Professional Documents

Culture Documents

100%(2)100% found this document useful (2 votes)

209 viewsW587e 00

W587e 00

Uploaded by

Александр КулаковCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Delphi Scan Tool ManualDocument81 pagesDelphi Scan Tool ManualEdgardo Spinelli100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ford Mondeo 2012Document12 pagesFord Mondeo 2012Александр КулаковNo ratings yet

- EX75UR Engine Harness: Attach To Vol. No.: TT197E-00Document1 pageEX75UR Engine Harness: Attach To Vol. No.: TT197E-00Александр КулаковNo ratings yet

- W587E-00 Updated+infomation 1pagesDocument1 pageW587E-00 Updated+infomation 1pagesАлександр КулаковNo ratings yet

- EX60 Hydraulic Circuit Diagram: Attach To Vol. No.: TT152E-02Document16 pagesEX60 Hydraulic Circuit Diagram: Attach To Vol. No.: TT152E-02Александр Кулаков100% (1)

- TT197E 00 - Ex75ur 5+connectorDocument1 pageTT197E 00 - Ex75ur 5+connectorАлександр КулаковNo ratings yet

- EX75UR Electrical Circuit Diagram: Attach To Vol. No.: TT197E-00Document1 pageEX75UR Electrical Circuit Diagram: Attach To Vol. No.: TT197E-00Александр КулаковNo ratings yet

- TT197E 00 - Ex75ur 5+hydDocument1 pageTT197E 00 - Ex75ur 5+hydАлександр КулаковNo ratings yet

- EX75UR Cab Harness: Attach To Vol. No.: TT197E-00Document1 pageEX75UR Cab Harness: Attach To Vol. No.: TT197E-00Александр КулаковNo ratings yet

- T580e 01Document290 pagesT580e 01Александр КулаковNo ratings yet

- Mev17 4Document6 pagesMev17 4Александр КулаковNo ratings yet

- 6 - Powershuttle TransmissionDocument21 pages6 - Powershuttle TransmissionАлександр КулаковNo ratings yet

- 9 - Hydraulic SystemDocument86 pages9 - Hydraulic SystemАлександр Кулаков100% (1)

- Toyota Turbo's: Applications ListDocument33 pagesToyota Turbo's: Applications ListАлександр КулаковNo ratings yet

- 3 - Engine (NEF)Document76 pages3 - Engine (NEF)Александр КулаковNo ratings yet

- ЭБУ в машинахDocument93 pagesЭБУ в машинахАлександр КулаковNo ratings yet

- New Trasdata (Jtag/Bdm/Boot) Ecu Application ListDocument9 pagesNew Trasdata (Jtag/Bdm/Boot) Ecu Application ListАлександр КулаковNo ratings yet

- 2006 Toyota Tundra (GSK30, UCK30, UCK31, UCK40, UCK41)Document120 pages2006 Toyota Tundra (GSK30, UCK30, UCK31, UCK40, UCK41)Александр КулаковNo ratings yet

W587e 00

W587e 00

Uploaded by

Александр Кулаков100%(2)100% found this document useful (2 votes)

209 views686 pagesOriginal Title

W587E-00

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(2)100% found this document useful (2 votes)

209 views686 pagesW587e 00

W587e 00

Uploaded by

Александр КулаковCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 686

Workshop Manual

€Xl2-2 €EX30-2

EX15-2 E€X35-2

Ex18-2 €EX40-2

EXe2e--2 E€EX45-2

EXe25-2

Excavator

HITACHI

vases

INTRODUCTION

TO THE READER

‘This manual ig writen for experienced techn

cian to provide tochicalinformaton needed to

‘mantain and ropa this machin,

Be sure to thoroughly road this manva! fr cor

‘ect product inematon and sence procodue,

try have any questions or comments regard

ng the contents ofthis manual.

‘+ Two typos of manual are avaiable. One is Tech

nical ManvalTM). The eter is Workshop Man

usw.

Use the manuals according to purpose.

Information incaded inthe Tt

tectncal information nacced for redelvery and

alvery, operation and actvaton of all dovces

and sytem, oporeional pecormance tt, and

trobioshooting procedures

Posse contact using “Service Manual Revision Re-

‘quest Form’ at the end ofthe manval

{Wote: Do not tear of the form. Copy for usage.

Publications Markating & Product Suppor

FitsoniConeructon Machinery Ca. Li.

‘Tet: 61-208592.7179

Fa 81-298-81-1162

‘oformtion included inthe Wt

‘octal infomation needed for maintenance

and ropai of the machine, tools and. doves

hveded for maintenance ane ropa, maintenance

Standaras, and rorvainstalaton and asm:

Blotasassombie procedures.

ADDITIONAL REFERENCES

© toate role to the mate listed below in adtion

tots manual

Tha Operator's Manus!

“ih Pars Catalog

* Operation Manual ofthe Engine

Parts Catalog ofthe Engine

Hitch Tring Mater

PAGE NUMBER

‘ach page has a numb, lcatd onthe centr tower

part of the page, and each number cotains the To

owing iformaton:

Sample: 7.01-08-05

‘Concocuive Pago Number for Each Group

Group Nubor

‘Section Number

1: Technical Manual

We Workshop Manus

wor

INTRODUCTION

SAFETY ALERT SYMBOL AND HEAD-

LINE NOTATIONS

tn this manual, tho folowing safety alr symbol and

‘Sina words ae used to alert the reader fo the po.

‘ental or persona injury or machine damage.

By Tris sth safety aon symbol. When you soo

‘he eyo, be sl tothe potent Yor peraone! n=

by

Neverfail to felow the sey instucions proscribed

long wih tho safety alert synbo.

The seloty alot symbol is ako used to draw ator

tin to componenipart woh

To avad injury and damage, be suo to use appo-

priate Ming techeuques and ogupment we ing

hoavy pars.

© Ay CAUTION: indtcsts 2 potently hazardous

‘stuation which cout, ot avoided, rest in

Berson nuy or death,

© IMPORTANT: snseates a shuston which, # nat

‘vcdad, could resutn damage tothe machine

© NOTE: indcates supplementary techical informa

ton oc knowhow

UNITS USED

‘81 Unis (intratonal Systom of Units) are used

inthe mamas

MKSA System units ana English uns 9 also in

Seat in parentheses just bohing SI uns.

Example: 24.5 MPa (250 kaon’, 9 $60 psi)

‘A tie for conversion trom 1 units to oer sy8-

{tem unds ls shown below for efrence puposes.

amy To Conver TRB Gomay TSO Tay

Guentty | Fem et By | OY | From bo By

re ca Th | “0837 eseare MPa | on [107

Eee i [on 267 1" He te.

Tg oat 103882 Teer i Ps ts60

Volume = Usa [1087 i HP [131

a = yg — [08 — rene oF [os

i a 20s ; a ro

Force N Terese [eects FR om — [40

W a er

Toru Ts] “retes 11.0197 muter—[—estev J “10

a ETE

IN-02

SAFETY

RECOGNIZE SAFETY INFORMATION

1 Tisis the SAFETY ALERT SYMBOL.

When you see tis symbol on your machine or in

this manual, be alot tthe potental or personal

inury

Follow recommended precautions and safe

operating praices.

UNDERSTAND SIGNAL WORDS

4x machine sty sans sonal words dexgning

Se dogs orl! oi hasid “DANGER, WARNING

SrCAMTION se costo ey ar ayrog ANGER

DANGER indicates an imminently hazardous

Siuatlon whic, # nt avolded, wi result i death of

Sat A WARNING

WARNING incicatos a potentially hazardous

siuaton which, itnotaveded, could rest n ceath

coro A CAUTION

CAUTION incicates a potentially hazardous

Situation whieh not avoided, may resutn minor

rmederae nut,

orveer or warn aney sige ne cee = IMPORTANT

oar pects hazards, General precautons er ls.

(.on CAUTION safety signs

CAUTION aca ator to sloy masses n NOTE

themanval

To avoid confusing machine protection vith parsonat

ssiey messages, a signal word IMPORTANT Ind

ats a staston whieh ot avoided, could result

‘tamage tothe macnie,

(© NOTE incites an adstional explanation for an el

rent of inoraton,

eo

SAFETY

FOLLOW SAFETY INSTRUCTIONS ea

‘© Caretuly read and follow all safety signs on the —

‘machine anda aslety messages ns manual.

Safety signs should be installed, maintained snd

replaced when necessay

1 satety sgn or operator's manuals damped or

‘missing, replace wits new one. J

+ Lean how to operate the machine and ts cones

corey and ea woe

‘Alon ony trained, qualied, uthozed personnel to

‘pera the machine

‘op your machine In proper working conto

Unauthorized modiicatons to the machine may

impair the funcion andlor safely and atect machine

We

1 The safety messages in thls SAFETY chacior are

intended to ilustvate asc safety procedures of

rachis. However Is Impossblo for these salty

messages to cover every hazardous stuaton you

may encourta. if you have any questions, you

‘shoul fst consut your eupen/sorbelore operat

‘or perioming maintenance work on se machine.

PREPARE FOR EMERGENCIES

‘Bo prepared fre ears ori an accent occurs.

Keep att i tan fr extngusher on hand,

Thorough fead and uncestand the label atiachod

cote re extinguisher to se it propery.

Eealen emergency procedure. guidlines to cope

with ros and aceon

Keep emergency numbers fo doctors, ambulance

seroe, nosptal, and fre department posted neer

Your telephone

re

SAFETY

WEAR PROTECTIVE CLOTHING

‘Wear close fiting clothing and safety equipment

approprat to ho ob.

You may need

‘Ahad pat

Safety shoes

Safety gasses, goggles, o fac shies

Heavy gloves

Hearing protection

Retecive cotung

Wet weather gear wo

Respirator o ater mask

ae aure to wear the corect equipment and clothing

{or tho[ob- Do pet ake any chances

98 «ap

—

POLS

Avoid wearing ote lating, jowsry, or oer ts

that can catch on coral avers or ther pars ofthe

machine,

‘Operating equipment safely requires the fl attention

of the operator. Do not weer radio of music

Deadghones while operating machine

PROTECT AGAINST NOISE

+ Prolonged exposure to loud nolse can cause

[mpaimens or ae of hearing

Woar a sulabie hearing protective device such as

‘armulleor earplugs to protct against cbjectonable

(FUncemforaly loud noses.

INSPECT MACHINE

‘Inspect your machine caellly each day or shit by

walking around bofore you star it to aves personal

inure

In the walkcaound inspection be aure to cover all

pons described inthe "PRE-START INSPECTION’

hapten the apeators mana

se ©

oo

SAFETY

USE HANDHOLDS AND STEPS.

«Folin ison of the major causes of persona ru.

When you got on and of the machine, avays face

‘hemabting and maintain 8 tree-pot contact with

‘he Seps ana handrale

Do ntuse any convols as handhold.

Never jump on or of

Adsmoueta moving maznins

aching. Never meunt or

Be caret of sippory condtons on plaiorms, steps,

and hancras when faving the machine.

‘ADJUST THE OPERATOR'S SEAT

‘© A pooty dusted seat for ether the opertor of for

te work at hand may auesy fatigue the. operator

ang to risoperations.

‘The seat should bo adjusted whenever changing the

operator forthe machine

‘The operator should bo able to fuly depress the

pedals and to corecty operate the conte! lovers

‘nhs back gaint he seat back

"ct move the seat forward or backward, and

check gal,

oo

SAFETY

FASTEN YOUR SEAT BELT(IF EQUIPPED)

ifthe machine shouls overturn, the operator may

become injured andlor thrown tram the. cab.

Additonal the operator may be crushed by the

fvenuring machine, resulting in serous injury oF

death.

Piero operating the machine, thoroughly examine

webbing, Buckle an ataching rawr. any tam

IS damaged or wor, replace the saat belt oF

‘component before oparating the machine.

5e nue to emai sete wth to teat bet securely

fastened at all times when the machine Is in

Wa recommend that the set bat be replaced every

‘hres your regardless ote apparent sonaion.

MOVE AND OPERATE MACHINE SAFELY

«Bystanders can bo rn over

Tako exra care roto run over bystanders. Confirm

the locaton of bystanders before moving, singh,

‘or operating he machin.

‘Aways Koop the travel alarm and om in working

oration (t equipped), k warns people when the

machine stats to move.

Use a signal pecon when moving, swinging, ot

‘operating the machine In congested. areas,

Coordinate hand signals ‘before starting the

rrachine,

e

SAFETY

OPERATE ONLY FROM OPERATOR'S

SEAT

« lnszeropiate engine staring procedure may cause

the mashing to runaway, pos=bly resting in ecus

Inyo death

Sarthe angne ony rom the operators seat

NEVER star the engine whe standing on tho rack

ron grouna

De nat start engine by shorting across starter

Beloe staring te engine, confi that all contol

SUMP STARTING

«Batery ges can explode, resting in serious iy.

ite engine must be jumpstart, be surat flow

the lnstuctions shown in the “OPERATING. THE

ENGINE” chapter nthe operator's marval

‘The oparator must bo in te operators seat so that

the machine wil be under conto! when the engine

stats, Jump starting isa twoperson operation.

Never use a fozen bate

False to folom cost jump staring procedures

coud recut n'a batary explosion oF 8 raway

‘machine,

KEEP RIDERS OFF MACHINE

‘© Riders on machine are subject to injury such as

boing suc by foreign bjects and being town of

emactine

COniy alow the operator an the machine. Keep riders

of

Fliers also obstrt the operator's view, rosin in

‘he machine beng opratod nan unsae mare,

—s6—

SAFETY

PROVIDE SIGNALS FOR JOBS INVOLVING

MULTIPLE NUMBERS OF MACHINES

‘© For jobs involving multle numbers of machines

| * provide signals cemmonly known by all persone!

Irveved Also, appoint signal paxeon to coordi

tho jb sto. Make suo that all personne obo

‘gral poreer's directions,

CONFIRM DIRECTION OF MACHINE TO

BE DRIVEN, a

«© Incorect travel pedallever operation may resut in s [otetw.

1 | Engine cushion rubber mouning ut ee ee le | al

ne) tame

Engine bracket mounting Bok (Fron) wolel 7 |*@is | =

2 rats a

Engine bracket mounting bolt Rear) cil ee eee

3 | Tank mounting bot ws] 7 || s | a

loNer620 w|i 3s | 2

4 Hyrautc hoes and Union Joes LnFare-r8 elo ae

nro or | os | es fw

5 | Pap mouning bot wz [2] 0 || 9 | 6

6 | arp cover mounting bt ee a

Contra valve meuning bok 0 |e) 7 [ots

gee [ale peecczeees| arate coe

7| cone vavetackst mounting tot eal

= ree | als Jee ciate | aed (Tote ete

3 | Sving device mounting bat 2 fe] af et os

| Batery mounting bot e fel ws fee pa ra

w |e} 7 [wis to

10 | Oarepy mouning bok se [4 | oes ter | 52

71 [Ca mounting bot we fe | [vr fsa fa

72| Swing besing mouring bok vpperrustze | 12 | 14 | 19 | woe t 1 feo

Swing beng mounting toto undecarane | 12 | 6 | 12 | 100 | 11 | oo

75 | Tveldevies mounting bot 2 [2 | 1 [wei |

14 Sprocket mooning bot [ee [wet too

15 | Gude mouning bok 2 [2 | | 9 6

7 CT

cas | 4 [v6] 2 | ws | wt 100

17] Cover mounting bot a vw fe;tye

2 wo | wie je

76 [ Pretecor mousing bok wo «|v | «| s |

12 Coserwognt mounting bat we [2] a | 2} of a

NOTE: (1) Aplyiubvicant (i.e. white zinc B cssalved io spindle ol) fo bots and nus fo tabetha eon

‘onfiants

(2) Mako sure bot and rut reads are clean befor insatng

(9) Apply Loctte to treads of engine cushion rubber mounang bats, lower roller mounting bots, and

‘Swing post vericatpin mourtng balls baer naling thm,

wo1-02.02

GENERAL INFORMATION / Tightening

aes5are

fs Demin BR | ey [ren Sn

wm

ovo |e fel [a

Ee baat nas Fa a] 7 | «

2 a

xo bit may nt Fy mle} ow La

aut song a ealserimen el

pRerieas]—| es

A nmtcronesiionsion ins] | 2 | o

weve! | |e

papaya = >e> ete

Soa mer isaac ani [ea

7 | Control valve bracket mounting bot Ba 5 a a ia a

1 [Sag soma a eopet eet ss

7 10 2 Ww 49 i 5 | 96

7 |e mei eo

nomena etetoa te

1 |Seogterm nontgpaoumanae | te par]

Sugierramamete means | (a) 0 |x

|i cr rg eee

1 [Sona ang se a

tsleaenanmata = obetow

[er nega uote ash

7 [ee nora be] ba

18] Cover mourting bot 2 |e

° un ieisie

20] Counterweight mounting bot 22 2 32 sag {55 | 998

NOTE: (1) Apply rian

octets.

(2) Make sure bolt and nut reads are clean bole nstaing

ite zinc 8 cssoved ito spine oi to bolts and nuts to stabilize tor fiction

(8) Apa Loctte to theads of engne cushion ruber mourang bots, lower roller mounting bos, and

‘swing-postvrtcalpin mounting bots before nstalng tram.

wor-02-08

GENERAL INFORMATION / Tightening

roe, Base

| omeptns sotoia |g |en sco

vn me

Ere cain ntker mania re a

1 |Engine cushion rubber mounting bolt 318 e 24 205,

7 [Fra ect meus bt Fon eee en meee ce

Eng cet mnin bt oe mel lb aL

3 [vera ok 8 ue nk mei ok [v0 | 6 [17 | a

loner 1 |

4] rungs torneo hoses and png funeari- 2 |

UNFai36 a _| ee

| Big mang bo 2 fe] [es

6 | Puno oor movning bok wo fe[ 7 [Ts

7 [cont ave mourig ot era) ara

'8| Control valve bracket mounting bolt ° “ v “o

2 [i] w |e

3 | Svng doves rosin bk so |e | «| 208

@ fe] pests

10] ater reuning ra Peete

77 Caney ning tok sofa | ee | mos taf se

12 [5 mung tot wef « [ee er fe fot

13] Sug bewna mounina tokio mpmamicure | | a2 | 22 | 75 | xe | 100

suing taxing mouring boro undwariage | 12 | 20 | 19 | wos | os | oo

74 Tre! doves moun bt ao | 2 [vs tet sao

15 | Serctst mening bok “ [oe fe ao

1 | Une er mening ta rm zor Pw to

17 [Lower ror mong bat wee] 27 | a0 | ao | aaa

3 al con es

18 cone marina bot eI ees

2 w | wisie

7o | Prtcormauig bak 0 f«[ 7 [ets a

2 Gast mouning BoE we | [as | wf a7

NOTE: (1) Apply iuvicant (i. wht zine B cssolved ino spindle oi) t bots and nus 10 stabilize thor Hoton

‘ootint,

(2) Make sire bat and rut treads a clean before intalig.

(9) Aaply Lecue to tvesss of engine cushion rubber mounéng bots, lower roller mounting bots, and

‘swing-postvertcakpn mounting bls beter insaling thor

‘wo1-02.04

GENERAL INFORMATION Tightening

aaa Ee,

Bi cauT0% tne woe serps forte work

Pasir eet ieeneeeenion

arte ate tr fa en et

Span sate anh ae Sere ae

See ae ists we ey ab re

een pera ey

Bott Types

Tighon ruts oF bolts corsety to torque specications.

Four dlerent types and grades of bolt are empoyed soe

Make sure to employ caret bats and tghtan them cr.

recly when assombing tbe machine or components.

Noncen Test Hop HBat Hoan Mc Set

‘Spectied Tightening Torque Chart

Feagon] tba fi i

‘bon | wronen HEH@990] 7 Boh, Socket bot Hot Bot

Oa. | sizo "S20" | Wm itm | wen | Nm igim | wt | Nm igtm | ee

re en me ree Oe [oO er [eR etter

Mio} ir vee eg earn dg org ae fia ea

Mere] ag in| oa ab ogg ggg ae ga

Mabe ge ag gee aah ay a ion | eae a

6 ata gag aaa a age ae

Mae apa began ag Baa Sopa ae

(M3080 beans aba rea

(a A a

aa ap ge ea be gab] 680 0 bog | re apo

Mar ar ag gpa ag 0b 680s E760 | ga 390

Mayas pe 4 gta ag ani [430 sas 060 | sad 65a

Messy eo" ba geo" 90 aed 1 810 tas ano | a0 8a

ese) ee ay |S ao a0 a 810 an ne 0 | oS

GENERAL INFORMATION Tightening

IMPORTANT:(1) Apply lubricant (6. white zine B

dissolved into spindle ol) t0 nuts

fand bolts to stabilze thet ction

Contents

@ Torque tolerance is #10 2%

(@) Be sure to use bolts of correct

length. Bolts that are too long

cannot be tightened, 26 the bolt

ip comes Into contact with the

bottom of the Bolt hola. Gols that

fare too short cannot develop su:

ont tightening free.

(4 The torques given in the chart are

{or general use ony

Do Mot use these torques Ifa at-

ferent torque is glven for = spe-

‘ie application.

(©) Mako. ture that nut and bolt

‘threads ate clean before instaling.

Remove dit or corrosion, i any.

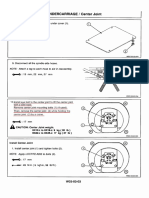

Bott Tightening Order

Wien tightsing two or more bots, sghtn them aber

natal, 25 shown, to ongure oven bgeenng.

as win ve “any Tat cnr

Sey a

‘£rD 800 oe oe

Rod ooo $ oe0

wor-02-06

GENERAL INFORMATION Tightening

‘Service Recommendations for Spit Flange

IMPORTANT: (1) Be sure to clean and inspect seal-

Ing surfaces, Soratehes / rough:

nets cause leaks and seal wear

Unevenness causes seal oxtru-

‘sion I defects cannot be polished

‘out rplace the component.

(@) Be sure to use only speciied O-

fings. Inspect O-rings. for any

‘damage. Take care not to Tle O-

fing surfaces. When instaling an

(Oring into 2 groove, use grease

to hold iin place,

@) Loosely assemble spit flange

halves. Make sure that spit is cen

tally located and perpendicular to

the port. Handstighten bolts to

hol parts in place. Take care not

te pinch the O-ring,

(Uy Tignten bolts altemately snd diag

onal, a& shown, to ensure even

tightening.

(6 Do not use at wrenches. Using an

‘ir wrench often causes ughtoning

{of one Bolt fully before tightening

‘of the others, resulting In damage

{fo Orings or uneven ghtening of

bots

[Nut and Bolt Lockings

© Lock Pats

IMPORTANT: Do not rouse lock plates. Do not try to

bend the same point twice

«spit Pin

IMPORTANT:Do not reuse splt pins. Match the

‘holes inthe bolt and mut while tight-

‘ning, not while loosening,

© Lock Wie

IMPORTANT: Apply wire to bolts in. the bolt

tightening dlvection, not In the bolt

loosening direction.

RIGHT

oo

nicht

WRONG 6

wrona

&

‘wo1-02.07

GENERAL INFORMATION /Tightening

PIPING JOINT o Qe

Pipe Thread Connection / Union Joint Tightening

“Torque Specieations

Union Joint

Metal sosing surfaces (4) and (6) of adaptor (1) and

tos (2 og bl ress Une ot —

tod ton sit dato Eee

IMPORTANT.) Do net overstghten nut (2). Eee a

eee

Seeing srace (and (), post =

Biy racking daptor {Be ure =

{olignen nut) to specteatins soe on tf in et

€@) Scratches or other damage to enor

Seating tutaces (or (wl

Shue ou leaage at ejomt rane [ Wena See] —_Tahonng Tore

Sie oot to eamage tere When mn fm afm, et)

Cennecing kiesonnecting a mame}

2 5 (0.28)

% fs (ae)

2 ser (ieto!)

& 175 (12,190)

Oring Sea Joint eo zs (20, 188)

ea (6) sot agaist ond fen of sar (7) 0

seal prossure ol

IMPORTANT:(1) Be sure to replace O-ring (6) with

‘anew one when reconnecting

(@) Before tightening nut (9, contm

that Oring (6 is seated coractly

in Ong groove @, Tamerng

fut @) Wit O-ing (6) csi

sl damage ring (resting n

oll leakage.

(0) Toke care not to damage O-ing

‘groove (8) sealing surtace (10),

Samant Cuan wi oe ot

Bane o Ong © a

a nmin, ot)

(0 Jone ut found tbe 7 erewen

Sasang’a esage do et 2 Sse)

‘onan te stop lenge stent H] (84 101)

‘lace Osi @ ath new one oP BS (38 190)

then Ughten nut (@) aftr confi

Ing tnat ing () is securely seat

an pace,

wo1-02-08

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Delphi Scan Tool ManualDocument81 pagesDelphi Scan Tool ManualEdgardo Spinelli100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ford Mondeo 2012Document12 pagesFord Mondeo 2012Александр КулаковNo ratings yet

- EX75UR Engine Harness: Attach To Vol. No.: TT197E-00Document1 pageEX75UR Engine Harness: Attach To Vol. No.: TT197E-00Александр КулаковNo ratings yet

- W587E-00 Updated+infomation 1pagesDocument1 pageW587E-00 Updated+infomation 1pagesАлександр КулаковNo ratings yet

- EX60 Hydraulic Circuit Diagram: Attach To Vol. No.: TT152E-02Document16 pagesEX60 Hydraulic Circuit Diagram: Attach To Vol. No.: TT152E-02Александр Кулаков100% (1)

- TT197E 00 - Ex75ur 5+connectorDocument1 pageTT197E 00 - Ex75ur 5+connectorАлександр КулаковNo ratings yet

- EX75UR Electrical Circuit Diagram: Attach To Vol. No.: TT197E-00Document1 pageEX75UR Electrical Circuit Diagram: Attach To Vol. No.: TT197E-00Александр КулаковNo ratings yet

- TT197E 00 - Ex75ur 5+hydDocument1 pageTT197E 00 - Ex75ur 5+hydАлександр КулаковNo ratings yet

- EX75UR Cab Harness: Attach To Vol. No.: TT197E-00Document1 pageEX75UR Cab Harness: Attach To Vol. No.: TT197E-00Александр КулаковNo ratings yet

- T580e 01Document290 pagesT580e 01Александр КулаковNo ratings yet

- Mev17 4Document6 pagesMev17 4Александр КулаковNo ratings yet

- 6 - Powershuttle TransmissionDocument21 pages6 - Powershuttle TransmissionАлександр КулаковNo ratings yet

- 9 - Hydraulic SystemDocument86 pages9 - Hydraulic SystemАлександр Кулаков100% (1)

- Toyota Turbo's: Applications ListDocument33 pagesToyota Turbo's: Applications ListАлександр КулаковNo ratings yet

- 3 - Engine (NEF)Document76 pages3 - Engine (NEF)Александр КулаковNo ratings yet

- ЭБУ в машинахDocument93 pagesЭБУ в машинахАлександр КулаковNo ratings yet

- New Trasdata (Jtag/Bdm/Boot) Ecu Application ListDocument9 pagesNew Trasdata (Jtag/Bdm/Boot) Ecu Application ListАлександр КулаковNo ratings yet

- 2006 Toyota Tundra (GSK30, UCK30, UCK31, UCK40, UCK41)Document120 pages2006 Toyota Tundra (GSK30, UCK30, UCK31, UCK40, UCK41)Александр КулаковNo ratings yet