Professional Documents

Culture Documents

Falcon Zinc Metal Industries L.L.C

Falcon Zinc Metal Industries L.L.C

Uploaded by

cyril nbhhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Falcon Zinc Metal Industries L.L.C

Falcon Zinc Metal Industries L.L.C

Uploaded by

cyril nbhhCopyright:

Available Formats

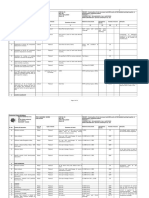

Format. No.

: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.07.2020

L.L.C. Rev :1.0

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009 / ASTM A 123-17

Certificate No: - 012 Date: 05-08-2021

Customer: - Nael Steel

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009 /ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading

Corresponding Mass of Zinc

Item Description in

Average Coating – g/m2

Microns

1) Grating Panel (50 ×5m) – 86 No’s 125

2) 50×50 Angle with flat bar- 02 No’s 140

3) Support Frame (100×10m) – 02 No’ s 116

4) T-Support – 02 No’s 128 131 935.71

135

144

Status of the Galvanization: Temperature of Zinc Bath : 445˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009 / ASTM A 123 with respect of material

thickness, 610 G/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

Adhesion Test: Coating does not lift off in large flakes when tested with Stout

Knife as per BS EN ISO: 1461: 2009/ASTM A 123-17.

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

Format. No.: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.07.2020

L.L.C. Rev :1.0

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009 / ASTM A 123-17

Certificate No: - 09 Date: 05.07.2021

Customer: - Nael Steel

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009 /ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading

Corresponding Mass of Zinc

Item Description in

Average Coating – g/m2

Microns

1) Fabricated Frame – 2 Nos 166

95

2) Fabricated Angles – 32 Nos 125

133 137 979

3) Fabricated Beams – 9 Nos 145

158

4) Fabricated Beam Support – 2 Nos

(D/N)- 05830

Status of the Galvanization: Temperature of Zinc Bath : 445˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009 / ASTM A 123-17 with respect of material

thickness, 610 G/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

Adhesion Test: Coating does not lift off in large flakes when tested with Stout

Knife as per BS EN ISO: 1461: 2009/ASTM A 123-17.

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

Format. No.: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.07.2020

L.L.C. Rev :1.0

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009 / ASTM A 123-17

Certificate No: - 10 Date: 14.07.2021

Customer: - Nael Steel

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009 /ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading

Corresponding Mass of Zinc

Item Description in

Average Coating – g/m2

Microns

1) Fabricated Beam Support – 28 Nos 166

95

2) Fabricated Beam T-Support – 06 Nos 125

133 137 979

3) Fabricated Channel Frame – 04Nos 145

158

4) Fabricated Angle Support – 44 Nos

(D/N)- 05836

Status of the Galvanization: Temperature of Zinc Bath : 445˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009 / ASTM A 123-17 with respect of material

thickness, 610 G/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

Adhesion Test: Coating does not lift off in large flakes when tested with Stout

Knife as per BS EN ISO: 1461: 2009/ASTM A 123-17.

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

Format. No.: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.07.2020

L.L.C. Rev :1.0

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009 / ASTM A 123-17

Certificate No: - 11 Date: 16.07.2021

Customer: - Nael Steel

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009 /ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading

Corresponding Mass of Zinc

Item Description in

Average Coating – g/m2

Microns

1) Fabricated Beam Connection– 19 Nos 147

133

2) Fabricated Beam T-Support – 02 Nos 125

97 121 863

3) Fabricated Channel Frame – 02 Nos 108

115

4) Fabricated Angle – 41 Nos

(D/N)- 05838

Status of the Galvanization: Temperature of Zinc Bath : 445˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009 / ASTM A 123-17 with respect of material

thickness, 610 G/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

Adhesion Test: Coating does not lift off in large flakes when tested with Stout

Knife as per BS EN ISO: 1461: 2009/ASTM A 123-17.

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

Format. No.: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.07.2020

L.L.C. Rev :1.0

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009 / ASTM A 123-17

Certificate No: - 12 Date: 19.07.2021

Customer: - Nael Steel

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009 /ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading

Corresponding Mass of Zinc

Item Description in

Average Coating – g/m2

Microns

1) Fabricated Beam Support– 14 Nos 147

133

2) Fabricated T-Support – 03 Nos 125

97 121 863

3) Fabricated Channel Frame – 02 Nos 108

115

4) Fabricated Angle Frame – 22 Nos

(D/N)- 05839

Status of the Galvanization: Temperature of Zinc Bath : 445˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009 / ASTM A 123-17 with respect of material

thickness, 610 G/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

Adhesion Test: Coating does not lift off in large flakes when tested with Stout

Knife as per BS EN ISO: 1461: 2009/ASTM A 123-17.

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

Format. No.: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.07.2020

L.L.C. Rev :1.0

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009 / ASTM A 123-17

Certificate No: - 13 Date: 29.07.2021

Customer: - Nael Steel

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009 /ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading

Corresponding Mass of Zinc

Item Description in

Average Coating – g/m2

Microns

1) Fabricated Beam Support– 56 Nos 164

124

2) Fabricated T-Support – 12 Nos 133

187 142 1014

3) Fabricated Channel Frame – 08 Nos 114

130

4) Fabricated Angle Frame – 88 Nos

(D/N)- 05842

Status of the Galvanization: Temperature of Zinc Bath : 445˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009 / ASTM A 123-17 with respect of material

thickness, 610 G/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

Adhesion Test: Coating does not lift off in large flakes when tested with Stout

Knife as per BS EN ISO: 1461: 2009/ASTM A 123-17.

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

Format. No.: FZM-IMS-FO-11E

Falcon Zinc Metal Industries Date : 20.07.2020

L.L.C. Rev : 00

ZINC COATING CERTIFICATE

Inspection and Testing in compliance with BS EN ISO 1461:2009 / ASTM A 123-17

Certificate No : - 007 Date : 22-06-2021

Company :-NBHH

Customer :- NAEL STEEL, AL

AIN Client :ALDAR :- Abu Dhabi,

Project: Saadiyath Reserve :- Abu Dhabi

ZINC COATING APPEARANCE

The acceptability of coating finish as judged by the inspection criteria laid down in BS EN ISO 1461:

2009 /ASTM A 123-17 was found to be within the acceptable limits for smoothness, and continuity.

Zinc coating is free of gross surface imperfections.

COATING THICKNESS AND MASS OF ZINC COATING

Reading

Corresponding Mass of Zinc

Item Description in

Average Coating – g/m2

Microns

151

1. I Beam Supports - 21Nos 127

2. Gratings -90Nos 133

3. T plates -34Nos 116 138 985.71

4. Channel Frames -02Nos 154

5. Angle -42Nos 126

165

134

Status of the Galvanization: Temperature of Zinc Bath : 448˚ Celsius

Dipping time in Zinc : 5min

Corresponding coating as per BS EN ISO 1461:2009 / ASTM A 123-17 with respect of material

thickness, 600 G/m2 i.e. = 85 Microns. (1 G/m2 = 0.14 Micron)

We certify that the above material has been Hot Dip Galvanized to BS EN ISO 1461:2009 / ASTM

A123-17.

QC Engineer Division Manager

Test By Approved By

Tel : 00 (971) 2 5510018

Fax :

Address : ICAD II Musaffah Tower, Floor 24, Office 2352

E-mail : info@falconzinc.com

Website : www.falconzinc.com

You might also like

- Methodology High MastDocument12 pagesMethodology High MastAmis VenturesNo ratings yet

- ITP For PV Mounting Structure and Module Installation-2023!05!19Document3 pagesITP For PV Mounting Structure and Module Installation-2023!05!19Mohammad BayisNo ratings yet

- Face Mask Detection System Paper Research Paper - PDFDocument5 pagesFace Mask Detection System Paper Research Paper - PDFPrashant VermaNo ratings yet

- Test CertificateDocument1 pageTest CertificateAvinash JadhavNo ratings yet

- Q A P (QAP) - S Inverter: Uality Ssurance LAN OlarDocument5 pagesQ A P (QAP) - S Inverter: Uality Ssurance LAN Olarsasikumar100% (2)

- Pre Commissioning Check ListDocument4 pagesPre Commissioning Check ListbajrangNo ratings yet

- Inspection Release Certificate For Part Shipment 3021&3022Document1 pageInspection Release Certificate For Part Shipment 3021&3022Mohammed NouzalNo ratings yet

- Before Dispatch Before Dispatch On The Day of Receipt at The Earliest After Receipt. Design, Engineering Standard DocumentsDocument24 pagesBefore Dispatch Before Dispatch On The Day of Receipt at The Earliest After Receipt. Design, Engineering Standard Documentsnarinder100% (1)

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- 2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTDocument25 pages2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTBhawani NayakNo ratings yet

- 1012835-NEROMASTIC 400 (I) Component (B)Document4 pages1012835-NEROMASTIC 400 (I) Component (B)Srikanth GantaNo ratings yet

- 1 DESIGN AND COSTING OF 10KW Solar ModuleDocument7 pages1 DESIGN AND COSTING OF 10KW Solar ModuleYash PratapNo ratings yet

- Company ProfileDocument18 pagesCompany ProfileAjay Singh LucknowNo ratings yet

- DTTN-DT2-PC-MET-EL-0004 A Method Statement For Inverter and Transformer Installation and CommissioningDocument13 pagesDTTN-DT2-PC-MET-EL-0004 A Method Statement For Inverter and Transformer Installation and CommissioningTariq Ali SialNo ratings yet

- Technical Specification For JINDAL ALUMINUM - GENERAL INFORMATIONDocument18 pagesTechnical Specification For JINDAL ALUMINUM - GENERAL INFORMATIONAkash SharmaNo ratings yet

- Method Statement - Solar Ground Mounting, Car Park Structure Installation & Mounting of PV Panels - Cocacola - Al AinDocument10 pagesMethod Statement - Solar Ground Mounting, Car Park Structure Installation & Mounting of PV Panels - Cocacola - Al AinKarimo KilaniNo ratings yet

- Standard QAP - 4MWDocument2 pagesStandard QAP - 4MWSAEL SOLAR100% (2)

- KP-00+++-CY712-G0047-Rev 0-COMMISSIONING AND TEST PROCEDURE FOR MOTOR OPERATED VALVES MOV PDFDocument14 pagesKP-00+++-CY712-G0047-Rev 0-COMMISSIONING AND TEST PROCEDURE FOR MOTOR OPERATED VALVES MOV PDFrebinshwNo ratings yet

- QAP CI Flsnged PipesDocument11 pagesQAP CI Flsnged PipesNaveen NagisettiNo ratings yet

- D P Extension LetterDocument1 pageD P Extension LetterSwapnil ShahNo ratings yet

- Material Test Certificate: Diamond Pipe Supports Pvt. LTDDocument1 pageMaterial Test Certificate: Diamond Pipe Supports Pvt. LTDAneesh ConstantineNo ratings yet

- Appendix-2 (POWER PANEL Test Report)Document2 pagesAppendix-2 (POWER PANEL Test Report)hafed baccoucheNo ratings yet

- Hydro TestDocument1 pageHydro TestMilan BanerjeeNo ratings yet

- GTP - 16 33 KV Xlpe Cable 3c X 95 SQMMDocument3 pagesGTP - 16 33 KV Xlpe Cable 3c X 95 SQMMraj_stuff006No ratings yet

- Cable Laying Work Boq For Slice-101 Existing Rates: The Rate Shall Also Include The FollowingDocument4 pagesCable Laying Work Boq For Slice-101 Existing Rates: The Rate Shall Also Include The FollowingAmit JhaNo ratings yet

- TC Epilux 610 Prime CTNG.Document1 pageTC Epilux 610 Prime CTNG.Tarun KaushalNo ratings yet

- SUNGROW 320kW (295kW at 50 Degrees)Document2 pagesSUNGROW 320kW (295kW at 50 Degrees)Sampath Kumar100% (2)

- 01.technical Specifications With P&ID - 1Document176 pages01.technical Specifications With P&ID - 1MayankDubeyNo ratings yet

- Protocol Column AlignmentDocument9 pagesProtocol Column AlignmentManikandan elumalaiNo ratings yet

- BUET Calibration ReportDocument15 pagesBUET Calibration ReportjamilNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Reality of Gi Pipe EarthingDocument8 pagesReality of Gi Pipe EarthingjamessmithNo ratings yet

- 16 - Catalogue TTUDocument37 pages16 - Catalogue TTUsubmittal cetc50% (2)

- MTC - Astm A36 - Jis400 - Q235Document2 pagesMTC - Astm A36 - Jis400 - Q235nayeemNo ratings yet

- Is 4923 1997Document19 pagesIs 4923 1997Akhil GargNo ratings yet

- Inspection and Test Plan: Project NameDocument2 pagesInspection and Test Plan: Project NameehteshamNo ratings yet

- Material Approval (Ma) : Request Details From ContractorDocument8 pagesMaterial Approval (Ma) : Request Details From ContractorSyed abdul rahmanNo ratings yet

- Acsr Coyote GTP PDFDocument1 pageAcsr Coyote GTP PDFSamyak Deora100% (1)

- Purchase Indent Excel FormatDocument1 pagePurchase Indent Excel FormatSanjay RajputNo ratings yet

- QAP Plan Elect.Document2 pagesQAP Plan Elect.insap_dineshNo ratings yet

- Tender Document 500kW Solar Roof Top - 5Document119 pagesTender Document 500kW Solar Roof Top - 5Lawrence GeorgeMannanNo ratings yet

- To-101175 OspDocument5 pagesTo-101175 OspSIVANo ratings yet

- Calculation of Earthing - Thumb RuleDocument5 pagesCalculation of Earthing - Thumb Ruleaamer6789No ratings yet

- Rooftop Solar PV Feasibility ReportDocument6 pagesRooftop Solar PV Feasibility ReportSlnko EnergyNo ratings yet

- QCS 2014 - Marker Tape For Underground Power CablesDocument1 pageQCS 2014 - Marker Tape For Underground Power CablesBalaji NaikNo ratings yet

- Aviation Light BOQDocument6 pagesAviation Light BOQkkjha31No ratings yet

- CV - HVAC ENGINEER EN - 14 Years ExperienceDocument7 pagesCV - HVAC ENGINEER EN - 14 Years Experienceja3farNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationNileshNo ratings yet

- Attachment 12.4 - QA - QC Checklist - FDBDocument3 pagesAttachment 12.4 - QA - QC Checklist - FDBehteshamNo ratings yet

- GLN 703 Specs - TdsDocument1 pageGLN 703 Specs - TdsAnonymous MDkp0hnb3lNo ratings yet

- Sawaed PT Report No. 02 For SWCC Jubail Emergency LineDocument1 pageSawaed PT Report No. 02 For SWCC Jubail Emergency LineAlam MD SazidNo ratings yet

- 13 Fan Coil Unit: Location: - No.Document1 page13 Fan Coil Unit: Location: - No.JIJUNo ratings yet

- Paint Certificate 80A45-1Document1 pagePaint Certificate 80A45-1Shyam_Nair_9667No ratings yet

- Cable Tray Load Calculation PDFDocument10 pagesCable Tray Load Calculation PDFu5ur5zoro5luNo ratings yet

- Method Statement For Core CuttingDocument5 pagesMethod Statement For Core Cuttingahmedshah512No ratings yet

- Hand Gloves Test ReportDocument8 pagesHand Gloves Test ReportPower MuruganNo ratings yet

- Distribution Board ScheduleDocument1 pageDistribution Board ScheduleAnonymous SrVaQYNo ratings yet

- FQP GeneralDocument21 pagesFQP GeneralgaladrialNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument and Control CablesDocument2 pagesSaudi Aramco Pre-Commissioning Form: Instrument and Control Cableszahid1078No ratings yet

- Certificate No - 021Document1 pageCertificate No - 021RonNo ratings yet

- Certificate No - 020Document1 pageCertificate No - 020RonNo ratings yet

- BetaBeat Reviews:Is It Best Soultion For Diabetes?Document6 pagesBetaBeat Reviews:Is It Best Soultion For Diabetes?bohigg popixNo ratings yet

- Flexible Transportand DRTReportDocument64 pagesFlexible Transportand DRTReportDualDuelNo ratings yet

- HC700 SDK SpecificationDocument680 pagesHC700 SDK SpecificationTzahiKupfer0% (1)

- Rider's Manual: BMW MotorradDocument169 pagesRider's Manual: BMW MotorradDerya HaydarNo ratings yet

- PA3 v3.0 E Instruction ManualDocument30 pagesPA3 v3.0 E Instruction ManualcristianiacobNo ratings yet

- Type of Code Switching and Code MixingDocument16 pagesType of Code Switching and Code MixingmihaiNo ratings yet

- Matter Around Us: You May Have Heard The Phrases LikeDocument14 pagesMatter Around Us: You May Have Heard The Phrases Likedvrao_chowdaryNo ratings yet

- All Clear Kl8 TRF Basics U1Document5 pagesAll Clear Kl8 TRF Basics U1nexewe7544No ratings yet

- Peace Corps Administrative Assistant Receptionist - Vacancy AnnouncementDocument1 pagePeace Corps Administrative Assistant Receptionist - Vacancy AnnouncementAccessible Journal Media: Peace Corps DocumentsNo ratings yet

- Secp256k1: Technical DetailsDocument2 pagesSecp256k1: Technical DetailsJack in the googooNo ratings yet

- 2021 Ford® Ranger Midsize Pickup Truck - BrochuresDocument5 pages2021 Ford® Ranger Midsize Pickup Truck - BrochuresRizal Mohamad Al-AyyubiNo ratings yet

- Tuba JamilDocument1 pageTuba Jamil3J Solutions BDNo ratings yet

- JstackDocument69 pagesJstackMike TNo ratings yet

- What We Can Do For Street ChildrenDocument13 pagesWhat We Can Do For Street ChildrenAJMAL RASHEEK A HNo ratings yet

- Te Va A Servir en Cisco V2Document4 pagesTe Va A Servir en Cisco V2Bryant GamboaNo ratings yet

- Packing Type in Hysys 9Document11 pagesPacking Type in Hysys 9Mahdi koolivandNo ratings yet

- What Are The Signs of An Impending Geologic HazardDocument2 pagesWhat Are The Signs of An Impending Geologic HazardANTON GABRIEL PRECIOSONo ratings yet

- Ledw0020 03Document9 pagesLedw0020 03Serban StefanNo ratings yet

- Decision AnalysisDocument28 pagesDecision AnalysisAshley MorrisNo ratings yet

- CV Larissa Ayumi Kuramae Izioka 2016Document3 pagesCV Larissa Ayumi Kuramae Izioka 2016api-311920428No ratings yet

- Leading and Lagging Indicators PDFDocument35 pagesLeading and Lagging Indicators PDFtatony50% (2)

- Lab. Sheet Three: Data Structure LaboratoryDocument6 pagesLab. Sheet Three: Data Structure LaboratoryxzNo ratings yet

- Tio2 Membrane2Document12 pagesTio2 Membrane2petru apopeiNo ratings yet

- The Story of The Aral Sea: Reading ComprehensionDocument2 pagesThe Story of The Aral Sea: Reading ComprehensionGreceanu AlinaNo ratings yet

- 09 - Chapter5 Determinents of FDI PDFDocument13 pages09 - Chapter5 Determinents of FDI PDFdeepakadhanaNo ratings yet

- Haskell Ebook ReaderDocument1,610 pagesHaskell Ebook ReaderhoogggleeeNo ratings yet

- Embedment Strength of Stud PlateDocument3 pagesEmbedment Strength of Stud Platemathu100% (1)

- Algorithm and Validation of Tower of HanoiDocument2 pagesAlgorithm and Validation of Tower of HanoiKyaan MosqNo ratings yet

- Efl Learners' Perception On Different AccentsDocument26 pagesEfl Learners' Perception On Different AccentsLydiaNo ratings yet