31,75

A B

32,5

43

45

0,75

O

P

2,8 2,8

40,5 17

b 0 a 73

3-position directional valves

b 0

2-position directional valves

b/0 a with spools: B, Y / EB...WB

2-position directional valves

with spools: A,C,D / EA...WA

b/0

o

o

90

90

a b 1 - Rotary knob

2 - Sealing o-ring 9,2 x 1,8 - 4 pcs/set (P,T,A,B)

3 - Overall dimension - version WMD6...

4 - Overall dimension - version WMDA6...

8 5 - Stroke of rotary knob for 3-position directional valve

(spools diagrams: E,F,G,H,J,L,M,Q,R,T,U,V,W - page 6)

9

O

M5 depth 10 - 4 holes

7,6 (max) - 4 holes (P,T,A,B)

6 - Stroke of rotary knob for 2-position directional

valve (positions a, 0 - spools diagrams:EA,FA,GA,HA,

JA, LA, MA,PA,QA,RA,TA,UA,VA,WA - page 6,

positions a, b - spools diagrams: A,C,D - page 5)

T

7 - Stroke of rotary knob for 2-position directional valve

45 (min)

A B

31,75

32,5

26,55

(positions 0, b - spools diagrams:EB,FB,GB,HB,JB, LB,

P MB,PB,QB,RB,TB,UB,VB,WB - page 6)

8 - Positions of rotary knob for different versions of

16,25

0,75

directional spool valve

5,95

10,3

9 - Porting pattern - configuration of connection holes in

19 subplate in accordance with the standard ISO 4401

27,8

40,5

17

r 0,01/100 mm

0,63

designation ISO 4401-03-02-0-94 (CETOP 03)

fixing screws M5 x 50 -10.9 in accordance with

73 (min) PN - EN ISO 4762 - 4 pcs/set - must be ordered

separately; tightening torque Md = 9 Nm

10 10 - Subplate surface required

Type WMM6/ WMD6/ WMR6/ WH6 - 11 - WK 421 180 11.2015

OVERALL AND CONNECTION DIMENSIONS

Directional spool valve - roller operated

OO

type ... WMR6...-3X/... ; ...WMU6...-3X/...

74,5 9,4- 4 counterbores

O 16

57 5,3- 4 holes

S 24

5,6

50

42

23

2 1

6 2,8 (stroke) 3

5 5,6 (stroke)

~151 (max) 4

~ 27,7

31,75

A B

32,5

45

7 P

v

30 (max) 40,5 17

0,75

73 12

8

b a 2-position directional valves

b 0 a 3-position directional valves

2,8

5,6

1

backlash (not included in the operation

of directional valve) 1-Pin with roller - position for valve type WMR6...

2-Pin with roller - position for valve type WMU6...

9

O

M5 depth 10 - 4 holes

7,6 (max) - 4 holes (P,T,A,B)

3-

4-

Sealing ring o-ring 9,2 x 1,8 - 4 pcs/set (P,T,A,B)

Overall dimension of directional spool valve:

• type WMR6... (2 and 3-position versions)

• type WMU6... (2 and 3-position versions)

T

5 - Stroke of roller for 3-position directional spool valve

45 (min)

A B

31,75

32,5

26,55

(spools diagrams: E,F,G,H,J,L,M,Q,R,T,U,V,W - page 7)

P 6 - Stroke of roller for 2-position valve (spools diagrams:

A,C,D - page 7)

16,25

0,75

7 - Max angle of control cam

5,95

10,3

8 - Position of pin with roller for different versions of

19 directional valves (type WMR6... and WMU6...)

27,8 17 9 - Porting pattern - configuration of connection holes in

40,5

73 (min)

r 0,01/100 mm

0,63

subplate in accordance with the standard ISO 4401

designation ISO 4401-03-02-0-94 (CETOP 03)

fixing screws M5 x 50 -10.9 in accordance with

PN - EN ISO 4762 - 4 pcs/set - must be ordered

10 separately; tightening torque Md = 9 Nm

10 - Subplate surface required

WK 421 180 11.2015 - 12 - Type WMM6/ WMD6/ WMR6/ WH6

OVERALL AND CONNECTION DIMENSIONS

Directional spool valve - hydraulically operated

type ...WH6...-3X/...

O

OO

15,5 - 2 counterbores

G1/8 - 2 holes 9,4 - 4 counterbores

5,3 - 4 holes

1

7

~ 27,7

a b

50

42

23

1 3 2

6 125

T

A

31,75

B

32,5

S 24

P

0,75

38 40,5 17 9

5 125

4 158

1 - Cap with control port a

2 - Cap with control port b

3 - Sealing o-ring 9,2 x 1, 8 - 4 pcs/set (P,T,A,B)

4 - Overall dimension of directional spool valve:

•3-position directional spool valve springs centere d

(spools diagrams: E,F,G,H,J,L,M,Q,R,T,U,V,W - page 8)

•2-position directional spool valve without return

7

O

M5 depth 10 - 4 holes

7,6 (max) - 4 holes (P,T,A,B) springs and w ithout detent

•2-position directional spool valve without return

springs wit h detent

T

(positions: a, b - spools diagrams: A,C,D - page 9)

45 (min)

A B

31,75

32,5

26,55

5 - Overall dimension of directional spool valve:

P •2-position directional spool valve spring posit ioned

(positions a, b - spools diagrams: A,C,D - page 9;

positions: a, 0 - spools diagrams: EA,FA,GA,HA,JA,

16,25

0,75

5,95

10,3 LA ,MA,PA,QA,RA,TA,UA,VA,WA - page 8)

19 6 - Overall dimension of directional spool valve:

27,8 17 (min) •2-position directional spool valve spring positioned

(positions: a, b - spools diagrams: B, Y - page 9;

40,5 positions: 0, b - spools diagrams: EB,FB,GB,HB,JB,

73 (min) LB ,MB,PB,QB,RB,TB,UB,VB,WB - page 8)

7 - Porting pattern - configuration of connection holes in

r 0,01/100 mm

0,63

subplate in accordance with the standard ISO 4401

designation ISO 4401 -03-02-0-94 (CETOP 03)

fixing screws M5 x 50 - 10.9 in accordance with

PN - EN ISO 4762 - 4 pcs/set - must be ordered

8 separately; tightening torque Md = 9 Nm

8 - Subplate surface required

Type WMM6/ WMD6/ WMR6/ WH6 - 13 - WK 421 180 11.2015

PERFORMANCE CURVES

o

measured at viscosity ν = 41 mm 2/s and temperature t = 50 C

Flow resistance curves

• type WMM6...; WMM6.../F...

• type WMD6.../F...; WMDA6.../F...

• type WMR6...; WMU6...

• type WH6...; WH6.../O...; WH6.../OF...

Characteristic curves ∆p(Q) for all directional spool valves

for various spool types

A B C D E F G H J L M P Q R T U V W Y

P-A 3 3 1 5 3 2 5 2 1 1 2 2 1 5 5 3 1 1 5

P-B 3 3 1 5 3 3 3 4 1 1 4 3 1 5 3 1 2 1 5

A -T - - 3 3 1 3 6 2 2 2 3 3 2 4 6 3 1 2 3

B -T - - 1 3 1 5 6 2 1 2 3 5 1 6 3 1 2 3

Operating limits curves

• type WMM6 ...

Flow curves p-Q for directional spool valve type WMM6 ... - versions with various spools

springs centered

1 2 3 4 5

E1, M , E, J,

L, Q, U, W, C, A, B V F, P T

D, Y, G, H, R

WK 421 180 11.2015 - 14 - Type WMM6/ WMD6/ WMR6/ WH6

PERFORMANCE CURVES

o

measured at viscosity ν = 41 mm 2/s and temperature t = 50 C

Operating limits curves

• type WMM6.../F...

Flow curves p-Q for directional spool valve type WMM6.../F... - versions with

various spools positioned with detent

1 2 3 4 5 6 7 8 9

E1, M , E, J,

H, C, Q, L, A, B G, T F V P R T

D, Y U, W

• type WMD6.../F...

• type WMDA6.../F...

Flow curves p-Q for directional spool valve type: WMD6.../F...; WMDA6.../F...

versions with various spools positioned with detent

1 2 3 4 5 6 7 8

E1, M , H, C,

J, L A G, P F V R T

D, E, Q, U, W

Type WMM6/ WMD6/ WMR6/ WH6 - 15 - WK 421 180 11.2015

PERFORMANCE CURVES

o

measured at viscosity ν = 41 mm 2/s and temperature t = 50 C

Operating limits curves

• type WMR6...

• type WMU6...

Flow curves p-Q for directional spool valve type: WMR6... ; WMU6... - versions with various spools springs

centered

1 2 3 4 5 6 7 8

C, D, E, E1, H,

A F, P G J, L R T V

M , Q, U, W

• type WH6...

• type WH6.../O...

• type WH6.../OF...

Flow curves p-Q for directional spool valve type: WH6 ...; WH6.../O...; WH6.../OF...

versions with spools springs centered, positioned with detent and without detent

p = 0,6 MPa p = 1 MPa

1 A, B 1 A, B

2 C, D, Y 8 C, D Y, E, G, H, J

3 E, J, L, U, M, Q, V, W 8 L, U, M, Q, V, W

4 F, E 9 F, P

5 T 10 R

6 G, H 11 T

7 P - -

8 A/O, C/O, D/O 8 A/O, C/O, D/O, A/OF, C/OF, D/OF

WK 421 180 11.2015 - 16 - Type WMM6/ WMD6/ WMR6/ WH6

HOW TO ORDER

6

*

Number of service ports

3-way - for spools A, B =3

4-way - for the other spools =4

Type of operation

hand lever operated = WMM

rotary knob operated = WMD

lockable rotary knob operated = WMDA

roller operated (roller positioning according to page12) = WMR

roller operated (roller positioning according to page12) = WMU

hydraulically operated = WH

Nominal size (NS)

NS6 =6

Spool type

spool diagrams for directional spool valve:

type WMM - according to page 4, 5

type WMD/WMDA - according to page 5, 6

type WMR/ WMU - according to page 7

type WH - according to page 8, 9

Series number

(30-39) - connection and installation dimensions unchanged = 3X

series 32 = 32

Spool positioning

spring centering - possible for

directional spool valves type: WMM, WMR/WMU, WH = no designation

with detent - possible for

directional spool valves type: WMM, WMD/WMDA =F

without return springs, without detent - possible for

directional spool valves type WH =O

without return springs, with detent - possible for

directional spool valves type WH = OF

Throttle insert (in port P)

without throttle insert = no designation

throttle insert φ 0,8 = B 08

throttle insert φ 1,0 = B 10

throttle insert φ 1,2 = B 12

Sealing

NBR (for fluids on mineral oil base) = no designation

FKM (for fluids on phosphate ester base) =V

Further requirements in clear text (to be agreed with the manufacturer)

Directional spool valve should be ordered according to the above coding.

The symbols in bold are preferred versions in short delivery time.

Coding examples: 4WMM6 E -32/B08; 4WMD6 E -32/F B08; 4WMR6 E -32/B08; 4WH6 E -32/B08

Type WMM6/ WMD6/ WMR6/ WH6 - 17 - WK 421 180 11.2015

SUBPLATES AND FIXING SCREWS

Subplates must be ordered according to the data sheet Subplates and fixing screws M5 x 50 - 10,9 - 4 pcs/set

WK 496 480. Subplates: must be ordered separately.

G 341/01 - threaded connection G 1/4 Tightening torque for screws Md = 9 Nm

G 342/01 - threaded connection G 3/8

G 502/01 - threaded connection G1/2 Subplate symbol in bold is the preferred

G 341/02 - threaded connection M14 x1,5 version available in short delivery time.

G 342/02 - threaded connection M16 x1,5

EXAMPLES OF APPLICATION

IN HYDRAULIC SYSTEM

Directional spool valve - hand lever operated

type WMM6

A B

P T 4WMM6 J...

Directional spool valve - hydraulically operated

type WH6

3URED4 3URED4

A B

P T 4WH6 J...

PONAR Wadowice S.A.

ul. Wojska Polskiego 29

34-100 Wadowice

tel. +48 33 488 21 00

fax.+48 33 488 21 03

www.ponar-wadowice.pl

WK 421 180 11.2015 - 18 - Type WMM6/ WMD6/ WMR6/ WH6

You might also like

- TAKEUCHI TB219 Mini Excavator Parts ManualDocument306 pagesTAKEUCHI TB219 Mini Excavator Parts ManualRomeu Brandão Pinto100% (1)

- Eight Position Cylinders Service Information: Warnings-Installation and MountingDocument10 pagesEight Position Cylinders Service Information: Warnings-Installation and MountingyelmustafaaliNo ratings yet

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоNo ratings yet

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document26 pagesWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Teddy MatthewNo ratings yet

- wh22 enDocument12 pageswh22 enam0626554No ratings yet

- Weh22s13 enDocument32 pagesWeh22s13 engerin123456789No ratings yet

- Válvula Direcional RexRothDocument22 pagesVálvula Direcional RexRothrfcardNo ratings yet

- 2.structure and FunctionDocument30 pages2.structure and FunctionOscar Tello HuaripataNo ratings yet

- VL-O-3-1per4 - Rep AF2601Document1 pageVL-O-3-1per4 - Rep AF2601Budhi HermawanNo ratings yet

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureالمهندسوليدالطويلNo ratings yet

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document22 pagesWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Рома БлошенкоNo ratings yet

- WE10 S 15 XDocument12 pagesWE10 S 15 Xargo_arjieantoNo ratings yet

- WK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaDocument4 pagesWK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaРома БлошенкоNo ratings yet

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. Structuredeniden2013No ratings yet

- VPN1 06Document10 pagesVPN1 06Marcelo ArayaNo ratings yet

- Catalogo FestoDocument51 pagesCatalogo FestoThiago ArmondesNo ratings yet

- Tigerclassic ValvesDocument53 pagesTigerclassic ValvesPipe CastilloNo ratings yet

- UREZ6 XDocument10 pagesUREZ6 Xhai dangNo ratings yet

- 4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsDocument4 pages4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsSiddharth GajjarNo ratings yet

- 2-6 RCV PedalDocument6 pages2-6 RCV PedalErnesto EndaraNo ratings yet

- 2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedDocument16 pages2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedOgulcan CafNo ratings yet

- Re10460 PDFDocument20 pagesRe10460 PDFINVESTIGACION Y DESARROLLONo ratings yet

- Group 6 RCV PedalDocument6 pagesGroup 6 RCV Pedaldeniden2013No ratings yet

- Group 3 Main Control Valve: A. Main Control Valve (SC 3A, Up To #0616) 1. Dozer Manual Operated Type (Up To #0580)Document9 pagesGroup 3 Main Control Valve: A. Main Control Valve (SC 3A, Up To #0616) 1. Dozer Manual Operated Type (Up To #0580)Jet AcostaNo ratings yet

- 4we6 Series 6xDocument12 pages4we6 Series 6xJas SumNo ratings yet

- en v2.0 22-Way Stem Actuated ValveDocument2 pagesen v2.0 22-Way Stem Actuated ValveAdonaí MoralesNo ratings yet

- Series 4 - CAMOZZI General Valves and Solenoid Valves 1Document15 pagesSeries 4 - CAMOZZI General Valves and Solenoid Valves 1ShahNo ratings yet

- Valvaluas Neumaticas PDFDocument15 pagesValvaluas Neumaticas PDFWalter LrNo ratings yet

- Group 6 RCV Pedal: 1. StructureDocument6 pagesGroup 6 RCV Pedal: 1. StructureАлексейNo ratings yet

- 2-Way Flow Control Bosch-RexrothDocument12 pages2-Way Flow Control Bosch-RexrothKemal GokovicNo ratings yet

- Proprtional ValvesDocument60 pagesProprtional ValvesY.EbadiNo ratings yet

- Rolfo 2016Document51 pagesRolfo 2016Peter VargaNo ratings yet

- FP 450-60Document4 pagesFP 450-60Supakanit LimsowanNo ratings yet

- Ventielen A4p026e 00Document132 pagesVentielen A4p026e 00Dibutec Plaza HuinculNo ratings yet

- K35 Omx0069Document5 pagesK35 Omx0069PABLO BENJAMÍN CÉSPEDES FUENTESNo ratings yet

- Directional Valve PneumaticDocument74 pagesDirectional Valve Pneumaticmajid fardniaNo ratings yet

- Valves Data SheetsDocument11 pagesValves Data Sheetschhetrim21No ratings yet

- Solenoid/pneumatic Valves, Tiger ClassicDocument44 pagesSolenoid/pneumatic Valves, Tiger ClassicAJitnupNo ratings yet

- Re64354 2003-06Document20 pagesRe64354 2003-06thierrylindoNo ratings yet

- Catalogo GeneralDocument94 pagesCatalogo GeneralWidi PrasetyoNo ratings yet

- Re18302 07 - VS311 312 315Document8 pagesRe18302 07 - VS311 312 315diegokatoNo ratings yet

- R&I Electrohydraulic Unit #2Document3 pagesR&I Electrohydraulic Unit #2LuisCondoriNo ratings yet

- 50 450 60 Final Bermad Float ValveDocument4 pages50 450 60 Final Bermad Float ValveClinton BlackNo ratings yet

- ENG.4.2.15 (2) Series 4 ValvesDocument25 pagesENG.4.2.15 (2) Series 4 ValvesNayaz PashaNo ratings yet

- ECOSYS P2235dw-P2040dw SERVICE MANUAL 2Document73 pagesECOSYS P2235dw-P2040dw SERVICE MANUAL 2Ivan AvilaNo ratings yet

- Razvodni VentilDocument17 pagesRazvodni VentilalexkeserNo ratings yet

- BOSCH-REXROTH - RE18302-09 - VS241-245-246-247 F - NloDocument10 pagesBOSCH-REXROTH - RE18302-09 - VS241-245-246-247 F - Nloaron.maticNo ratings yet

- Equipment 3633 Catalog 585c8139Document8 pagesEquipment 3633 Catalog 585c8139RahulChampNo ratings yet

- Group 3 Swing Device: 1. StructureDocument12 pagesGroup 3 Swing Device: 1. StructureĐạt VươngNo ratings yet

- Airtec RE 44Document6 pagesAirtec RE 44GaborNo ratings yet

- Figure 1. Hydraulic Schematic SymbolsDocument20 pagesFigure 1. Hydraulic Schematic Symbolsamin chaabenNo ratings yet

- Re 28163Document12 pagesRe 28163ShortcutterNo ratings yet

- Weh 20 50Document26 pagesWeh 20 50waltervalverdemfNo ratings yet

- Parker Wheel Turn Hydraulic SystemDocument12 pagesParker Wheel Turn Hydraulic SystemEdward Erney Salas ValenzuelaNo ratings yet

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocument8 pages4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemNo ratings yet

- Chapter 14 - Valve Mechanism and CamshaftDocument12 pagesChapter 14 - Valve Mechanism and CamshaftsezarNo ratings yet

- Viking Xtreme: Extreme EnvironmentsDocument17 pagesViking Xtreme: Extreme EnvironmentsAnibal Jose Cruz LarezNo ratings yet

- Valve MCD10 Catalog2021Document4 pagesValve MCD10 Catalog2021Samuel Lopez BenitesNo ratings yet

- VLV X33394Document3 pagesVLV X33394Davidson GattoniNo ratings yet

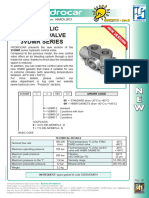

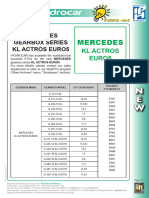

- New 008 2013 HyDocument2 pagesNew 008 2013 HyРома БлошенкоNo ratings yet

- New 012 2012 HyDocument1 pageNew 012 2012 HyРома БлошенкоNo ratings yet

- New 003 2011 HyDocument3 pagesNew 003 2011 HyРома БлошенкоNo ratings yet

- Presentazione SSU-idrostatiche HYDROCARDocument5 pagesPresentazione SSU-idrostatiche HYDROCARРома БлошенкоNo ratings yet

- New 001 2013 HyDocument1 pageNew 001 2013 HyРома БлошенкоNo ratings yet

- New 017 2012 HyDocument1 pageNew 017 2012 HyРома БлошенкоNo ratings yet

- Sub 80 (890794)Document1 pageSub 80 (890794)Рома БлошенкоNo ratings yet

- New 002 2011 HyDocument2 pagesNew 002 2011 HyРома БлошенкоNo ratings yet

- New 015 2012 HyDocument1 pageNew 015 2012 HyРома БлошенкоNo ratings yet

- New 010 2011 HyDocument1 pageNew 010 2011 HyРома БлошенкоNo ratings yet

- Sub 100 (890656)Document1 pageSub 100 (890656)Рома БлошенкоNo ratings yet

- New 011 2012 HyDocument1 pageNew 011 2012 HyРома БлошенкоNo ratings yet

- New 005 2013 HyDocument1 pageNew 005 2013 HyРома БлошенкоNo ratings yet

- Ahs Truck Gear PumpDocument1 pageAhs Truck Gear PumpРома БлошенкоNo ratings yet

- New 005 2012 HyDocument2 pagesNew 005 2012 HyРома БлошенкоNo ratings yet

- New 002 2012 HyDocument1 pageNew 002 2012 HyРома БлошенкоNo ratings yet

- SUB-1000 (890770-180 бар)Document1 pageSUB-1000 (890770-180 бар)Рома БлошенкоNo ratings yet

- V0110Document1 pageV0110Рома БлошенкоNo ratings yet

- Mannesmann Rexroth Uchebnyy Kurs Po Gidravlike Tom 3 C4593d8f5e7Document372 pagesMannesmann Rexroth Uchebnyy Kurs Po Gidravlike Tom 3 C4593d8f5e7Рома БлошенкоNo ratings yet

- Sub 400-S1Document1 pageSub 400-S1Рома БлошенкоNo ratings yet

- Sub 125 (895098)Document1 pageSub 125 (895098)Рома БлошенкоNo ratings yet

- Axial Piston Pump ABERDocument32 pagesAxial Piston Pump ABERРома БлошенкоNo ratings yet

- 01-7 Ge3k 2017 3Document4 pages01-7 Ge3k 2017 3Рома БлошенкоNo ratings yet

- Technical Data Sheets Recommendations: WWW - ABER.ptDocument13 pagesTechnical Data Sheets Recommendations: WWW - ABER.ptРома БлошенкоNo ratings yet

- 01-4 - Ge2 HC - 2017 - 3Document4 pages01-4 - Ge2 HC - 2017 - 3Рома БлошенкоNo ratings yet

- 01-1 Gem 2017 2Document4 pages01-1 Gem 2017 2Рома БлошенкоNo ratings yet

- Aft-Catalog s1 SecDocument34 pagesAft-Catalog s1 SecРома БлошенкоNo ratings yet

- Pump Drawing With Motor Flange MountedDocument2 pagesPump Drawing With Motor Flange MountedРома БлошенкоNo ratings yet

- Midland Gear Pumps Phase 1Document5 pagesMidland Gear Pumps Phase 1Рома БлошенкоNo ratings yet

- Oleodinamica M 25 32 EngDocument9 pagesOleodinamica M 25 32 EngРома БлошенкоNo ratings yet

- Wind TurbineDocument65 pagesWind TurbineAnkit KumarNo ratings yet

- Rheological Properties of Non-Newtonian Materials by Rotational ViscometerDocument5 pagesRheological Properties of Non-Newtonian Materials by Rotational ViscometerSantiiago VE100% (1)

- SQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFDocument12 pagesSQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFVishal Shah100% (1)

- Native Dynamic SQLDocument2 pagesNative Dynamic SQLRupesh PatraNo ratings yet

- Blind Stick NewDocument40 pagesBlind Stick NewPriya KabirNo ratings yet

- Enabler PDFDocument16 pagesEnabler PDFJose Luis Caceres SeverinoNo ratings yet

- Tree Traversals (Inorder, Preorder and Postorder)Document4 pagesTree Traversals (Inorder, Preorder and Postorder)Anand DuraiswamyNo ratings yet

- Digital Clubbing in Pediatric Age GroupDocument33 pagesDigital Clubbing in Pediatric Age GroupDeboprasad DasNo ratings yet

- Ia Checklist PDFDocument4 pagesIa Checklist PDFMuhammad FarhanNo ratings yet

- What Is The Continuity Correction Factor?Document3 pagesWhat Is The Continuity Correction Factor?BrianNo ratings yet

- Modern Optics - PHY5009 Course PlanDocument10 pagesModern Optics - PHY5009 Course PlanrevNo ratings yet

- 4PH0 1P Que 20140515Document28 pages4PH0 1P Que 20140515ramexistsNo ratings yet

- Java Important Question As Per Industry LevelDocument5 pagesJava Important Question As Per Industry Levelsamul102No ratings yet

- Cds13041 Yamaha PWC Plug-In EcuDocument1 pageCds13041 Yamaha PWC Plug-In EcuGérôme ZélateurNo ratings yet

- Base Processor Terminal CommandsDocument66 pagesBase Processor Terminal CommandssharadsirohiNo ratings yet

- HF13Document122 pagesHF13HonoluluNo ratings yet

- Technical Writing and Presentation Paper Summary: End To End Learning For Self-Driving CarsDocument3 pagesTechnical Writing and Presentation Paper Summary: End To End Learning For Self-Driving CarsNguyễn TựuNo ratings yet

- Simple MixturesDocument37 pagesSimple Mixturesumair35No ratings yet

- AABC Test Balance Proc PDFDocument189 pagesAABC Test Balance Proc PDFemrahNo ratings yet

- PBG Dgs 2Document2 pagesPBG Dgs 2Sandip MaityNo ratings yet

- 081 - ME8594 Dynamics of Machines - Anna University 2017 Regulation Syllabus PDFDocument2 pages081 - ME8594 Dynamics of Machines - Anna University 2017 Regulation Syllabus PDFKrish NarayananNo ratings yet

- Krohne OPTIFLUX 2000Document16 pagesKrohne OPTIFLUX 2000Anonymous 1LgoS05gvlNo ratings yet

- 3.5 & 3.6 Worksheet - DocaDocument3 pages3.5 & 3.6 Worksheet - DocaLevko SenarNo ratings yet

- Star Formation: ASTR 3730: Fall 2003Document10 pagesStar Formation: ASTR 3730: Fall 2003astnickNo ratings yet

- Alain Badiou - Wikipedia, The Free EncyclopediaDocument30 pagesAlain Badiou - Wikipedia, The Free EncyclopediaanfilbiblioNo ratings yet

- Centr Eur J BiolDocument8 pagesCentr Eur J Bioldhafer alhaidaryNo ratings yet

- Jurnal Inovasi 1Document13 pagesJurnal Inovasi 1Dewi Yanwari MadyaratriNo ratings yet

- Chemical Kinetics Reaction Mechanism Frederick LindemannDocument10 pagesChemical Kinetics Reaction Mechanism Frederick LindemannSaman AkramNo ratings yet

- Symmetry (Planes Of)Document38 pagesSymmetry (Planes Of)littlegusNo ratings yet