Professional Documents

Culture Documents

VAL MANUAL 008 InProcess and Bulk Drug Product Holding Times Sample

VAL MANUAL 008 InProcess and Bulk Drug Product Holding Times Sample

Uploaded by

Arifur RahmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VAL MANUAL 008 InProcess and Bulk Drug Product Holding Times Sample

VAL MANUAL 008 InProcess and Bulk Drug Product Holding Times Sample

Uploaded by

Arifur RahmanCopyright:

Available Formats

In-Process and Bulk Drug Product Holding Times

Regulatory Basis:

FDA Quality Systems Regulations

Reference: FDA CFR - Code of Federal Regulations Title 21

General Discussion:

This Document sets out guidelines for the determination and validation of in-process and bulk

product holding times.

Maximum allowable hold times should be established for bulk and in-process drug products

(where applicable). Typically one lot can be used for validating hold times. Data to justify the

hold time can be collected during development on pilot scale batches, during process validation,

via a historical review of batch data, or as part of a deviation with proper testing.

Although there are no specific regulations or document documents on bulk product holding times,

good manufacturing practice dictates that holding times should be validated to ensure that in-

process and bulk product can be held, pending the next processing step, without any adverse

effect to the quality of the material. This practice is supported by indirect references made to

determining holding times in various FDA document documents, FDA regulations as follows:

__ “if a firm plans to hold bulk drug products in storage…..stability data should

be provided to demonstrate that extended storage in the described containers

does not adversely affect the dosage form” .

__ “stability data also may be necessary when the finished dosage form is stored

in interim containers prior to filling into the marketed package. If the dosage

form is stored in bulk containers for over 30 days, real-time stability data

under specified conditions should be generated to demonstrate comparable

stability to the dosage form in the marketed package. Interim storage of the

dosage form in bulk containers should generally not exceed six months” .

__ “when appropriate, time limits for the completion of each phase of production

shall be established to assure the quality of the drug product.” .This

regulation could be interpreted to include the time for holding bulk product as

part of the production process. “holding times (includes storage times) studies

may be conducted during development or carried out in conjunction with

process validation lots and shall be representative of full scale holding conditions”.

For purposes of clarification, refer to Appendix A for definitions relating to bulk

holding time. Holding time data may be generated in the following situations:

• Bulk holding studies may be conducted on product developmental pilot scale

batches to demonstrate comparable stability to the dosage form in the marketed

package.

• Holding data may be generated as part of a process validation study. Data can

be collected on the bulk product itself after holding or collected after the held

product has been packaged.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by

electronic means are strictly prohibited. Page 2 of 6

In-Process and Bulk Drug Product Holding Times

Typically, if these in-process products are used within 24 hours of manufacturing, no

bulk holding time studies are deemed necessary. An in-process product that is held for

longer than 24 hours should be monitored for physical characteristics and microbial

contamination. A solution/suspension should be held for the defined hold period. At

the test points, a sample should betaken from the storage container and tested. Results

obtained should be compared with the initial baseline data of the solution/suspension

control sample results.

Typical tests include the following: Microbial count; Yeast/Mould count; Specific

Gravity; and Viscosity.

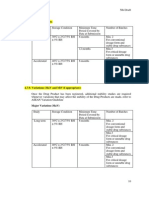

3) Holding time considerations for Tablet Cores, Extended-Release Beads or

Pellets.

Typically, in-process products such as cores, extended-release beads or pellets may be

held for up to 30 days from their date of production without being retested prior to

use. An in-process product that is held for longer than 30 days should be monitored

for stability under controlled, long-term storage conditions for the length of the

holding period. A representative portion of the core/bead/pellet should be held for the

defined hold period. At the test points, a sample should be taken from the storage

container and tested. Results obtained should be compared with the initial baseline

data of the core/bead/pellet control sample results.

Typical tests include the following: Hardness; Friability; Appearance;

Dissolution/Disintegration; Assay; Degradation Products (where applicable); and

Moisture Content.

4) Holding time considerations for Bulk Tablets and Capsules.

Typically, bulk tablets and capsules may be held for up to 30 days from their date of

production without being retested prior to use. A bulk product that is held for longer

than 30 days should be monitored for stability under controlled, long-term storage

conditions for the length of the holding period. Interim storage of the dosage form in

bulk containers should generally not exceed six months. At the test points, a sample

should be taken from the storage container and tested. Results obtained should be

compared with the initial baseline data of the tablet/capsule control sample results.

Typical tests include the following: Hardness; Friability; Appearance; Dissolution (in

the case of controlled and extended release products, the establishment of a

dissolution profile is recommended); Disintegration; Assay; Degradation Products

(where applicable); Moisture Content, and microcount (where applicable).

5) Holding time considerations for Oral Liquids and Semi-Solids (Suspensions,

Creams, and Ointments).

Typically, liquid and semi-solid dosage form products should be held for no more

than 5 days without a hold time study. Full scale batches should be used for these

studies. Samples should be taken from the holding vessel after transfer from the

manufacturing vessel, and again at the completion of the holding period. Multiple

samples should be taken at each time point if holding can impact product uniformity.

Samples would be taken to prove that product uniformity of actives and preservatives

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by

electronic means are strictly prohibited. Page 5 of 6

You might also like

- Tablet Process ValidationDocument38 pagesTablet Process Validationasit_m100% (6)

- Stability Testing Dietary SupplementsDocument27 pagesStability Testing Dietary SupplementsSophiaNo ratings yet

- Nursing Pharmacology Sample Exam QuestionsDocument3 pagesNursing Pharmacology Sample Exam QuestionsDhreambhig Ahrchorphul100% (1)

- Stability Study Guidance ProtocolDocument10 pagesStability Study Guidance ProtocolManish shankarpure100% (2)

- Rational Phytotherapy - A Physicians Guide To Herbal Medicine (2001) PDFDocument323 pagesRational Phytotherapy - A Physicians Guide To Herbal Medicine (2001) PDFLuiz Felipe100% (2)

- GuidelineDocument1 pageGuidelinenaeem186No ratings yet

- Presentation On Hold Time StudyDocument18 pagesPresentation On Hold Time StudyziadddNo ratings yet

- Hold Time Study ProtocolDocument9 pagesHold Time Study ProtocolMubarak Patel100% (1)

- Guidelines For Stability TestingDocument4 pagesGuidelines For Stability Testingloxfox100% (2)

- N Hold Time StudyDocument16 pagesN Hold Time StudyziadddNo ratings yet

- Hold Time Study GuidelineDocument4 pagesHold Time Study GuidelineYousifNo ratings yet

- 2.2.8. Stability Commitment: 2.2.7.6. Drug Products Intended For Storage Below - 20°CDocument7 pages2.2.8. Stability Commitment: 2.2.7.6. Drug Products Intended For Storage Below - 20°CKhuyen VoNo ratings yet

- Stability Testing of Pharmaceutical ProductsDocument45 pagesStability Testing of Pharmaceutical ProductsAzhar DkNo ratings yet

- SOP For Hold Time StudyDocument7 pagesSOP For Hold Time StudyMubarak Patel100% (2)

- 1 StabilityDocument20 pages1 StabilitykanhaiyabattaseNo ratings yet

- 22669-Article Text-113210-1-10-20180101Document4 pages22669-Article Text-113210-1-10-20180101apachaicrNo ratings yet

- Guidelines For Stability Testing of New Drug Substances and ProductsDocument44 pagesGuidelines For Stability Testing of New Drug Substances and Productsvijayns_250355172No ratings yet

- ICH - The Quality GuidelinesDocument55 pagesICH - The Quality GuidelinesPratik KulkarniNo ratings yet

- 4013 Stability TestingDocument5 pages4013 Stability TestingtghonsNo ratings yet

- Stability CosmeticDocument47 pagesStability CosmeticAgustin E SetiowatiNo ratings yet

- ASEAN Guidelines On Stability and Shelf Life TM V1.0 With DisclaimerDocument22 pagesASEAN Guidelines On Stability and Shelf Life TM V1.0 With DisclaimerjanggakabNo ratings yet

- Asean Stability Guideline 2013Document42 pagesAsean Stability Guideline 2013Ani Andriani75% (4)

- ANNEX V ASEAN GL Stability and Shelf-Life of TMHS V1 0 (13nov14) PDFDocument23 pagesANNEX V ASEAN GL Stability and Shelf-Life of TMHS V1 0 (13nov14) PDFmjamil0995No ratings yet

- Using Stability Testing To Determine Shelf LifeDocument7 pagesUsing Stability Testing To Determine Shelf LifeVũ Đình DũngNo ratings yet

- Guideline For Stability DataDocument10 pagesGuideline For Stability DatalovinghandsqcNo ratings yet

- MM-CHPA Voluntary Codes and Guidelines Stability TestingDocument9 pagesMM-CHPA Voluntary Codes and Guidelines Stability TestingPranav PatelNo ratings yet

- Stability Testing Guidance For Product Safety and Shelf LifeDocument5 pagesStability Testing Guidance For Product Safety and Shelf LifeCrystalNo ratings yet

- IchDocument15 pagesIchDIPALI TALELENo ratings yet

- PQA Stability TestingDocument21 pagesPQA Stability Testingbaby shazanaNo ratings yet

- Matrixing: FPP To Be Marketed in The ProposedDocument4 pagesMatrixing: FPP To Be Marketed in The ProposedRachel HowardNo ratings yet

- Annex4-TRS992 Hold Time Study GuidelineDocument8 pagesAnnex4-TRS992 Hold Time Study Guidelinensk79in@gmail.com100% (1)

- Hold Time Studies 1661741387Document8 pagesHold Time Studies 1661741387Cyclone Pharmaceuticals Pvt Ltd PuneNo ratings yet

- Glossary of Stability Testing Terms: ICH Q1 and FDA GuidanceDocument10 pagesGlossary of Stability Testing Terms: ICH Q1 and FDA Guidanceçağan ağtaşNo ratings yet

- Ich Stability Guidelines FinalDocument23 pagesIch Stability Guidelines FinalAjitha AzhakesanNo ratings yet

- Manual 045 SampleDocument5 pagesManual 045 SampleMostafa FawzyNo ratings yet

- WWW - Who.int Medicines Areas Quality Safety Quality Assurance GeneralGuidanceHoldTime-QAS13-521 20022013Document8 pagesWWW - Who.int Medicines Areas Quality Safety Quality Assurance GeneralGuidanceHoldTime-QAS13-521 20022013Pedro978No ratings yet

- Product Dev M1Document16 pagesProduct Dev M1Kishan YadavNo ratings yet

- Asean Drug Stability GuidanceDocument37 pagesAsean Drug Stability GuidanceIndah Nunik N100% (2)

- Cosmetic Stability TestingDocument10 pagesCosmetic Stability Testingshivampharma100% (3)

- Asean Stability GuidelineDocument42 pagesAsean Stability GuidelineriskawulandariiNo ratings yet

- Asean Stability Guideline (Version 6.0)Document50 pagesAsean Stability Guideline (Version 6.0)Ahmad Bayquni BayquniNo ratings yet

- Hold Time StudyDocument2 pagesHold Time StudyManivannan KathirvelNo ratings yet

- Guided by DR - Varsha Pokharkar Hod of Pharmaceutics Poona College of Pharmacy Presented by Debjani Baidya M.Pharm 1 SEM Poona College of PharmacyDocument55 pagesGuided by DR - Varsha Pokharkar Hod of Pharmaceutics Poona College of Pharmacy Presented by Debjani Baidya M.Pharm 1 SEM Poona College of PharmacyDebjani BaidyaNo ratings yet

- Asean Stability Guideline (Version 6.0) .12-13Document2 pagesAsean Stability Guideline (Version 6.0) .12-13Rifael Satrio AdinugrohoNo ratings yet

- 12-Stability of Drugs and Dosage FormsDocument161 pages12-Stability of Drugs and Dosage FormsKerolus Joseph AminNo ratings yet

- ANNEX V ASEAN GL Stability and Shelf-Life of TMHS V1 0 (13nov14)Document23 pagesANNEX V ASEAN GL Stability and Shelf-Life of TMHS V1 0 (13nov14)Malea RamosNo ratings yet

- Hold Time Stability StudiesDocument8 pagesHold Time Stability StudiesMartin RongenNo ratings yet

- Audit 022 Auditing An Oral Solid Solution Area SampleDocument4 pagesAudit 022 Auditing An Oral Solid Solution Area SamplemarwaNo ratings yet

- FDA Stability Practices For INDDocument28 pagesFDA Stability Practices For INDJumpLinNo ratings yet

- SOP of Stability Study - 1Document5 pagesSOP of Stability Study - 1YousifNo ratings yet

- Guidelines On Stability Testing of Cosmetics CE-CTFA - 2004Document10 pagesGuidelines On Stability Testing of Cosmetics CE-CTFA - 2004Dilfredo RuizNo ratings yet

- Chemistry, Manufacturing and Controls Requirements: Exhibit 1: CMC Requirements For A New PharmaceuticalDocument3 pagesChemistry, Manufacturing and Controls Requirements: Exhibit 1: CMC Requirements For A New PharmaceuticalPranav Patel100% (1)

- Usp 1151Document10 pagesUsp 1151Karnati PraveenaNo ratings yet

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Document8 pagesHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Quang Hiếu NgôNo ratings yet

- Asean Guideline On Stability Study of Drug ProductDocument45 pagesAsean Guideline On Stability Study of Drug ProductAzrii AprisoniasaritaNo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Flow charts of pharmaceutical quality control tests for different dosage formsFrom EverandFlow charts of pharmaceutical quality control tests for different dosage formsNo ratings yet

- Compatibility of Pharmaceutical Solutions and Contact Materials: Safety Assessments of Extractables and Leachables for Pharmaceutical ProductsFrom EverandCompatibility of Pharmaceutical Solutions and Contact Materials: Safety Assessments of Extractables and Leachables for Pharmaceutical ProductsNo ratings yet

- Role and Responsibility of Pharmaceutical Industry Plant PersonnelFrom EverandRole and Responsibility of Pharmaceutical Industry Plant PersonnelNo ratings yet

- Astm D3512 PDFDocument2 pagesAstm D3512 PDFEDGAR IMANNo ratings yet

- BKS Bahasa Inggris Kelas 9 Semester GasalDocument78 pagesBKS Bahasa Inggris Kelas 9 Semester GasalFeby Ayu Yogi WulandariNo ratings yet

- Thiol Modified Moringa Gum - A Potential Bioadhesive PolymerDocument24 pagesThiol Modified Moringa Gum - A Potential Bioadhesive PolymerPankaj GrewalNo ratings yet

- Guggulipid & The Ayurvedic Purification To Get Guggul ExtractDocument6 pagesGuggulipid & The Ayurvedic Purification To Get Guggul ExtractMukesh SharmaNo ratings yet

- Chitosan Pada Tablet Floating-MucoadhesiveDocument12 pagesChitosan Pada Tablet Floating-MucoadhesiveFadillah RamadaniaNo ratings yet

- Conversation at A PharmacyDocument4 pagesConversation at A PharmacyDandi Azmi100% (2)

- MP Pharmaceutics Batch 2017-19 - 09 - 2019Document33 pagesMP Pharmaceutics Batch 2017-19 - 09 - 2019Abhishek RampalNo ratings yet

- Cow Ayurvedic PANACEASDocument57 pagesCow Ayurvedic PANACEASmpidoh100% (1)

- Midterm Exam Reviewer: Surgical Handwashing QuizDocument9 pagesMidterm Exam Reviewer: Surgical Handwashing QuizOfficially RandomNo ratings yet

- Gujarat Council On Science and Technology, GandhianagarDocument42 pagesGujarat Council On Science and Technology, GandhianagarMergu Bala RajuNo ratings yet

- M Pharm Pharmaceutics Thesis PDFDocument8 pagesM Pharm Pharmaceutics Thesis PDFafknjdsta100% (2)

- PowdersDocument22 pagesPowdersAbdullah SajidNo ratings yet

- Development and Characterization of Orally Disintegrating Tablets Containing A Captopril-Cyclodextrin ComplexDocument19 pagesDevelopment and Characterization of Orally Disintegrating Tablets Containing A Captopril-Cyclodextrin ComplexValentina AnutaNo ratings yet

- 2022-PHARM TECH II LAB MANUAL 1Document117 pages2022-PHARM TECH II LAB MANUAL 1wanoNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0052239 A1Document22 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0052239 A1nikuNo ratings yet

- dm2016 0258Document2 pagesdm2016 0258Vincent John RigorNo ratings yet

- 704 712Document9 pages704 712Jorge Humberto HerreraNo ratings yet

- Scale-Up of A Pan-Coating Process: Preetanshu Pandey, Richard Turton, Nitin Joshi, Elizabeth Hammerman, and James ErgunDocument8 pagesScale-Up of A Pan-Coating Process: Preetanshu Pandey, Richard Turton, Nitin Joshi, Elizabeth Hammerman, and James Ergunbulkis aisyahNo ratings yet

- Equip of Dissolution PDFDocument25 pagesEquip of Dissolution PDFYuppie Raj100% (2)

- PoornimaDocument4 pagesPoornimamanojkumarNo ratings yet

- A Review On Qualification of Auto Clave, RMG, FBD, Cone Blender, Tablet Compression Machine.Document11 pagesA Review On Qualification of Auto Clave, RMG, FBD, Cone Blender, Tablet Compression Machine.DANIBATANo ratings yet

- Module 2Document36 pagesModule 2Mariela Lopez huamanNo ratings yet

- Chapter 17 - Rates of Chemical ReactionsDocument24 pagesChapter 17 - Rates of Chemical ReactionsDK01No ratings yet

- Pharmaceutical IndustryDocument67 pagesPharmaceutical IndustryBren SisonNo ratings yet

- Axon Drugs Pvt. LTD., Standard Operating Procedure: MasterDocument2 pagesAxon Drugs Pvt. LTD., Standard Operating Procedure: MasterDavid RodriguezNo ratings yet

- SaintyCo Updates All Tablet Press Machines Now Introduces 9 New Series of MachinesDocument3 pagesSaintyCo Updates All Tablet Press Machines Now Introduces 9 New Series of MachinesPR.comNo ratings yet

- OM VP and ID P and RDocument5 pagesOM VP and ID P and RTamara Kate HalicanNo ratings yet